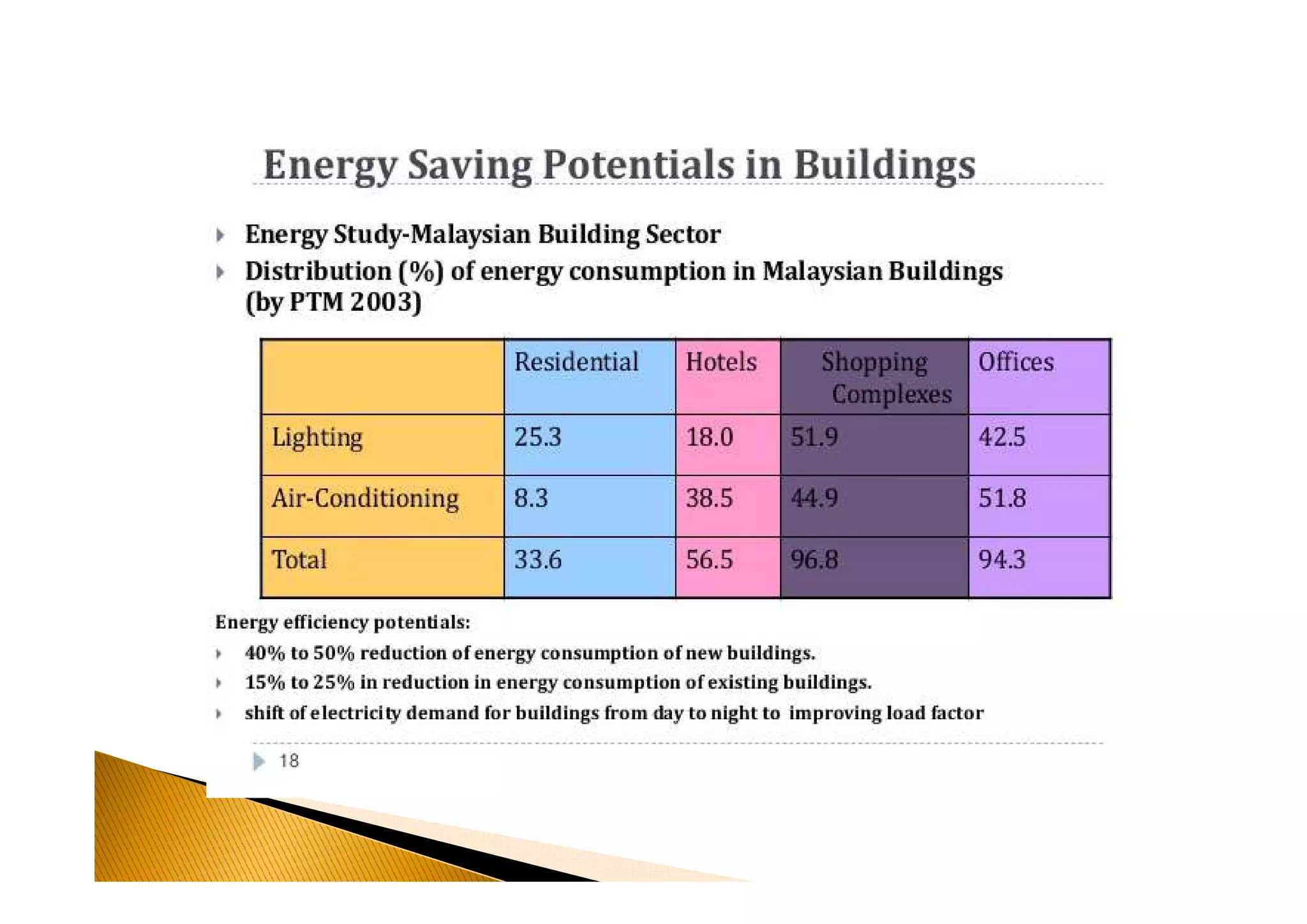

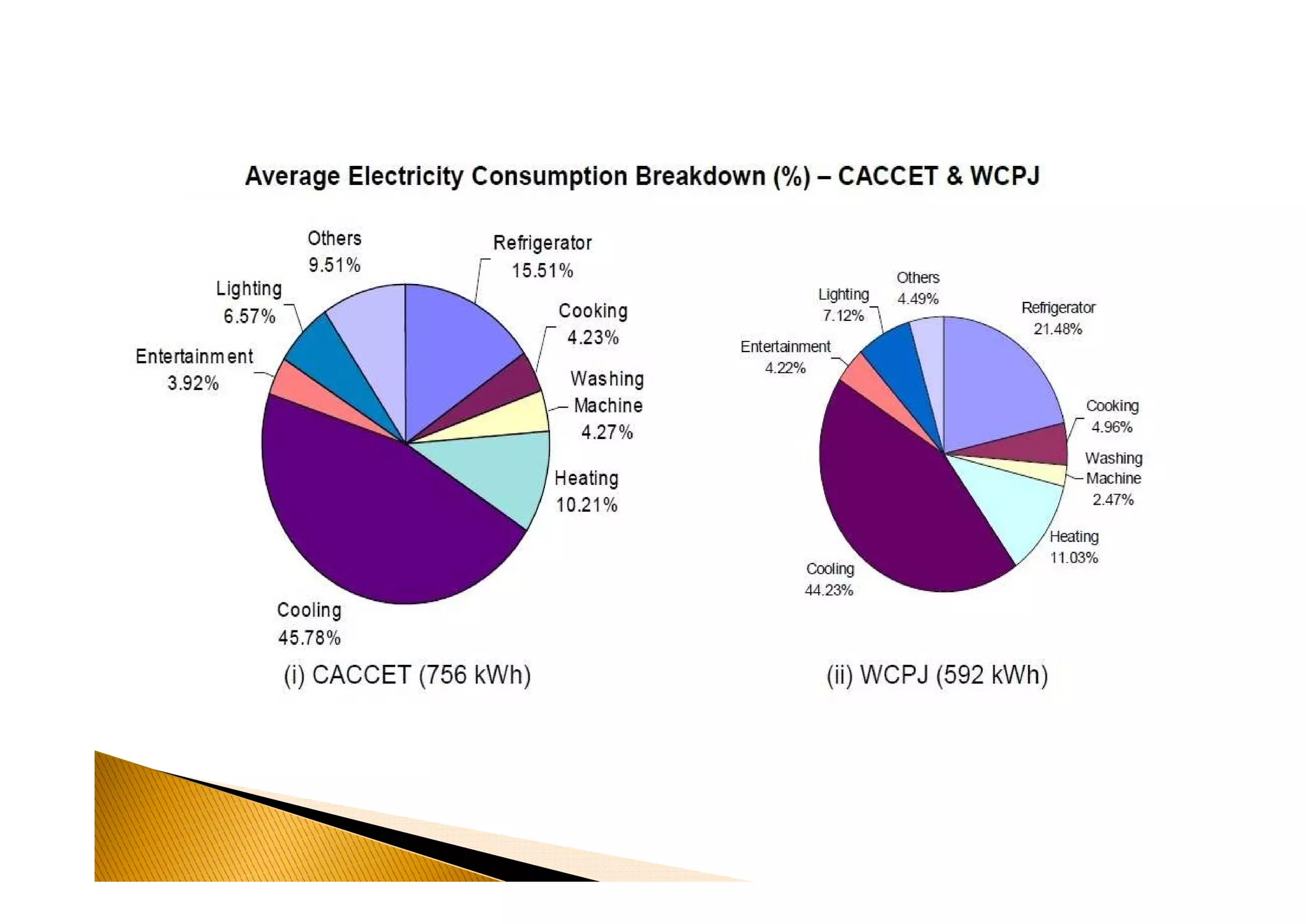

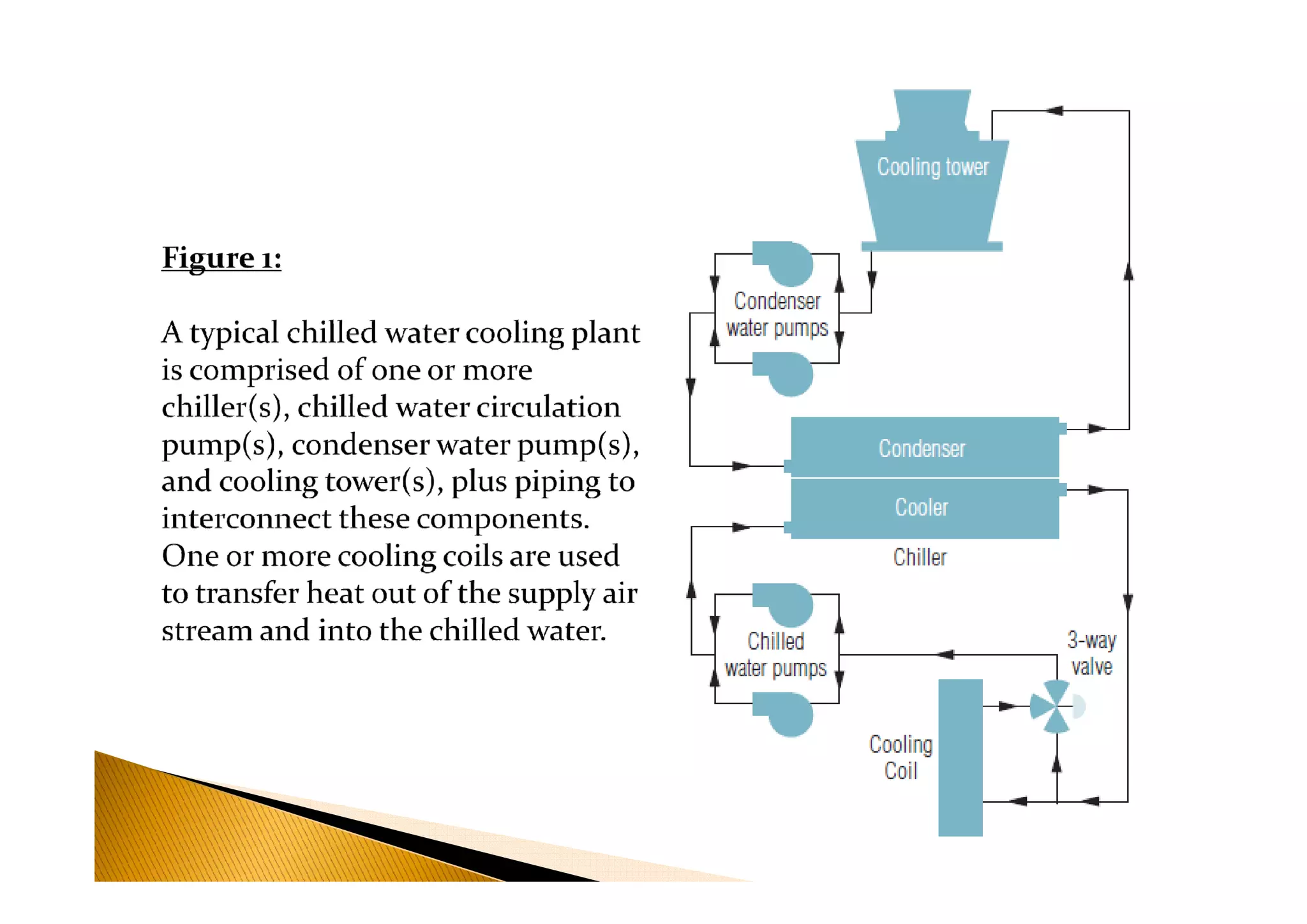

