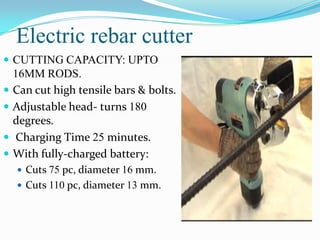

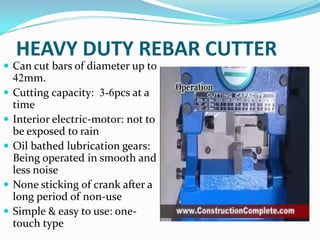

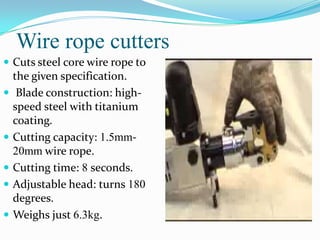

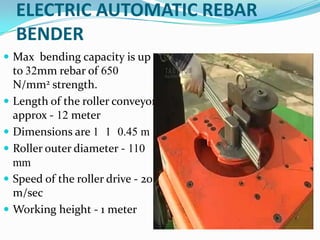

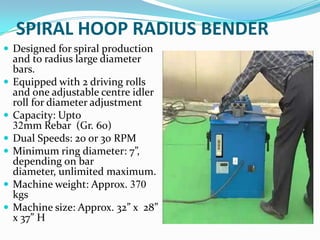

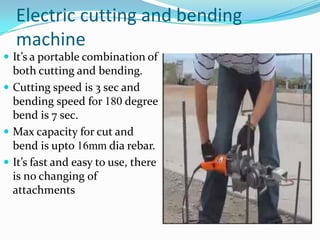

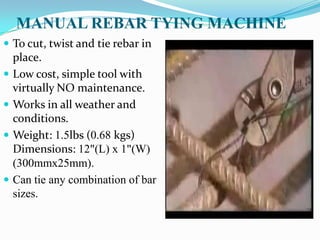

Growth in industrial technology is increasing demand for new equipment like rebar processing machines. The document discusses various types of equipment used for cutting, bending, and tying rebar, including electric cutters that can cut rebar up to 16mm, heavy duty cutters that can cut rebar up to 42mm, wire rope cutters that can cut steel rope from 1.5mm to 20mm, and automatic bending machines that can bend rebar up to 32mm. It also discusses manual and automatic rebar tying machines. The equipment allows for high production volumes in minimal time with minimal waste and flexibility.

![REFERENCES

GENSCO EQUIP.[ www.genscoequip.com]

BENNER-NAWMAN, INC [BNRebarTools.com]

STANLEY LABOUNTY [www.stanley-hydraulic-

tools.com]

SIMA REBAR PROCESSING [www.simasa.com]

MASTERS OF STEEL [www.stemapedex.com]

KODI KIPPLING FLAT MATS [kodikippling.com]

MEP REBAR MACHINERY[www.mep.com]](https://image.slidesharecdn.com/rebarprocessingequipmentce101614-120720230641-phpapp02/85/Rebar-processing-equipment-18-320.jpg)