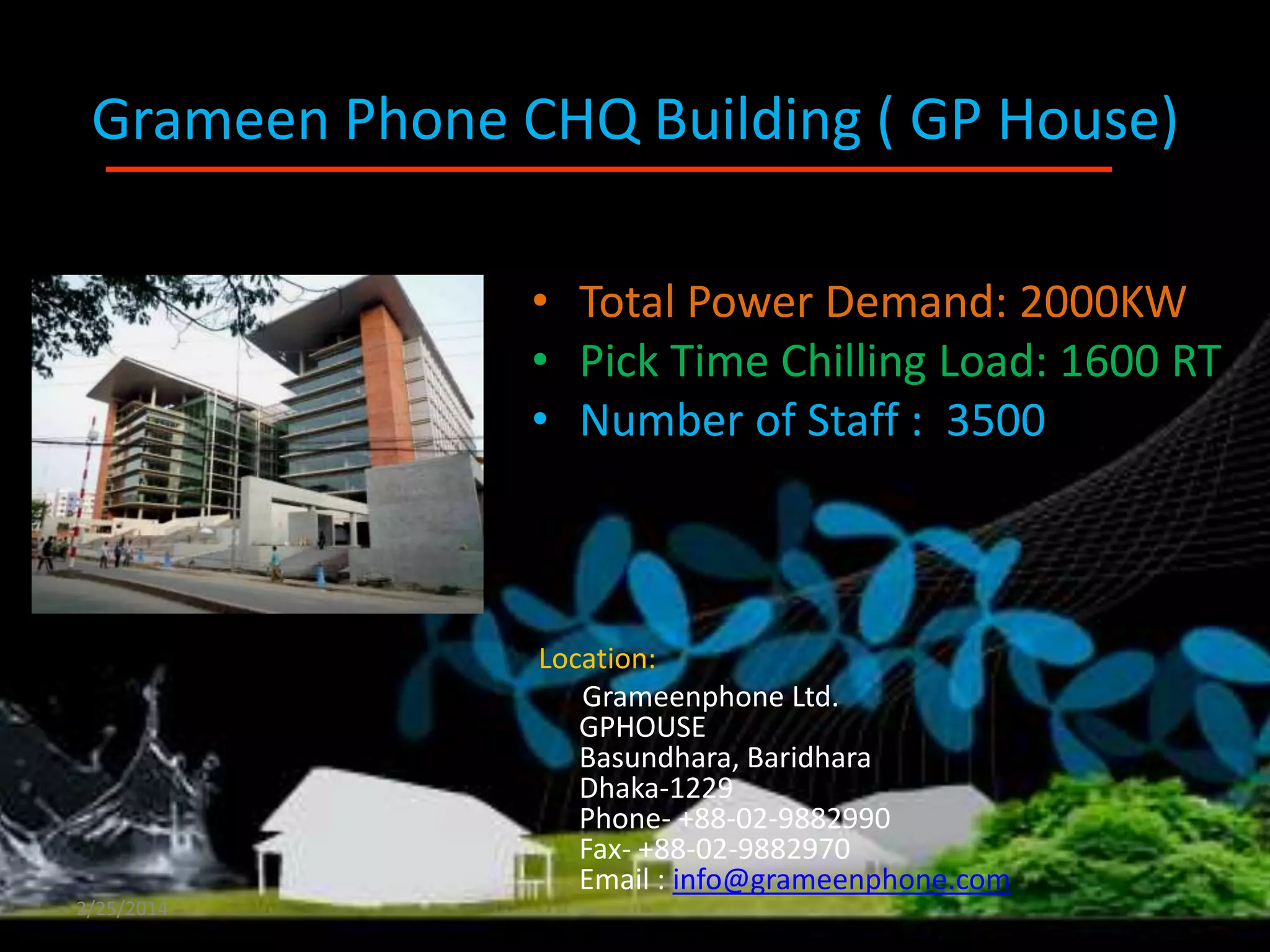

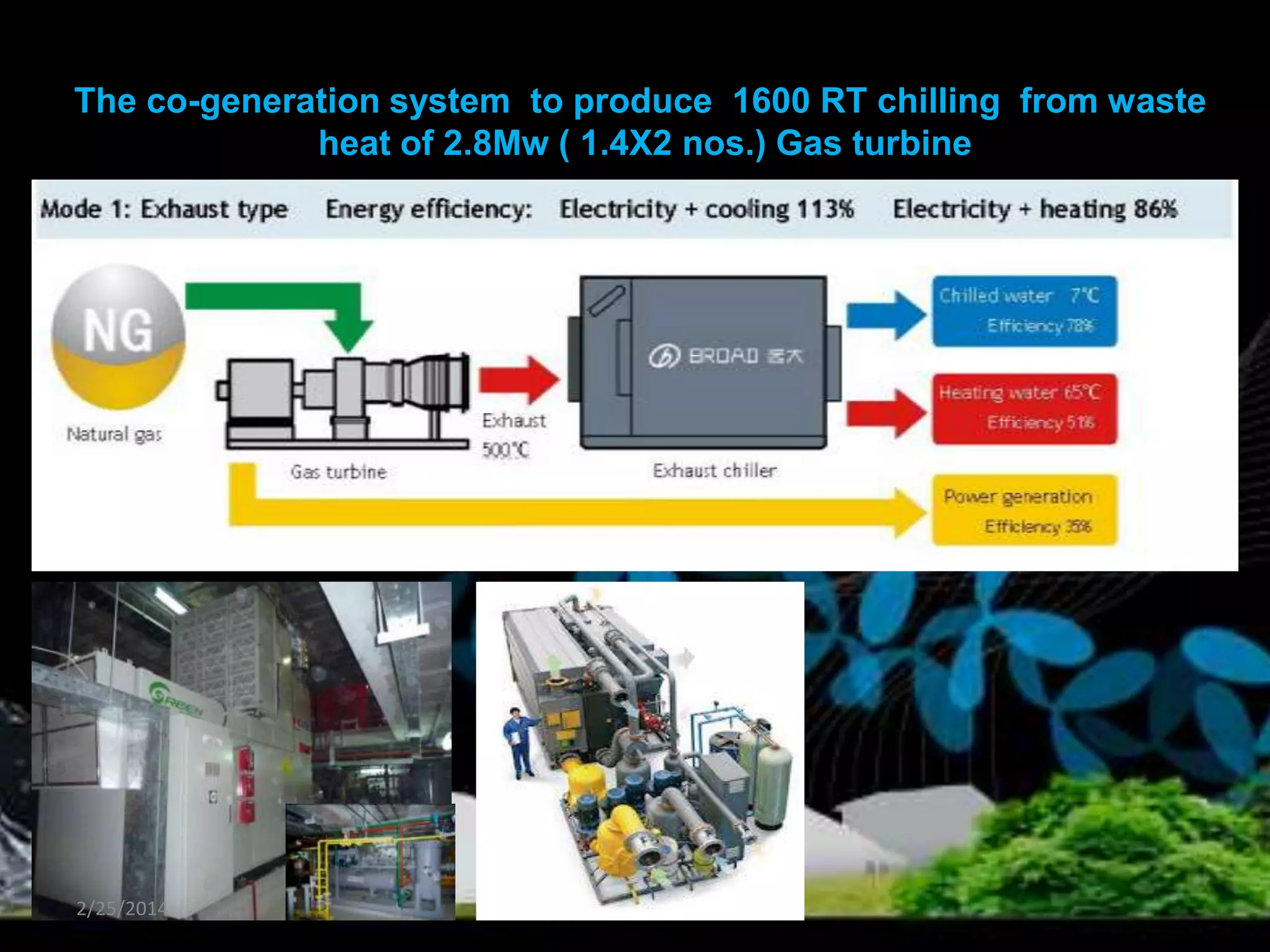

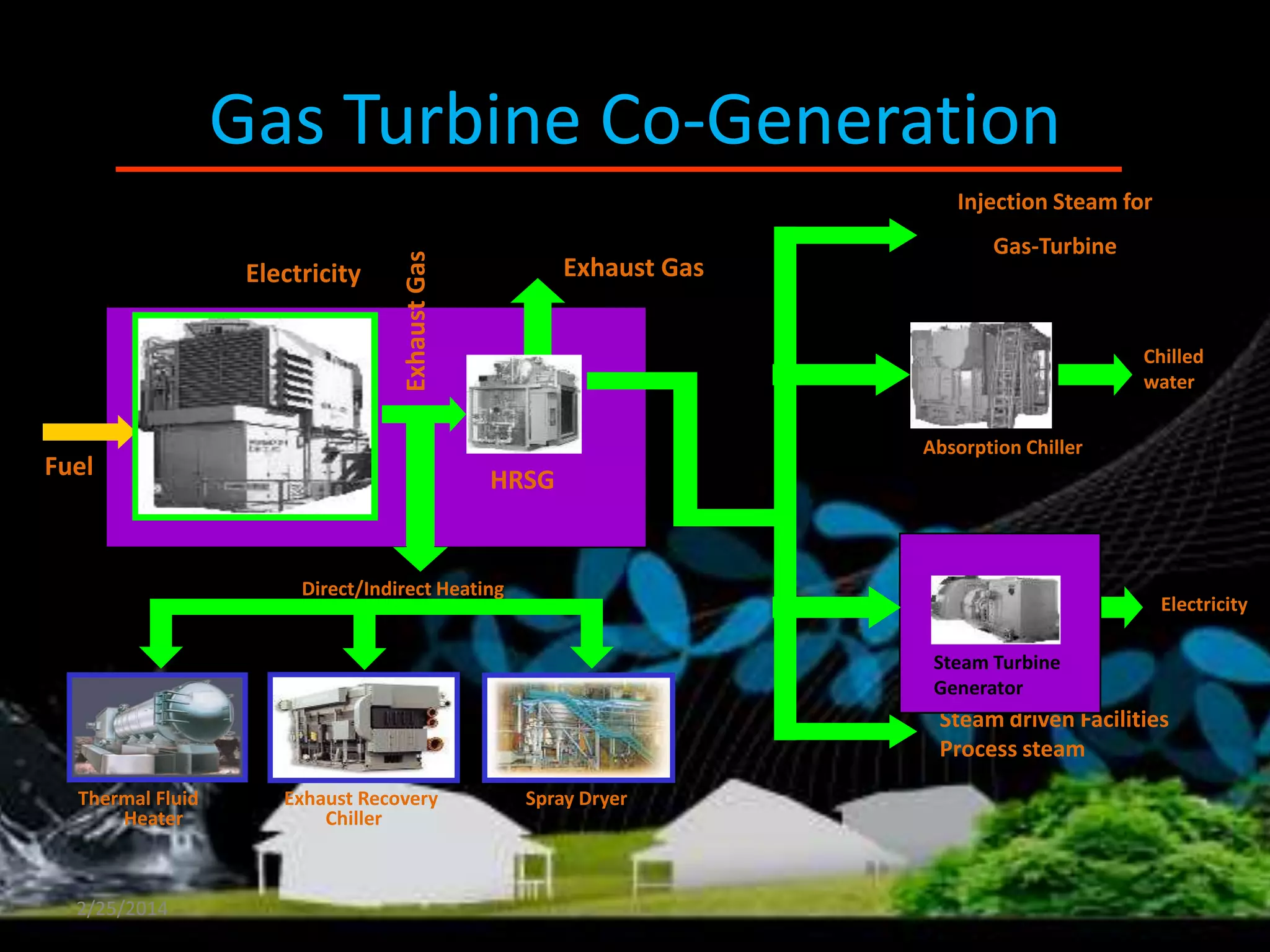