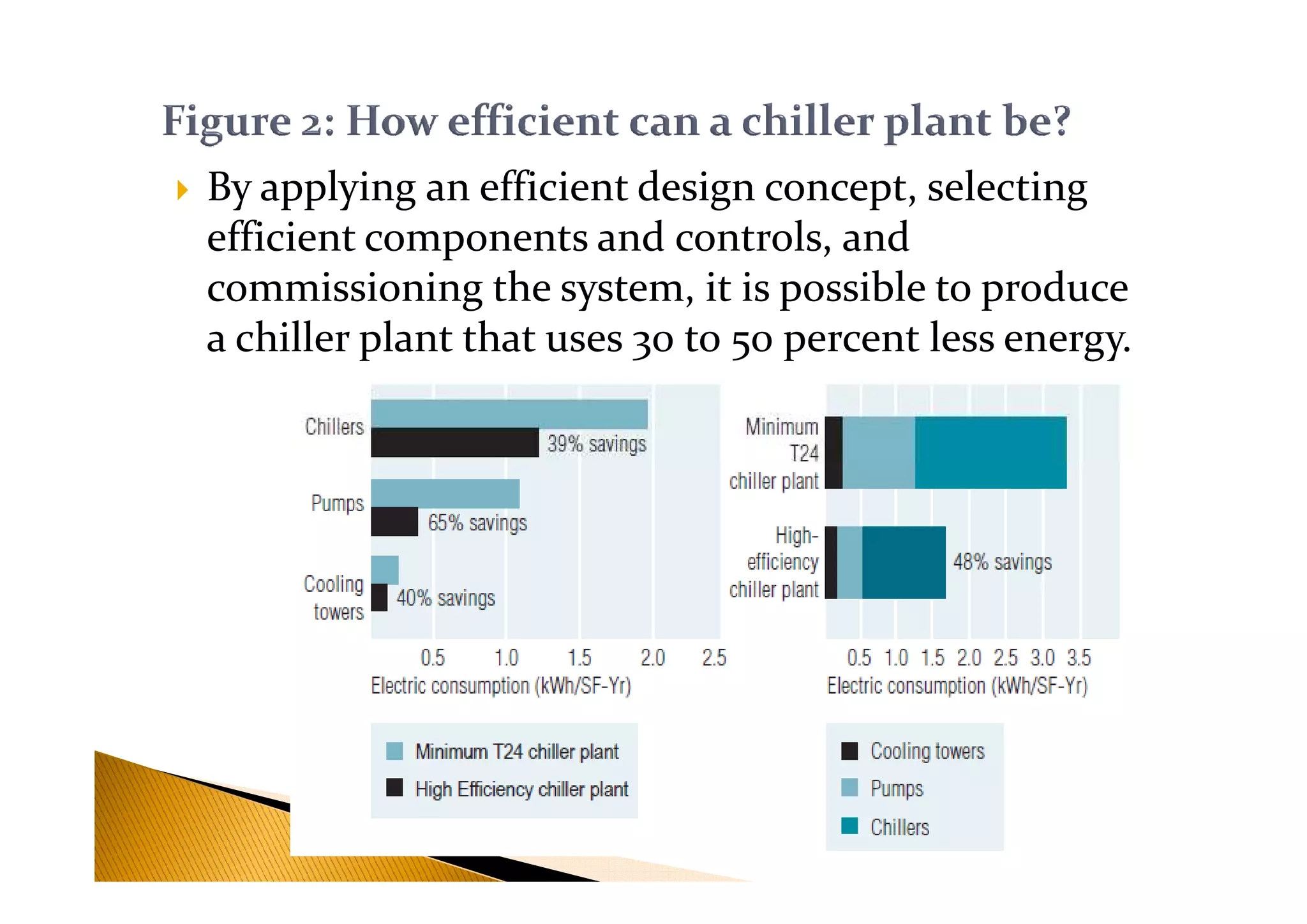

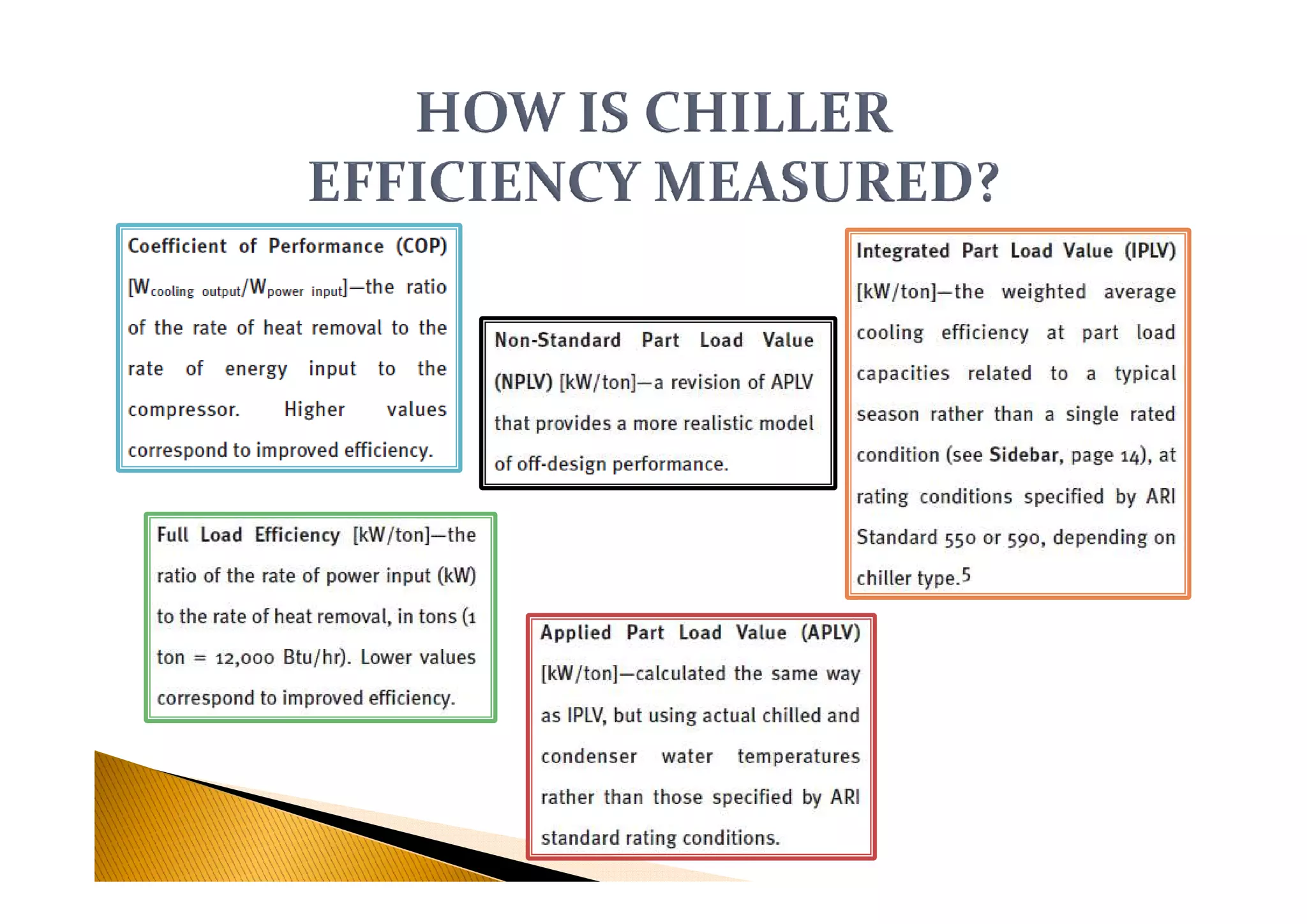

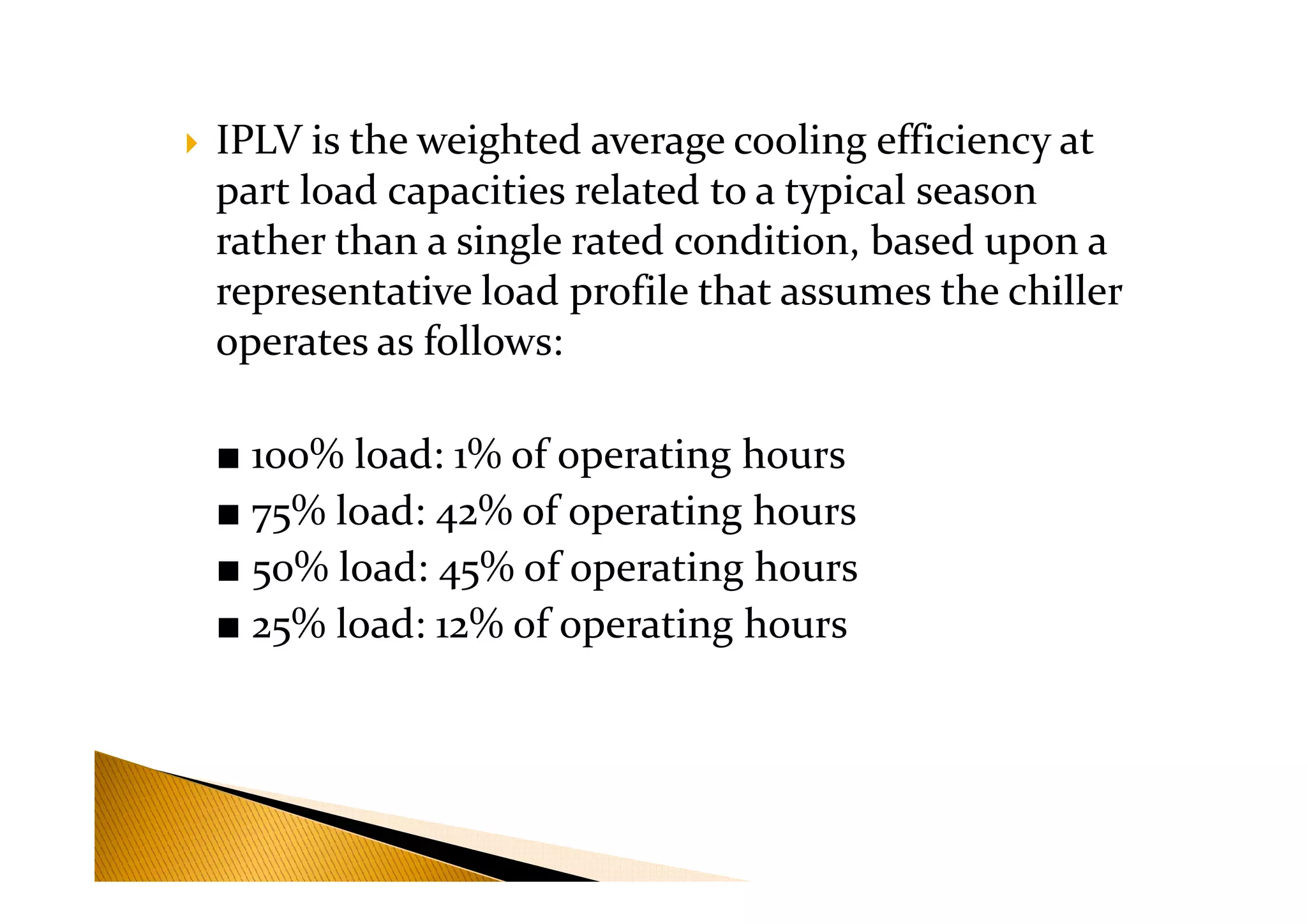

