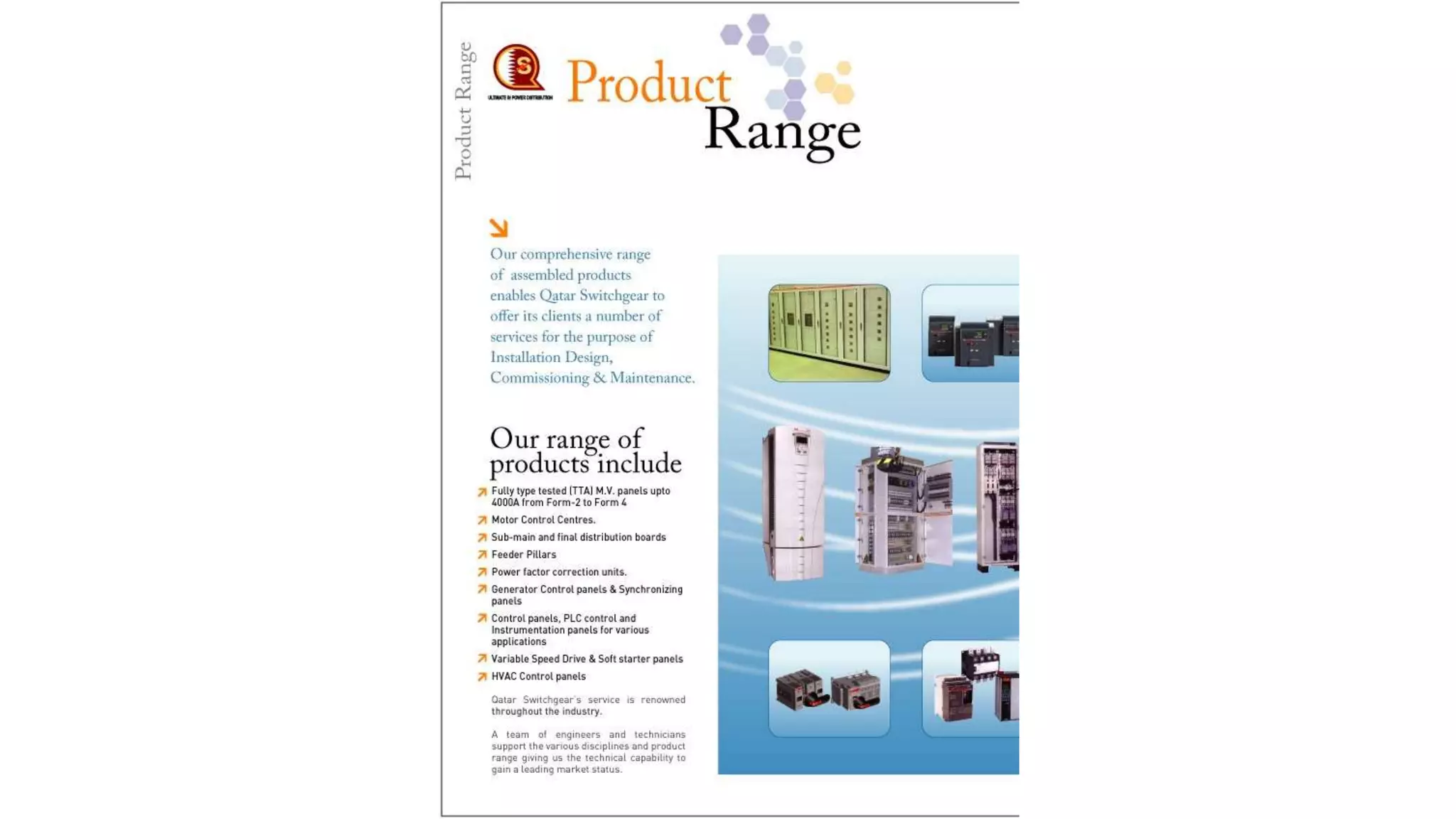

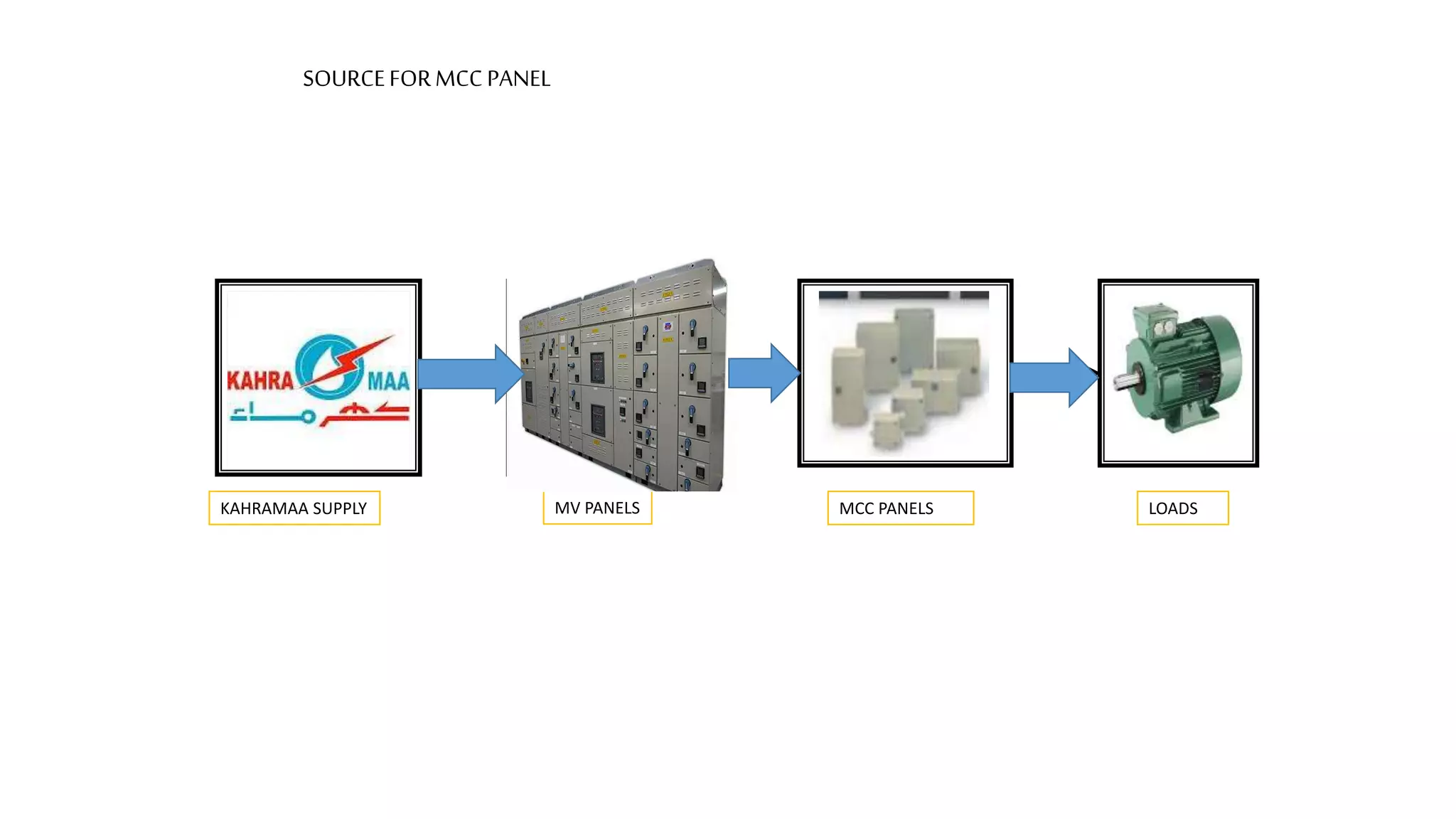

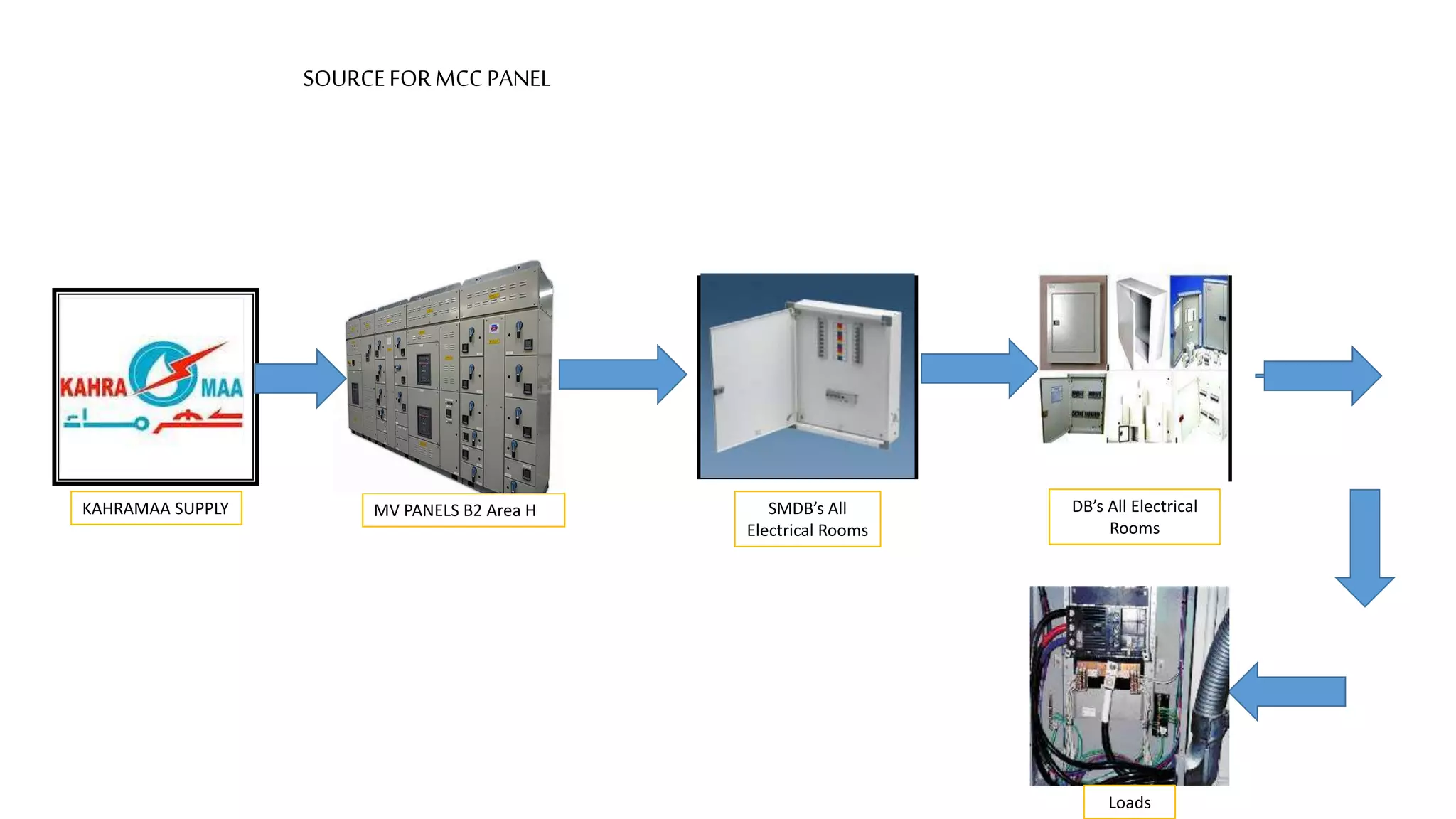

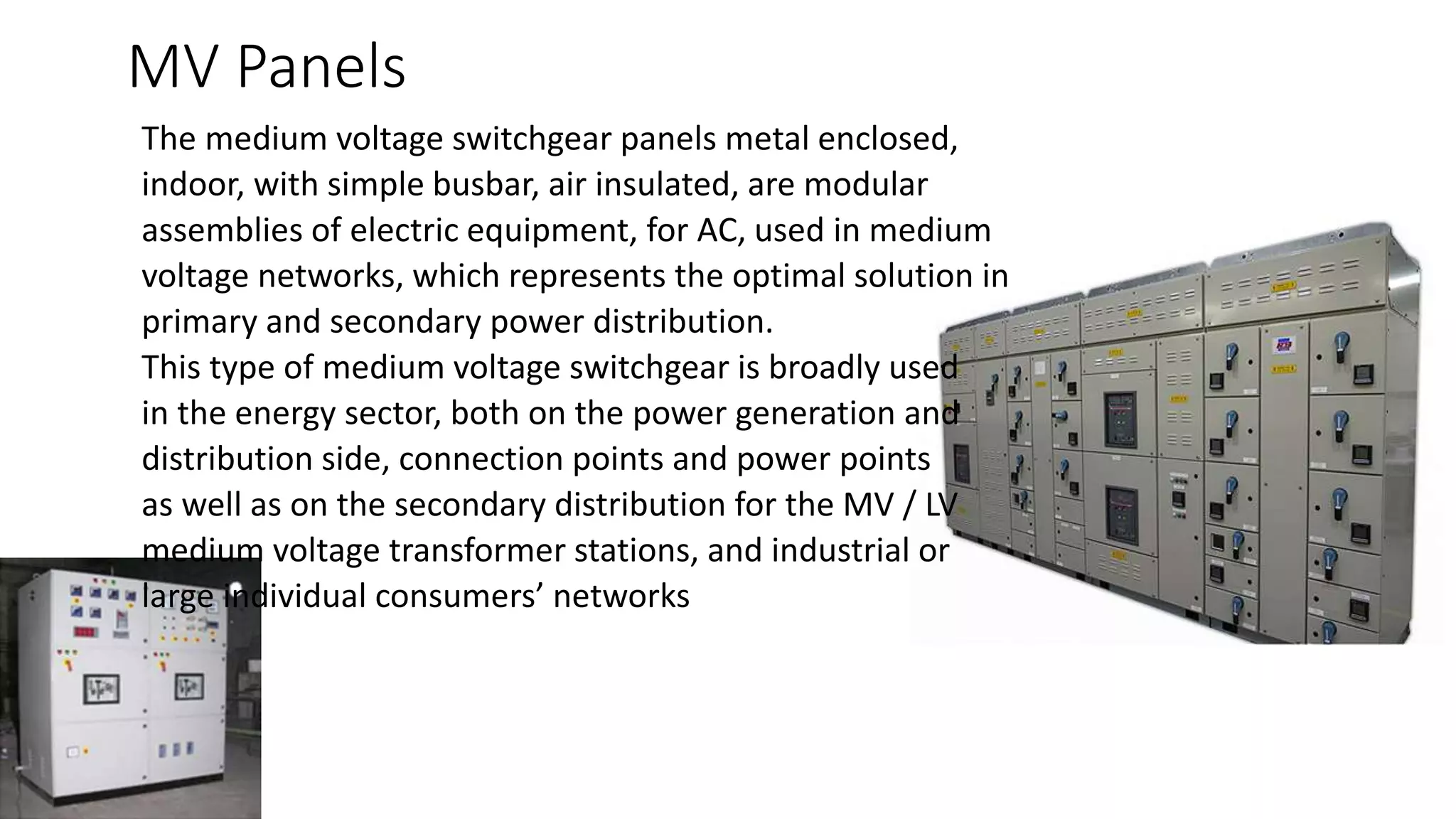

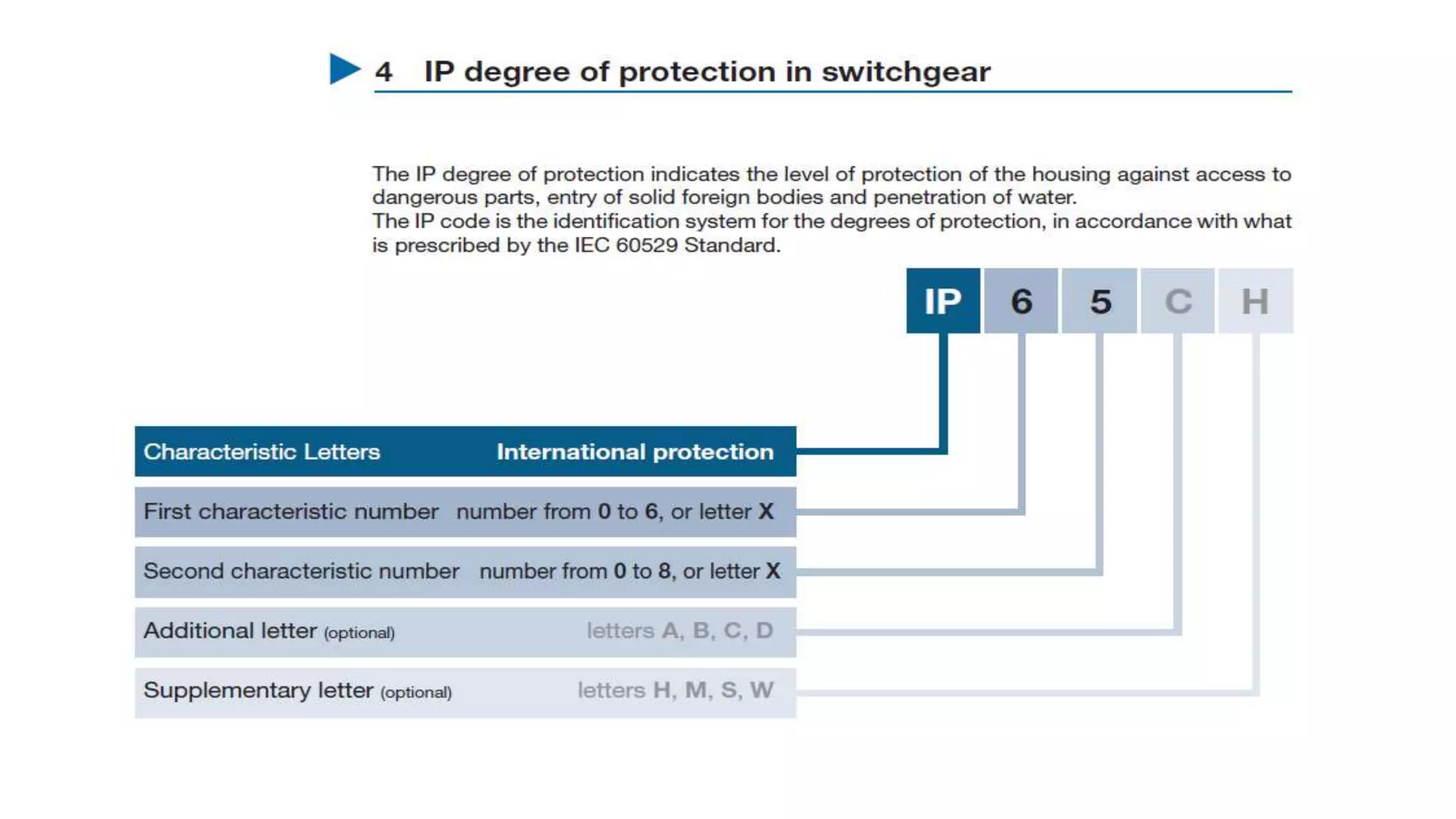

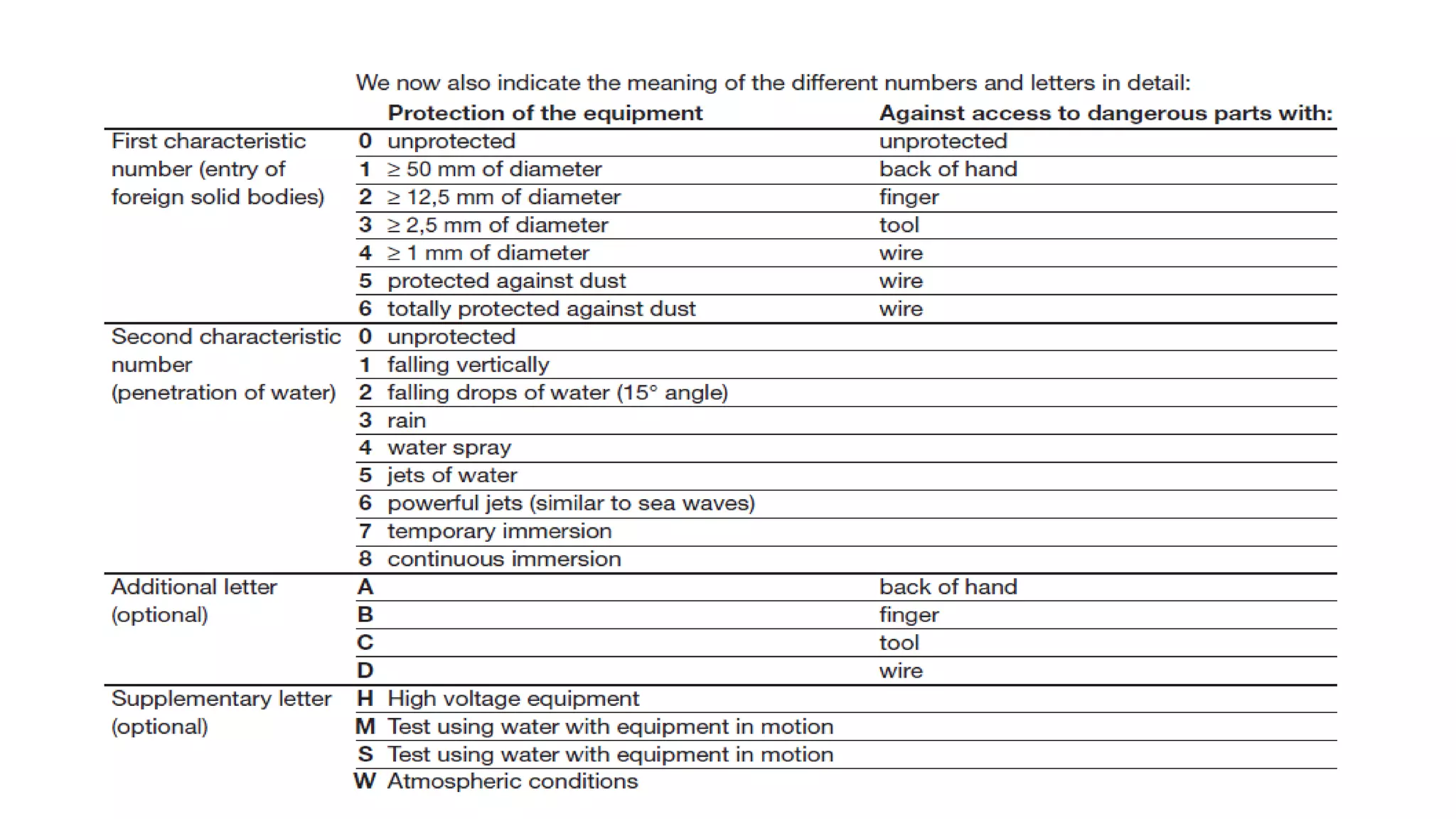

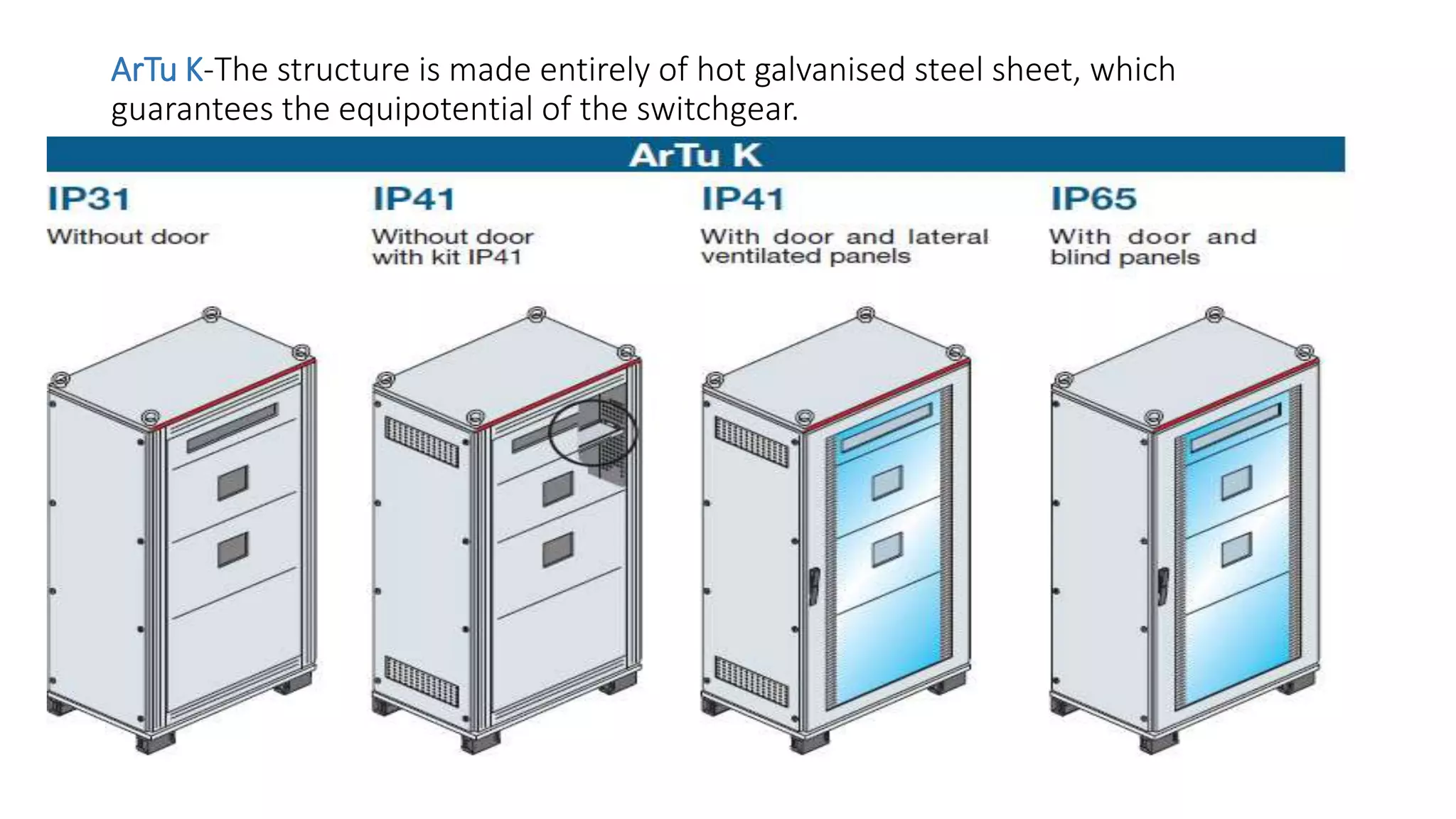

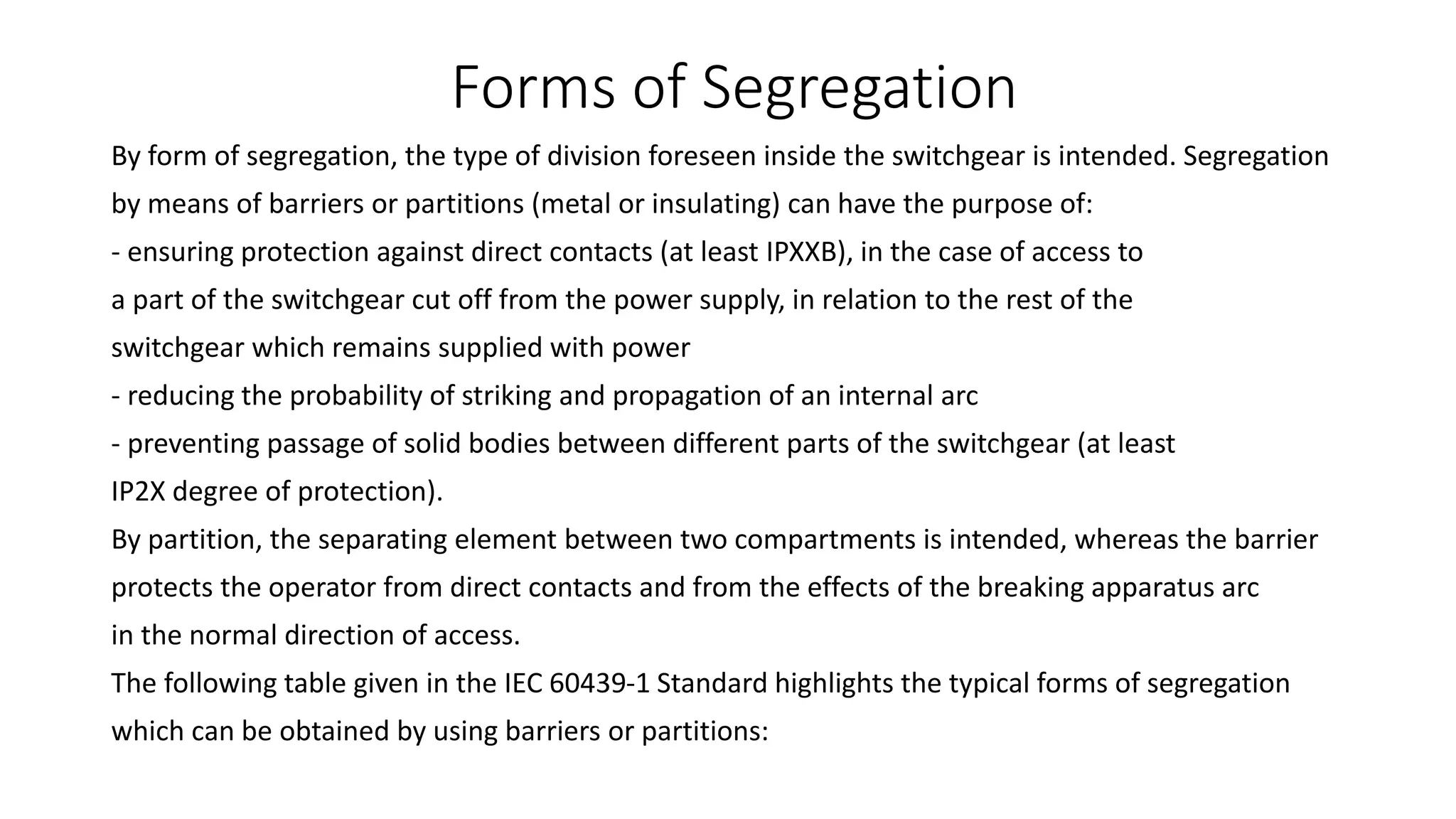

