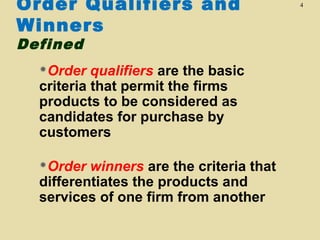

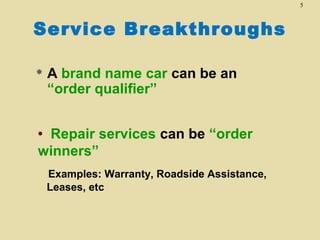

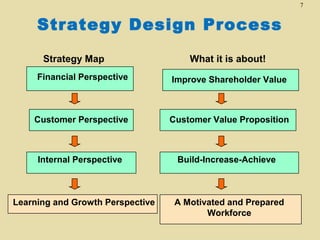

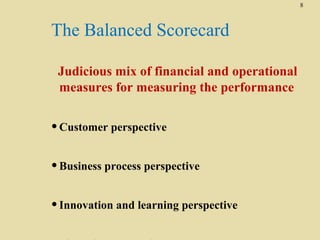

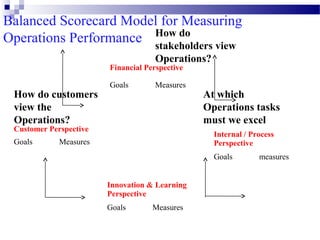

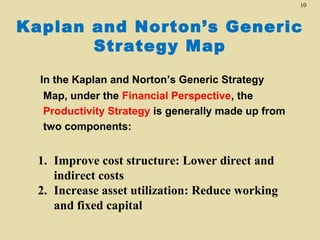

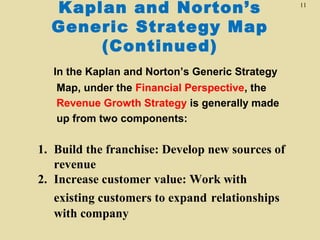

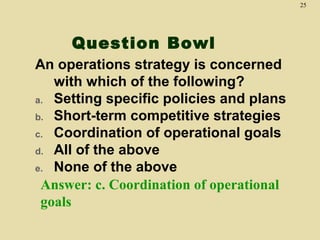

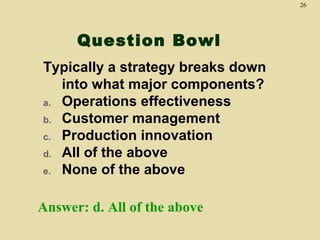

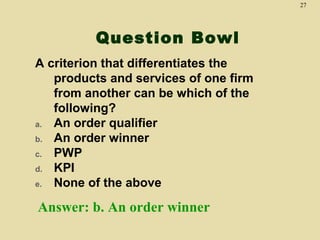

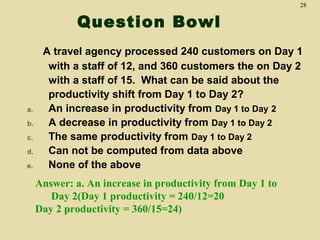

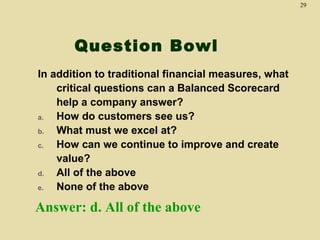

This document discusses operations strategy and competitiveness. It explains that operations strategy can be used as a competitive weapon through factors like shorter product cycles, production flexibility, low costs, product variety, quality, and more. It also discusses competitive dimensions like cost, quality, delivery speed and reliability, flexibility, and product-specific criteria. Order qualifiers are basic criteria that allow a product to be considered for purchase, while order winners differentiate products. The balanced scorecard and Kaplan and Norton's generic strategy map are presented as frameworks for developing operations strategies. Steps in developing manufacturing and service strategies are also outlined.