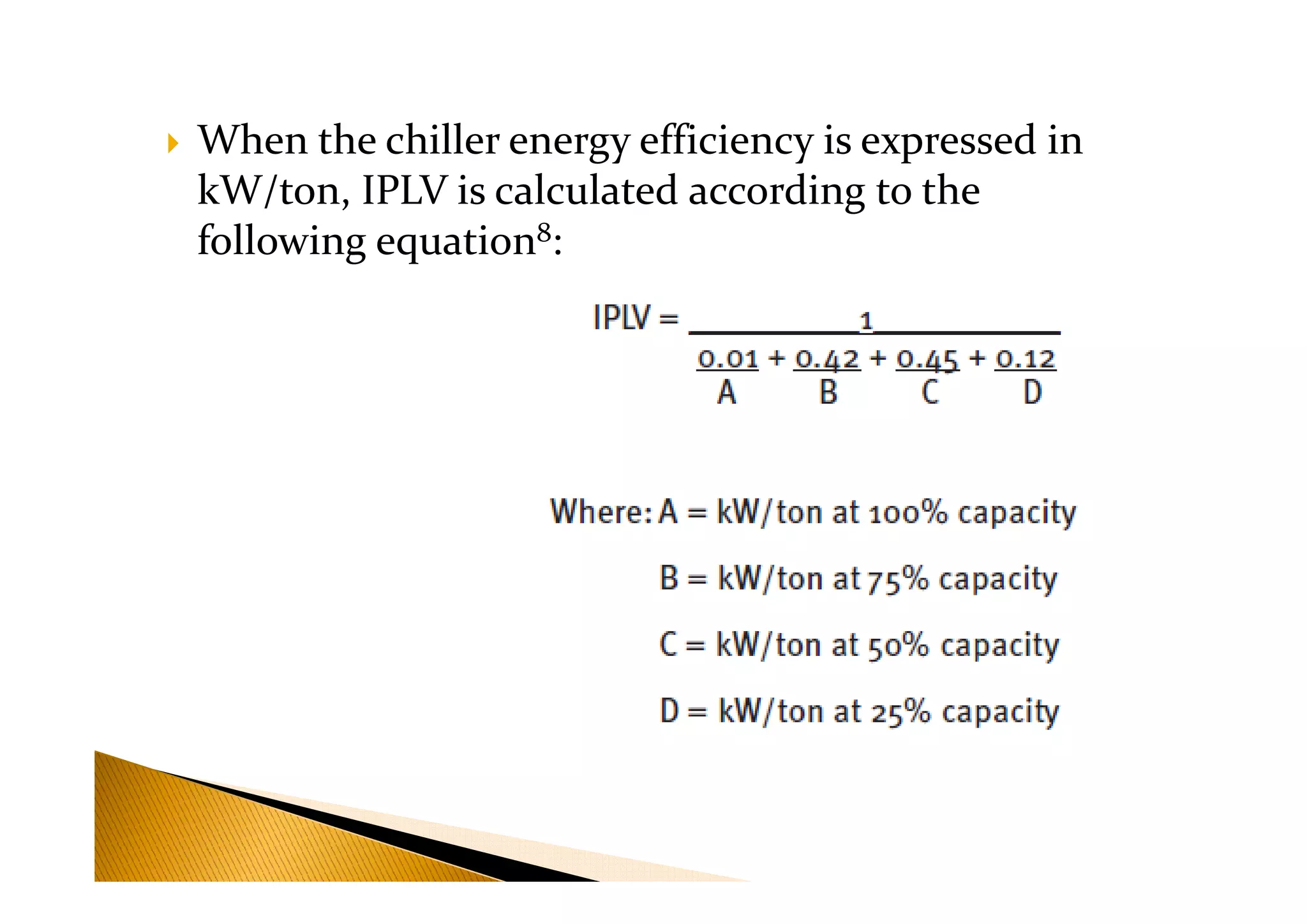

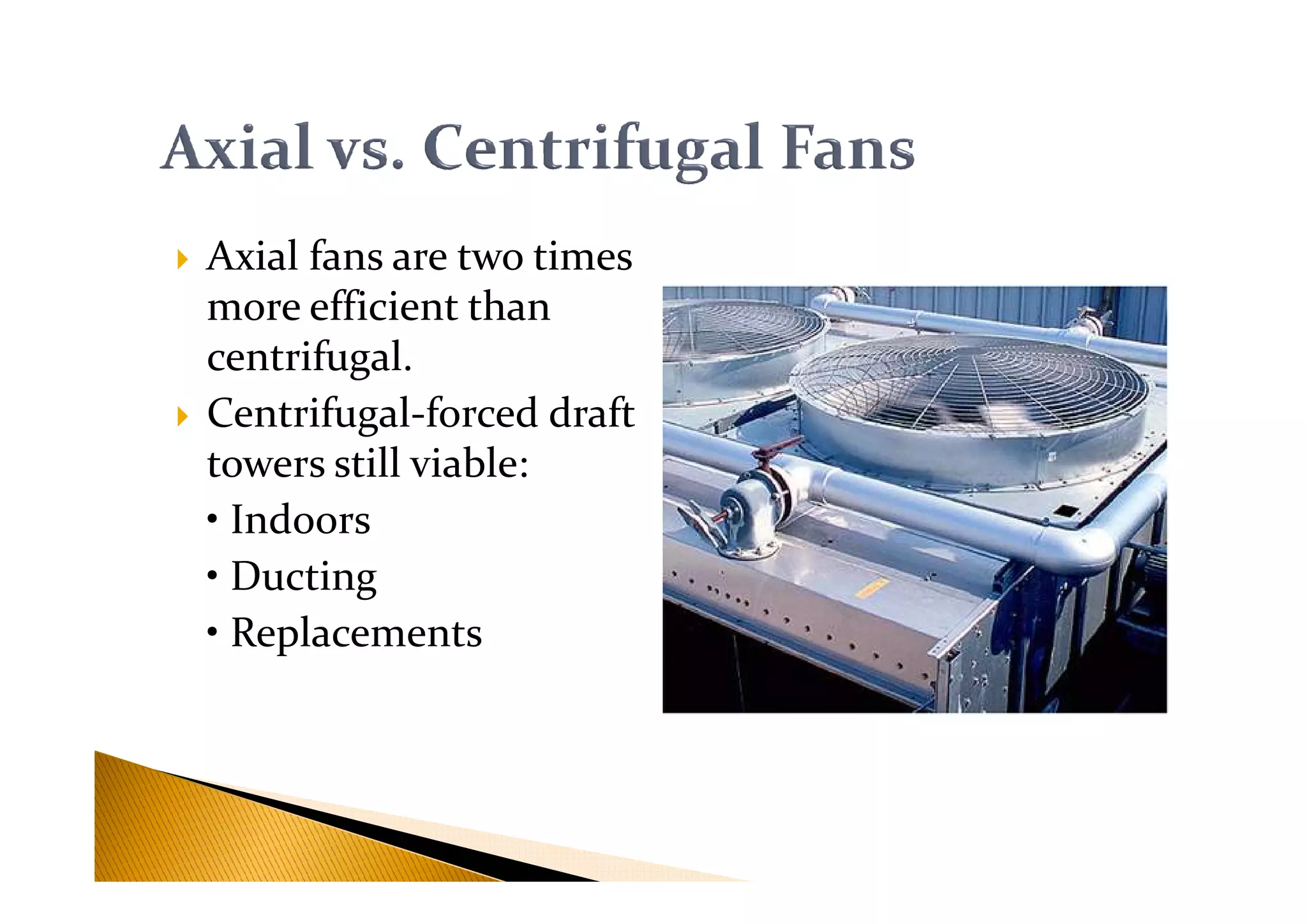

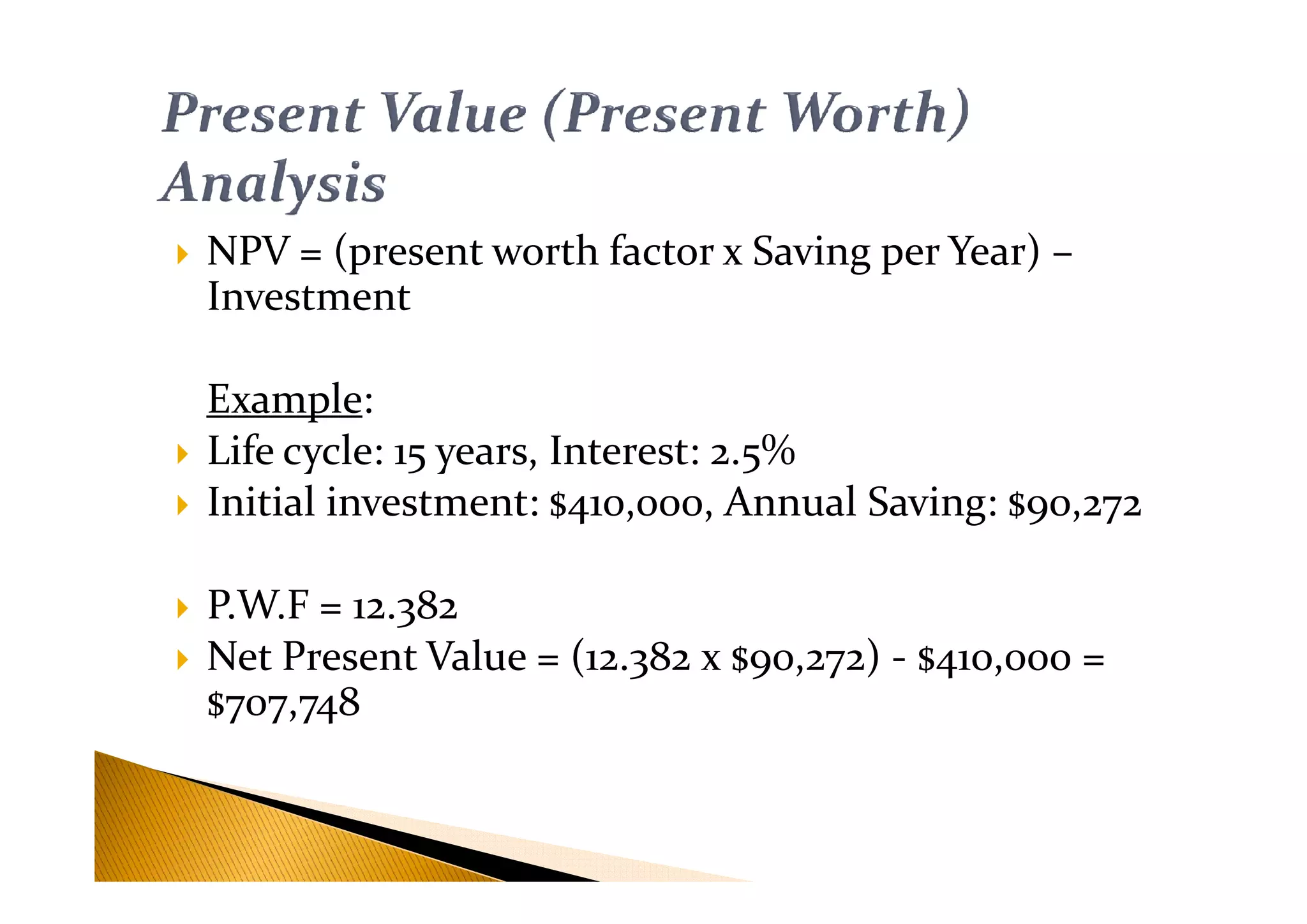

