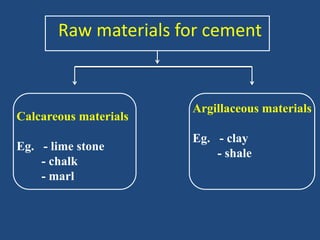

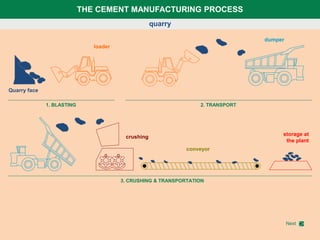

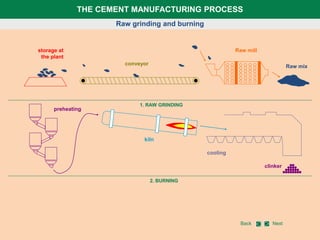

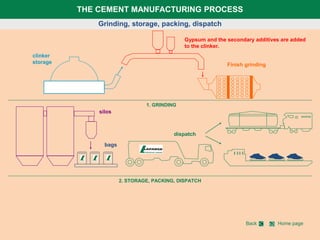

Cement is an adhesive material that bonds mineral fragments for construction. The manufacturing process includes blasting raw materials like limestone and clay, grinding them, and heating in a kiln to produce clinker, which is then ground with gypsum to create cement. Finally, the finished product is stored and dispatched for use in construction.