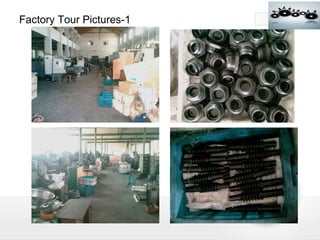

- The factory tour report summarizes Stephen's visit to Taizhou Xiang Yu Machinery Co., Ltd. to investigate issues with hardness in their manufactured parts.

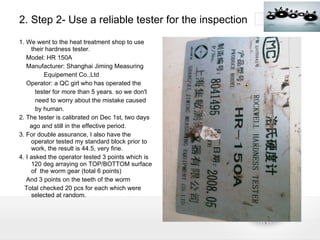

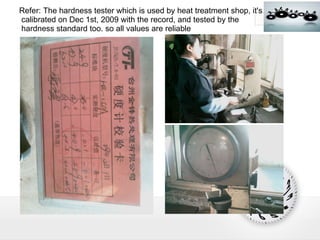

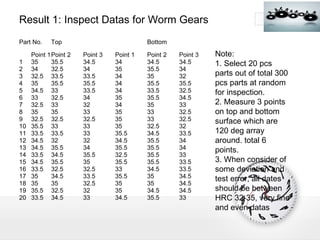

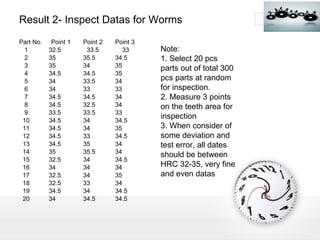

- Testing with a calibrated hardness tester showed that the parts met the required hardness specifications after heat treatment, indicating the previous failure was likely due to using an uncalibrated tester.

- Suggestions were provided to the manufacturer to appoint a quality manager, keep thorough inspection records, calibrate measuring tools, and double check tools before use to prevent future issues.