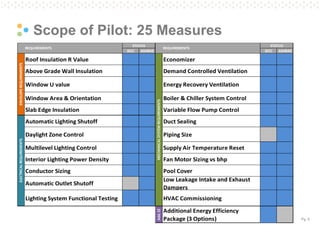

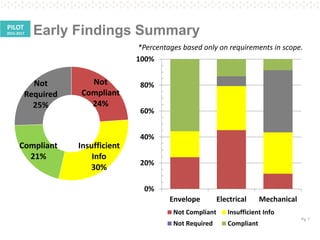

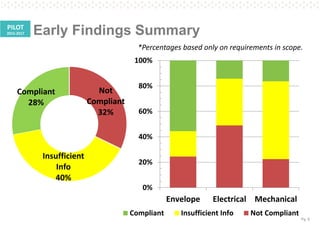

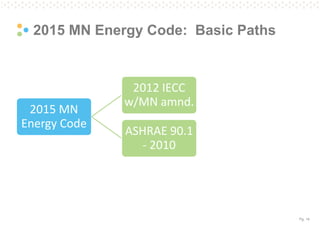

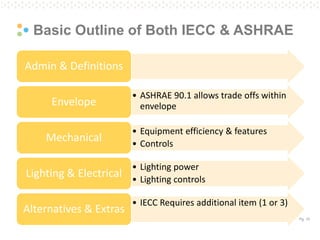

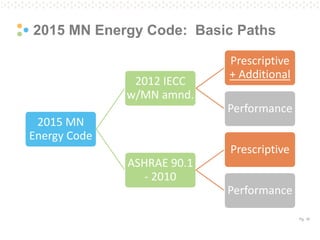

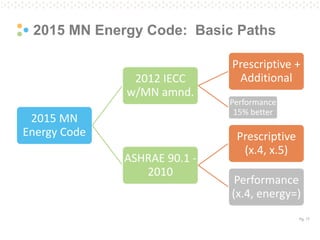

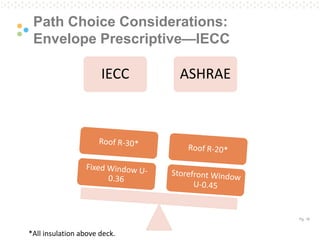

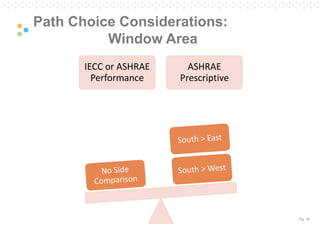

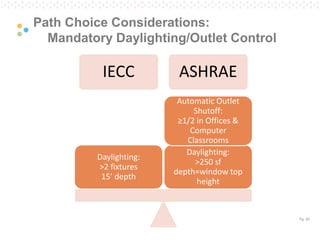

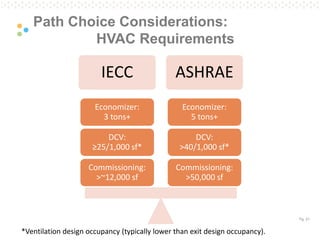

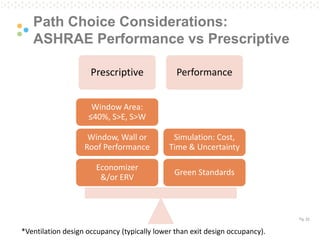

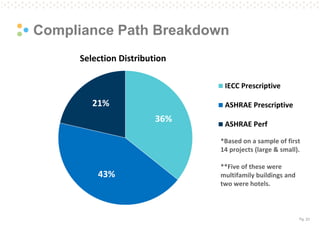

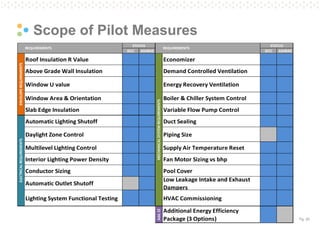

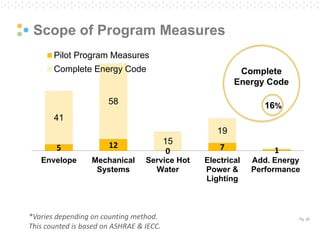

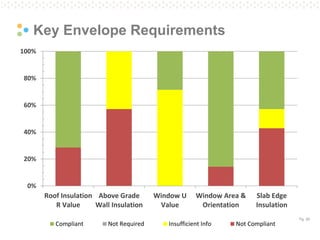

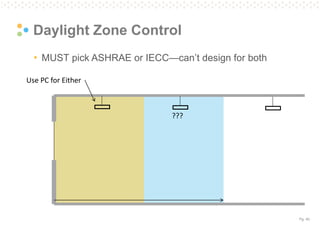

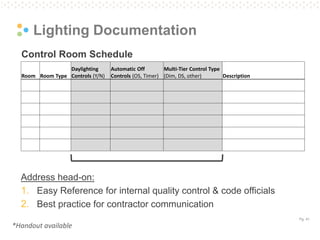

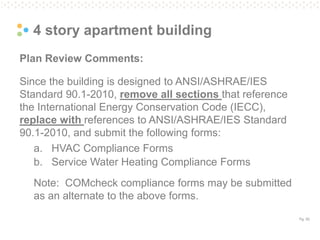

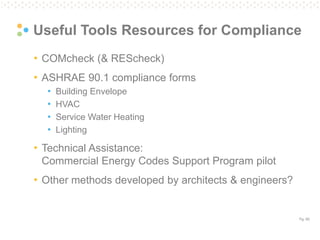

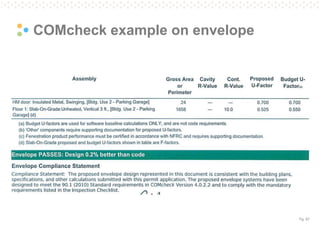