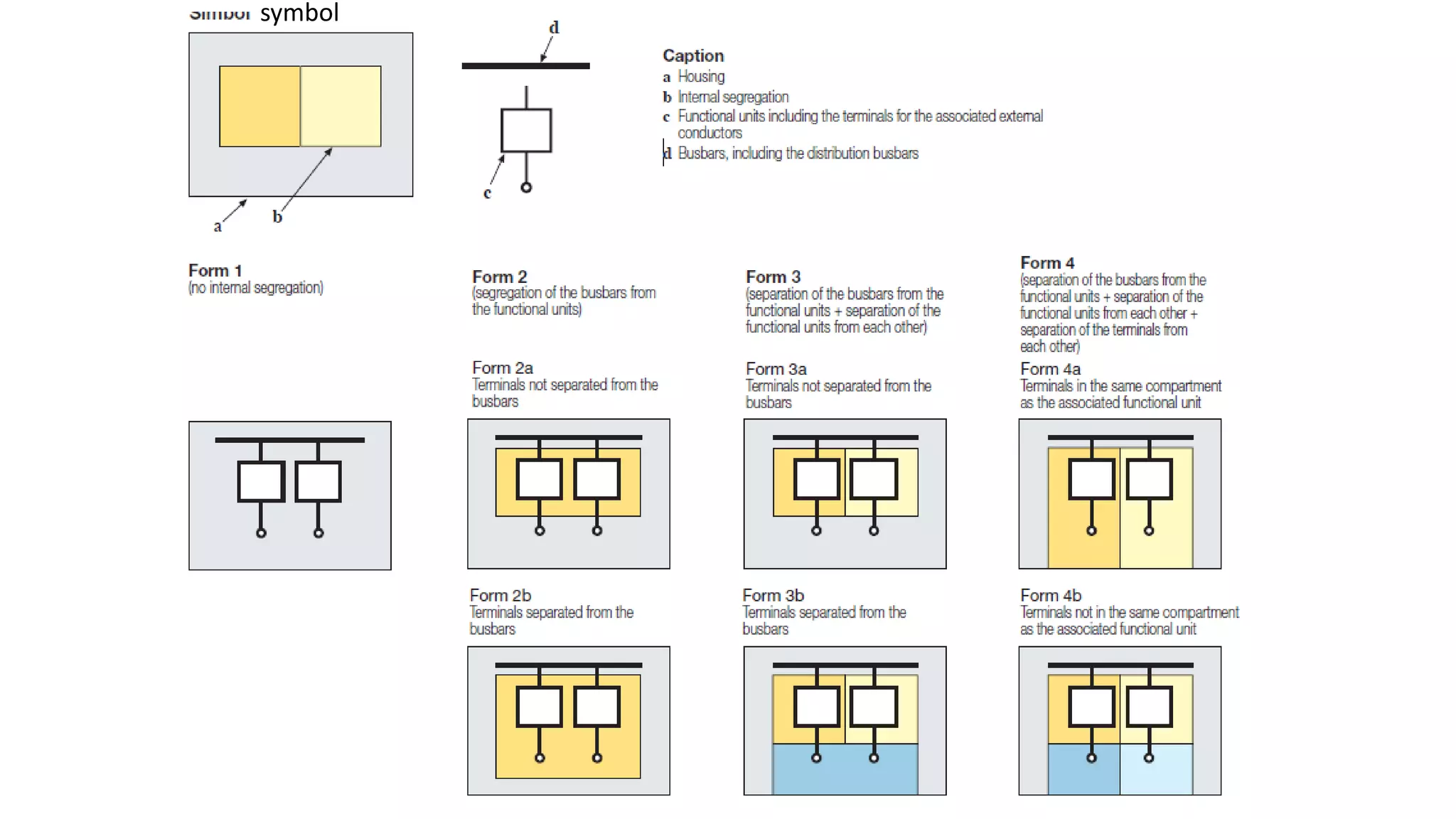

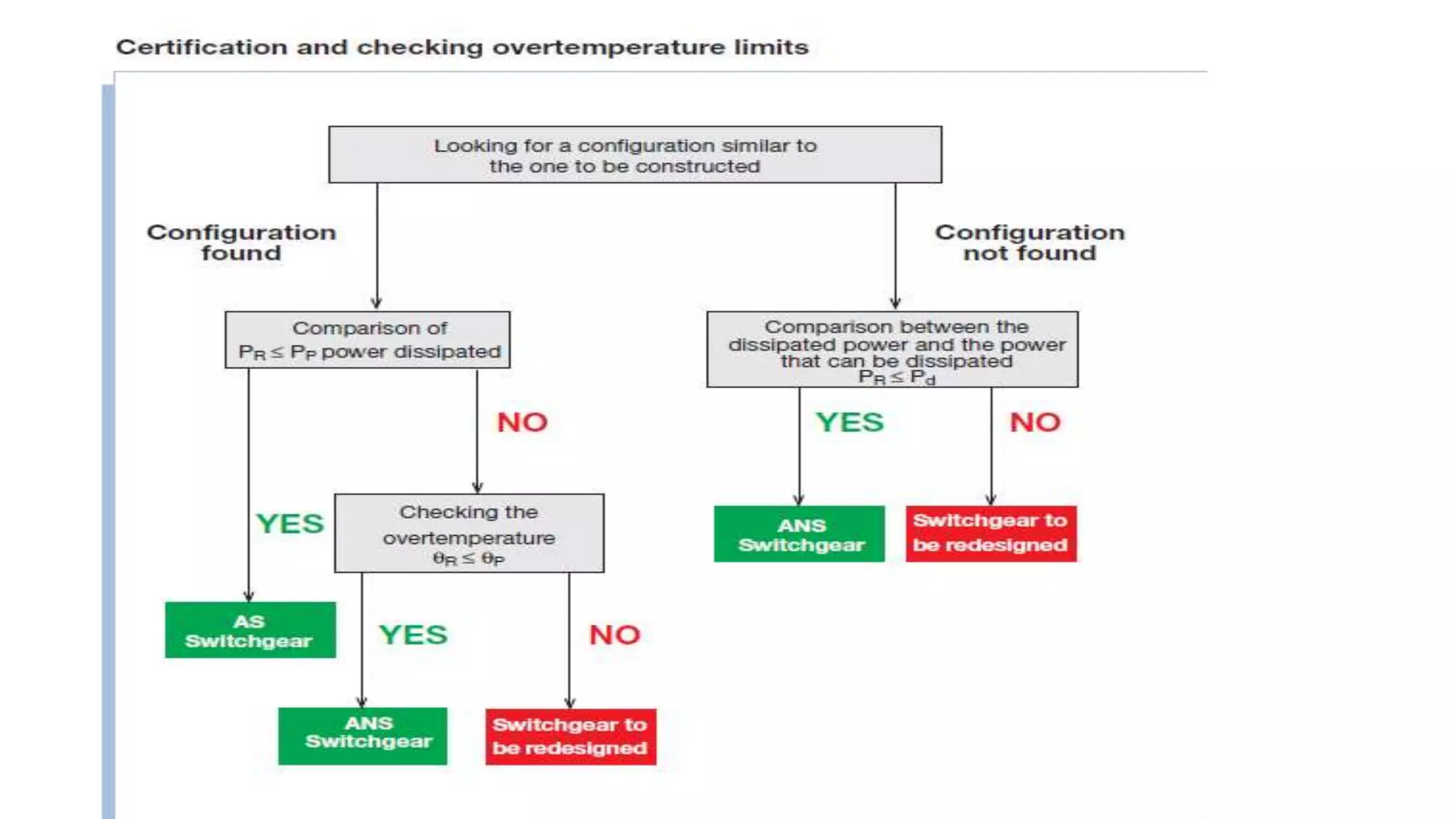

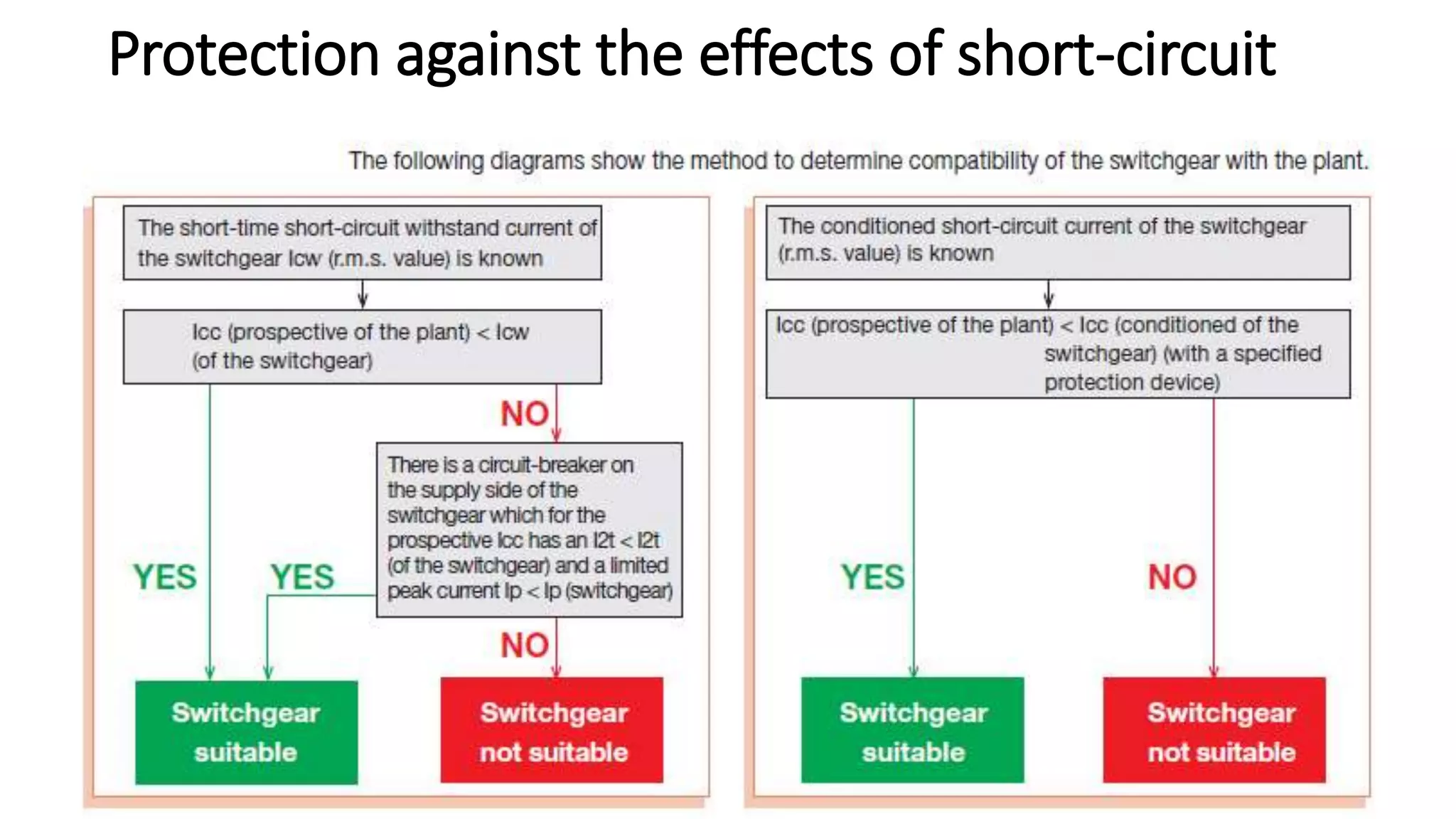

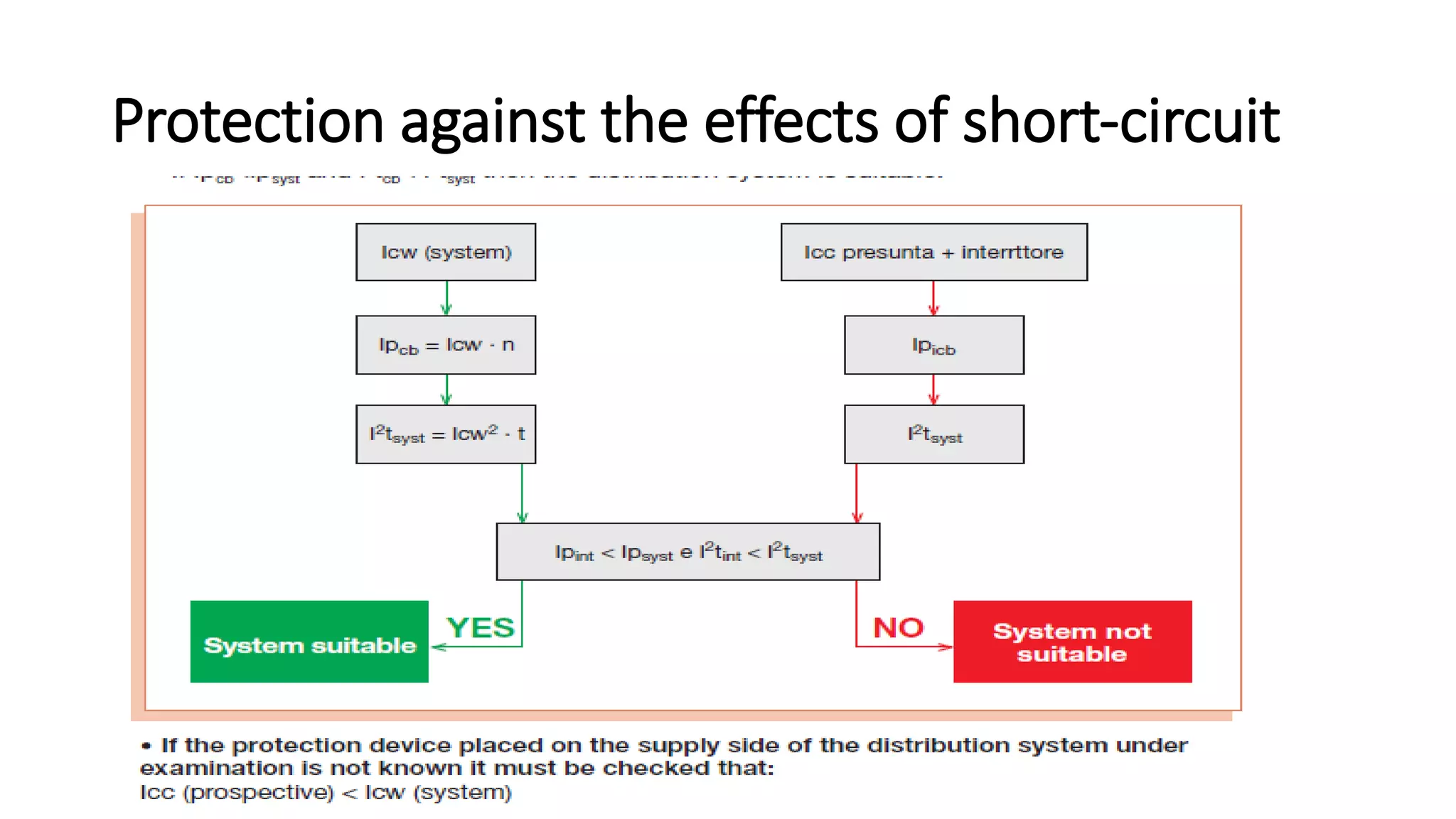

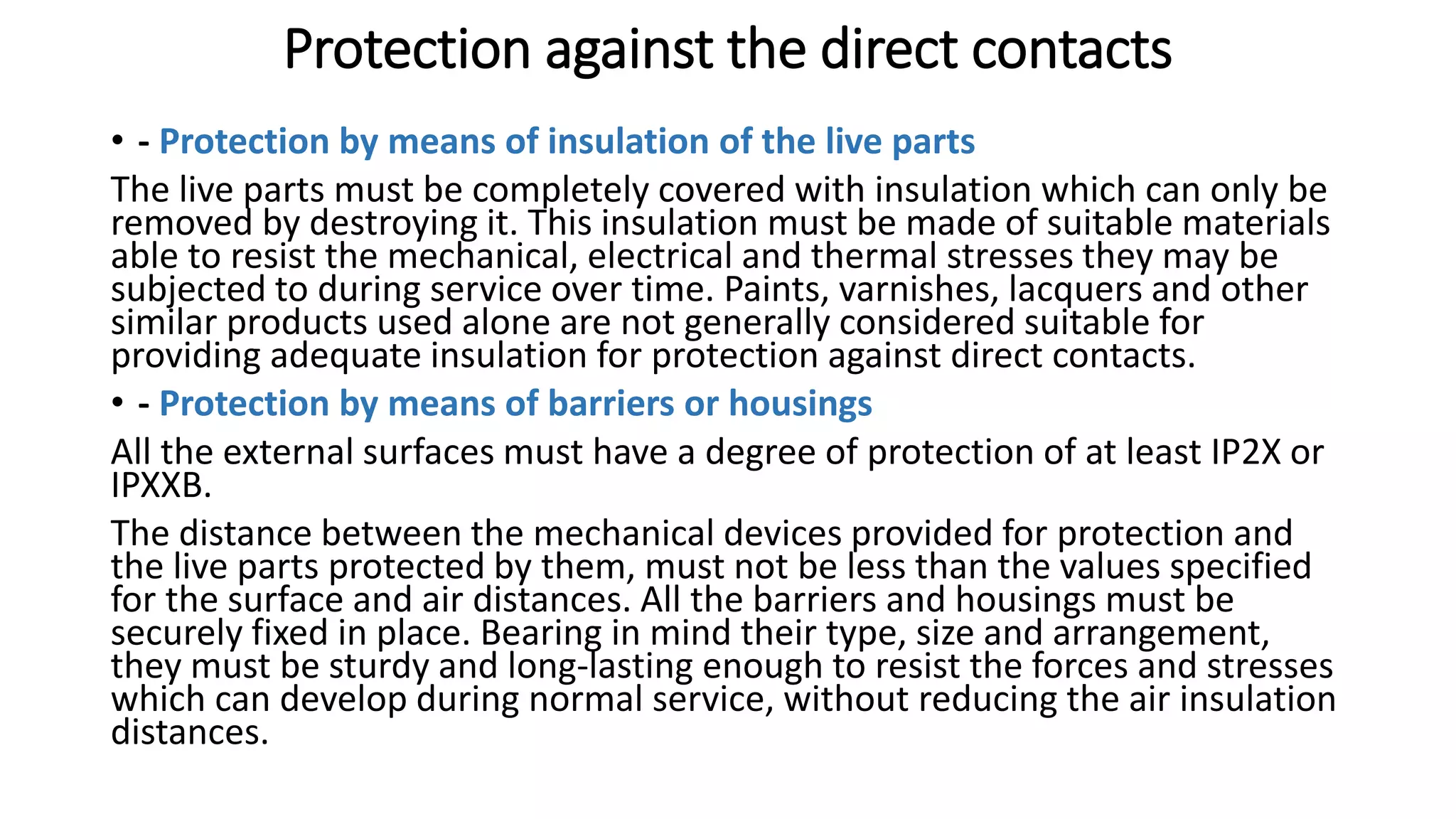

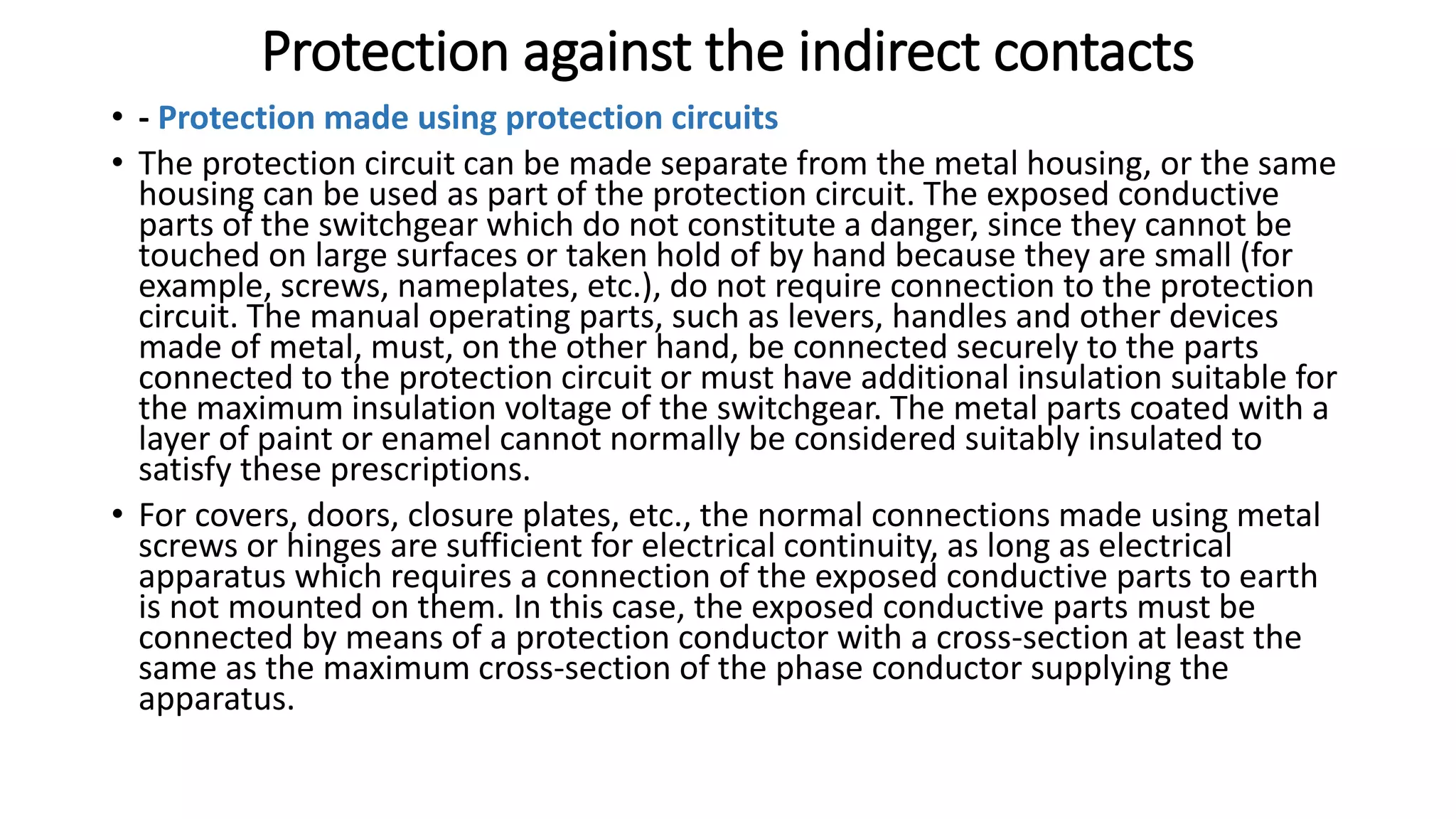

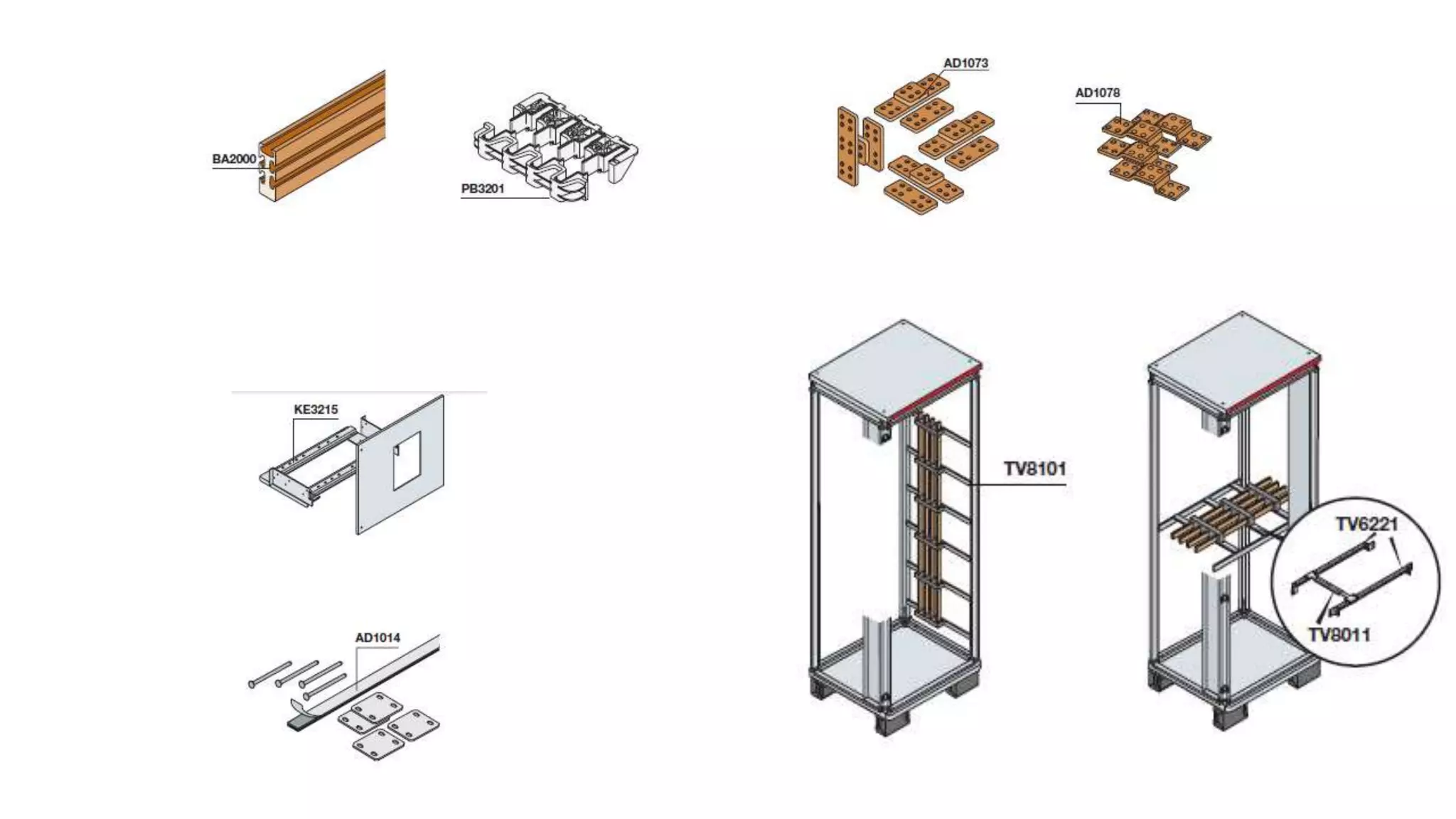

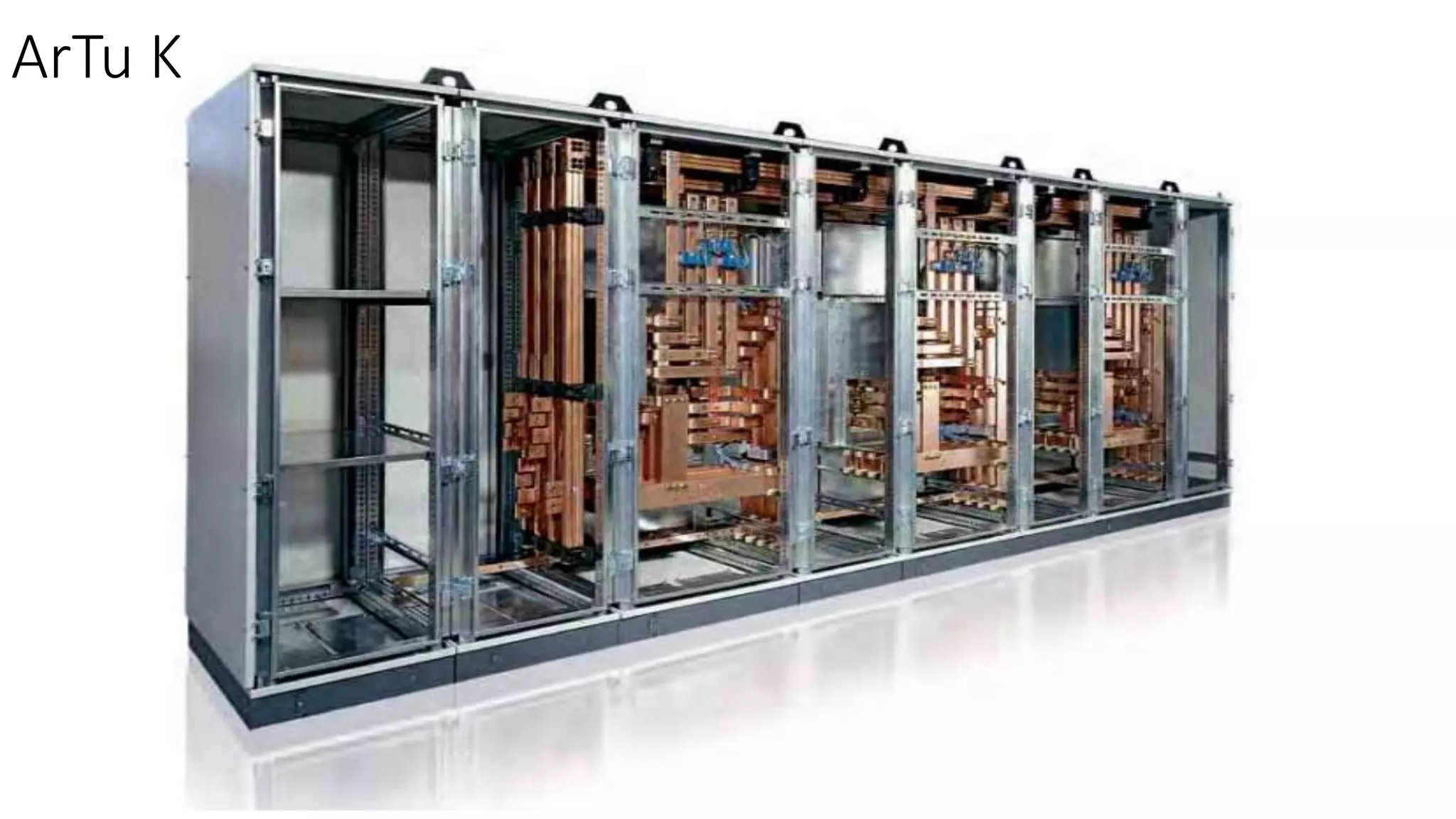

