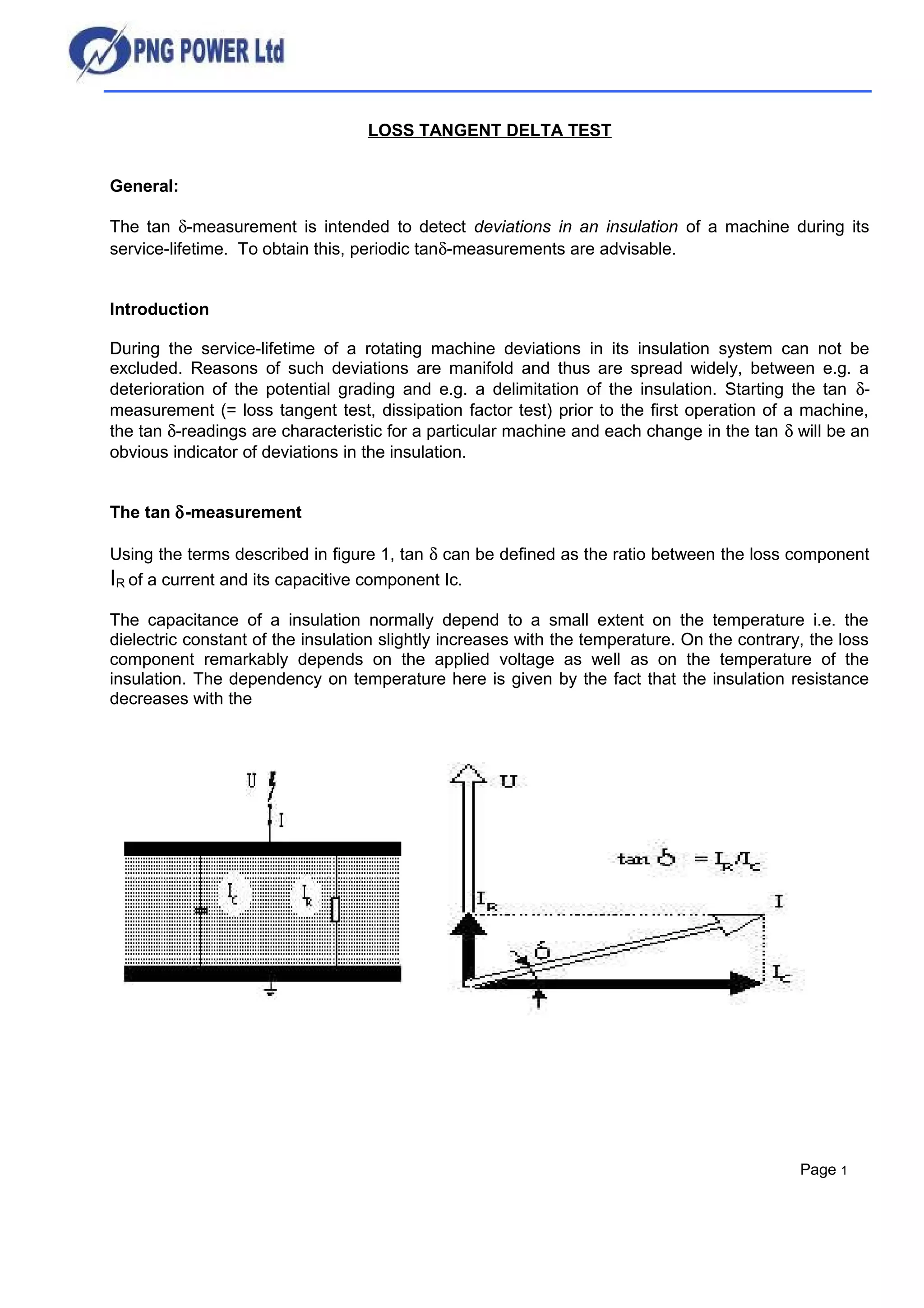

The document discusses the loss tangent delta (tan δ) test, which is used to detect deviations in the insulation of rotating machines during their service lifetime. Tan δ is a ratio that measures the loss component versus the capacitive component of current in an insulation. It increases with temperature and applied voltage. Periodic tan δ measurements are recommended to monitor changes from the baseline reading, as increases could indicate deterioration of the insulation system. The test procedure, safety precautions, and interpretation of results are described.