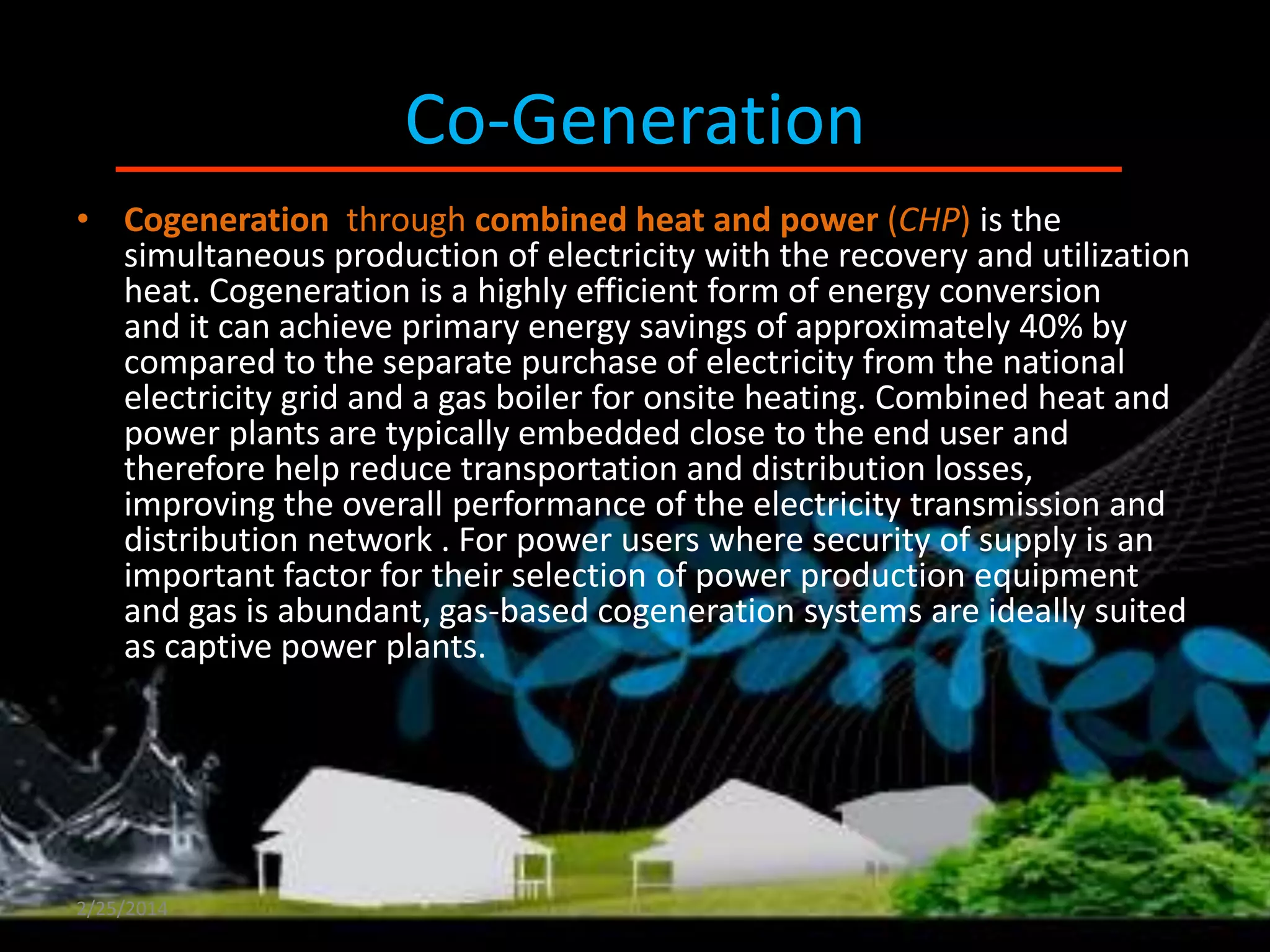

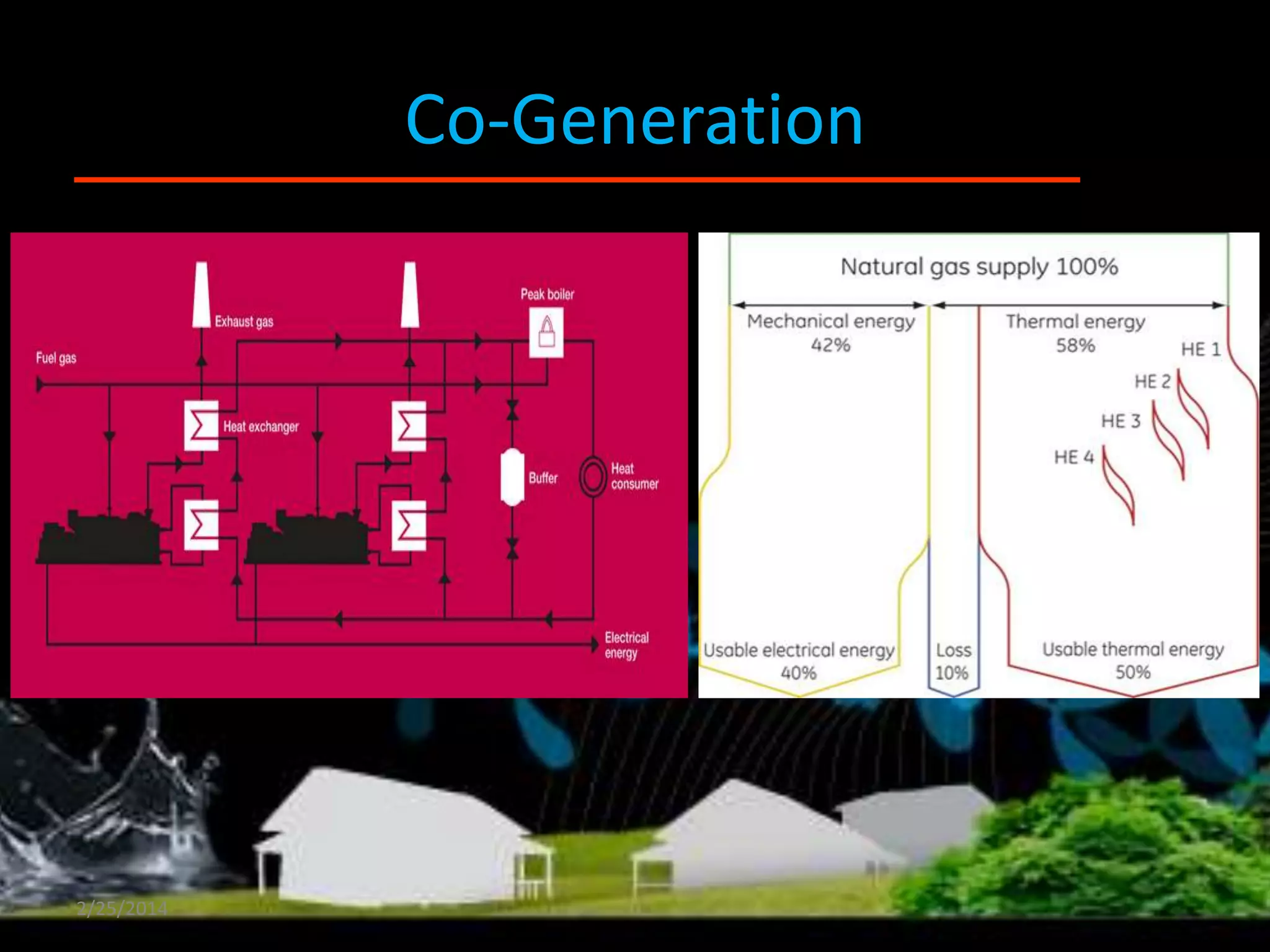

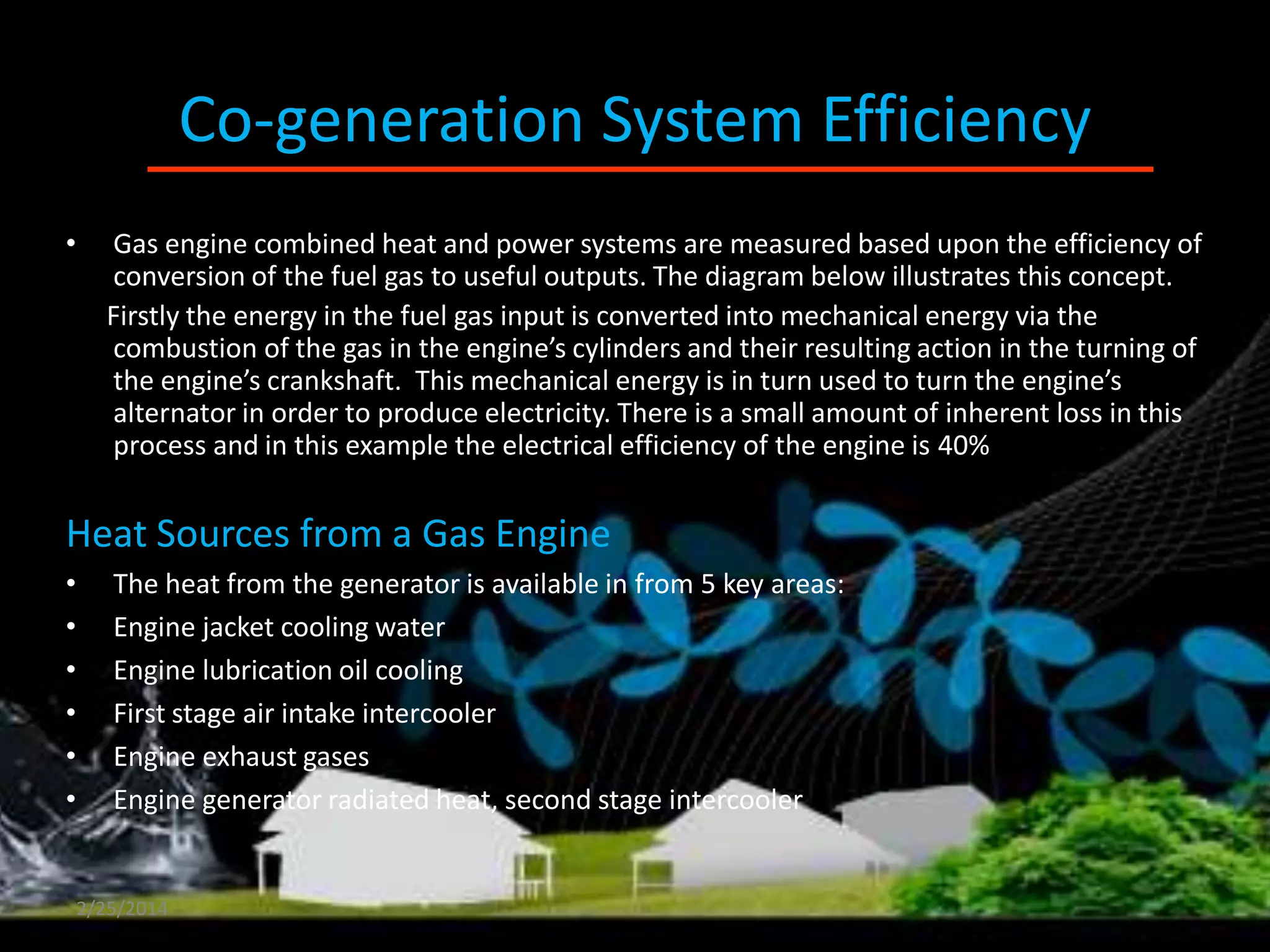

