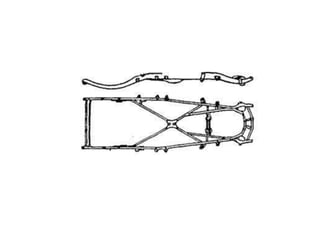

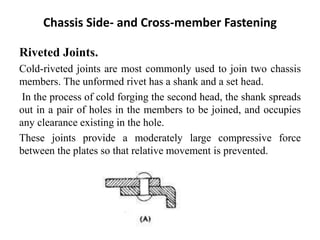

The chassis frame is crucial for supporting vehicle components while being light and strong enough to withstand loads without distortion. Common materials include cold-rolled open-hearth steel, and various fastening methods such as cold-riveted, bolted, and lap welded joints are used, each with its advantages and disadvantages. Care must be taken in joint design and assembly to prevent issues like fatigue failure and thermal distortion.