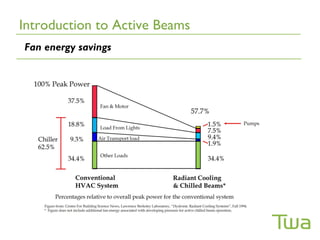

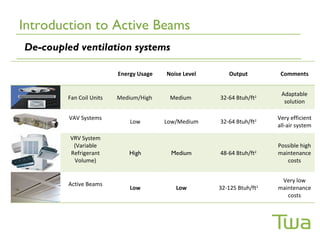

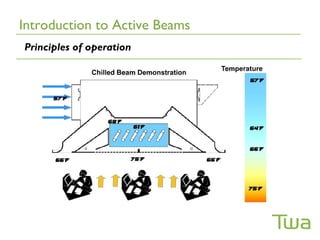

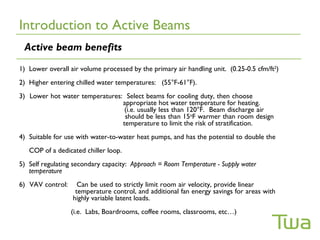

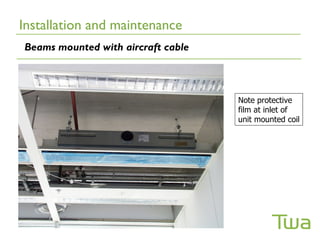

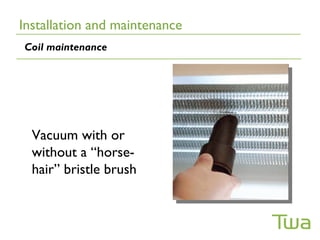

Active beams provide low maintenance cooling and heating through passive technology. They require low airflow which saves fan energy. During start-up, protective films must remain on beams until spaces are clean to prevent fouling. Commissioning involves carefully lowering secondary water temperatures, balancing primary airflow, and confirming water conditions to ensure proper operation. Active beams are a versatile solution that can be tailored for various space requirements with energy savings benefits.