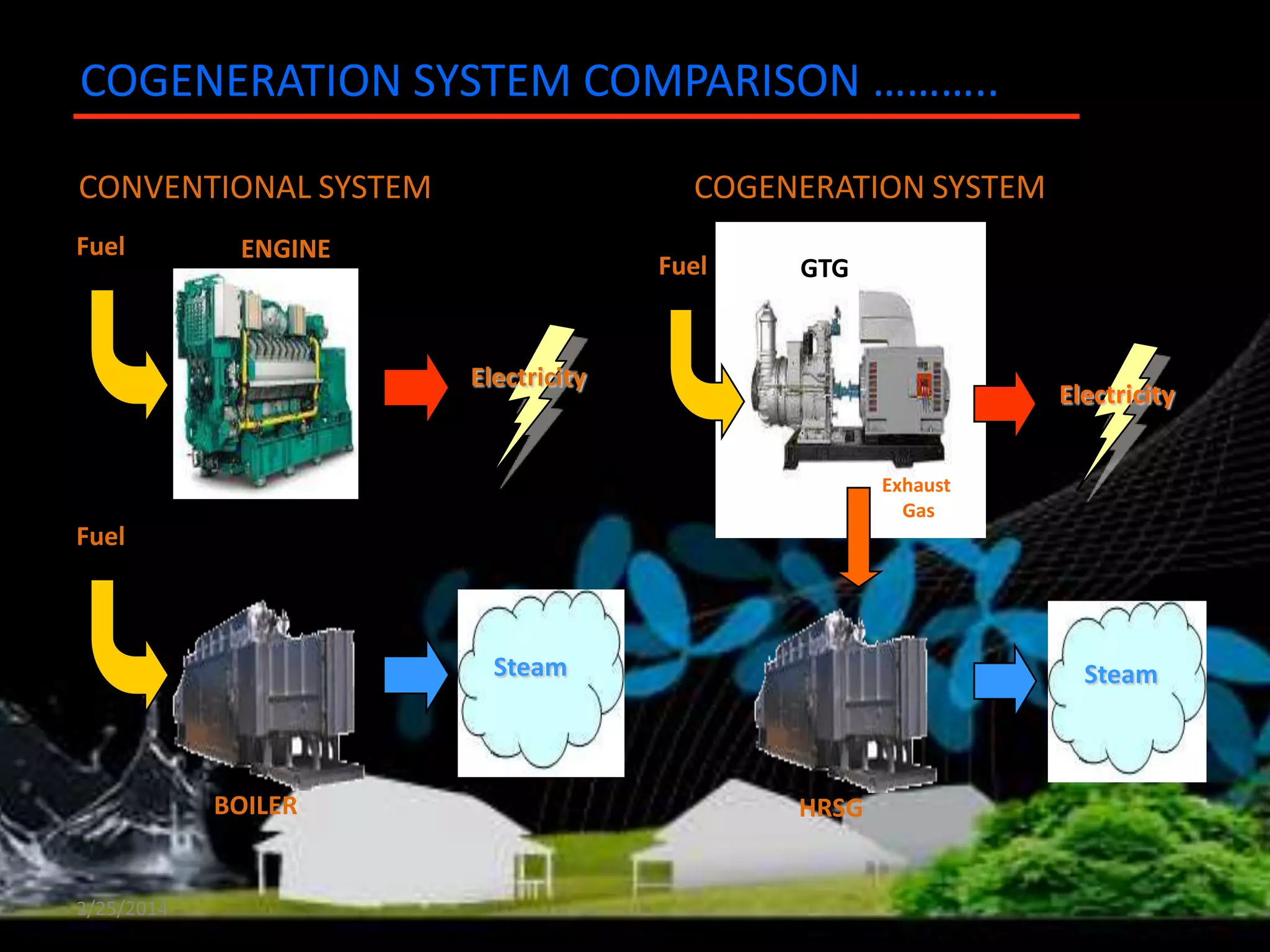

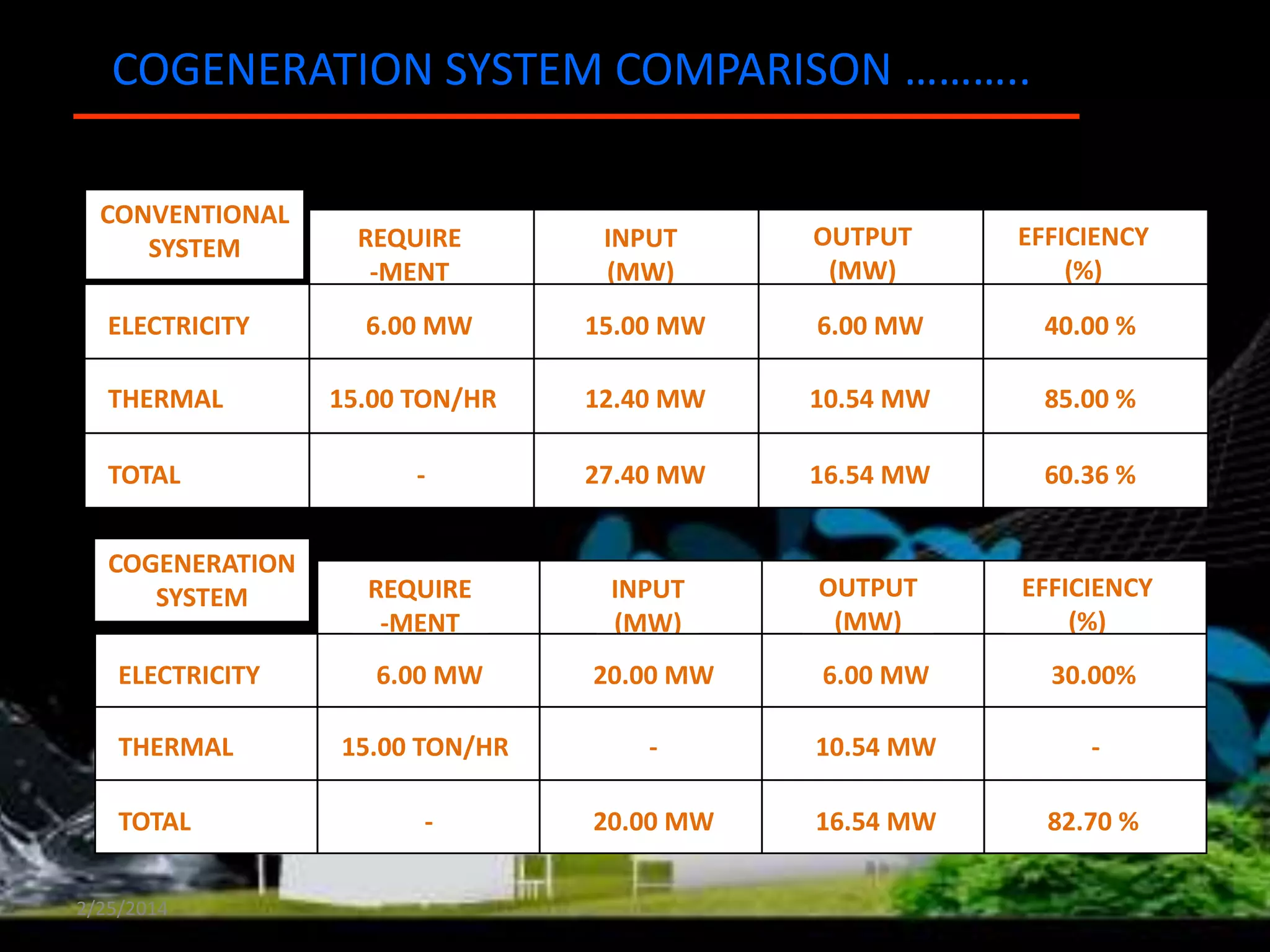

