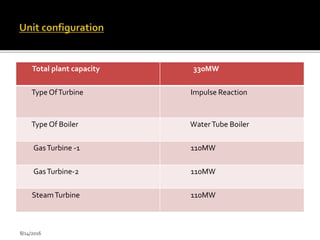

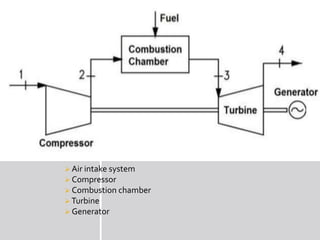

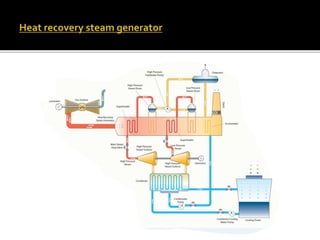

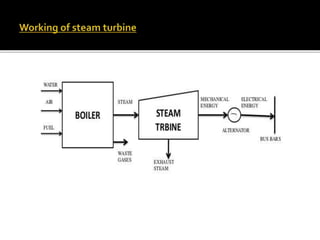

The document discusses the Dholpur combined cycle power plant in India. It generates 330 MW of electricity using two gas turbines and one steam turbine. The plant uses natural gas as its main fuel supplied by ONGC and transported by GAIL. It was established in 2007 with an estimated cost of 1155 Crore and is operated by Rajasthan Rajya Vidyut Utpadan Nigam Limited. The combined cycle power plant improves efficiency by capturing waste heat from the gas turbines to power a steam turbine.