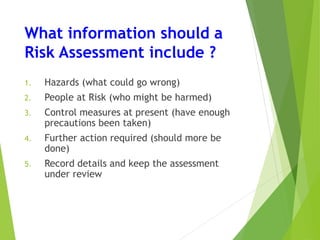

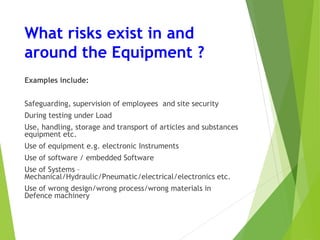

This document provides an introduction to risk assessments, including what they are, why they should be done, what information they should include, who is responsible for completing them, and answers frequently asked questions about risk assessments. A risk assessment carefully examines potential hazards and risks in an organization's work to ensure proper precautions have been taken to prevent harm. They are a legal requirement and help reduce liability, costs from claims/prosecutions, and uphold the moral duty of care owed to employees and others. Standard risk assessments templates are available to assist the process.