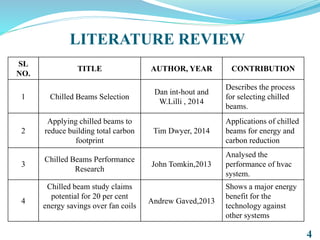

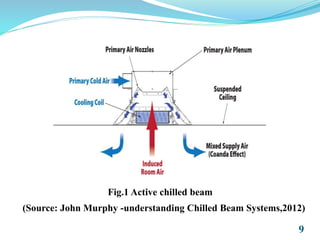

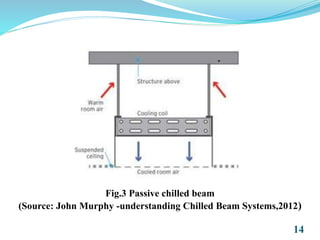

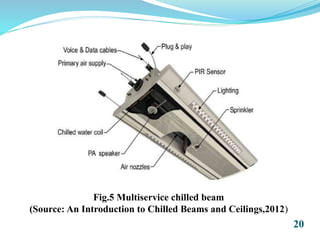

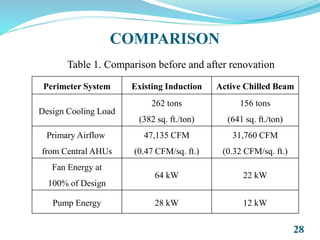

The document presents an overview of chilled beam systems, including their components, types, advantages, and disadvantages, as well as case studies demonstrating their application and effectiveness in energy savings. Chilled beams are identified as emerging HVAC technology developed for efficient heating and cooling in buildings, with specific designs for active, passive, and multi-service options. The conclusion emphasizes the lower lifecycle costs and reduced carbon emission potential of chilled beam systems compared to conventional HVAC solutions.