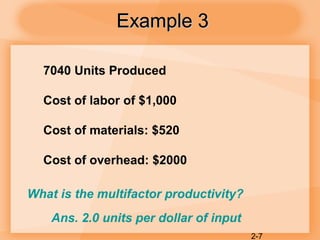

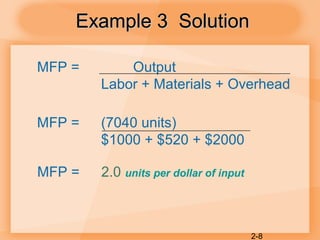

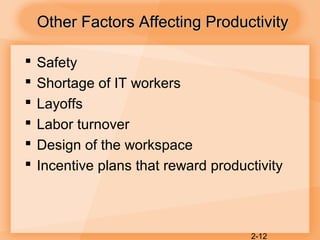

This document discusses productivity, including definitions, types of measures, and factors that affect productivity. It defines productivity as a ratio of outputs to inputs, and describes partial, multi-factor, and total measures. Productivity growth is calculated as the change from the current period to the previous. Examples are given for labor, machine, energy, and capital productivity. Process yield and factors influencing productivity such as technology, management, and work environment are also covered.