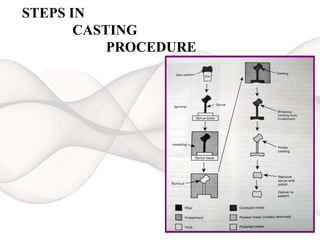

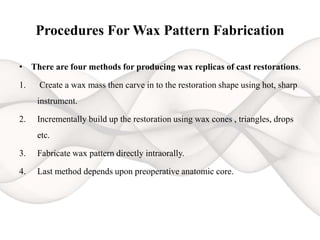

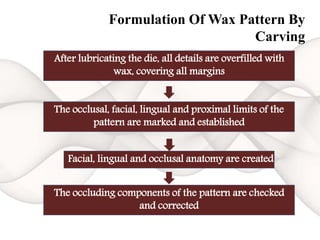

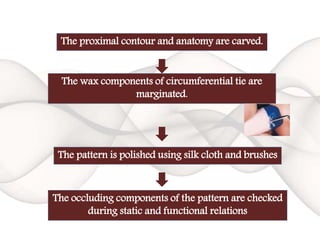

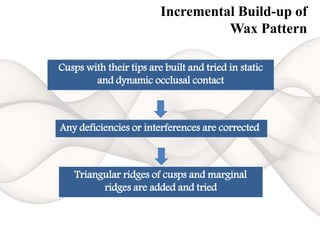

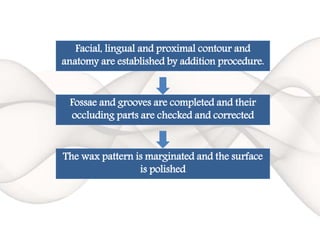

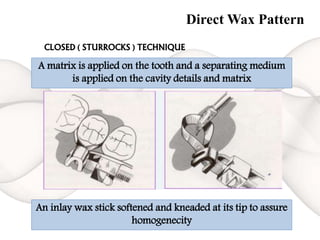

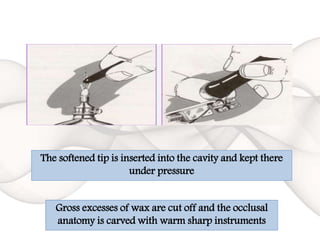

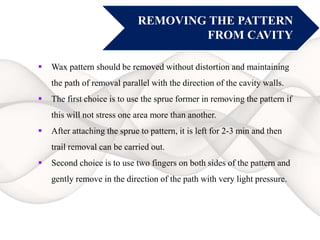

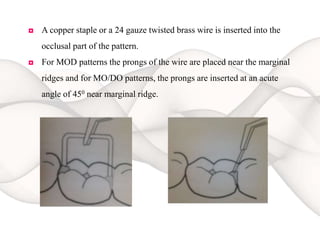

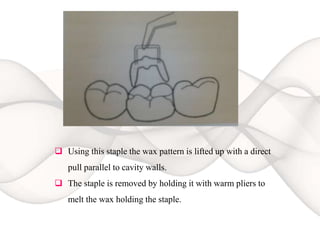

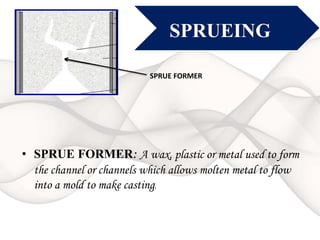

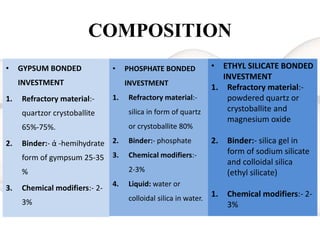

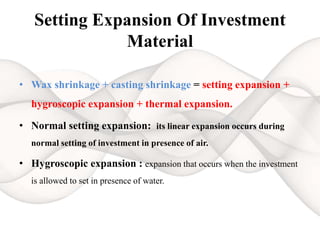

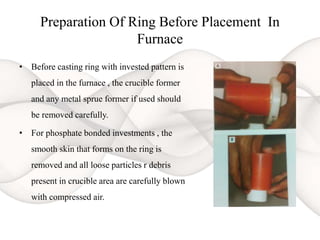

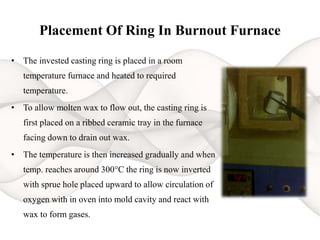

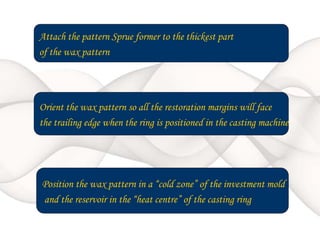

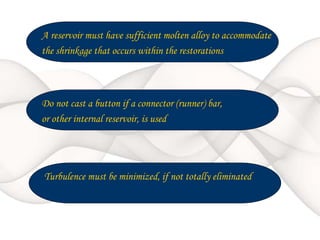

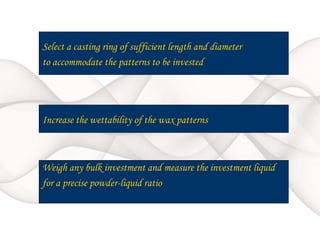

This document provides information on dental casting procedures. It discusses the history of casting, steps in the casting process such as wax pattern fabrication and sprue attachment, types of investments and burnout procedures. The key points are: casting has been used since ancient times to produce jewelry and was introduced to dentistry by Taggart in 1907; the process involves fabricating a wax pattern, investing it, then burning out the wax and casting dental alloys into the mold.