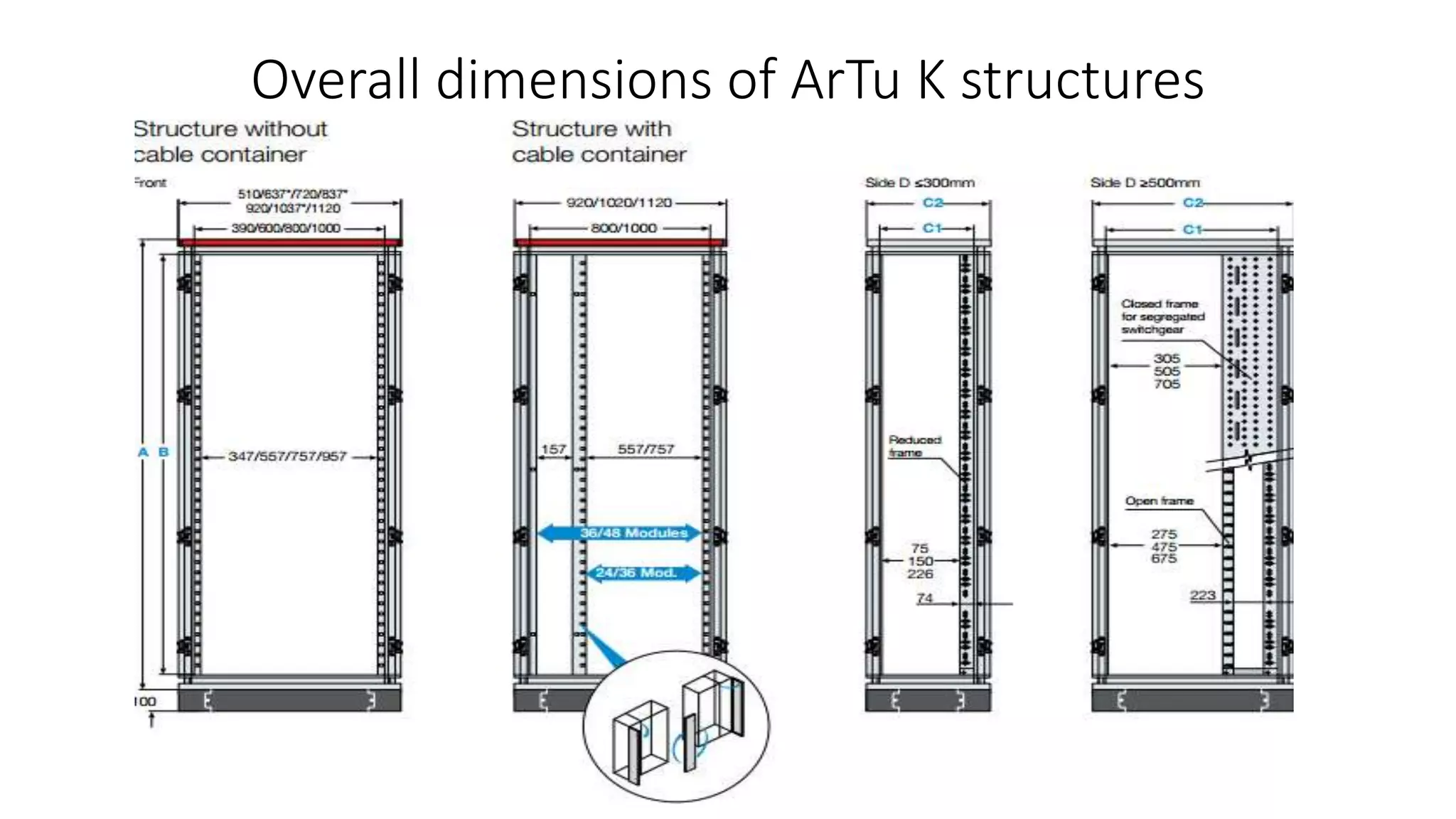

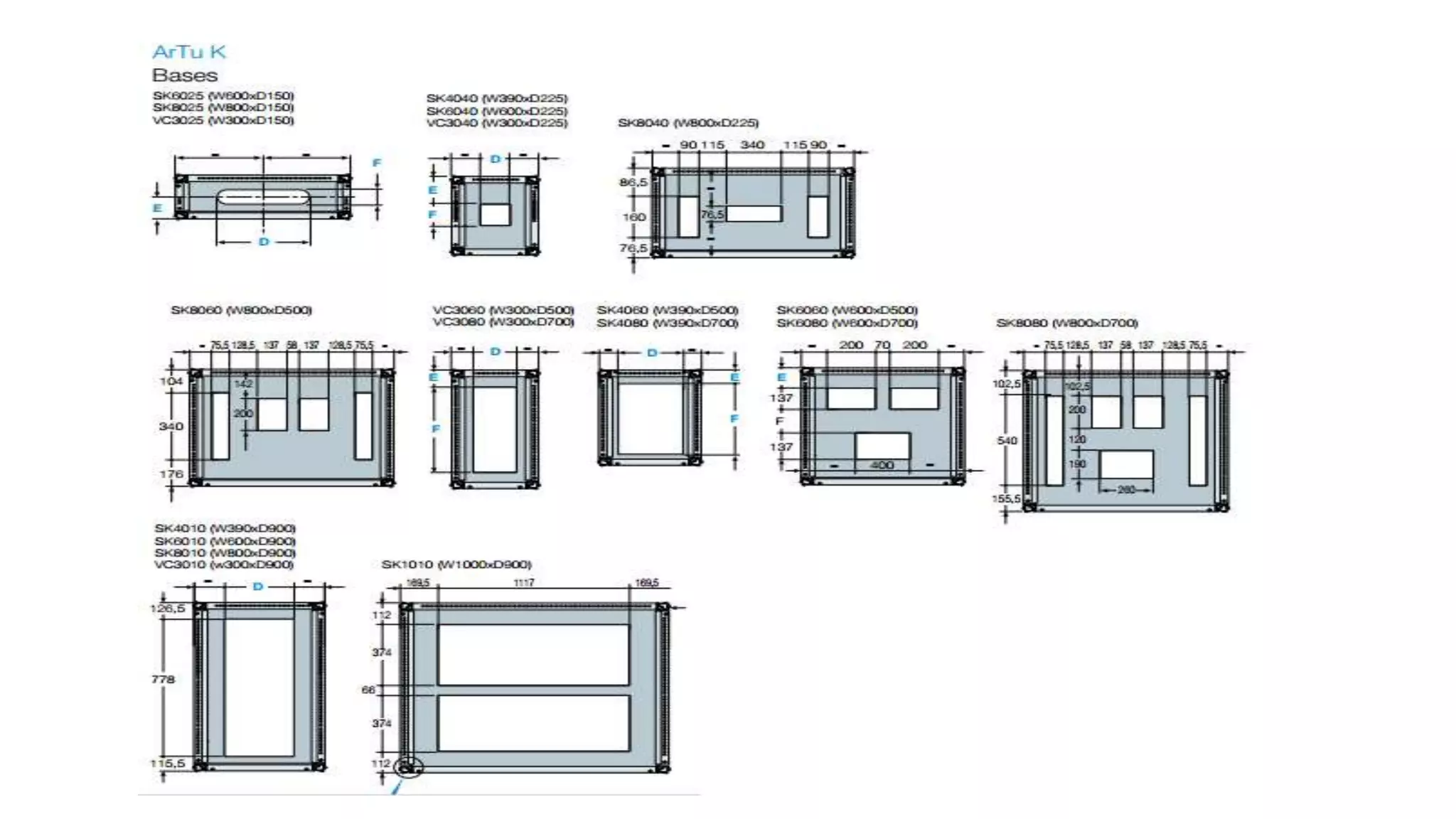

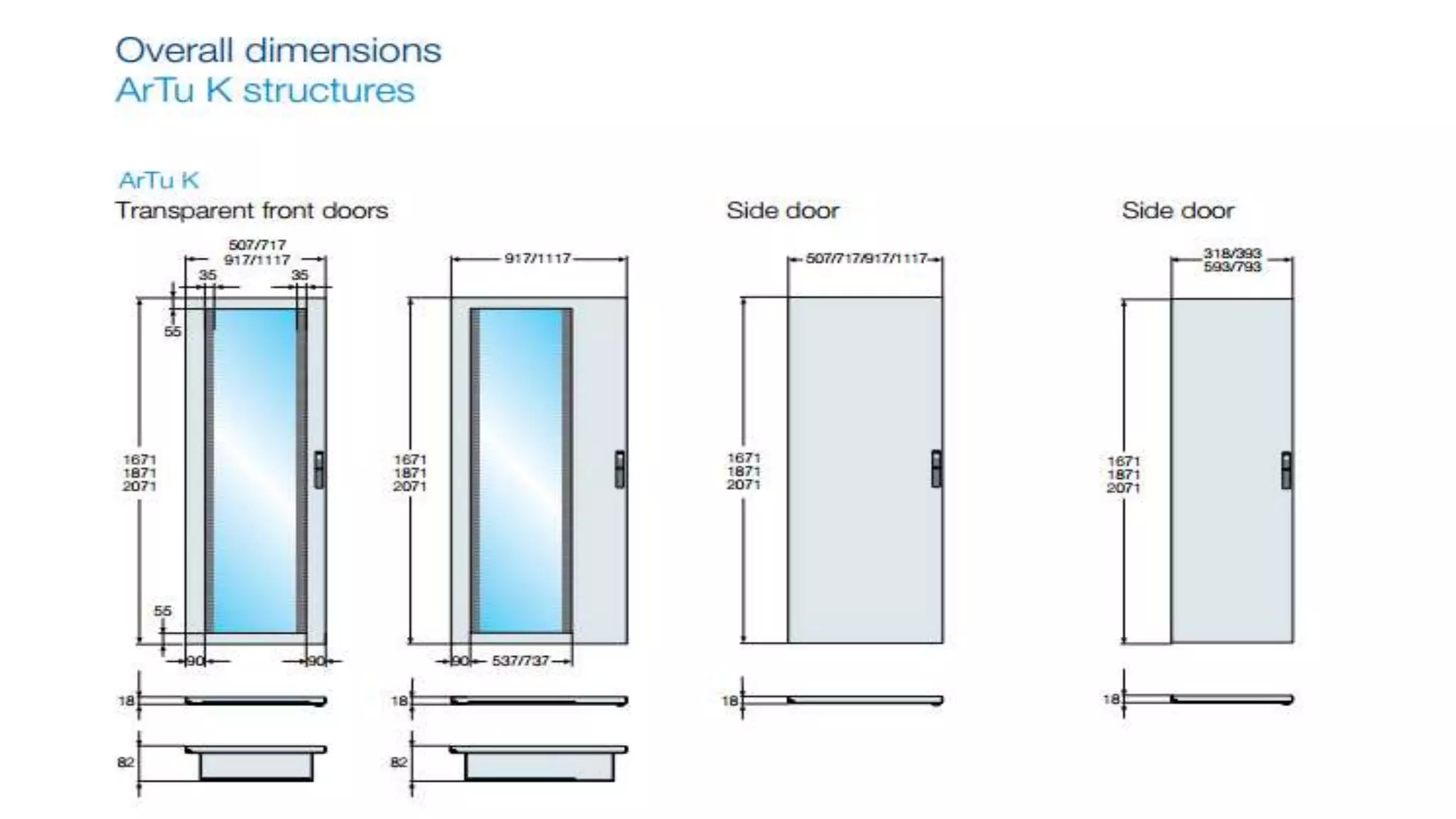

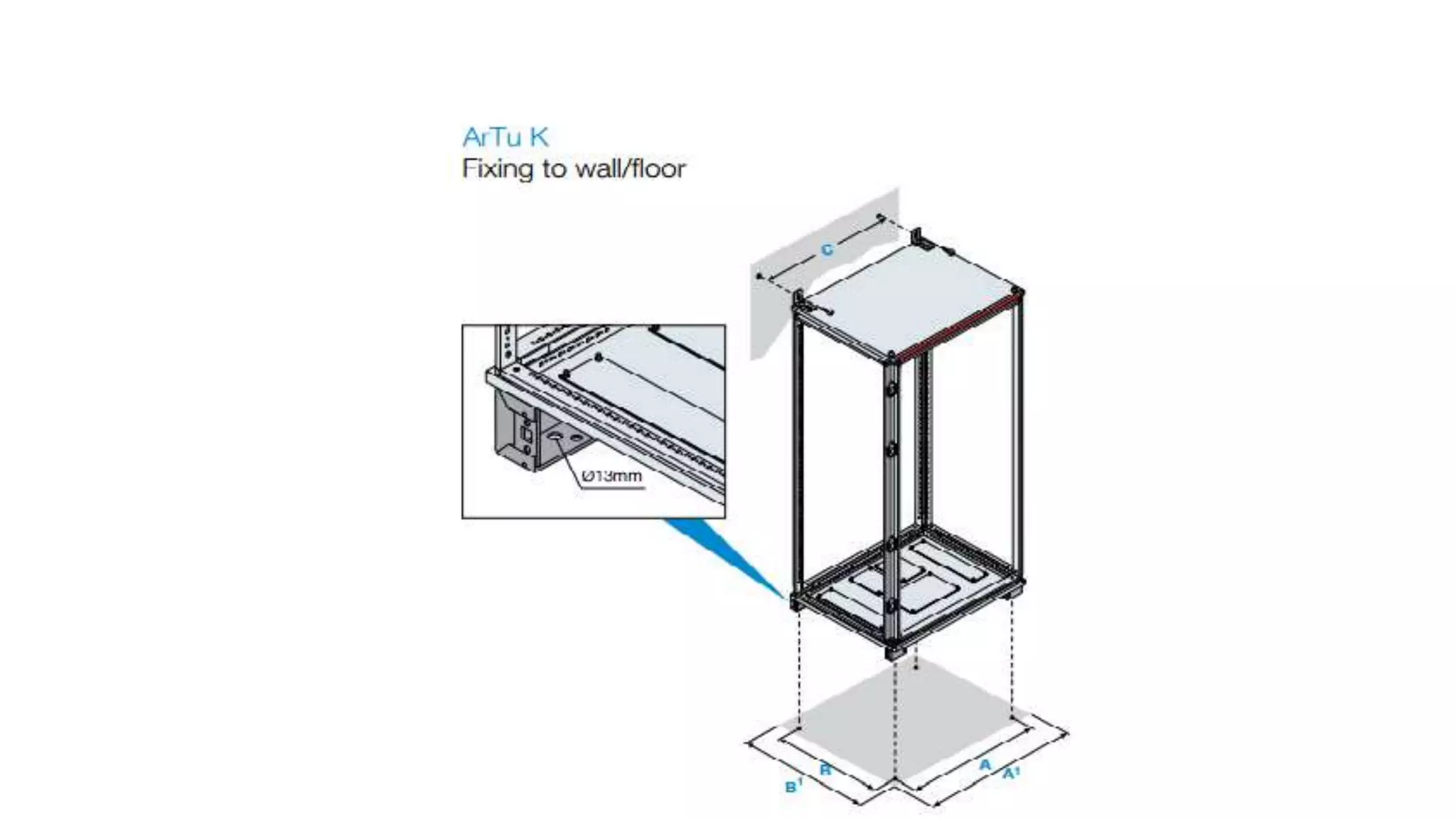

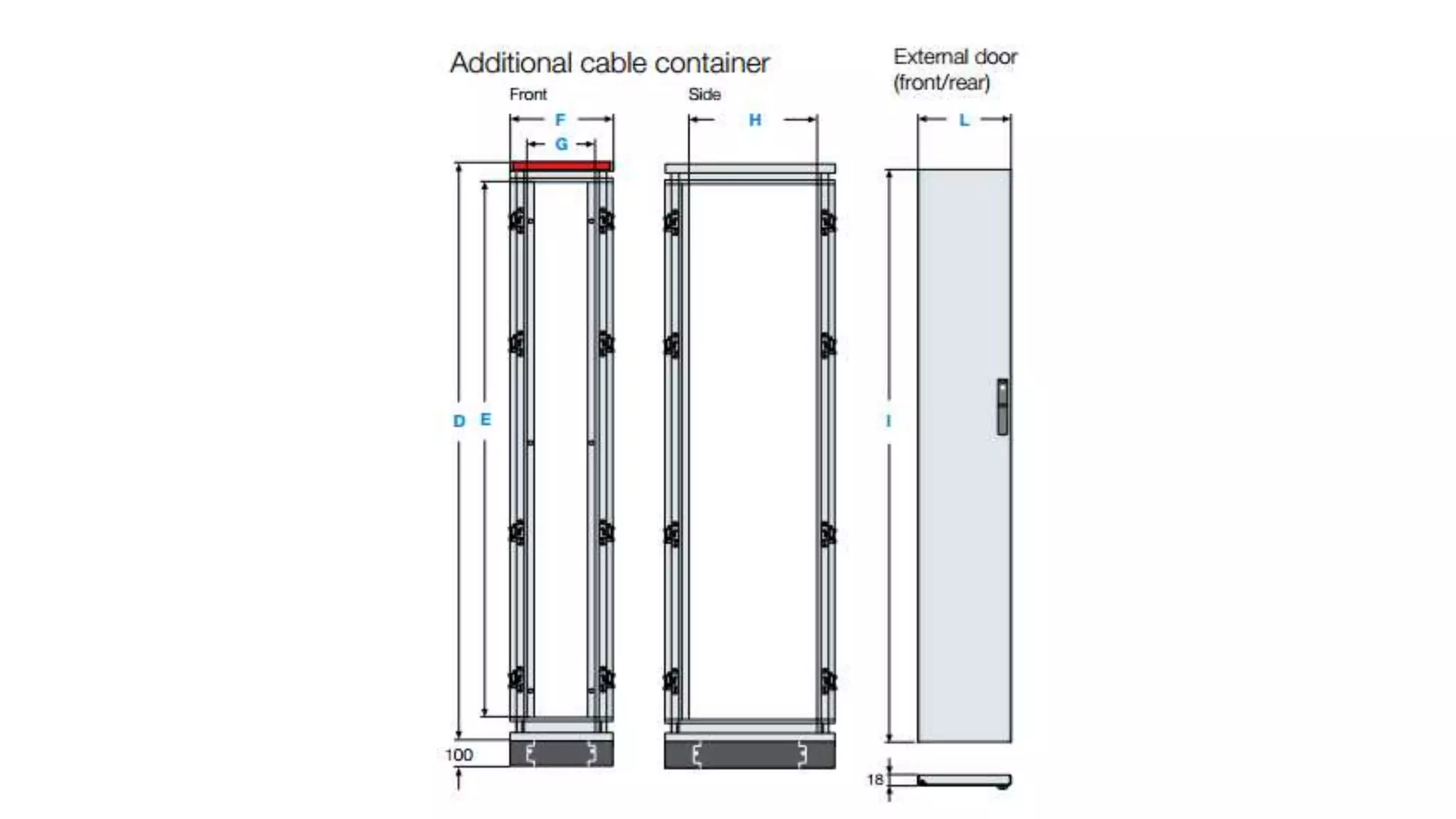

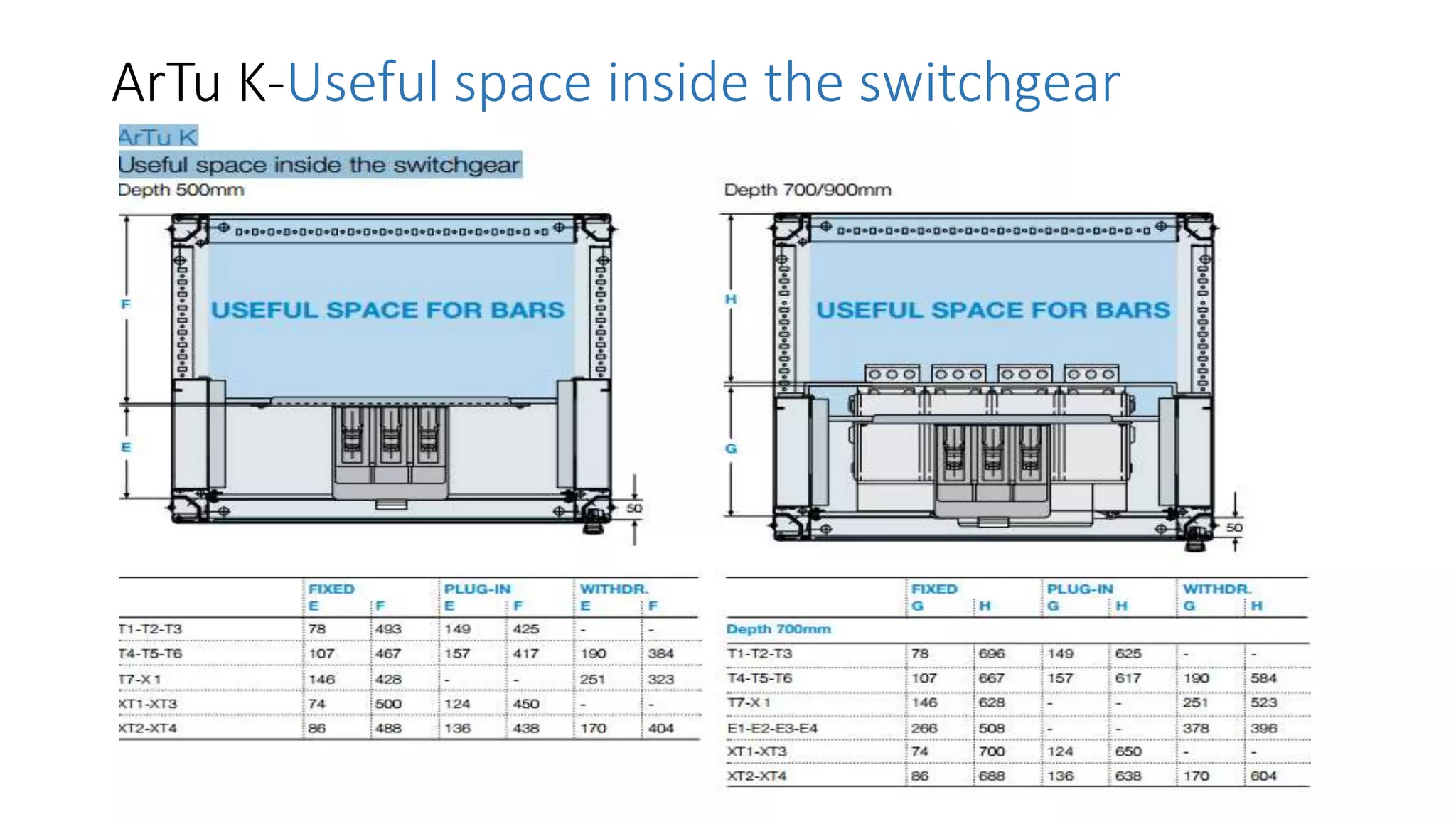

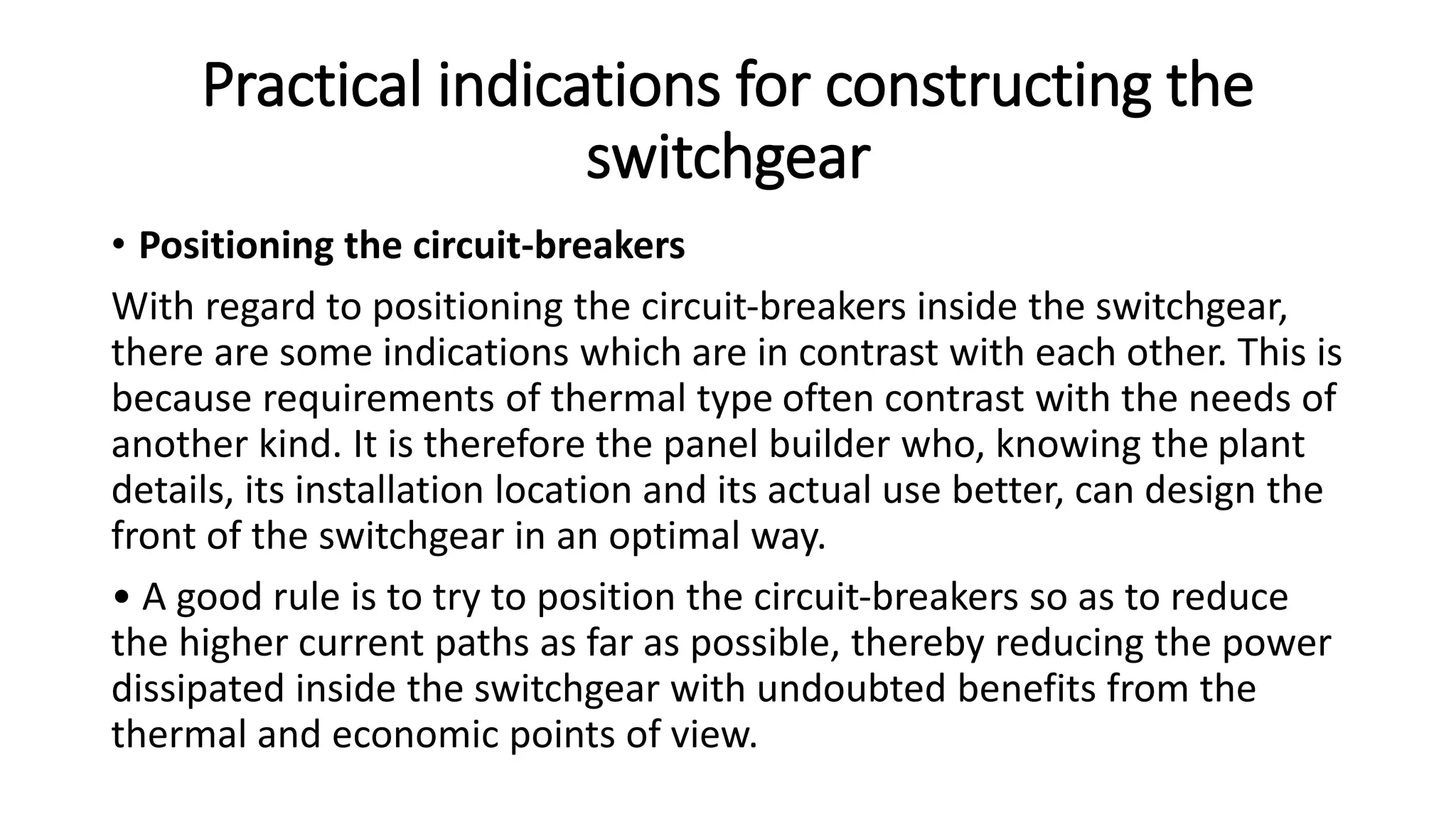

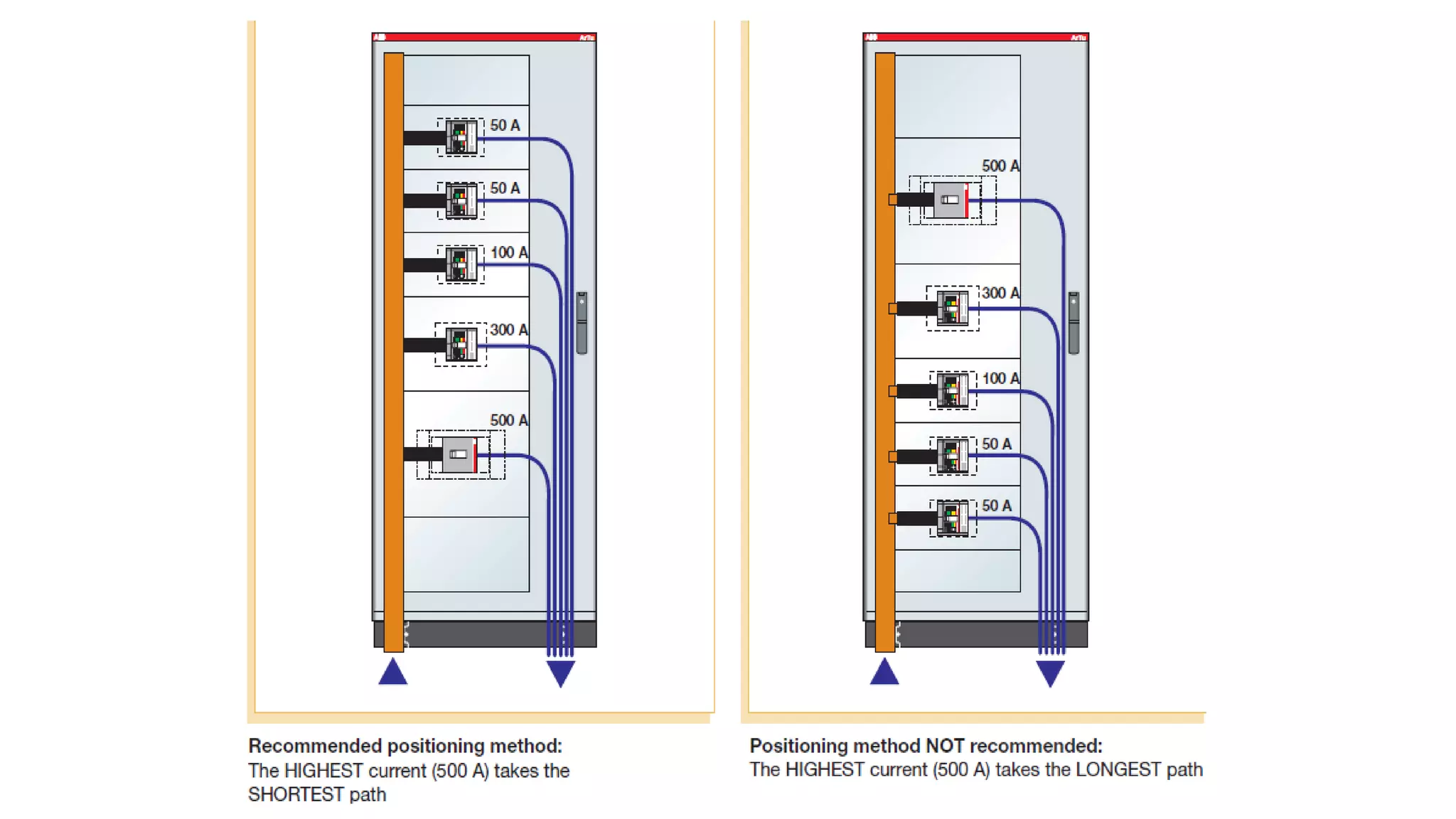

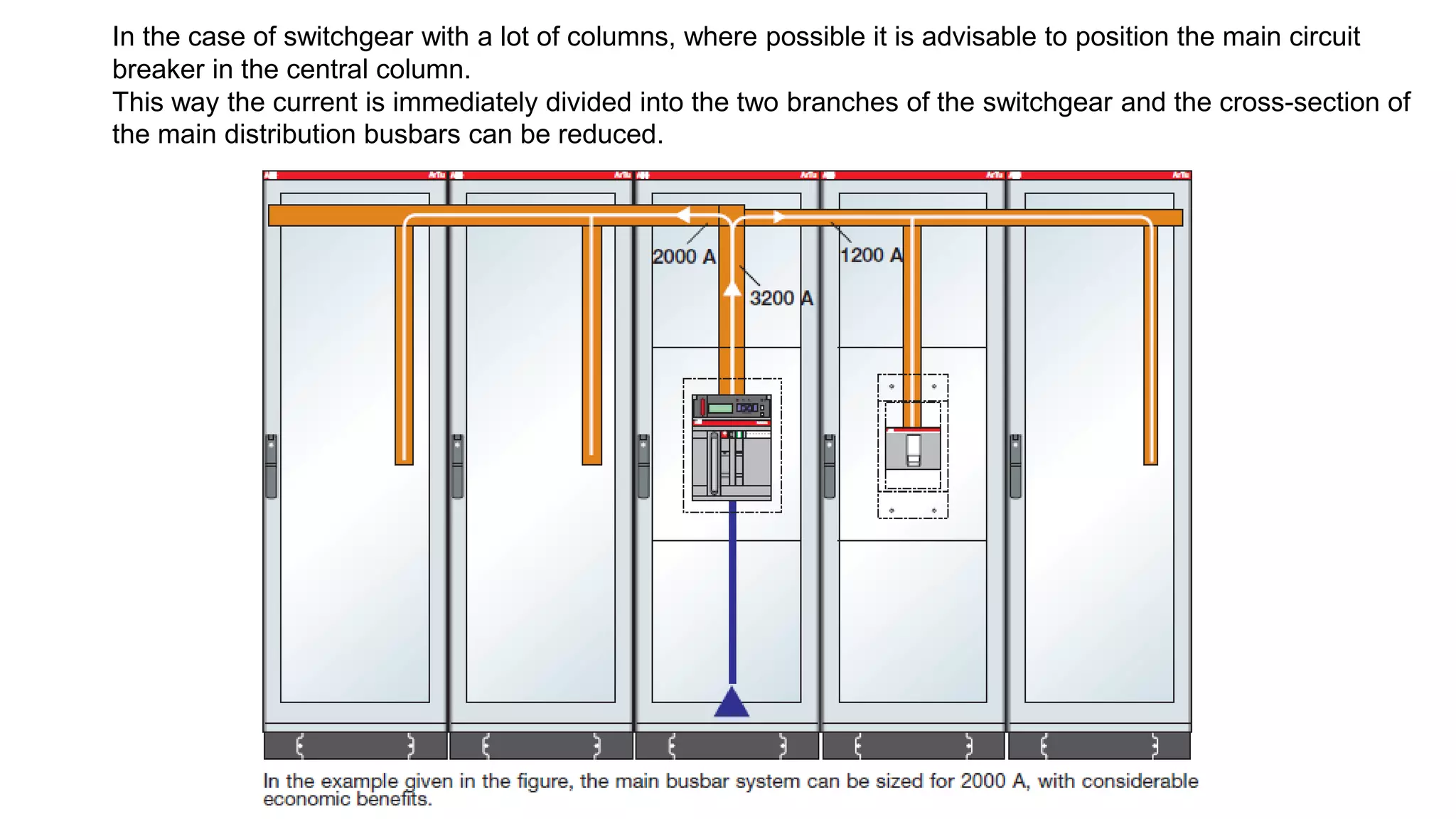

