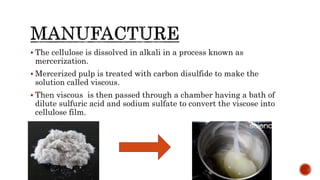

This document discusses the history, manufacture, properties, grades, uses, advantages and disadvantages of cellophane. Cellophane is a thin, transparent sheet made from regenerated cellulose that is useful for food packaging due to its low permeability. It is produced through a process involving dissolving cellulose in alkali and treating it with carbon disulfide to form viscose, which is then passed through acid and salt baths to form the cellulose film. Cellophane is biodegradable, transparent, and acts as a barrier to air, oils and bacteria, making it suitable for packaging foods. However, it also has some disadvantages like poor performance at low temperatures.