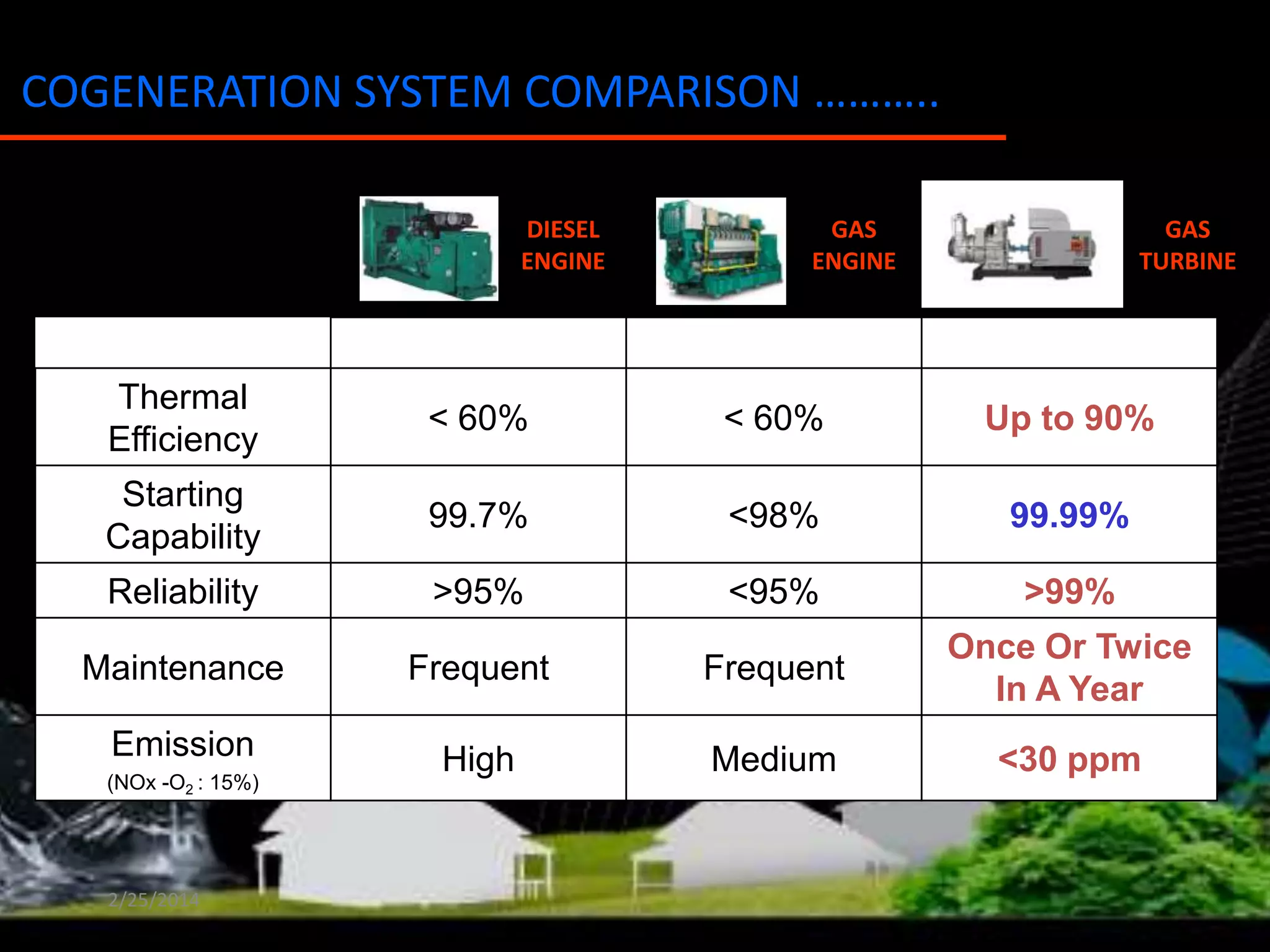

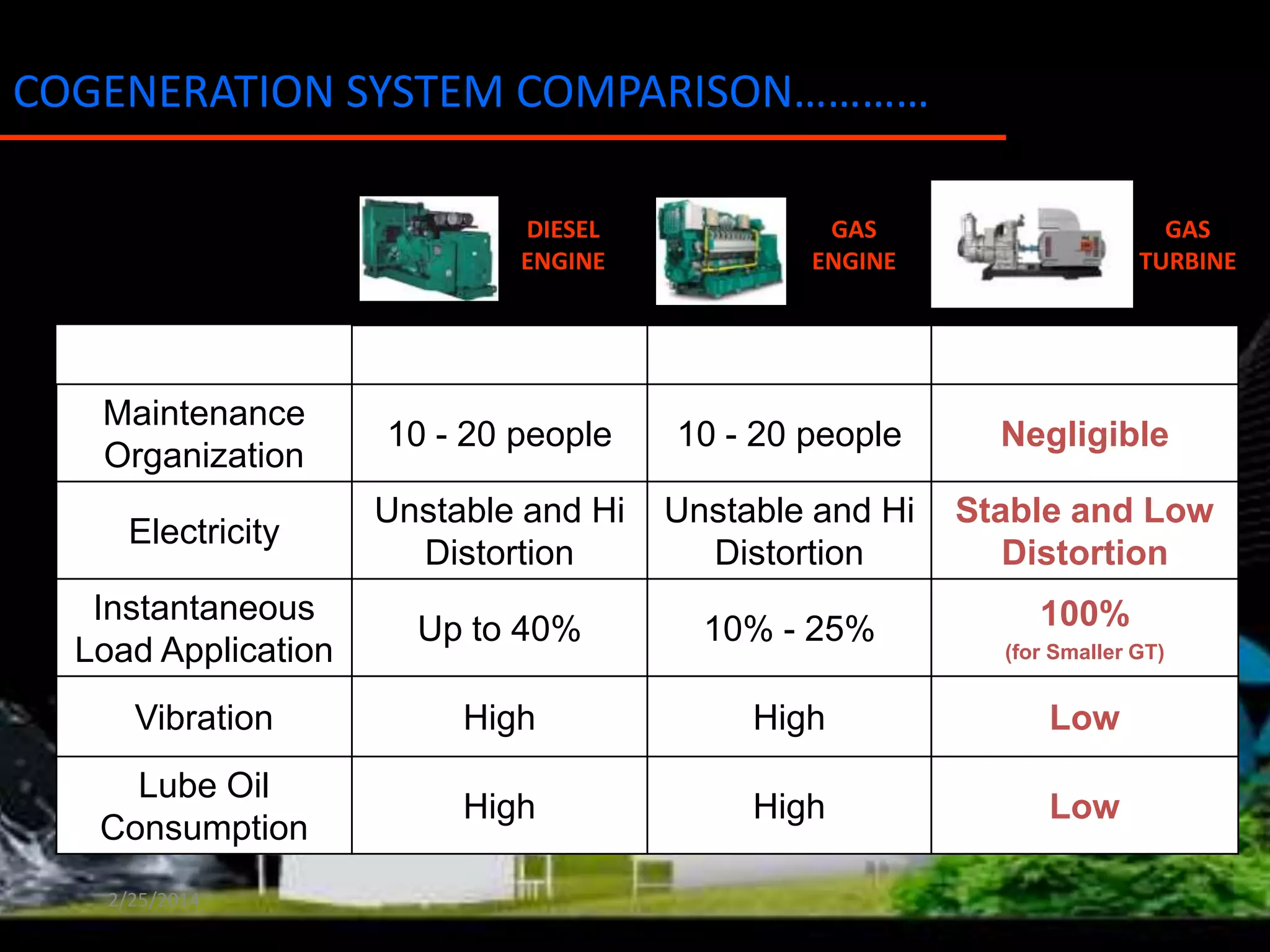

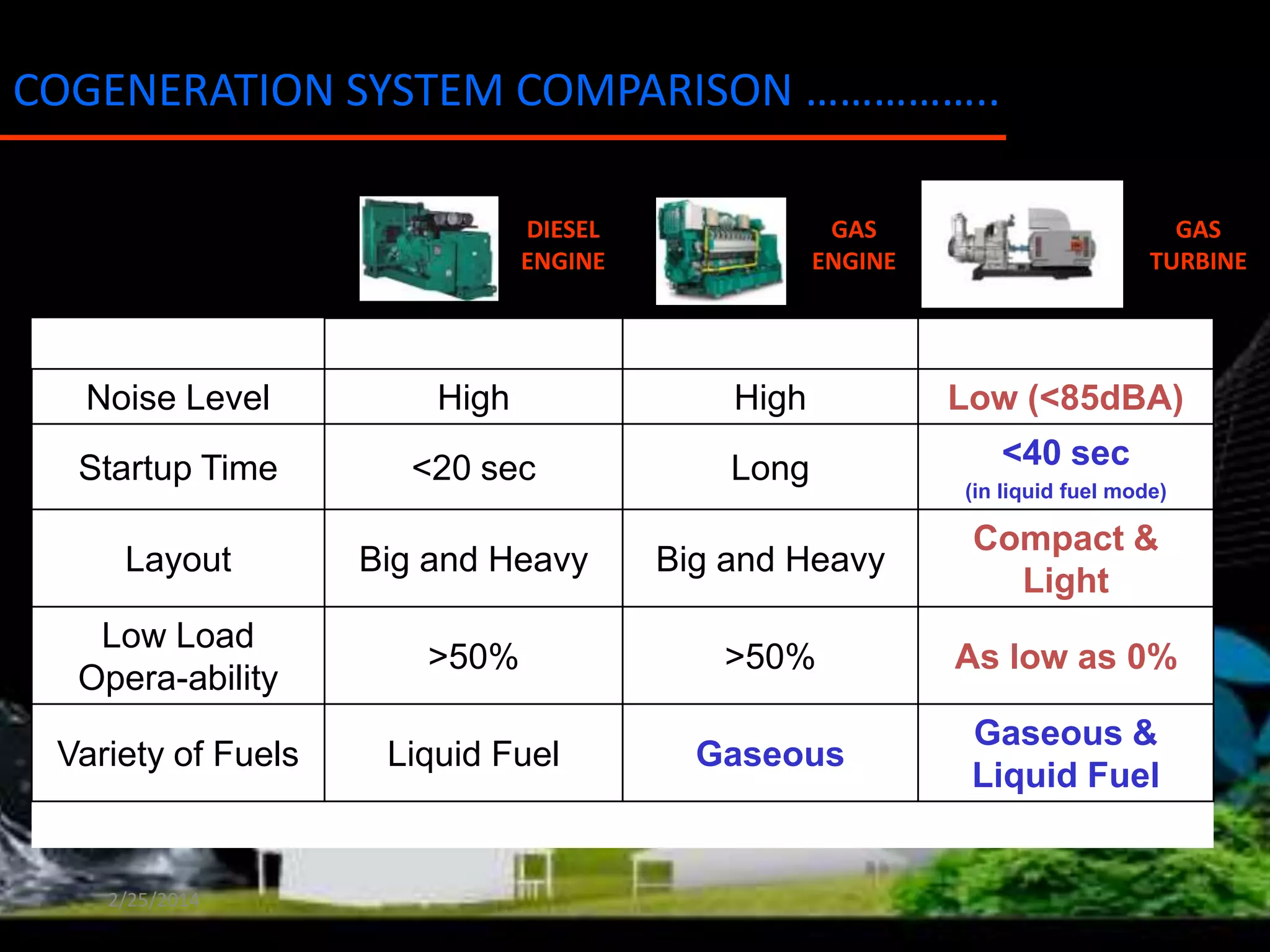

Grameen Phone operates a co-generation power system at their corporate headquarters (GP House) in Dhaka, Bangladesh to generate electricity and chilled water for air conditioning. The system uses two 1.4MW natural gas turbines that produce waste heat to power three 827RT absorption chillers. This co-generation system saves 2MW of power compared to separate power and cooling systems. Co-generation improves efficiency by capturing waste heat to produce useful outputs.