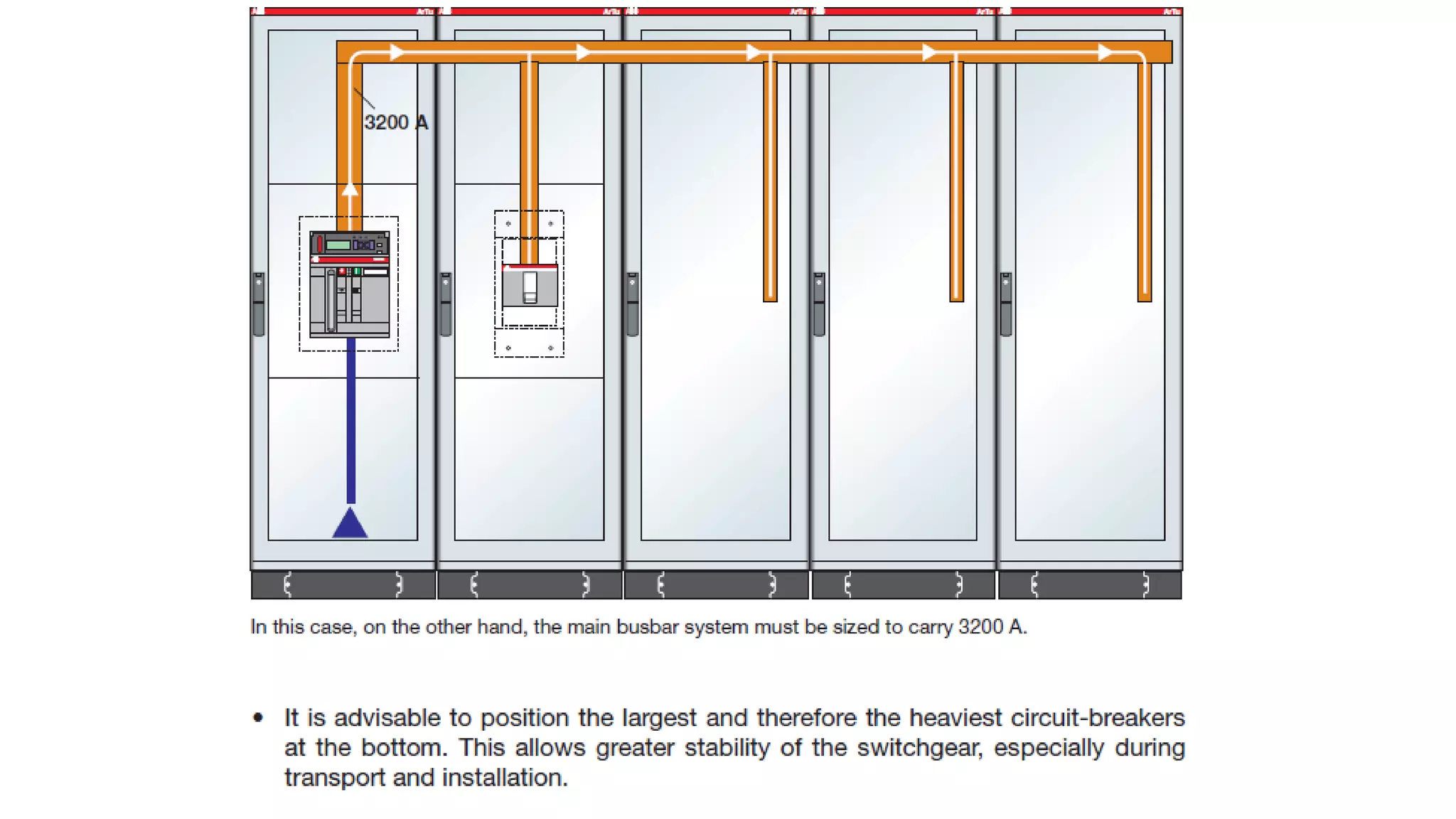

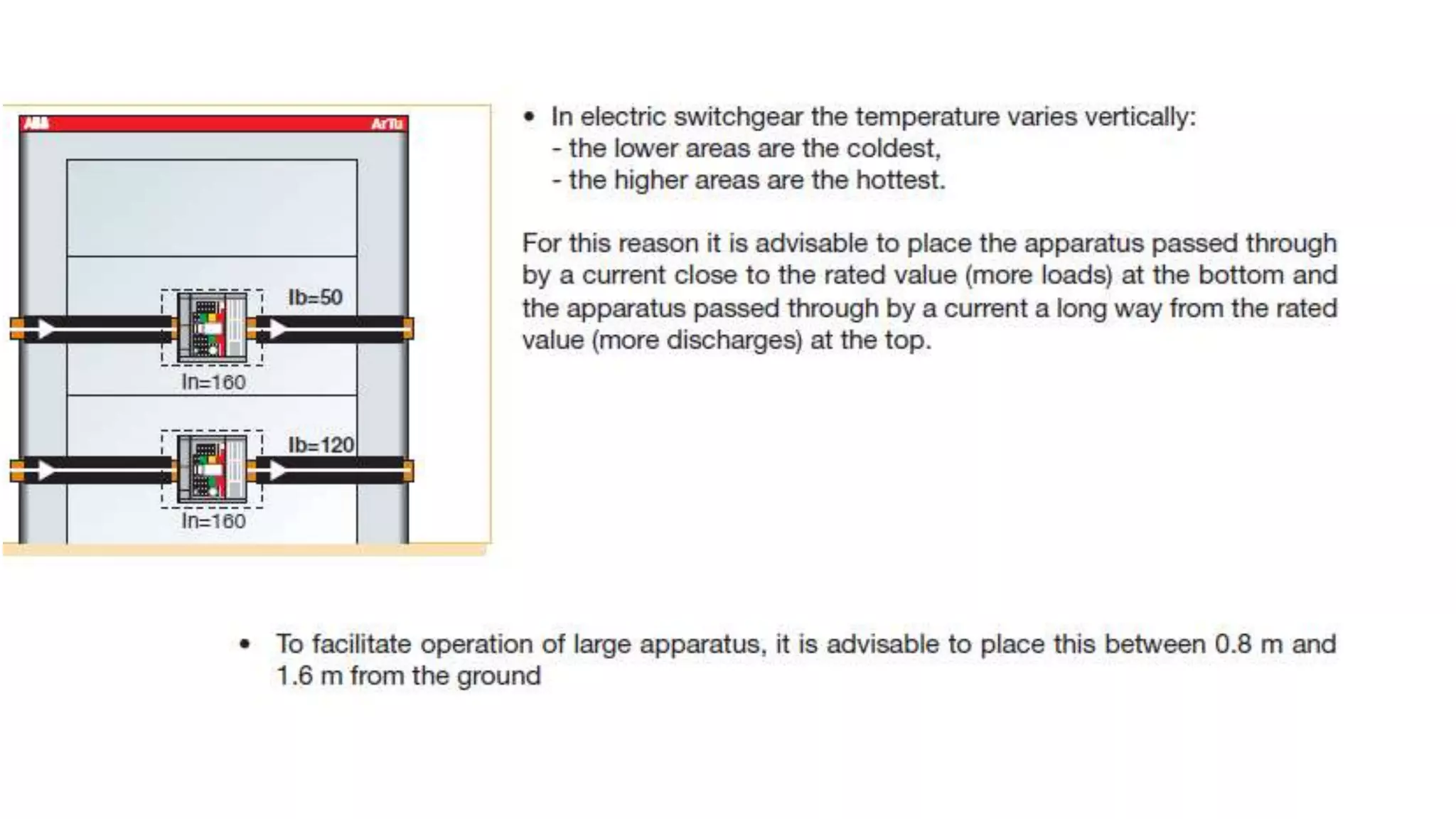

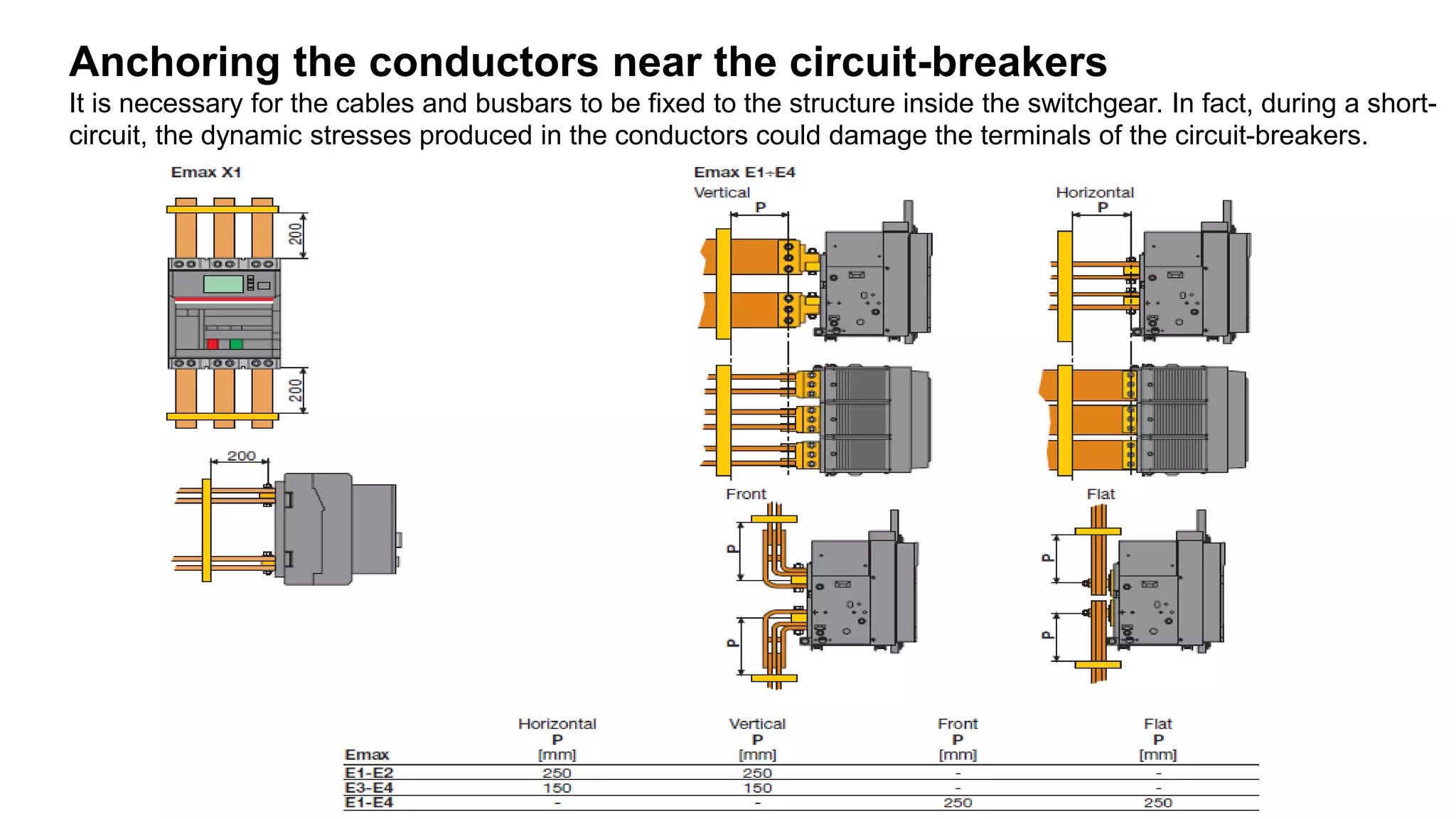

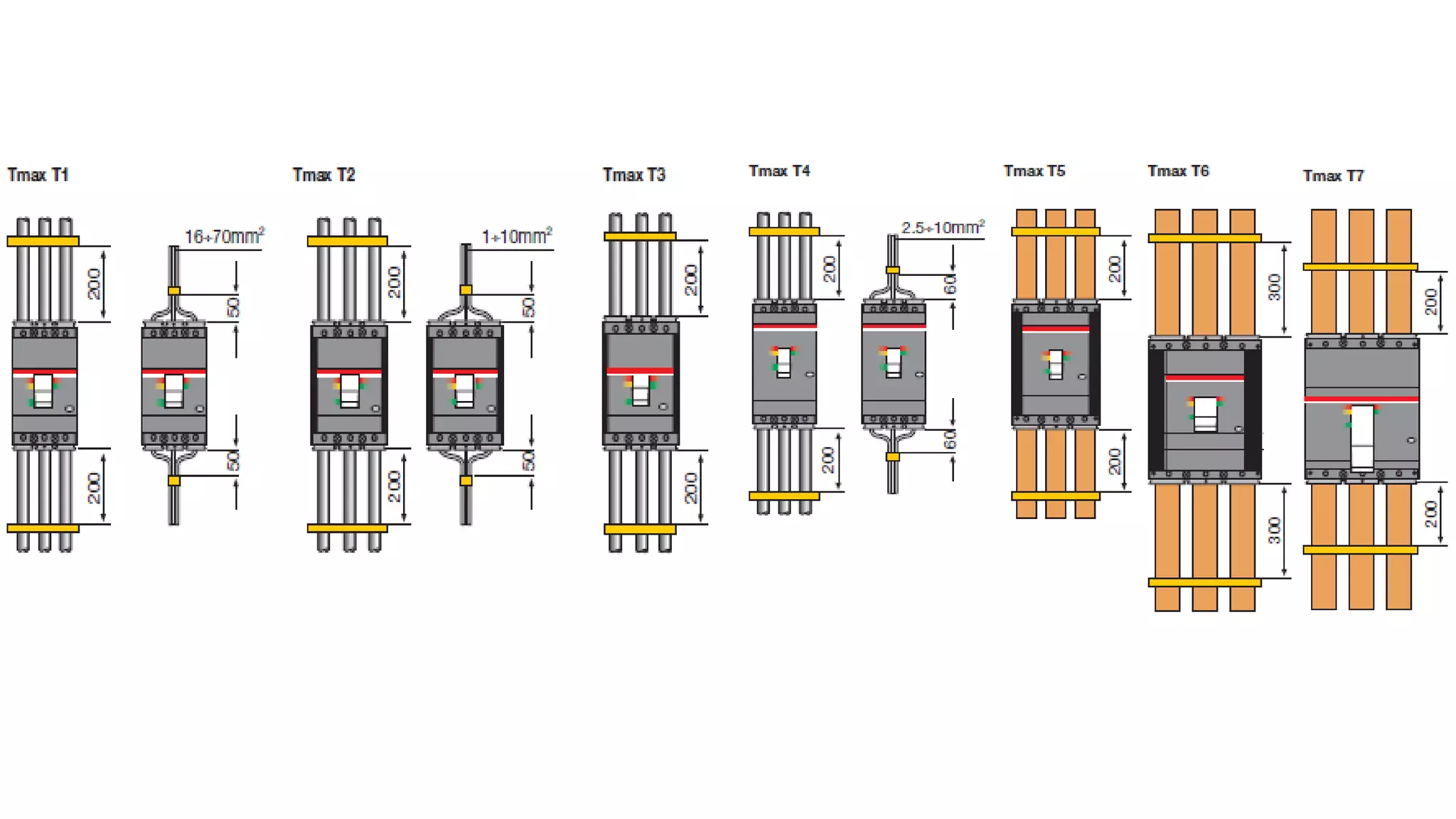

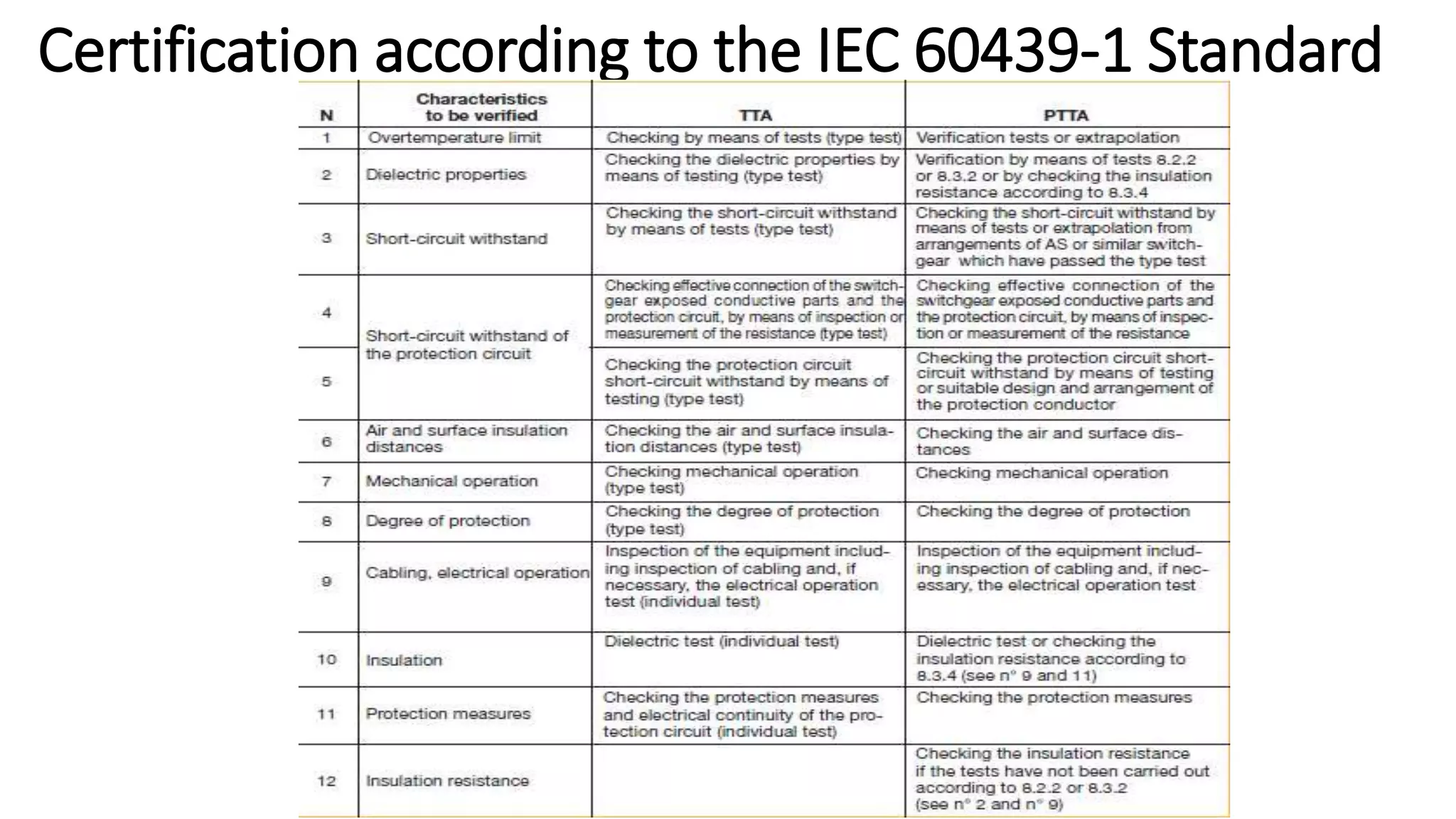

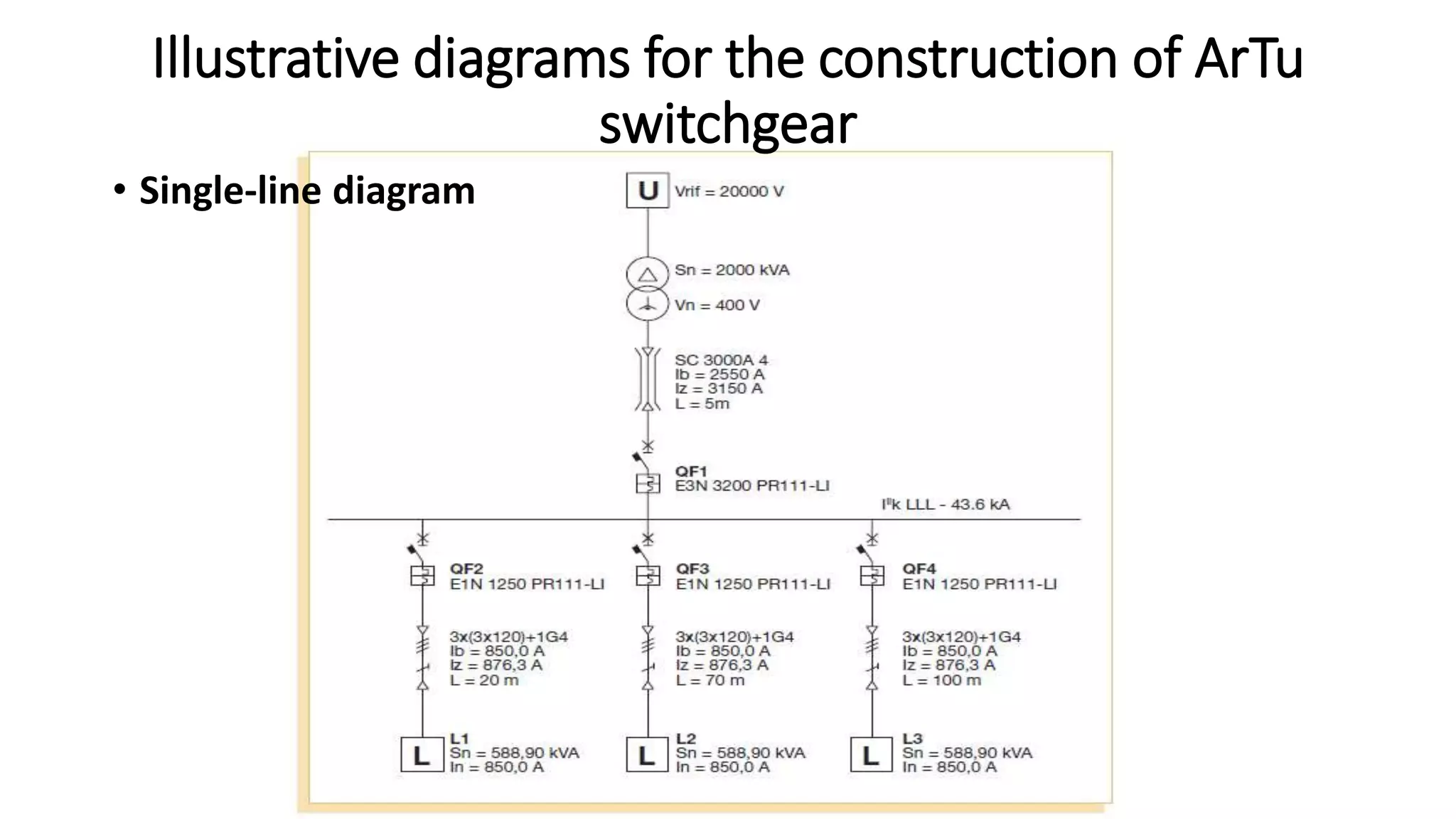

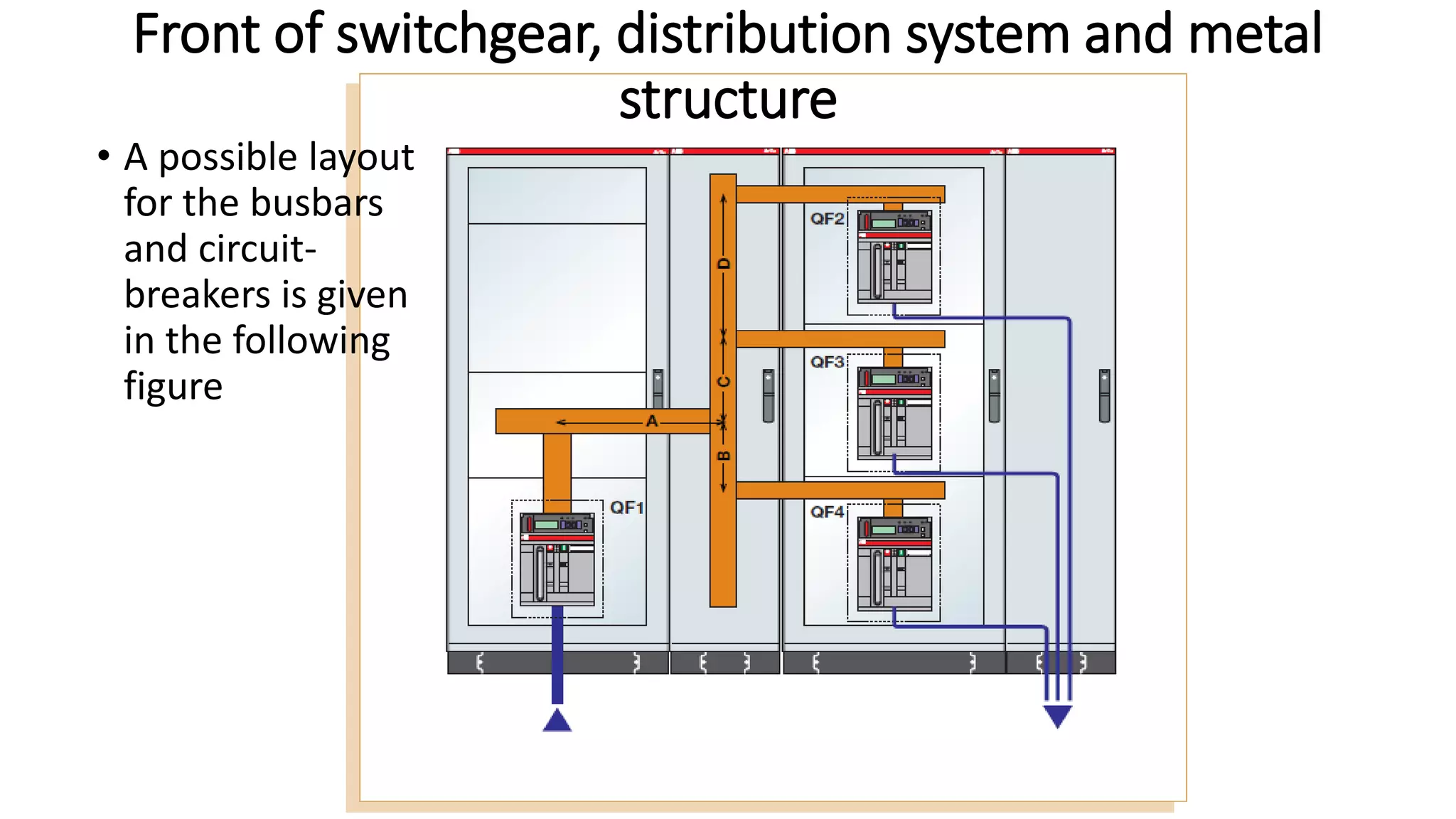

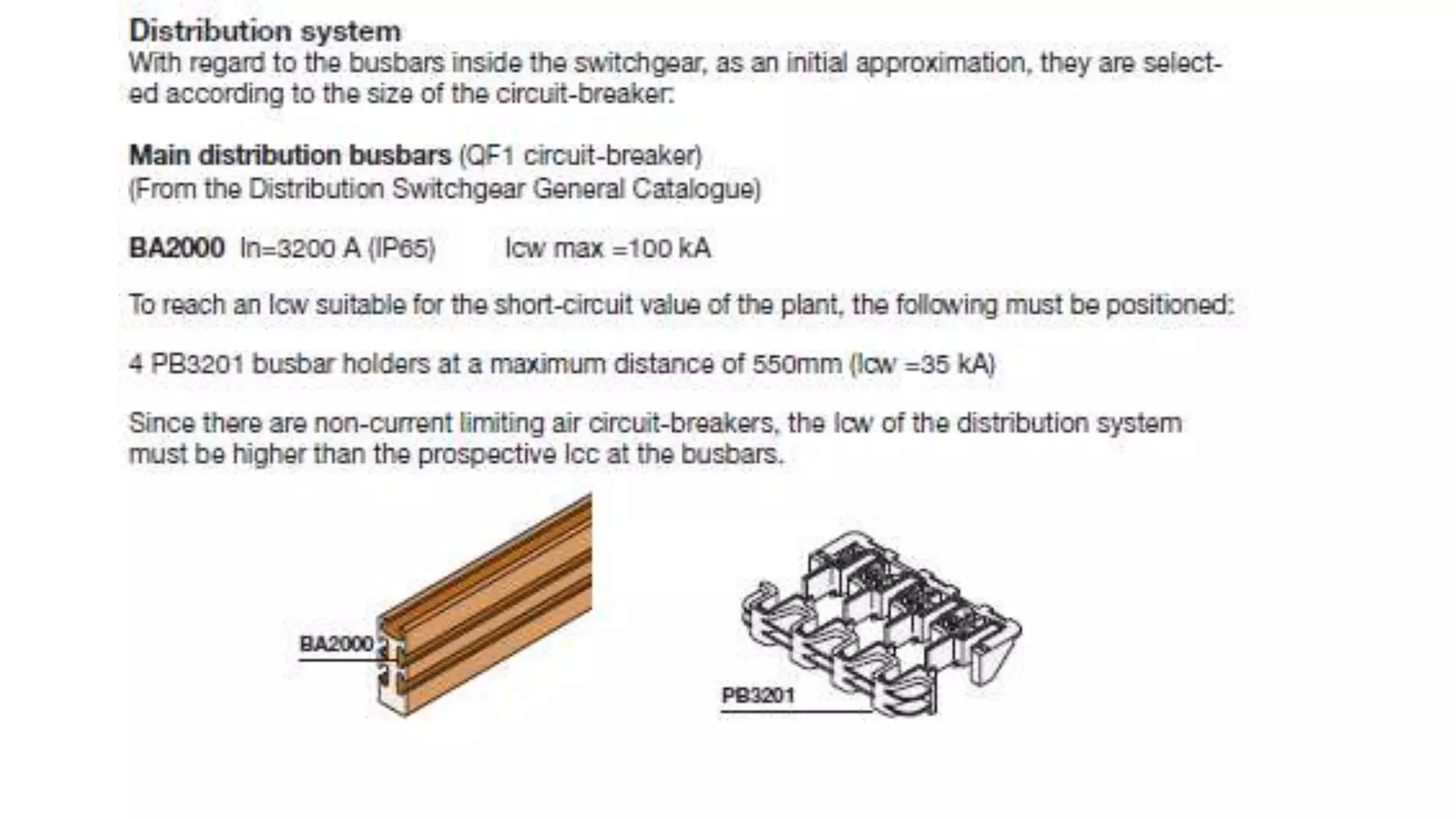

