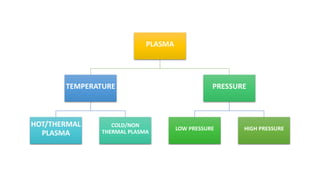

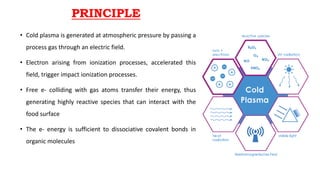

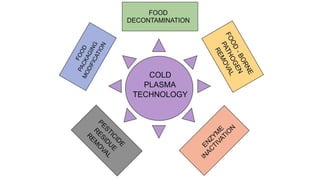

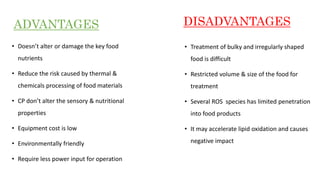

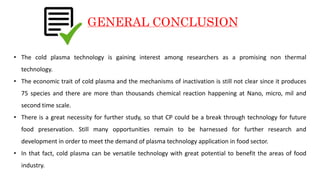

Cold plasma technology uses plasma generated at ambient temperature to sterilize food products and improve shelf life without degrading heat-liable nutrients. It works by using energized gases to inactivate microbes via UV light and reactive chemical byproducts. Different methods like dielectric barrier discharge can be used to generate cold plasma, which has applications in food processing. The technology offers advantages like minimal effects on sensory and nutritional properties of food while reducing risks from thermal and chemical processing. However, limitations include difficulty treating bulky or irregular foods and limited penetration into products.