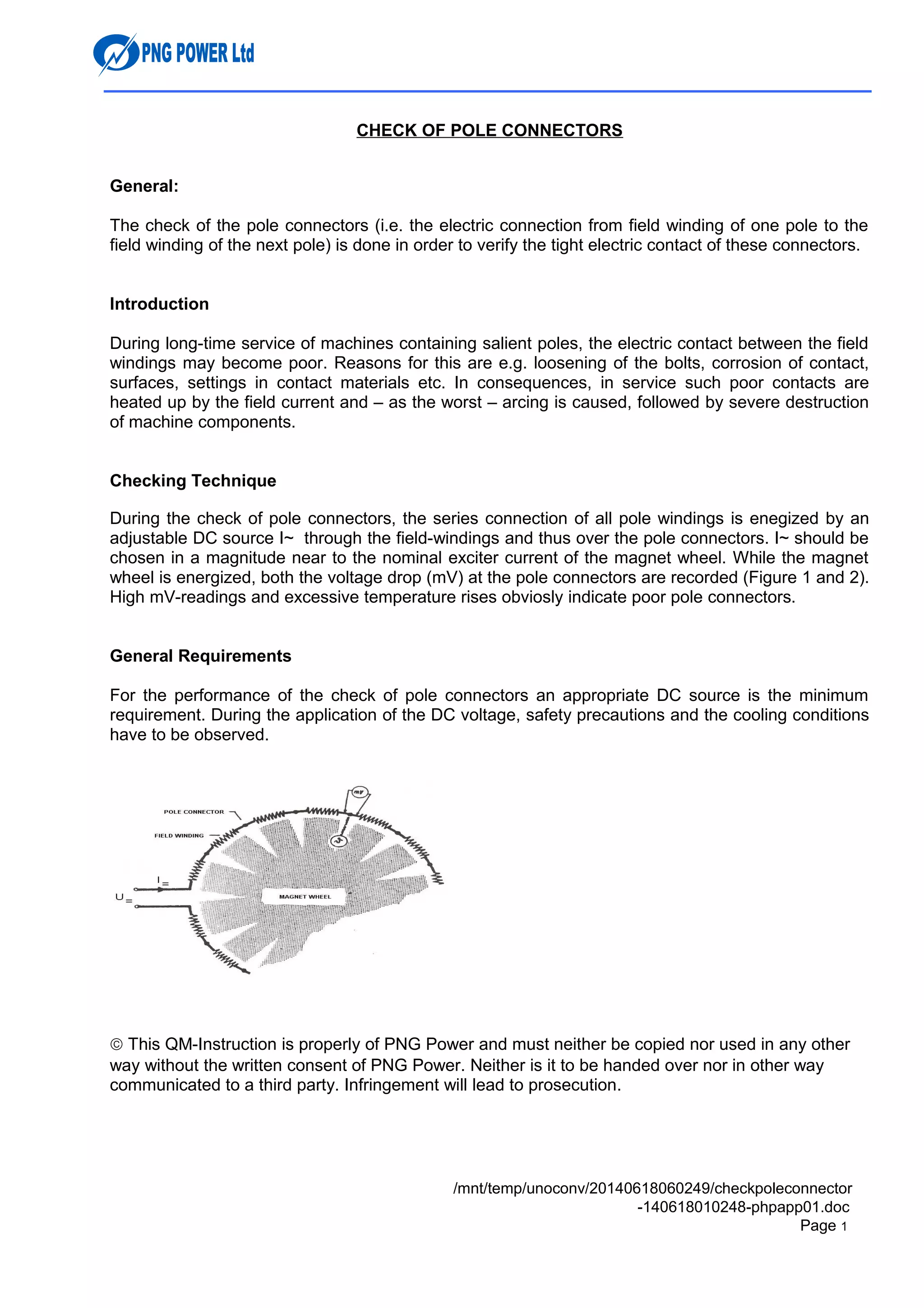

The document discusses checking pole connectors in machines containing salient poles to verify tight electric contact. Over time, poor contacts between field windings can develop due to loose bolts, corrosion, or material changes. This causes heating and potential arcing, damaging machine components. To check connectors, an adjustable DC source energizes the series pole windings, and the voltage drop across connectors is measured. High readings or excessive temperature indicate poor connectors. Properly checking requires a DC source and safety precautions during voltage application and cooling.