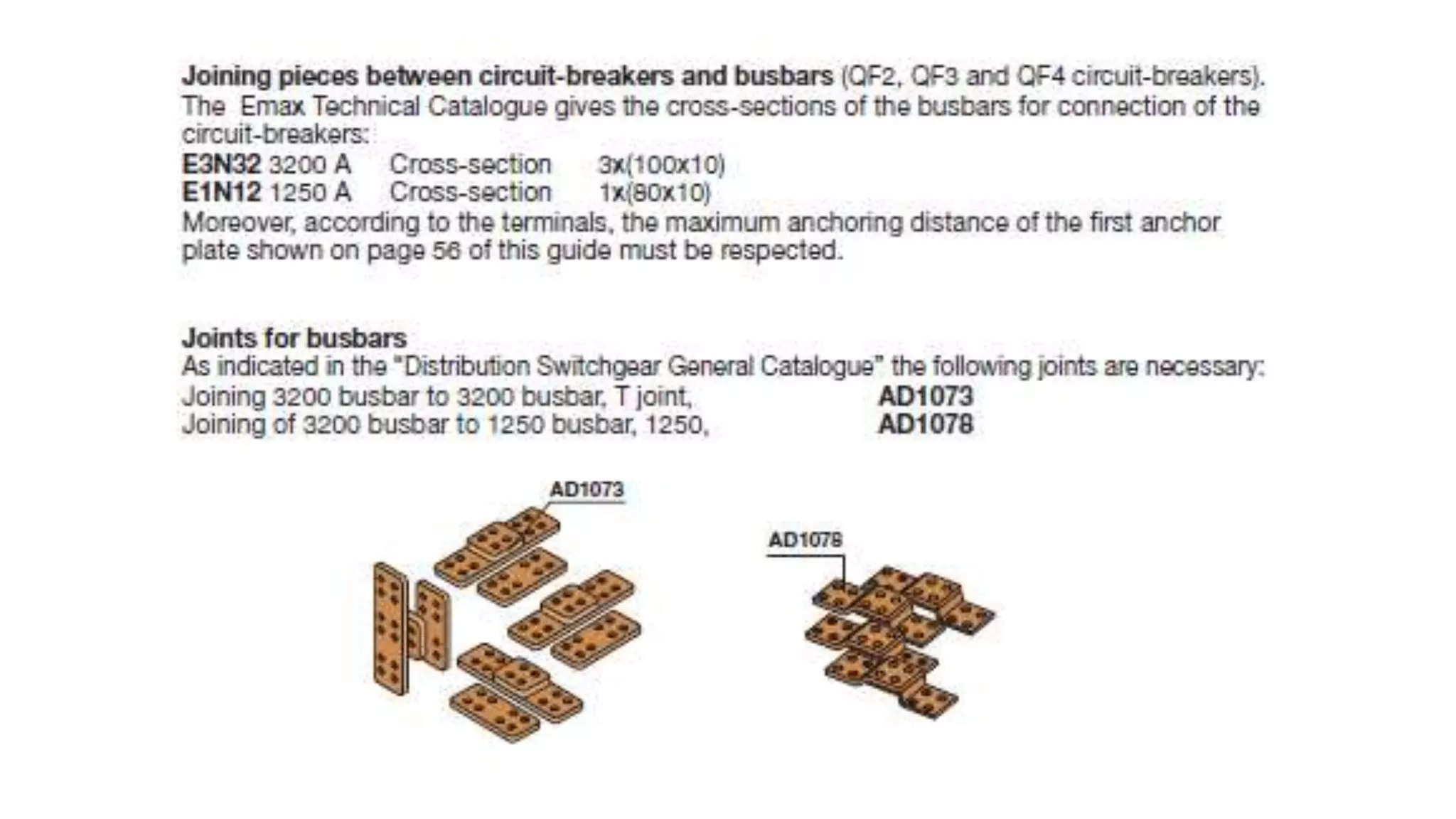

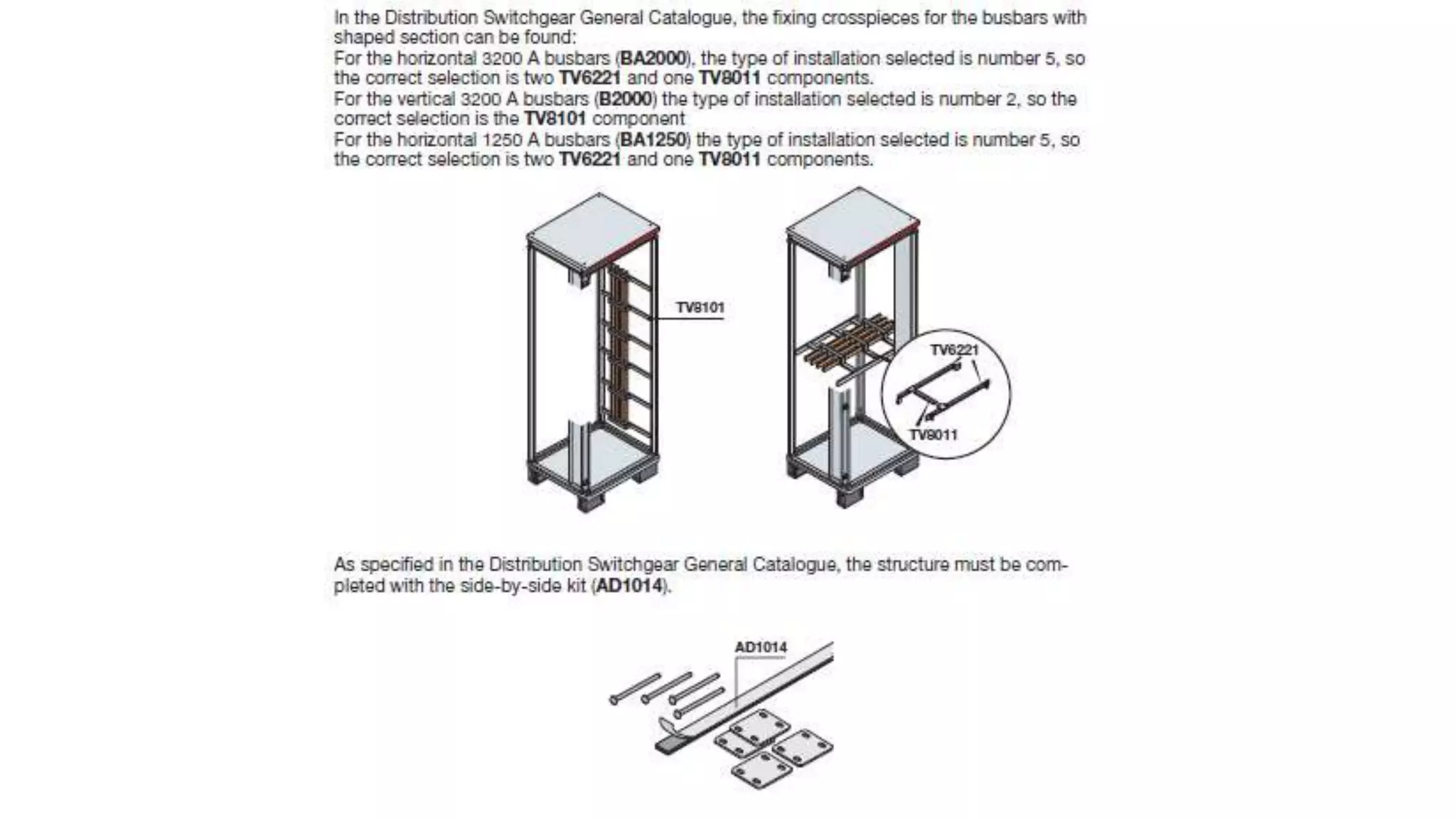

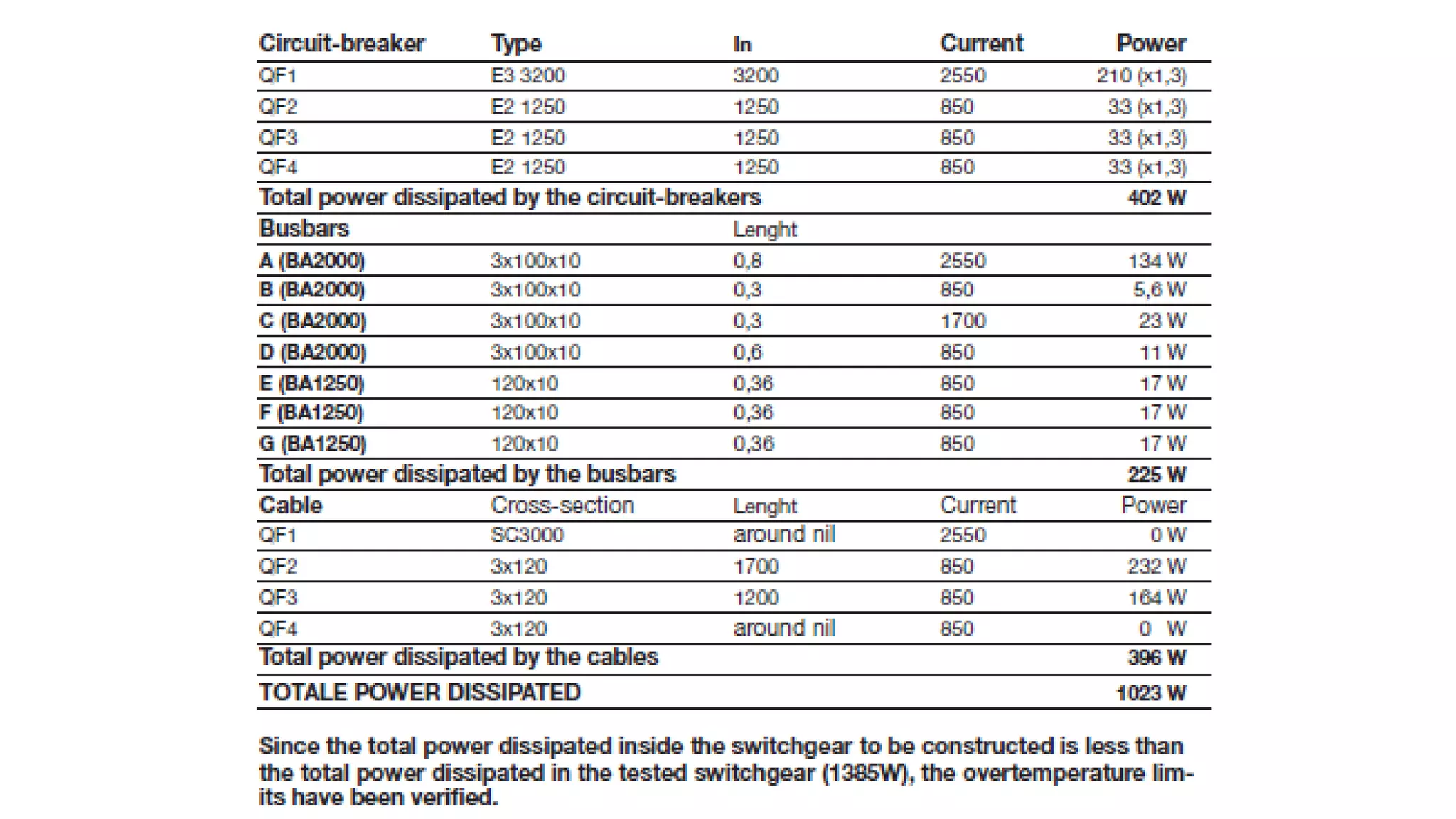

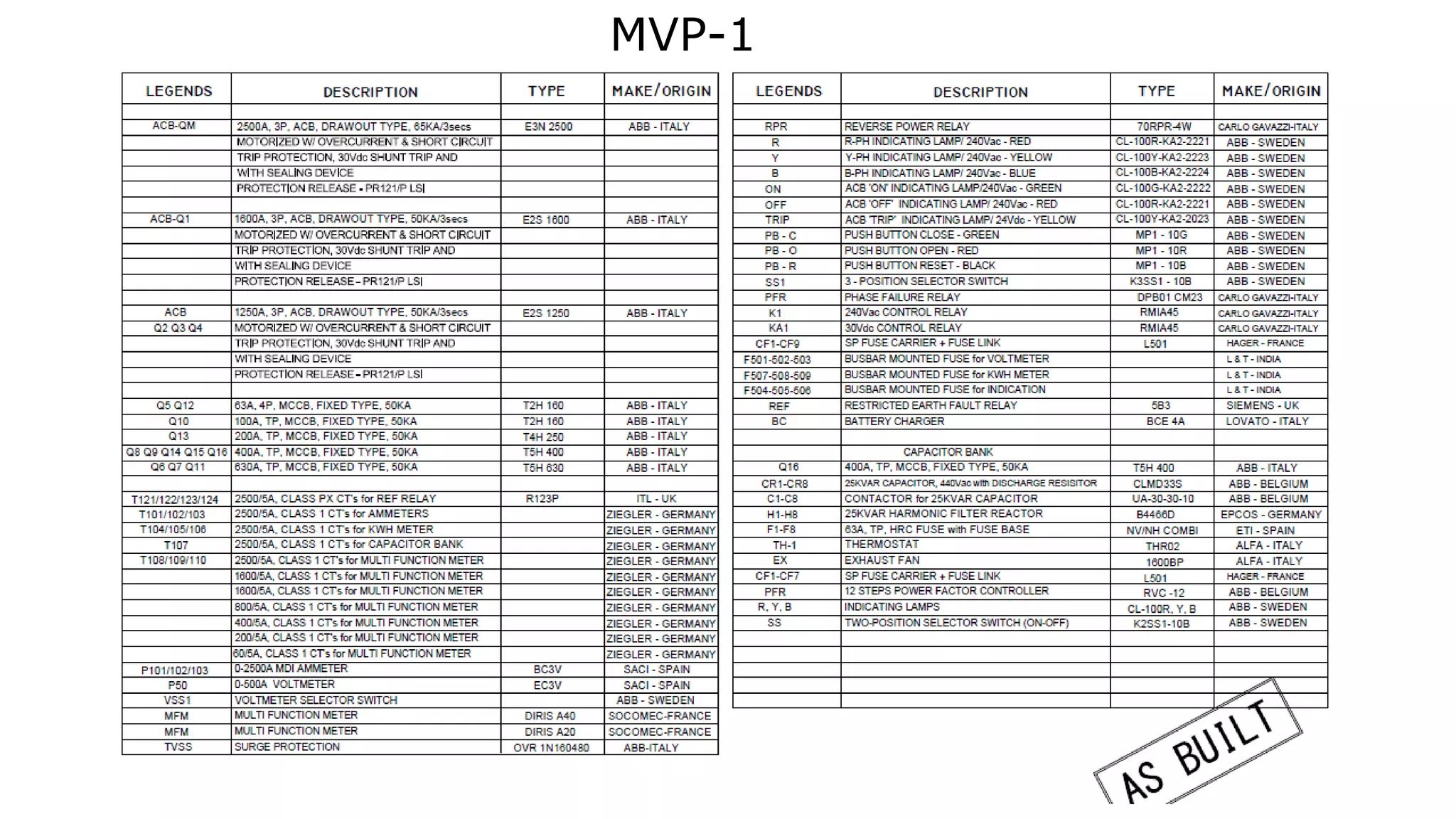

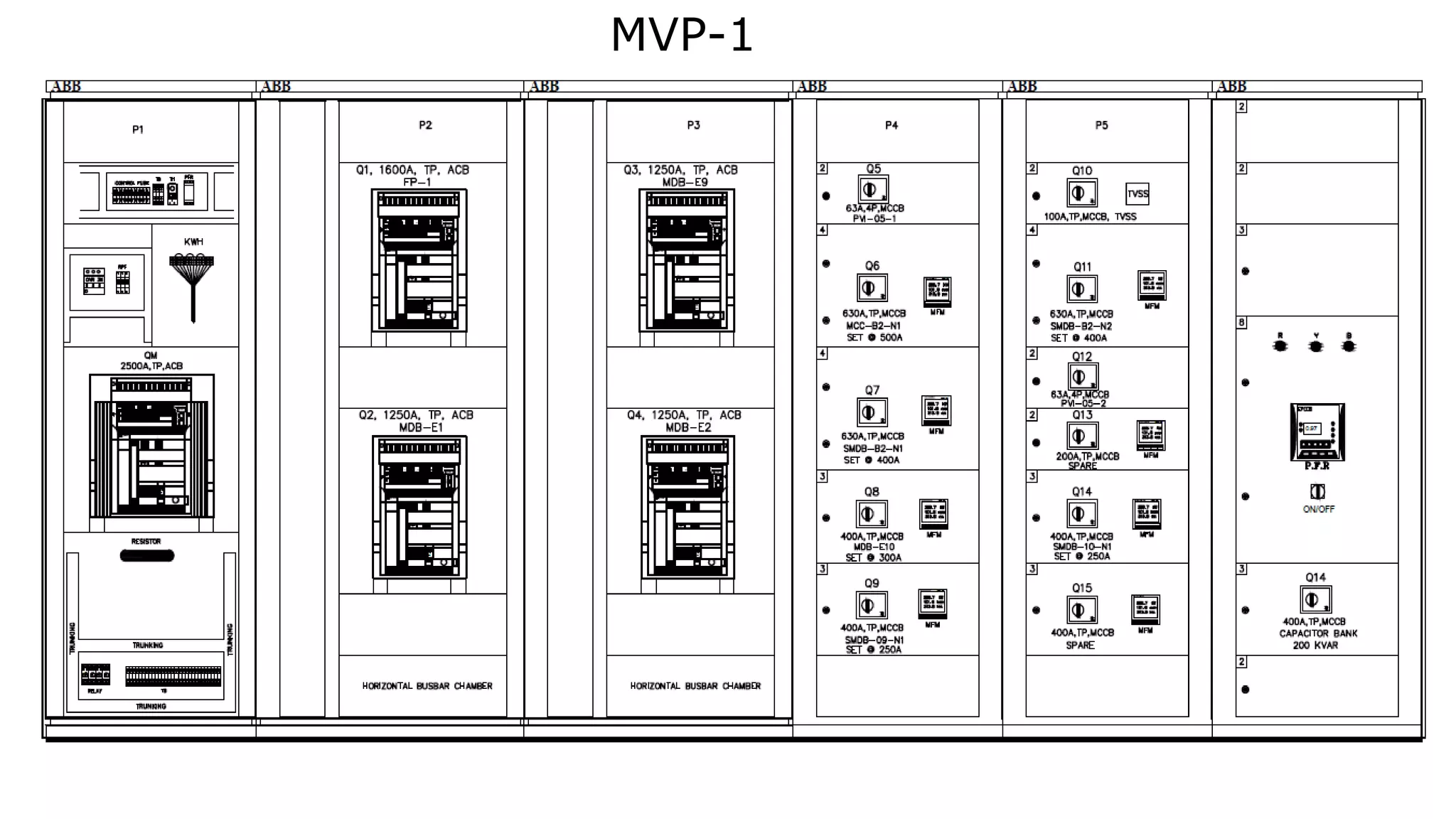

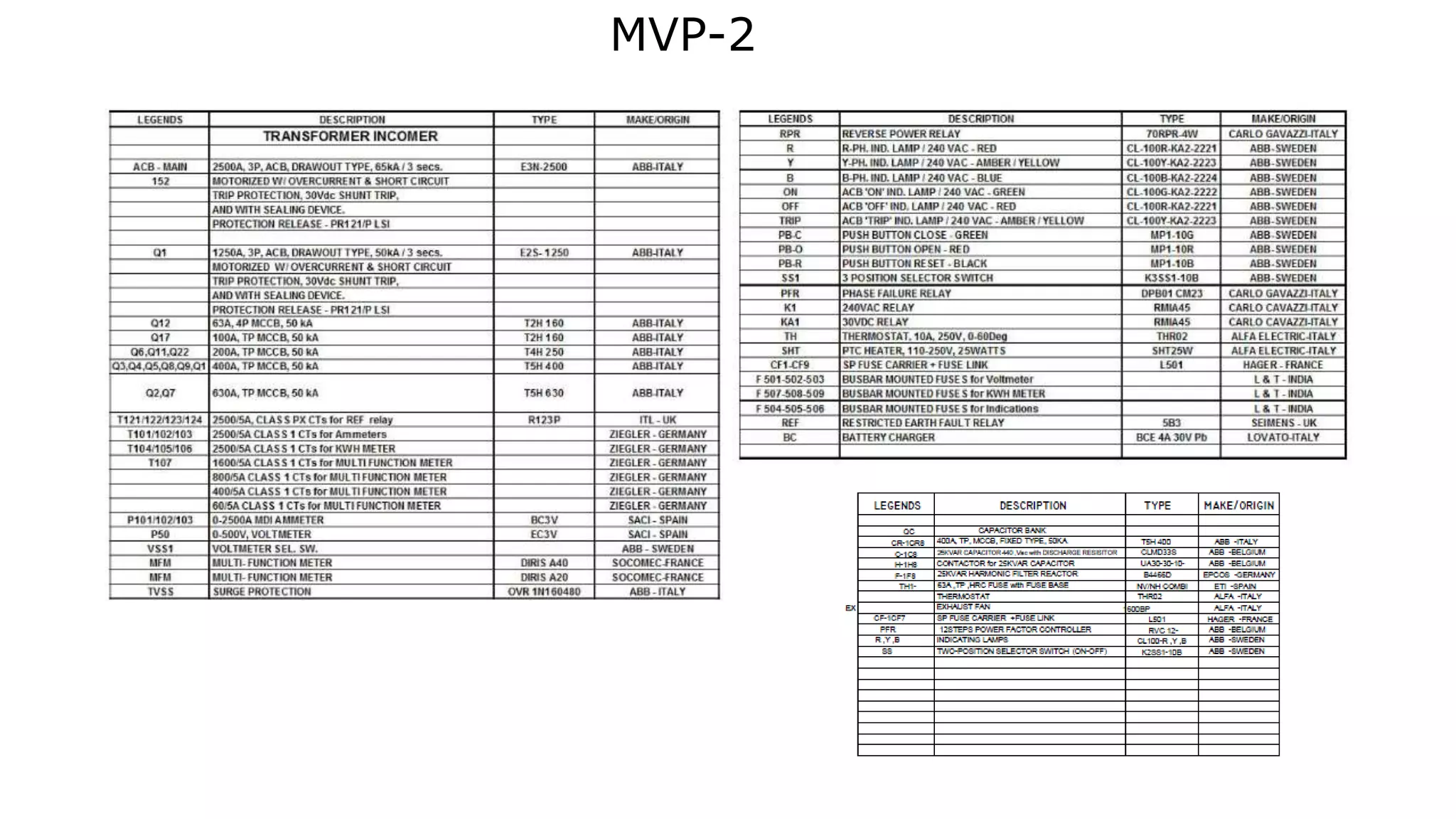

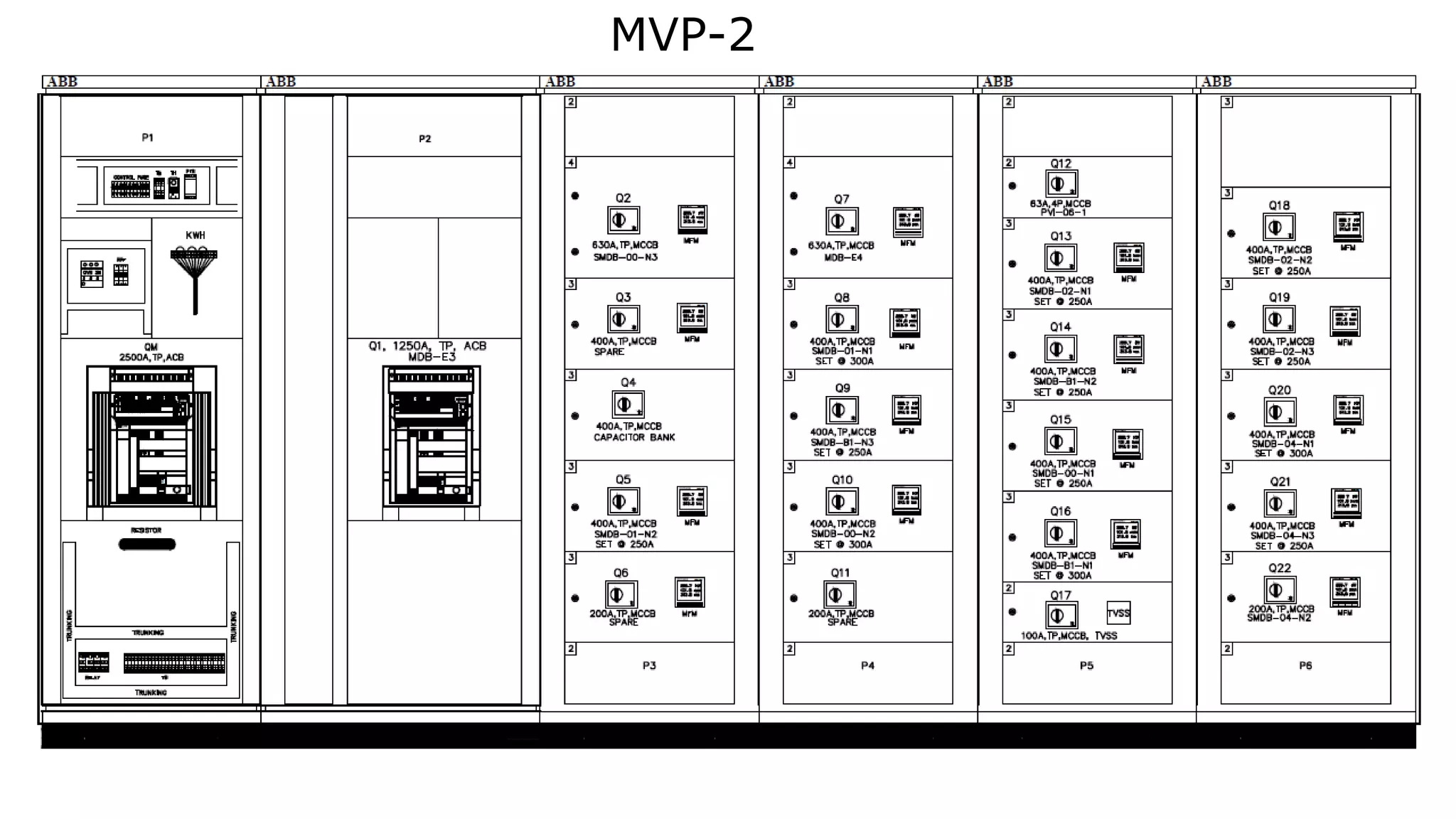

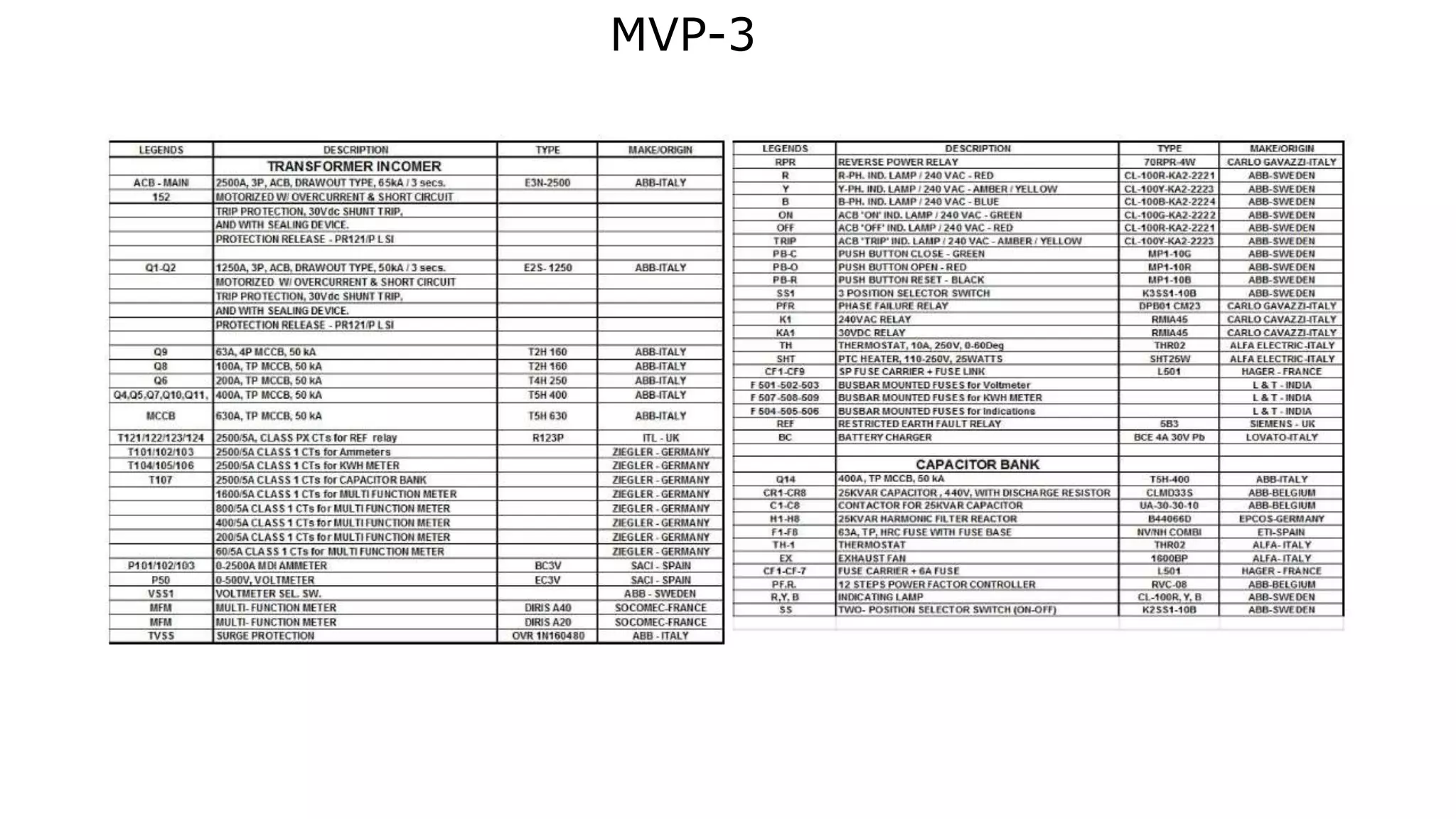

