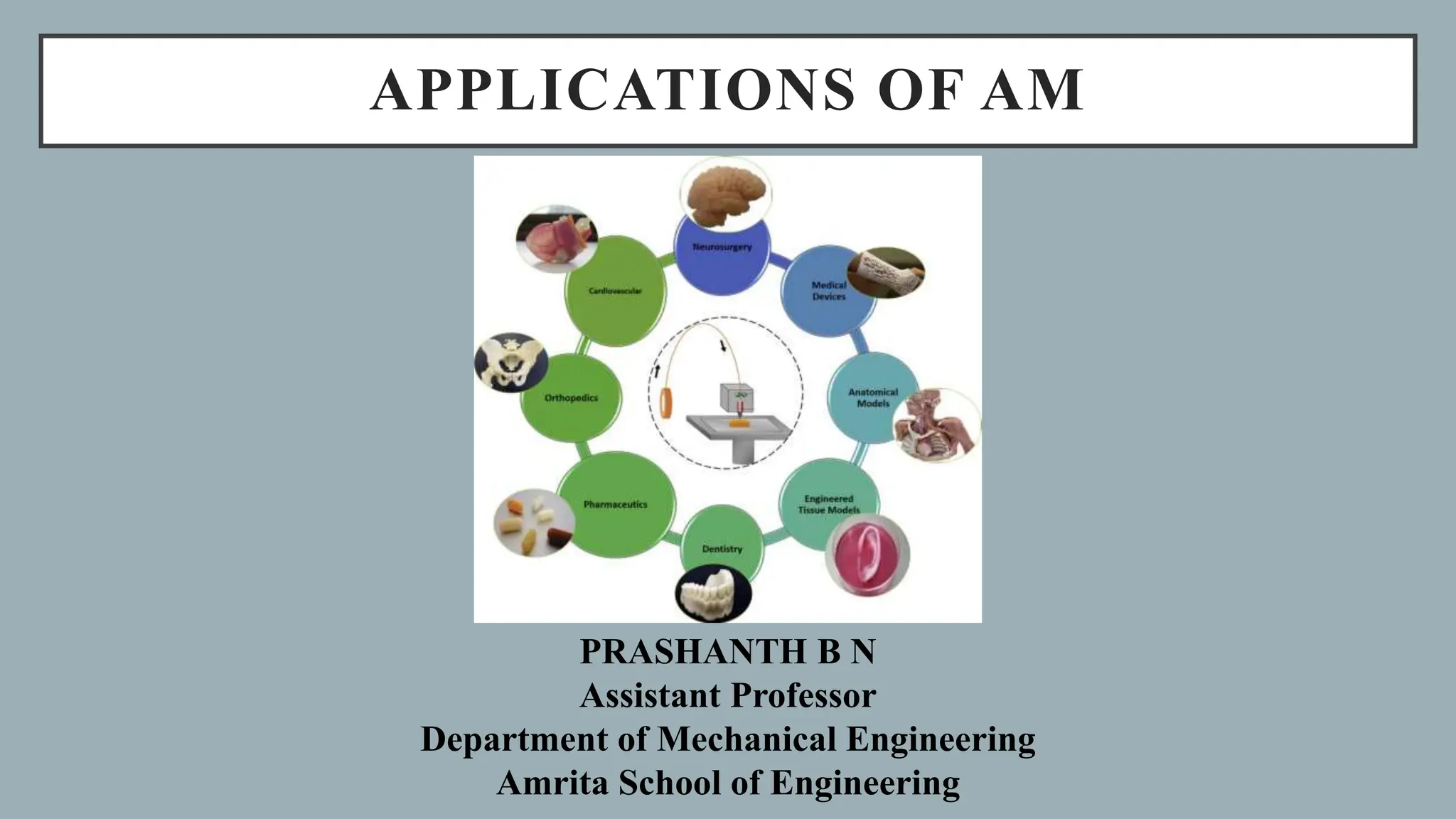

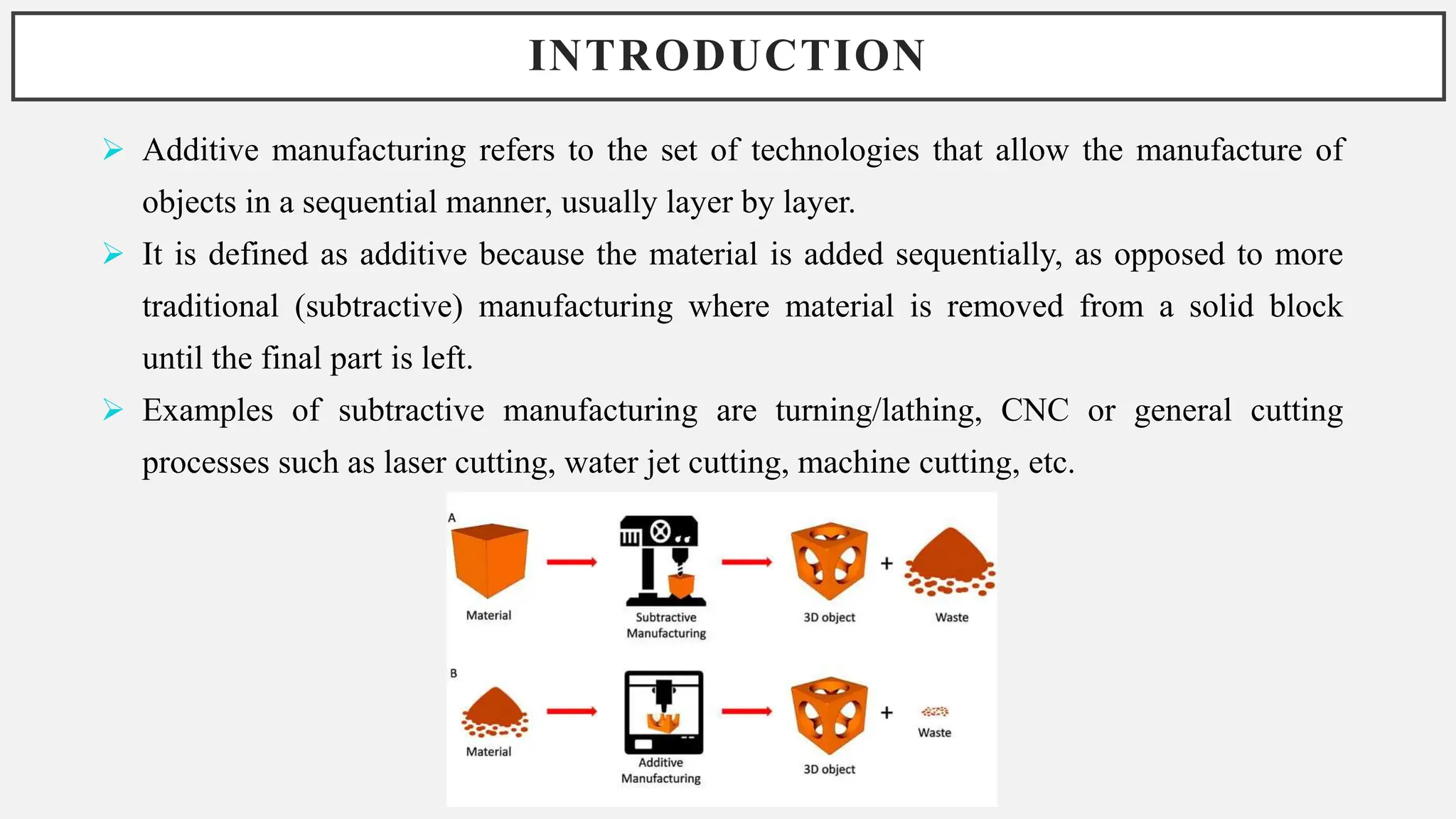

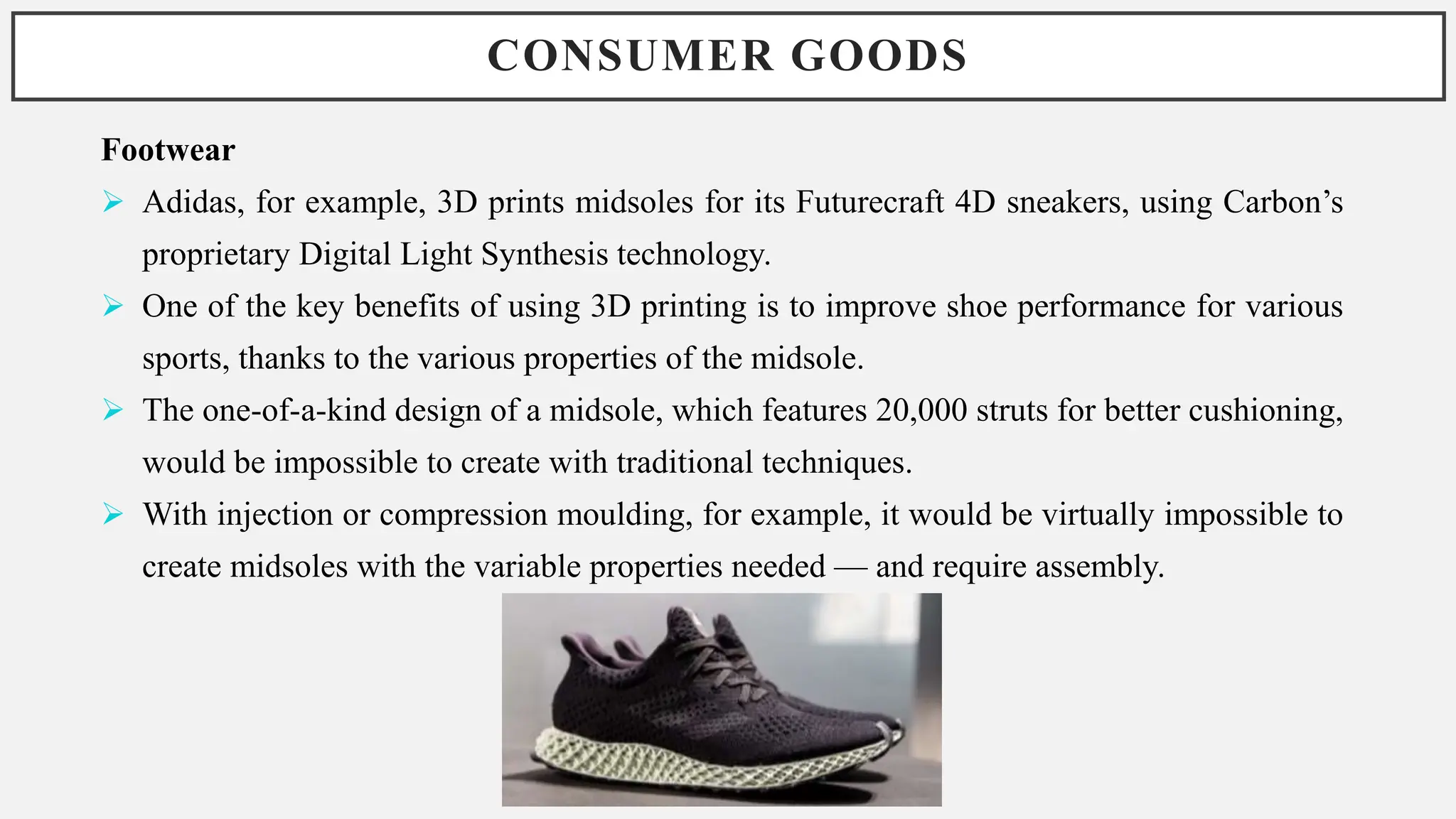

This document provides an overview of applications of additive manufacturing (AM) in various industries, with a focus on aerospace/defense and automotive. For aerospace/defense, AM is used for low-volume production of complex parts, weight reduction, maintenance/repair, rocket components, aircraft interiors, and tooling. Benefits include cost savings, design flexibility, reduced lead times. For automotive, benefits are faster product development, greater design flexibility, customization, and ability to produce complex geometries. Overall the document discusses how AM is increasingly being used for end-use parts and components in both industries.