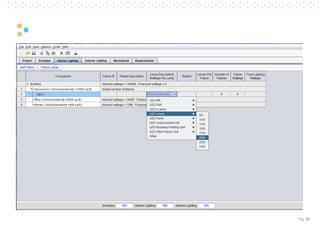

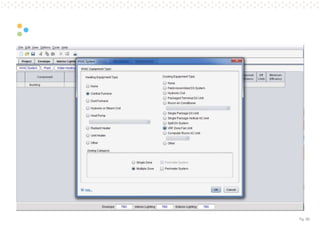

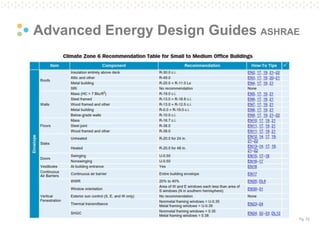

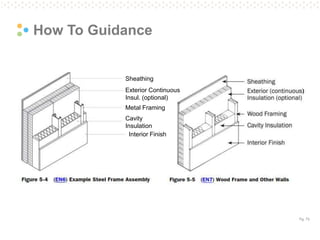

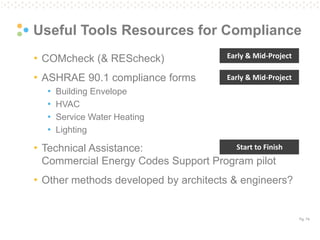

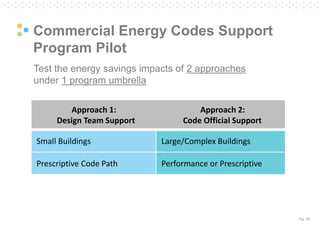

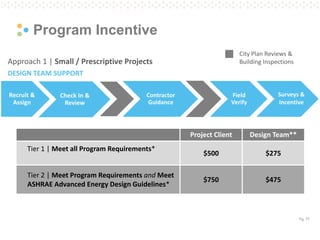

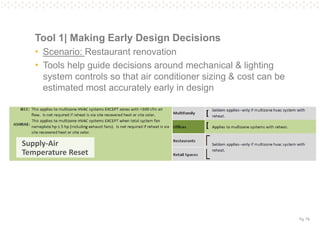

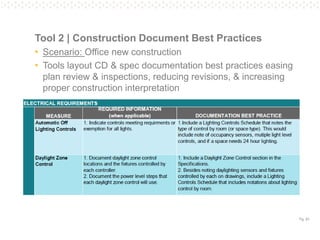

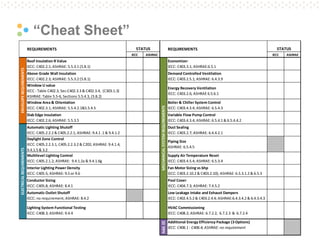

This document outlines a pilot program aiming to enhance commercial energy code compliance in Minnesota through targeted strategies and evaluations from 2015 to 2017. Key findings emphasize the importance of selecting compliance paths early, enhancing documentation for user-friendliness, and utilizing available tools effectively. The program also analyzes various energy measures and compliance levels across different categories, providing insights for future programs and best practices.