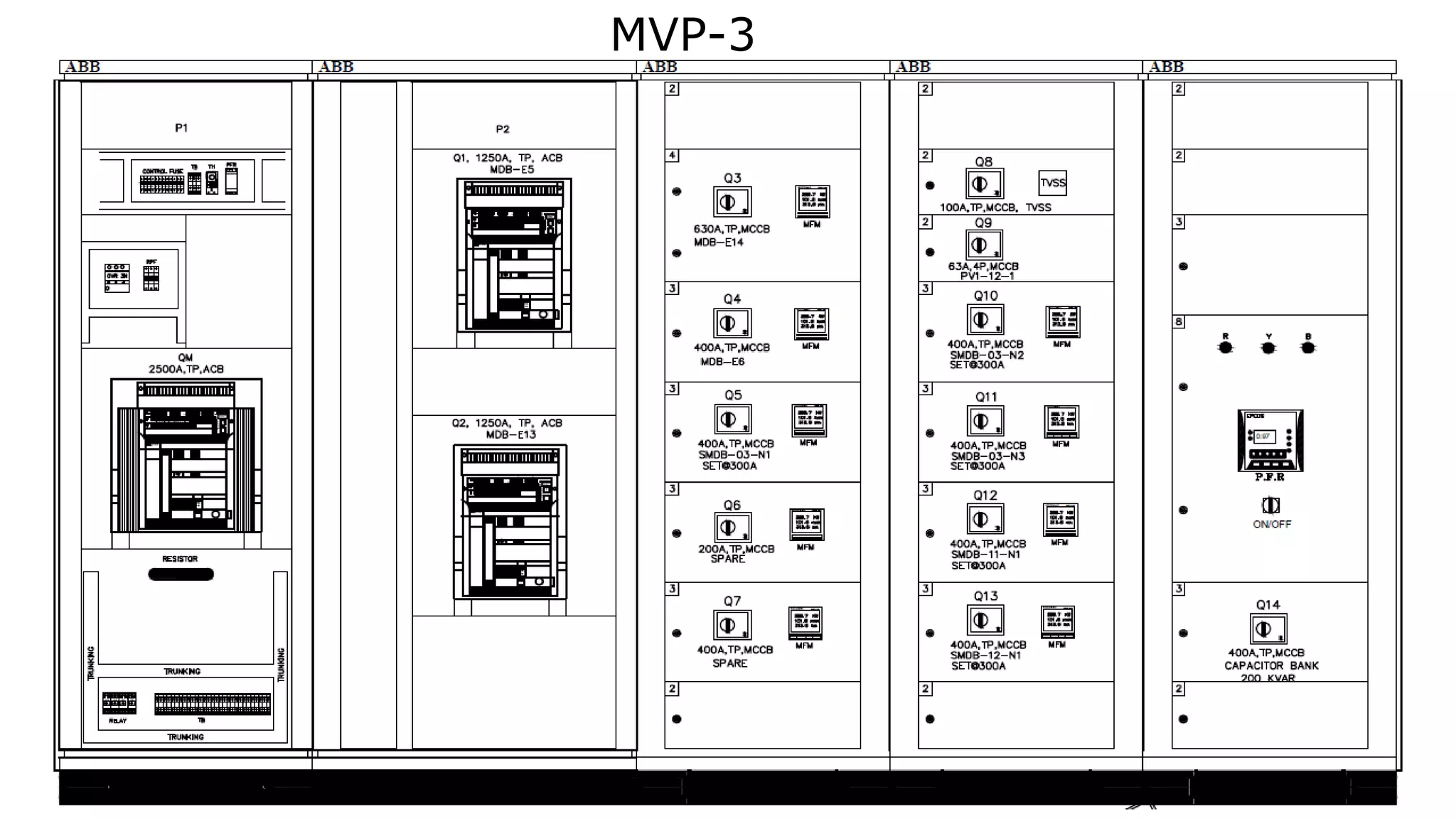

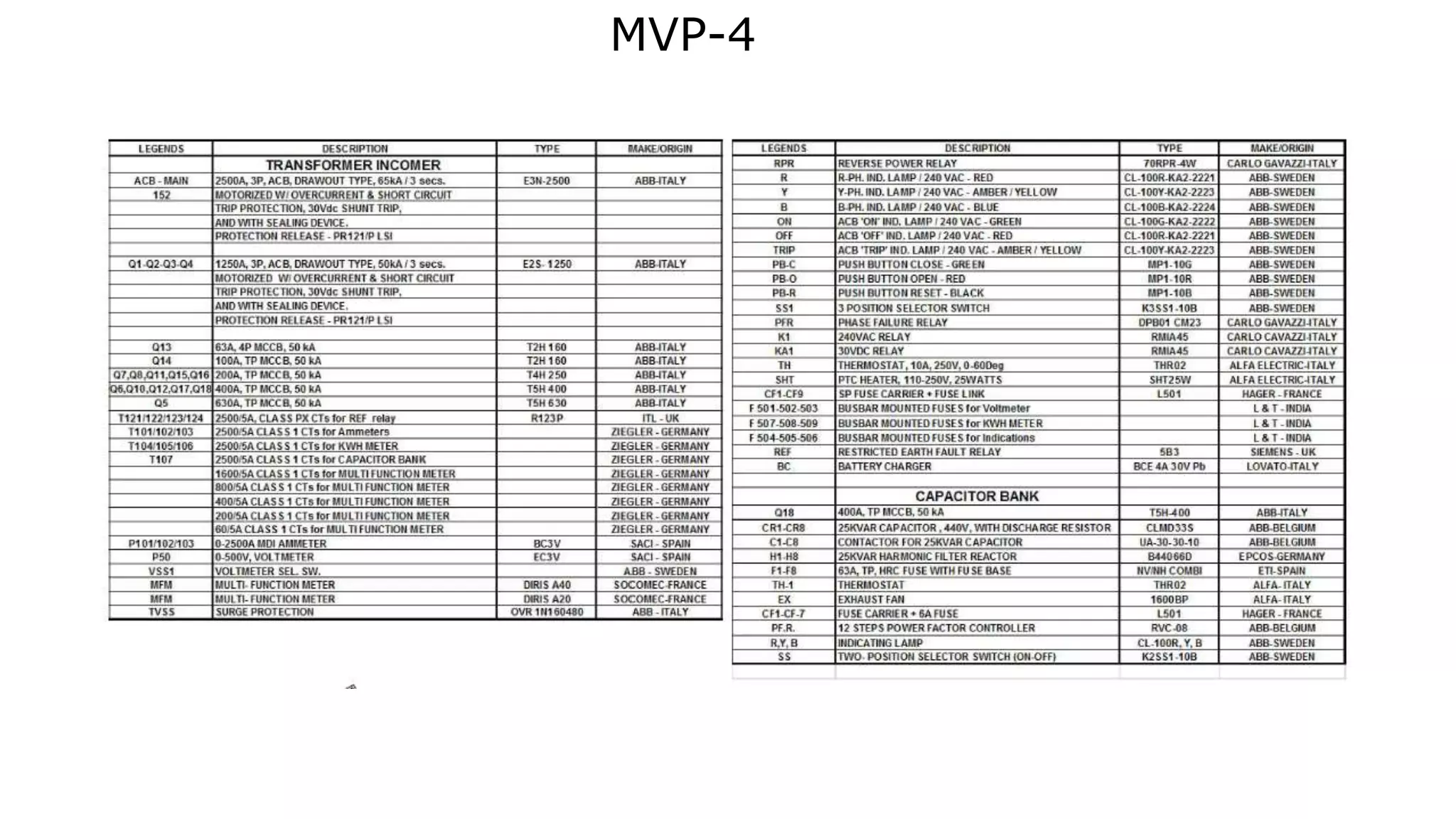

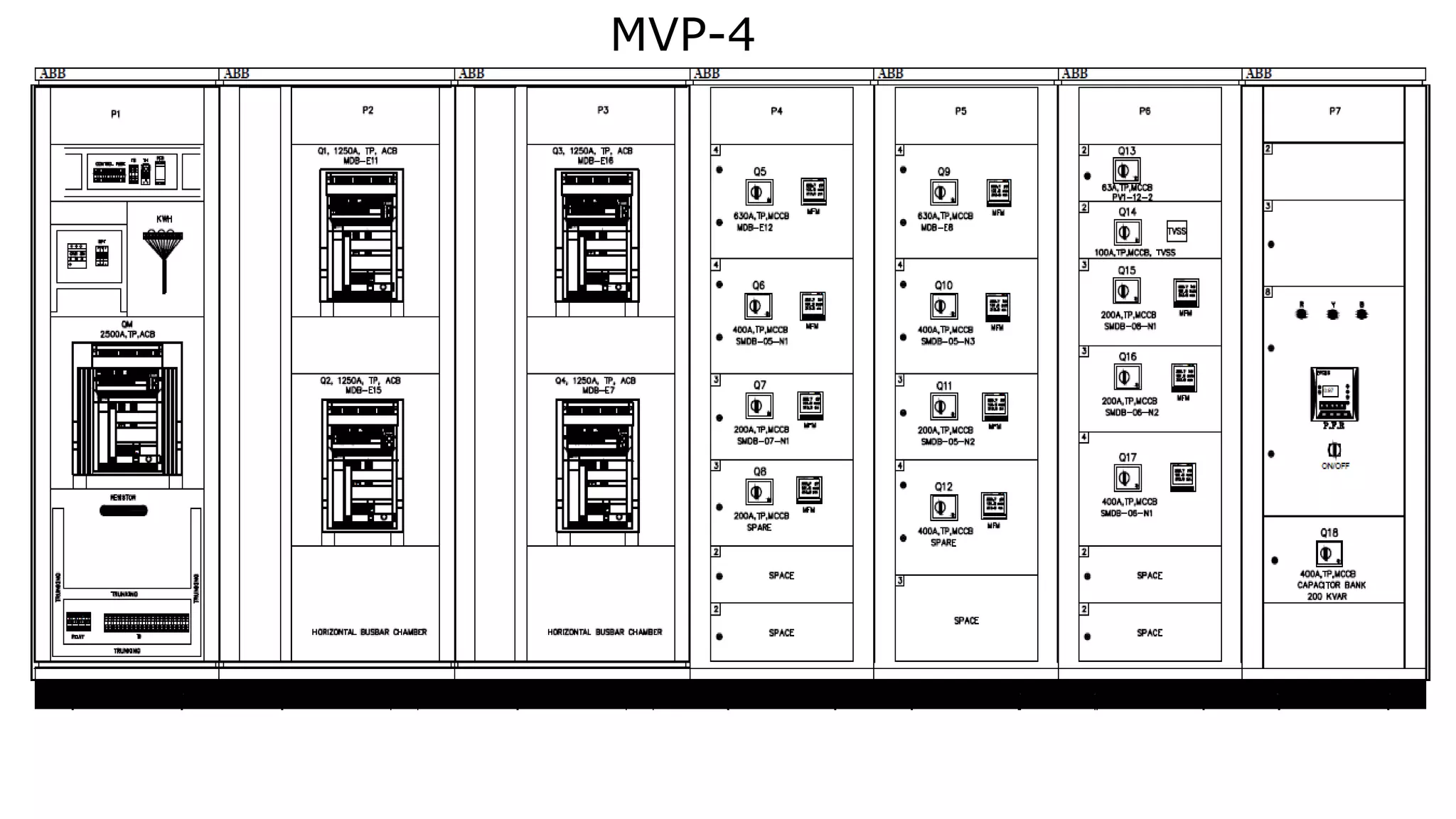

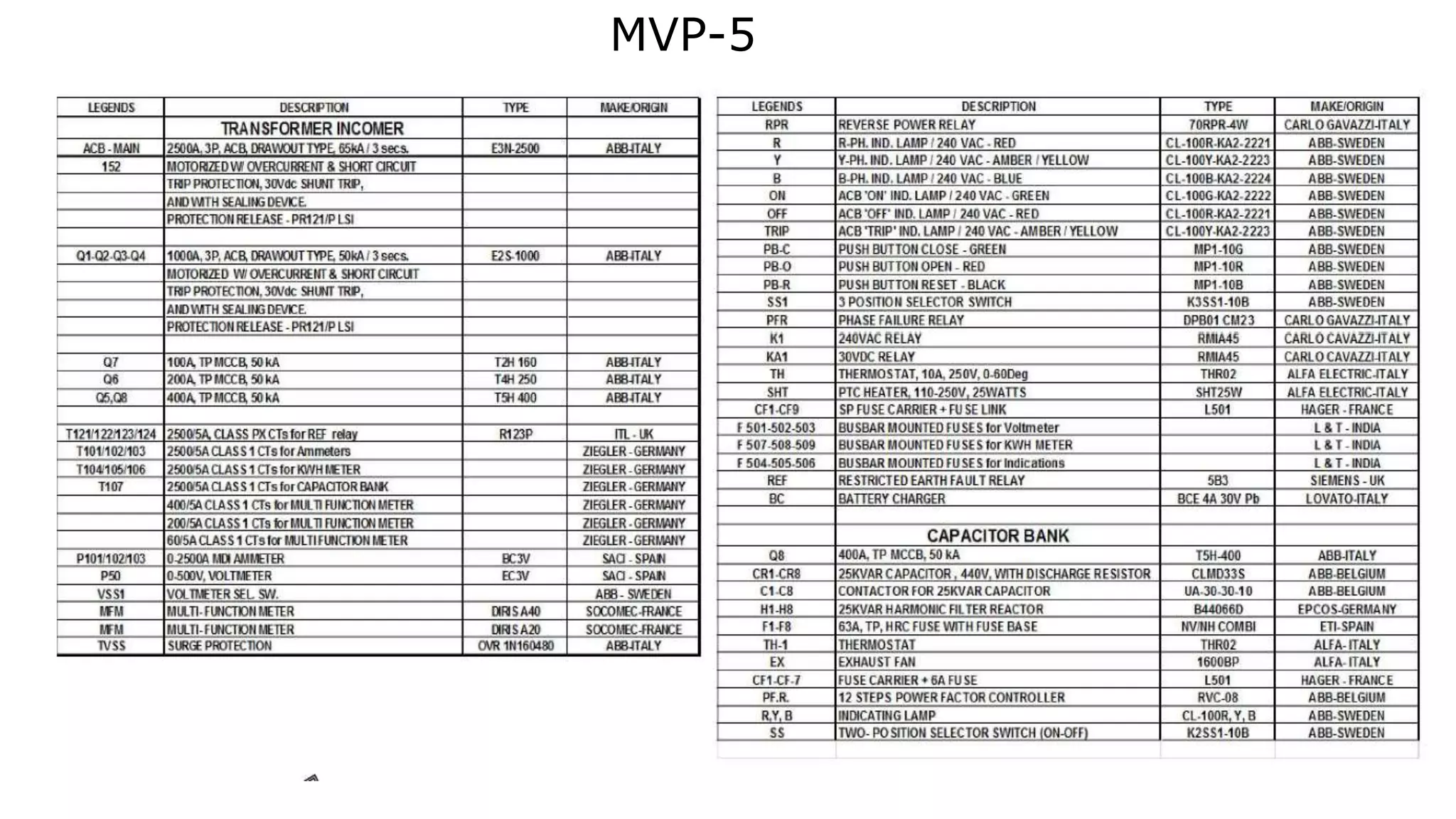

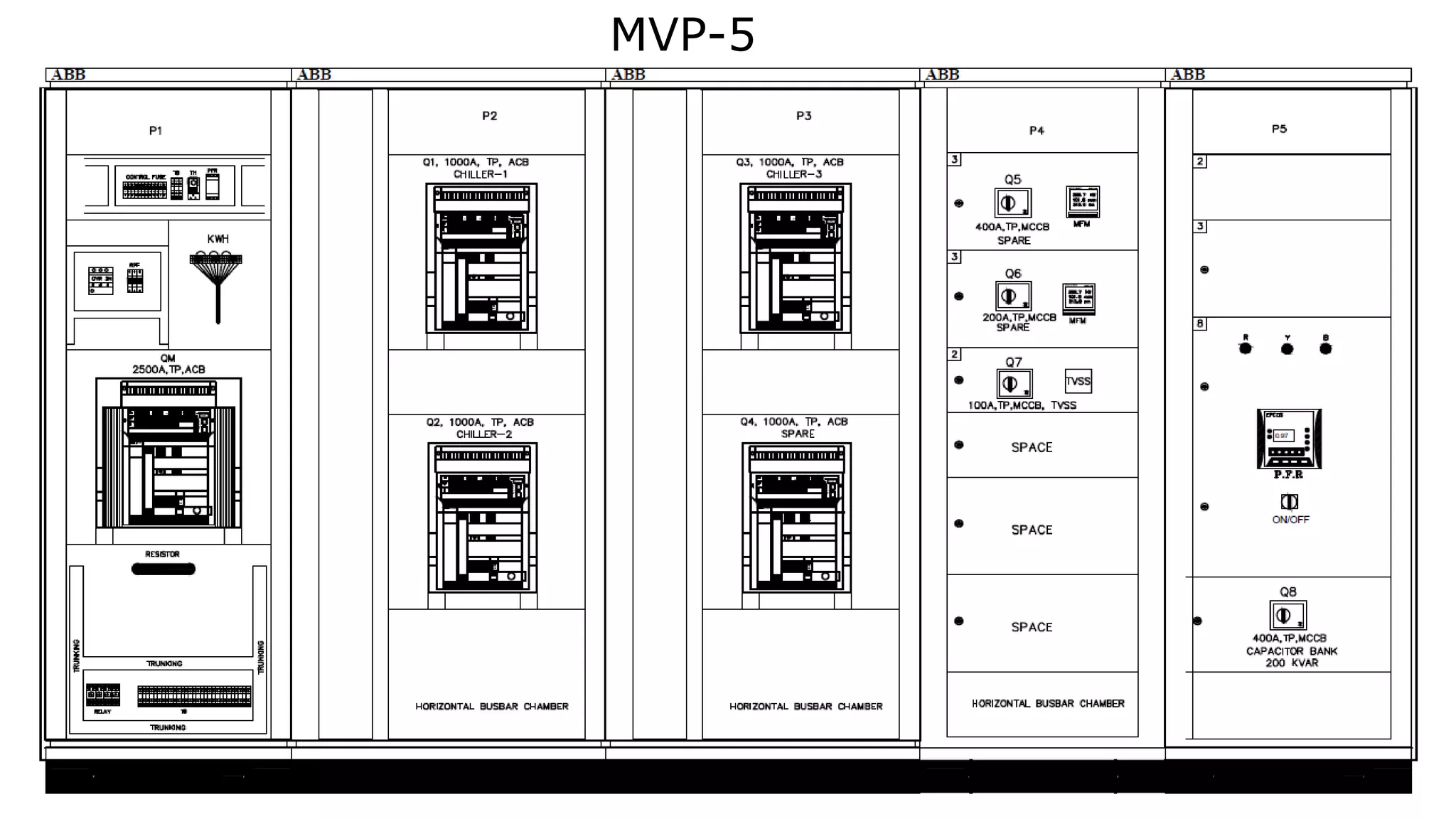

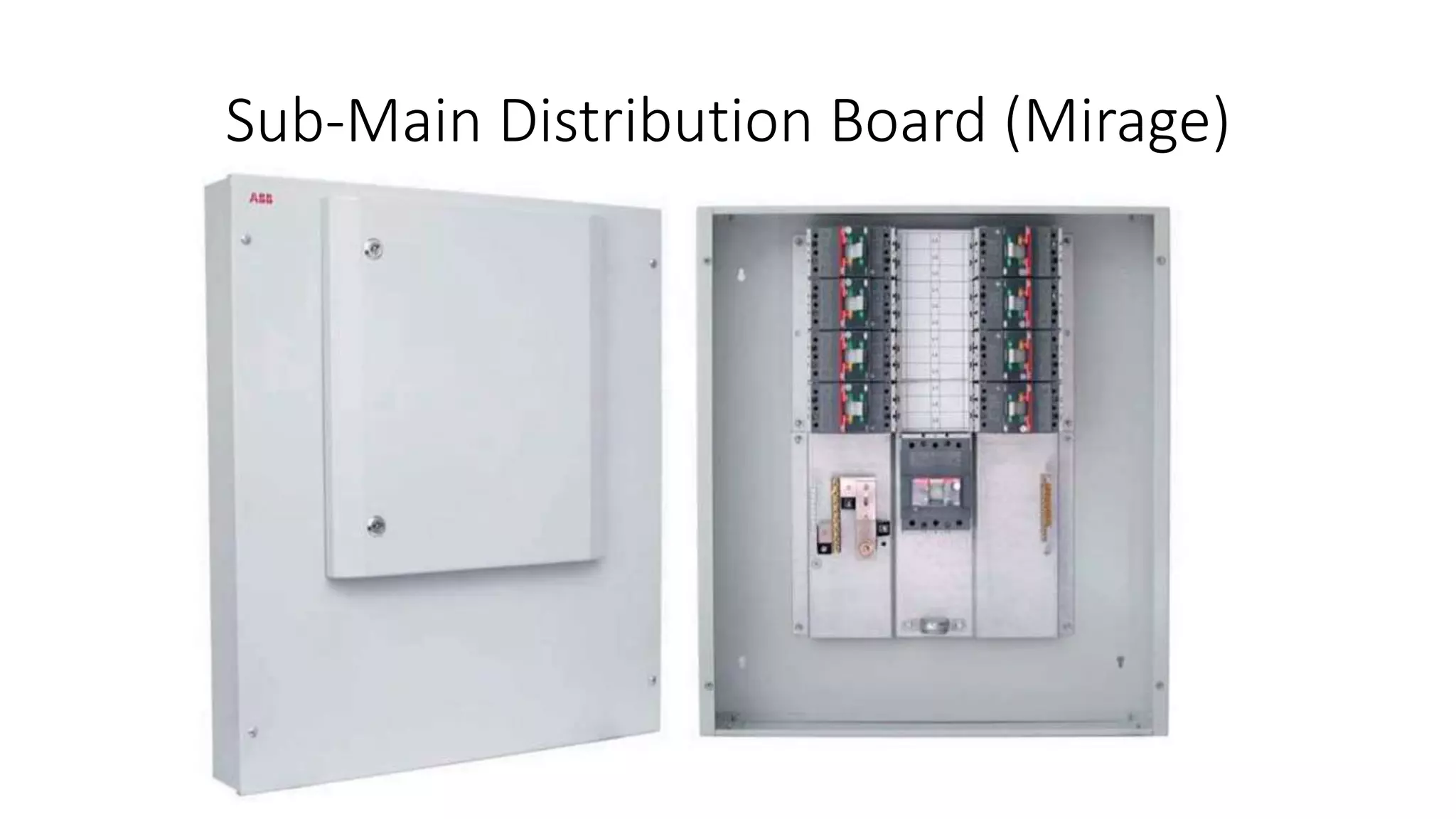

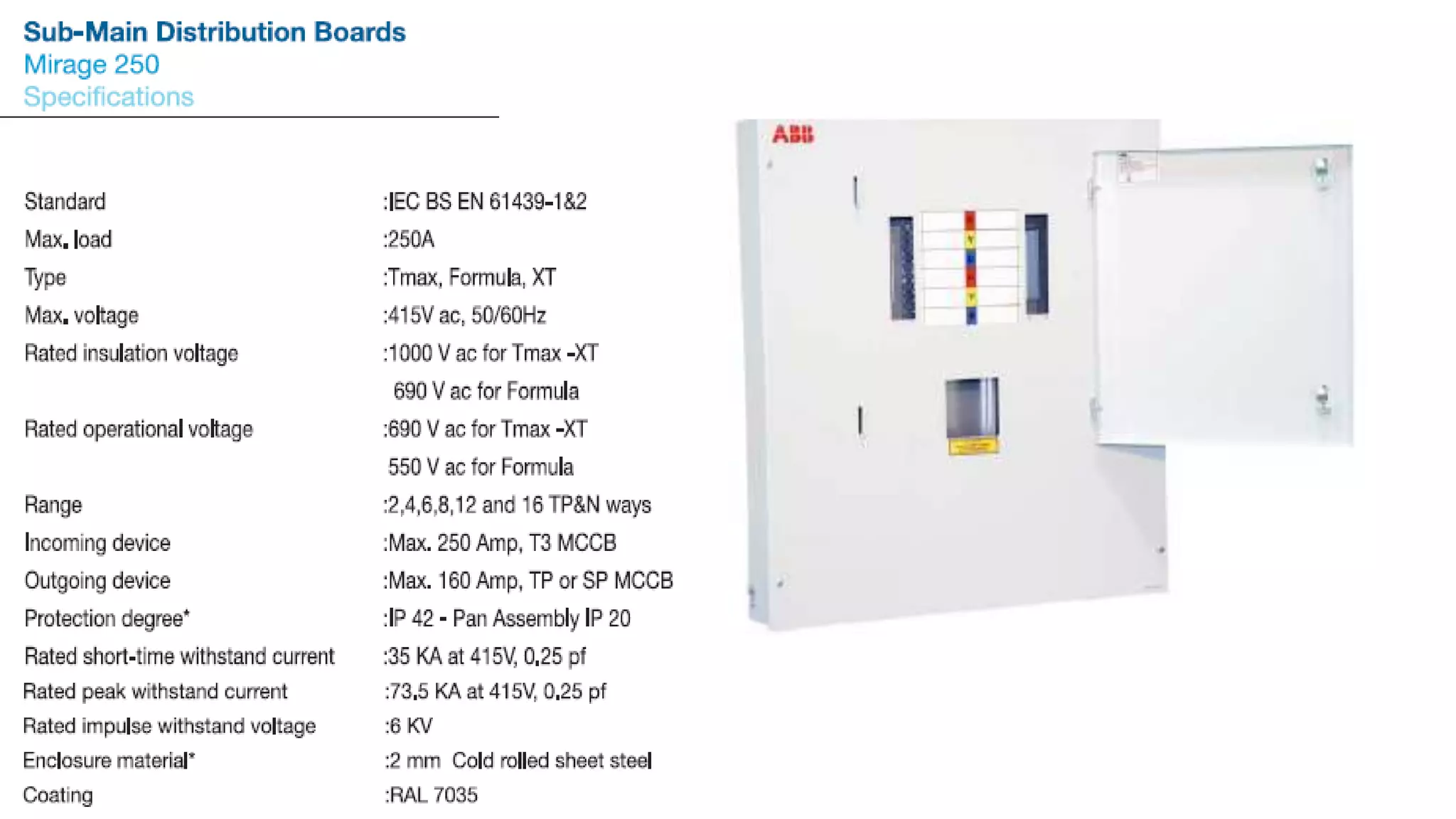

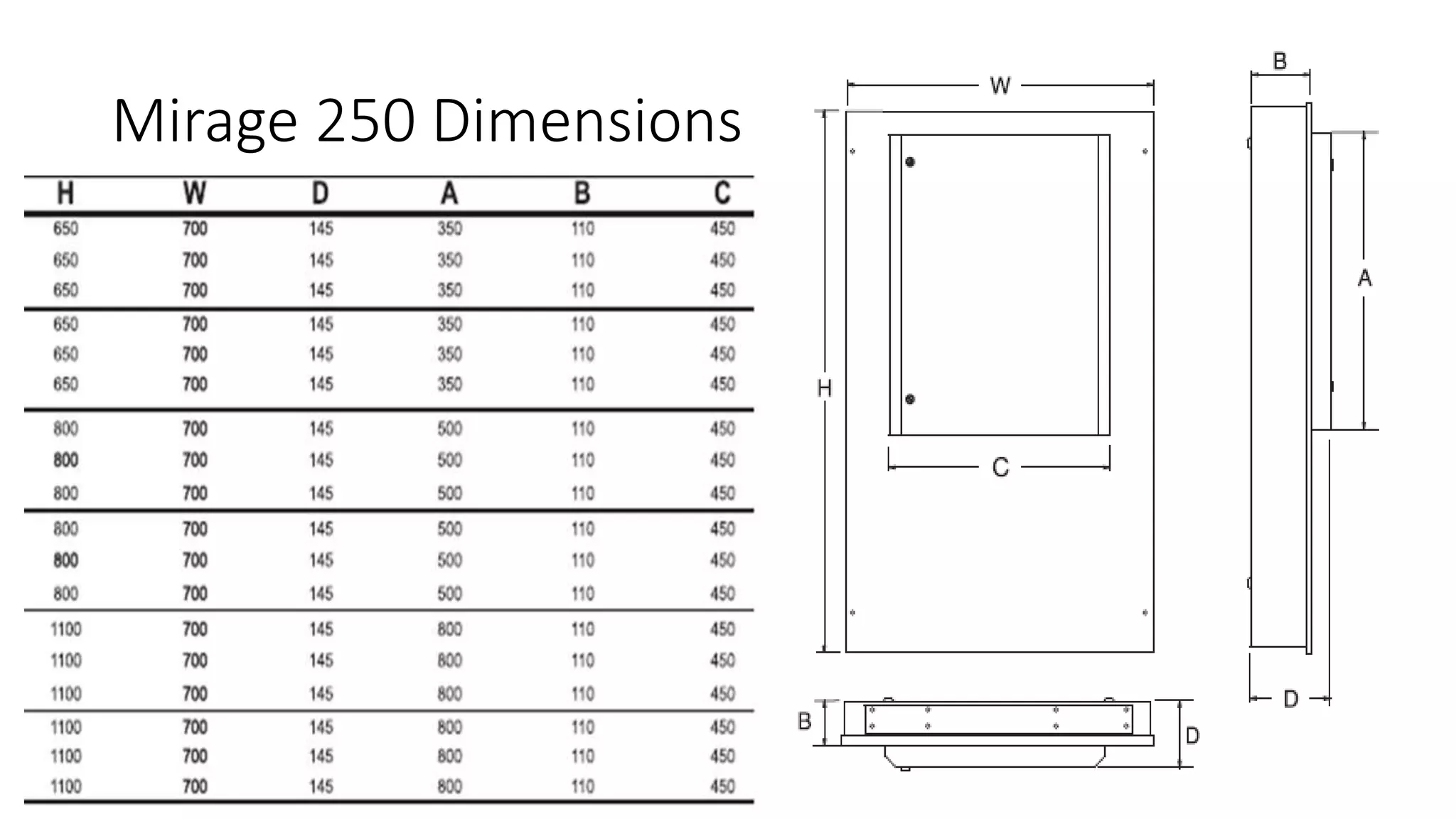

