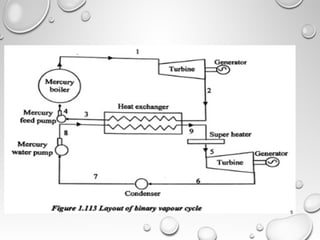

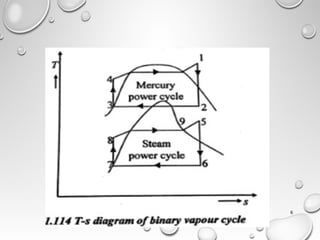

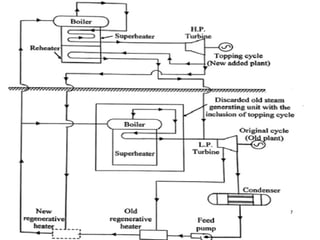

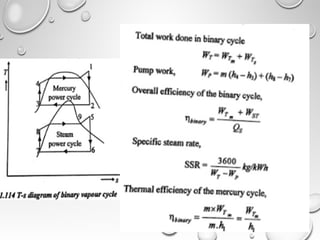

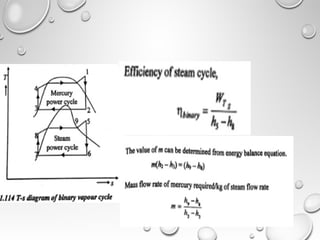

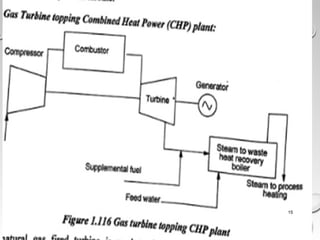

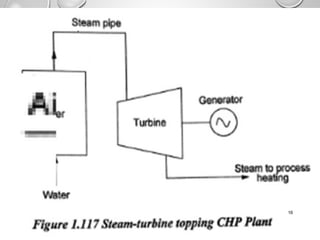

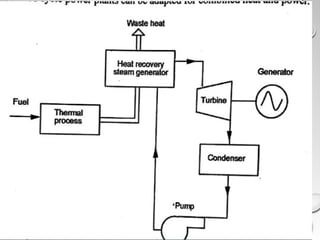

The document discusses power plant engineering with a focus on Rankine cycle vapor power cycles and methods to enhance thermal efficiency, including superheating, regeneration, and cogeneration. It explains how increasing boiler pressure, lowering condenser pressure, and utilizing multiple expansion and reheat stages can improve efficiency. Additionally, it covers binary and combined cycles as methods for maximizing energy utilization in power generation.