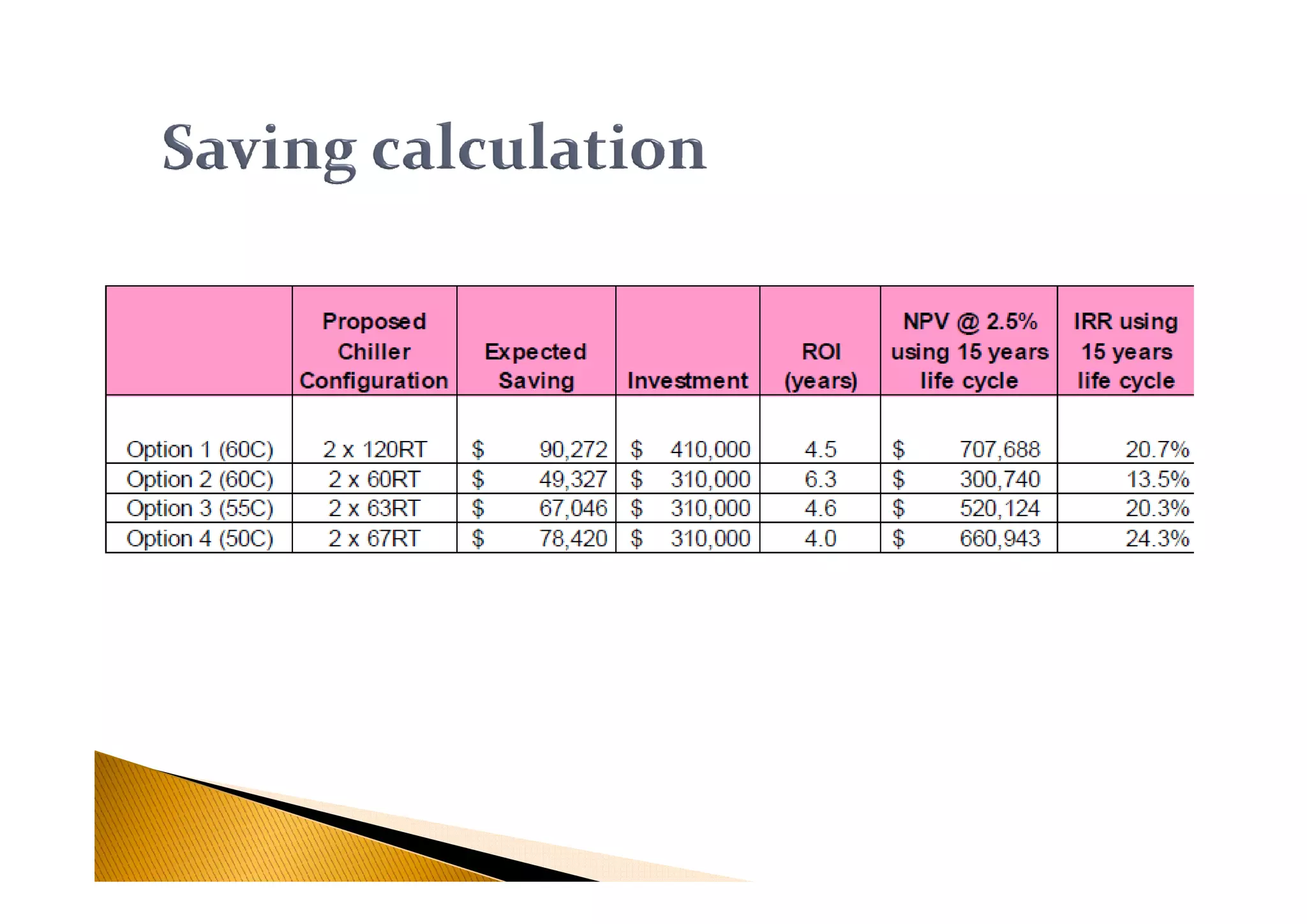

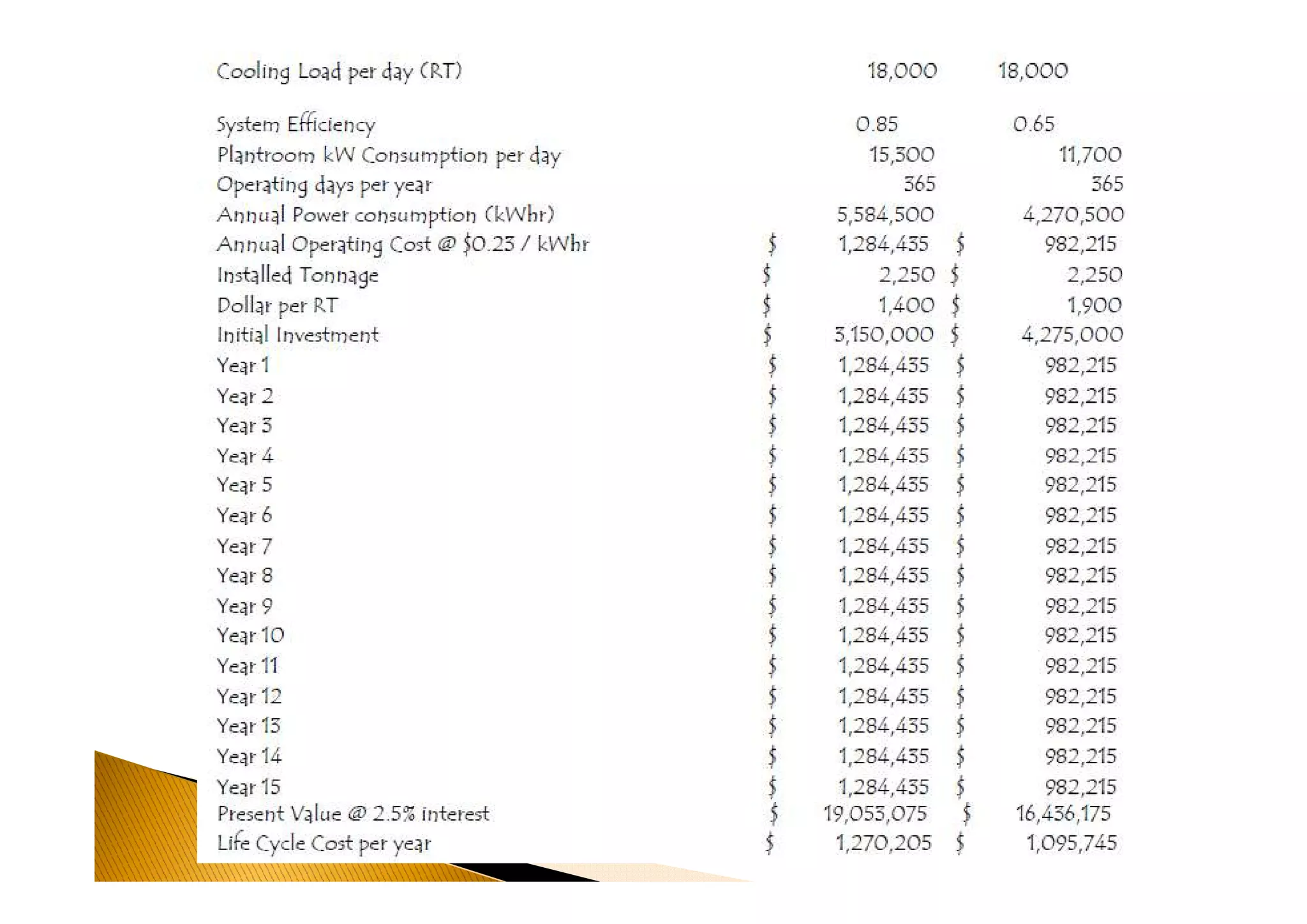

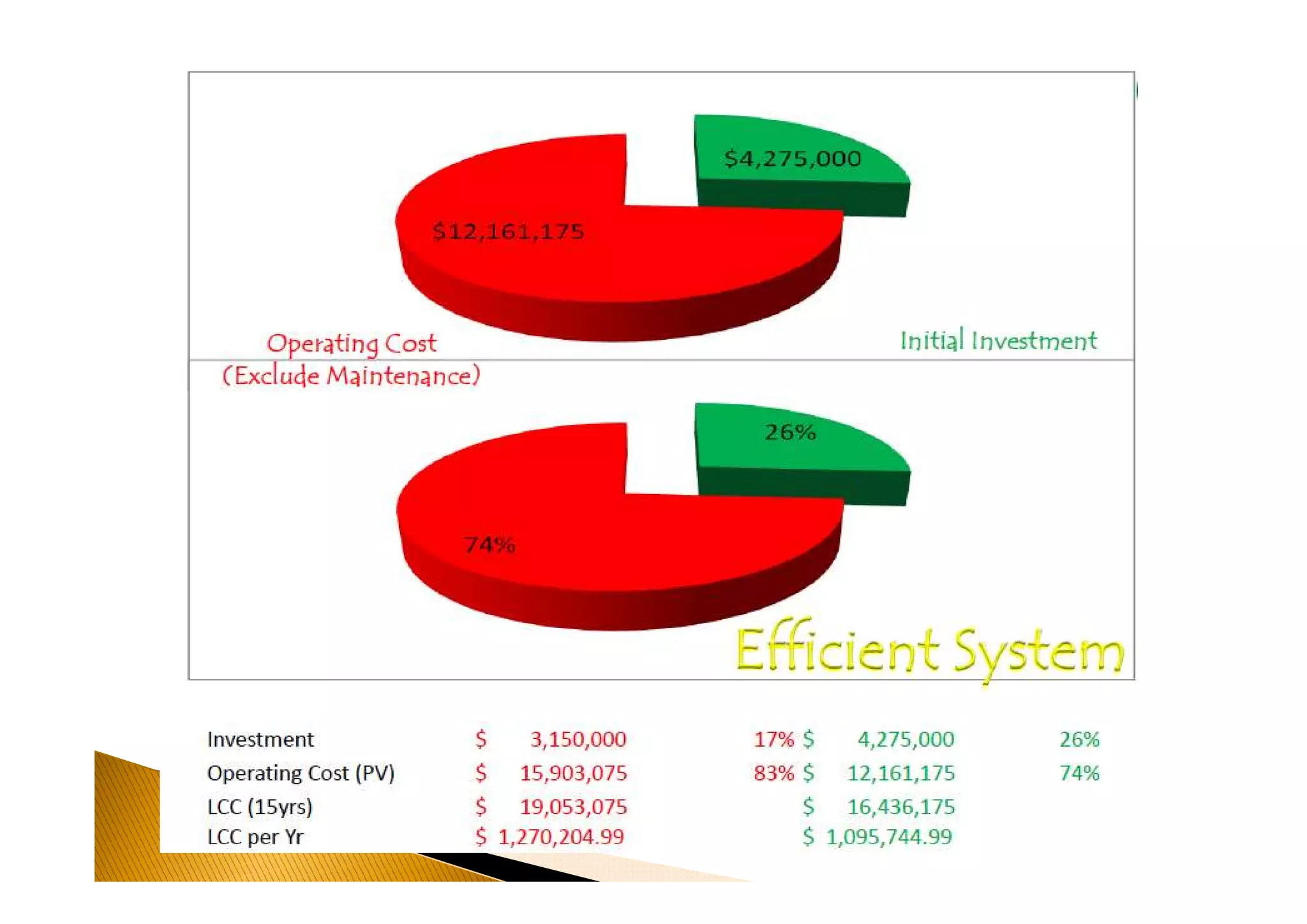

This document discusses several methods for optimizing energy consumption in air conditioning plant systems, including improving chiller efficiency, fan power, humidity controls, cooling tower efficiency, chilled/condenser water pumps, chiller plant system control, under-floor systems, and energy recovery systems. It provides case studies on topics like chiller plant design concepts, efficient component selection, installation, commissioning, and operation to reduce energy usage by 30-50%.