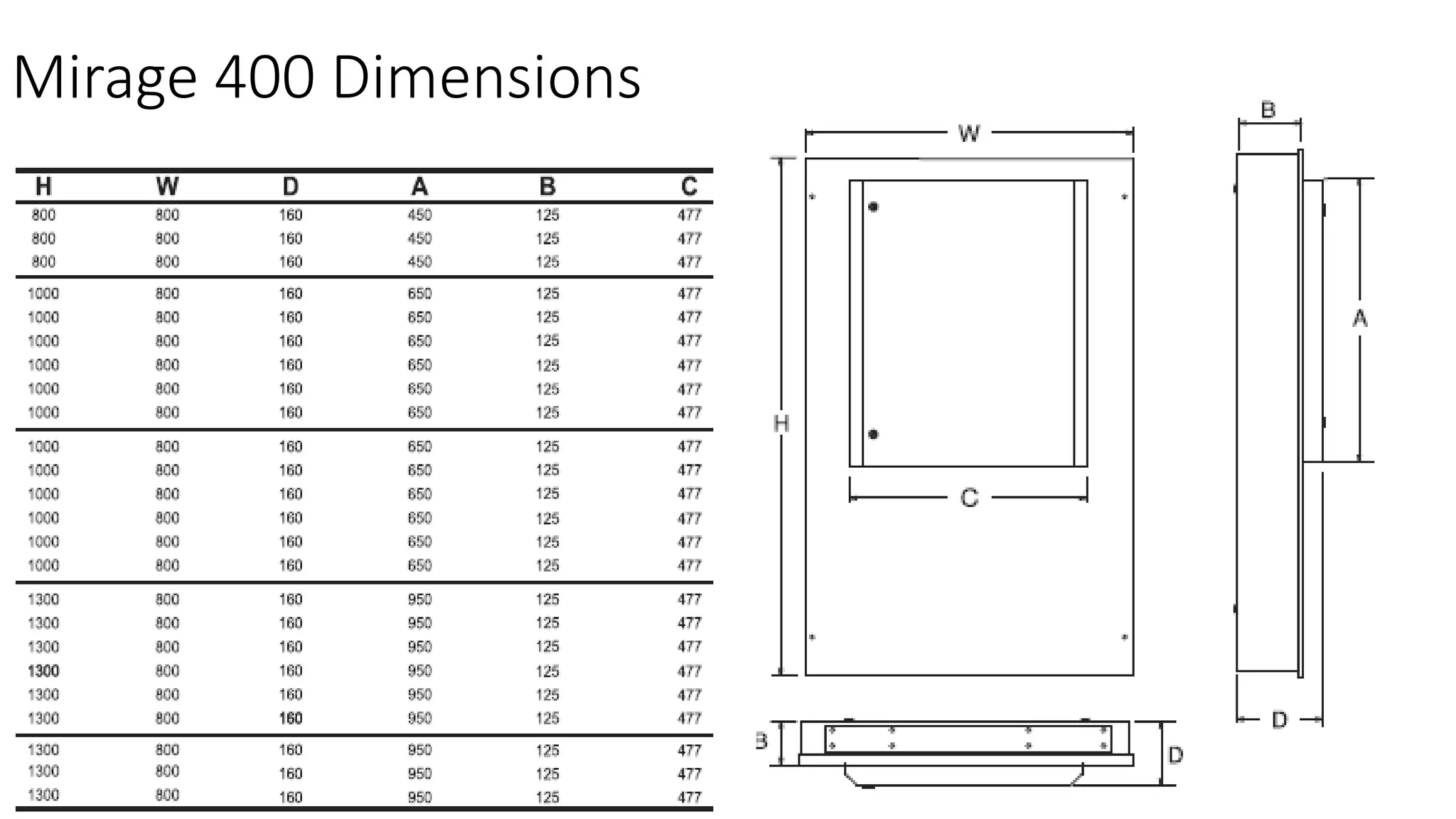

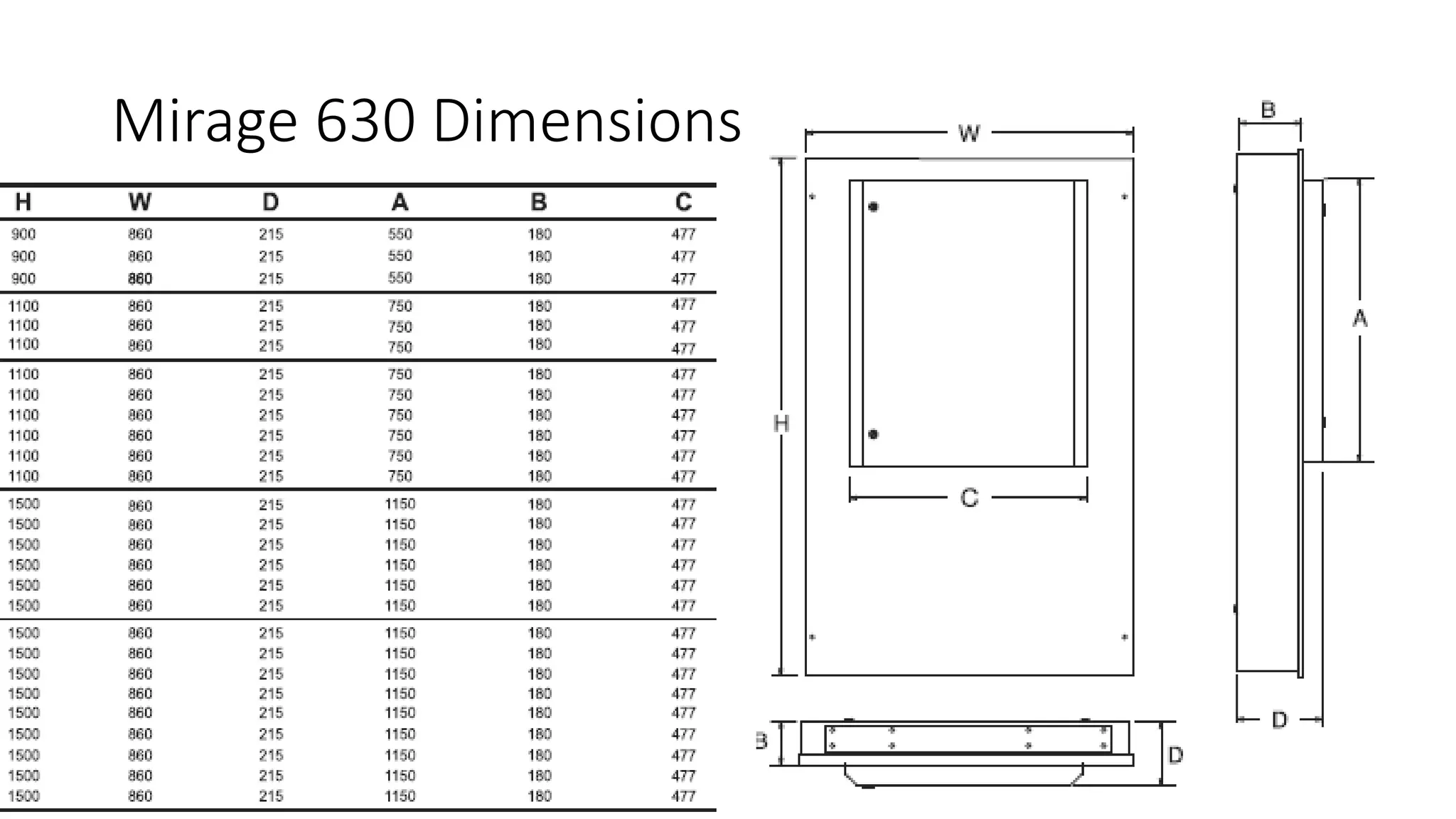

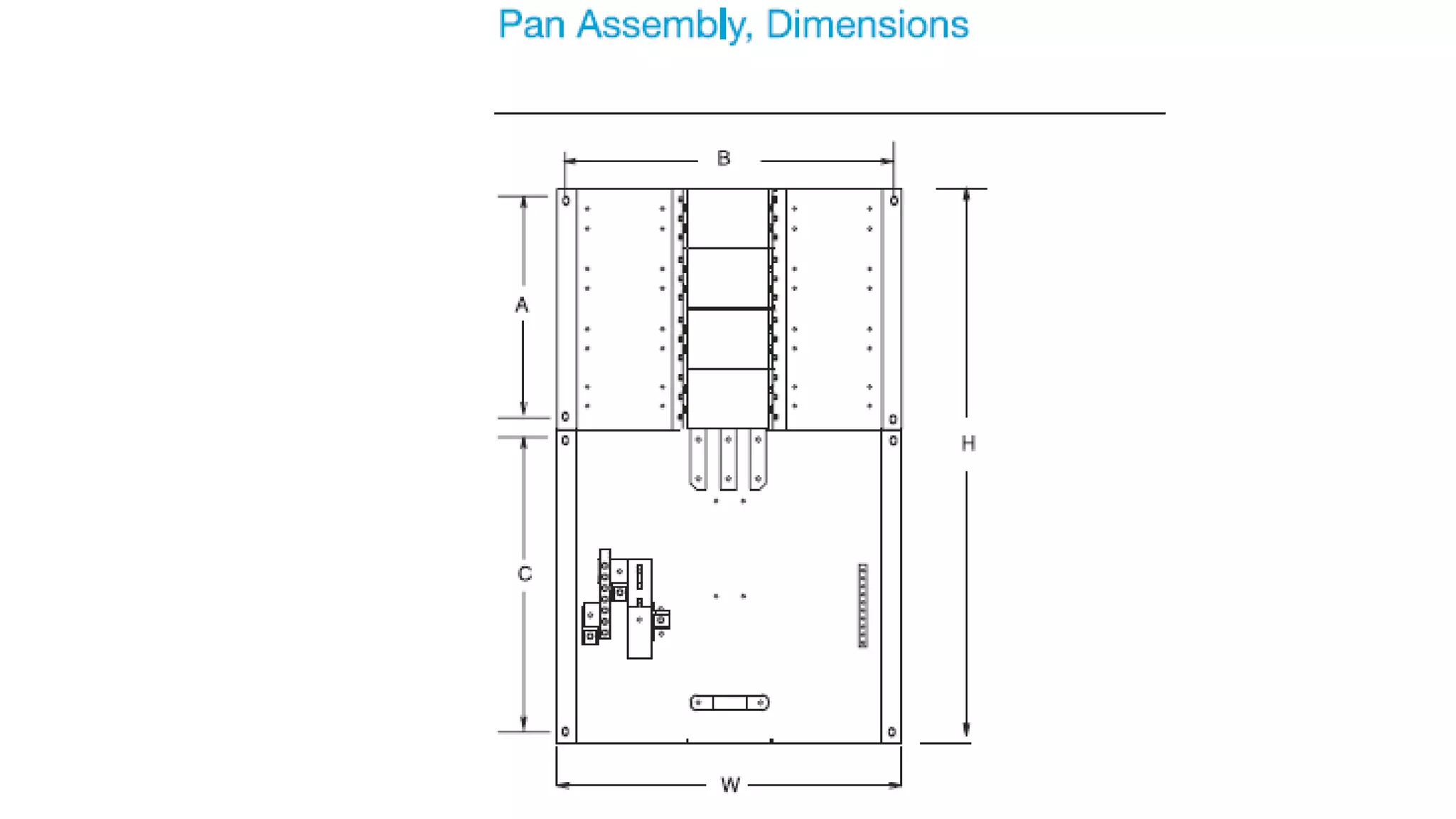

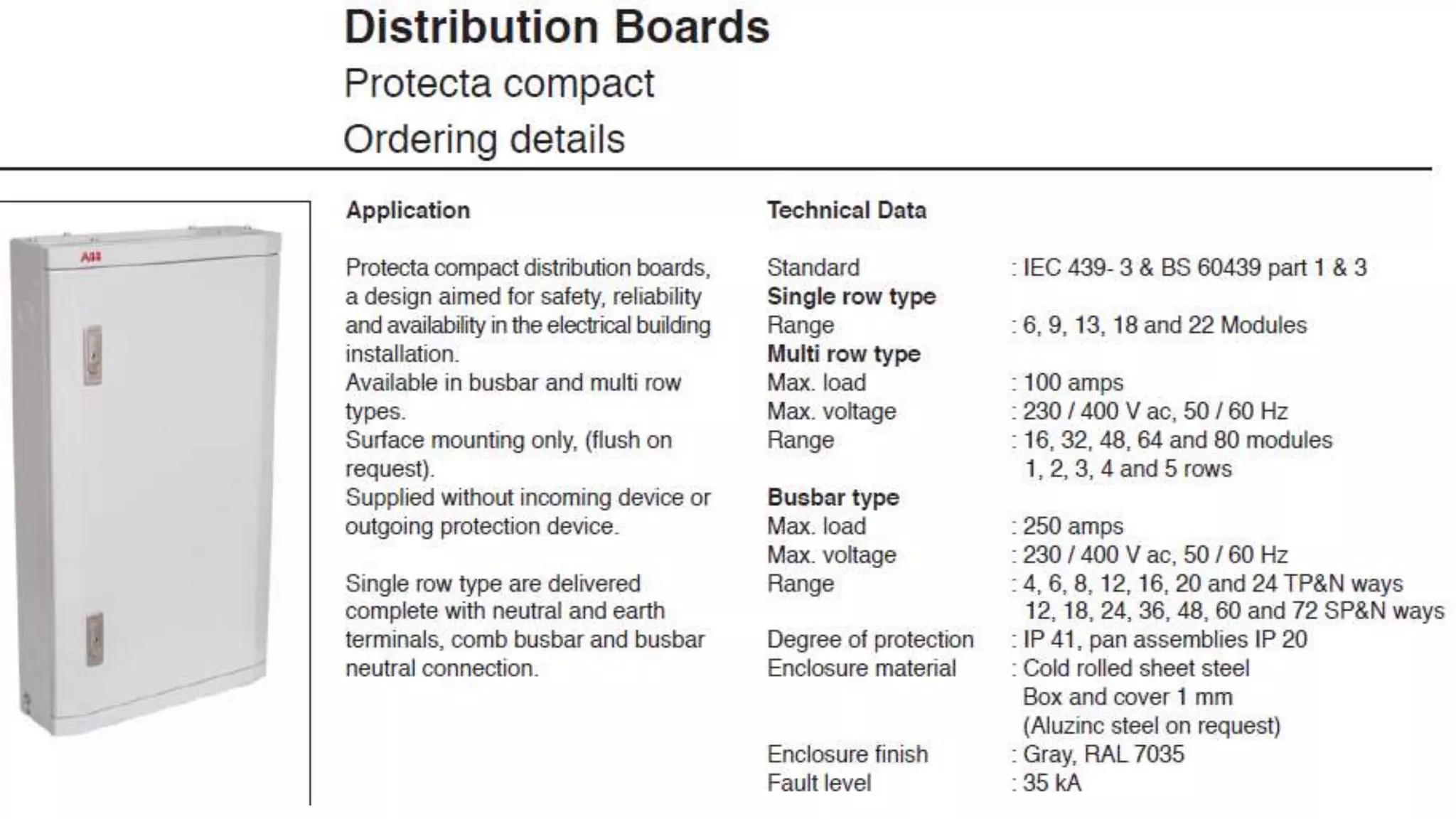

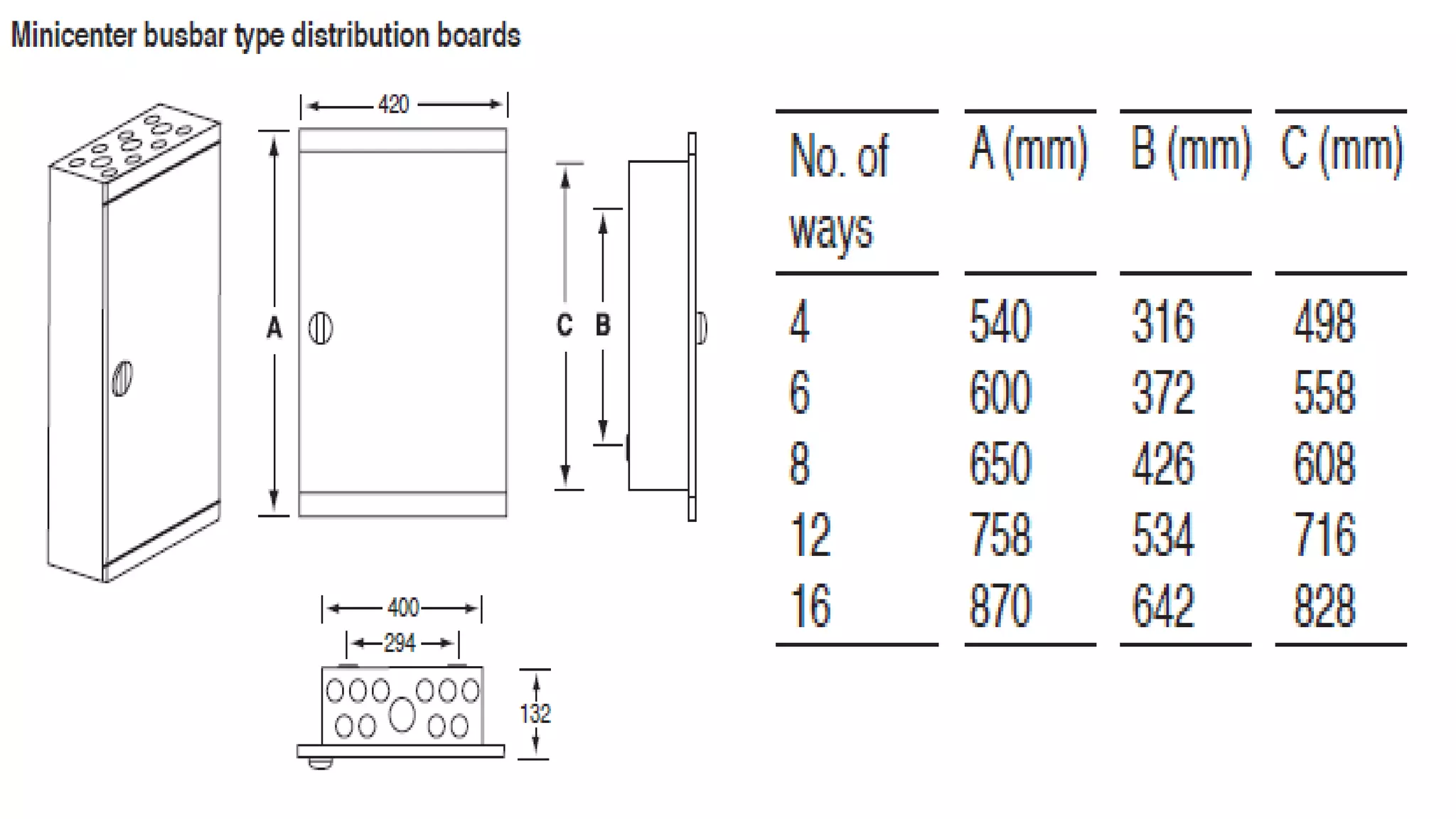

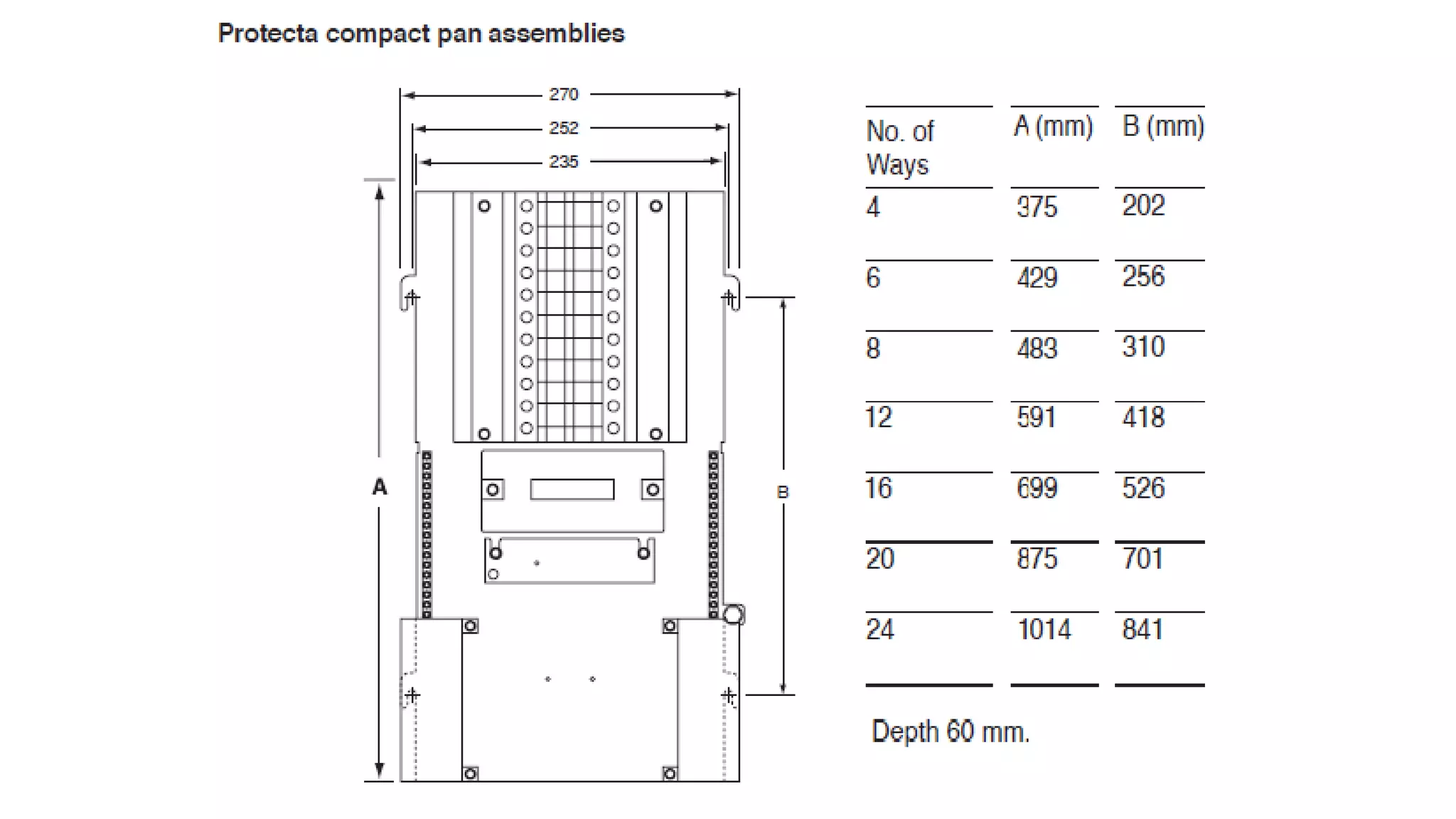

The document discusses medium voltage (MV) switchgear panels and sub-main distribution boards. It provides details on MV panel components, tests conducted, and protection against short circuits and direct/indirect contact. It also includes dimensional details and breaker information for Mirage sub-main distribution boards in 250A, 400A, and 630A sizes. Single-line diagrams and examples show potential layouts and component selection for MV panel construction.