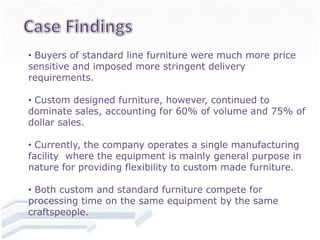

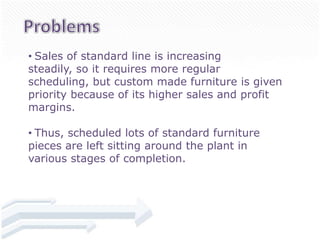

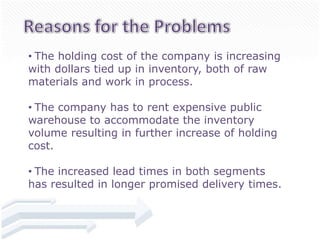

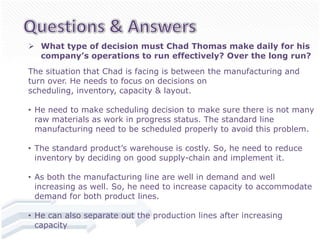

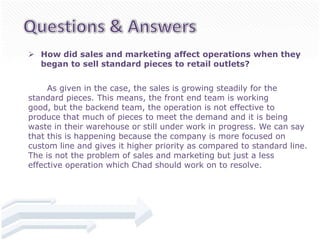

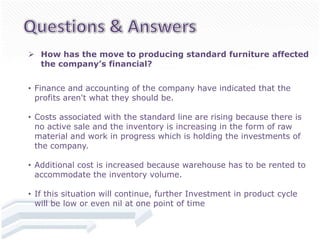

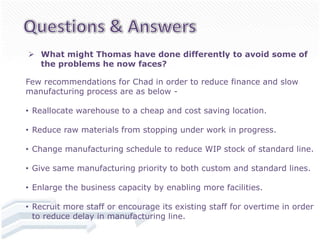

Chad's Creative Concepts produces custom and standard wood furniture. While custom furniture dominates sales, standard furniture sales are growing steadily. However, standard furniture production faces scheduling issues, high inventory holding costs, and longer delivery times. Chad must make decisions to improve operations for both custom and standard lines to meet growing demand effectively and efficiently.