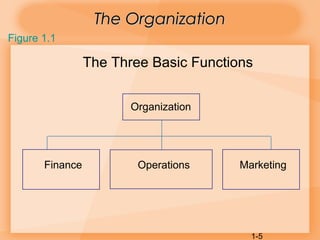

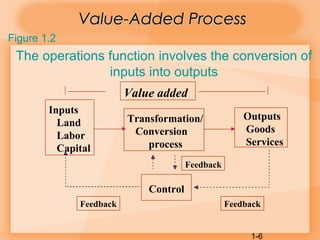

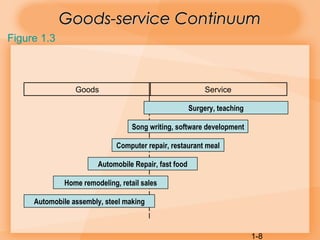

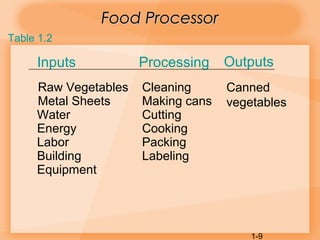

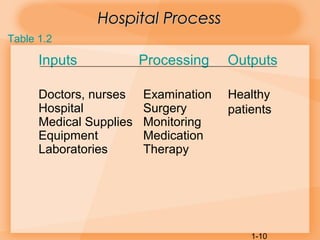

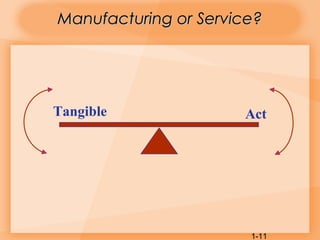

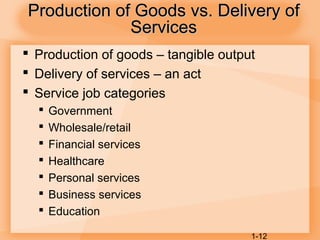

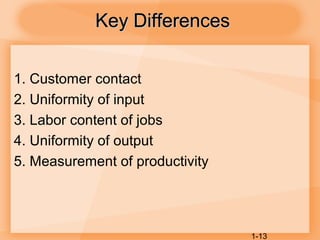

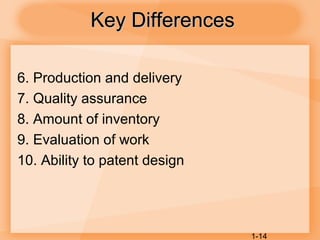

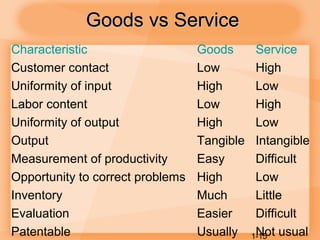

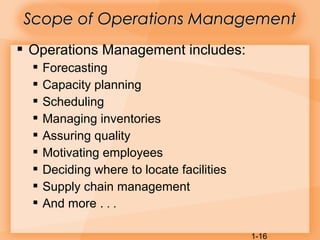

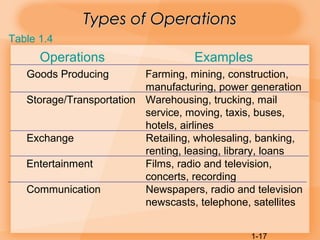

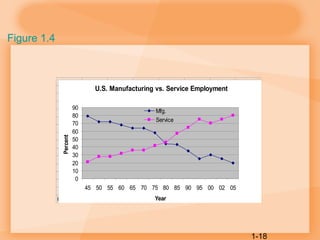

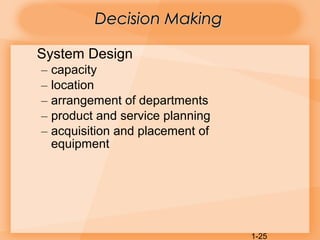

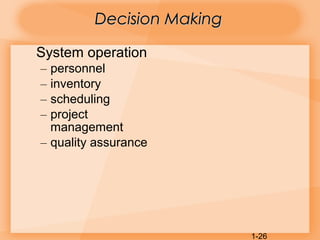

This document provides an introduction to operations management. It defines operations management as managing systems or processes that create goods and services. It describes the three major functional areas of organizations - operations, finance, and marketing - and how they interrelate. It compares manufacturing and service operations, outlining key differences. The document also discusses the scope and challenges of operations management decision making.