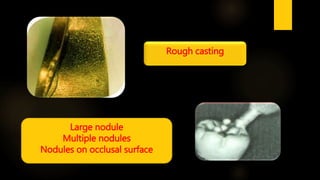

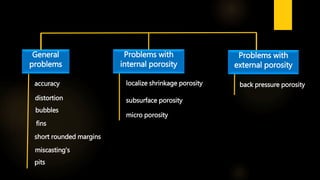

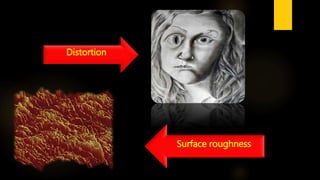

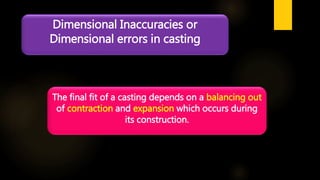

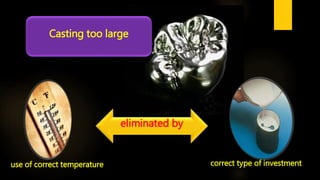

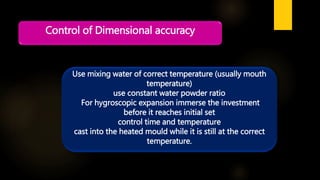

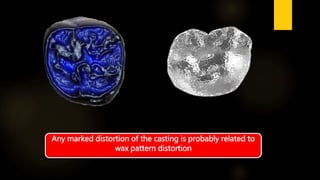

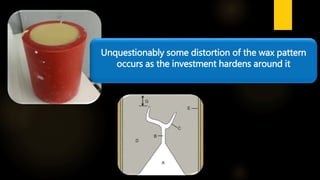

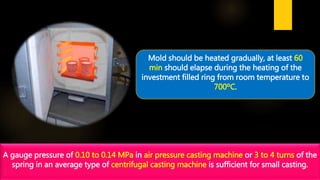

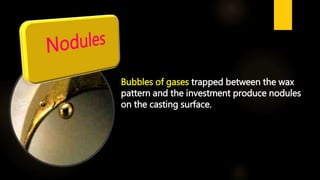

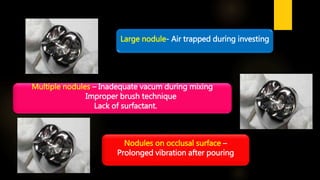

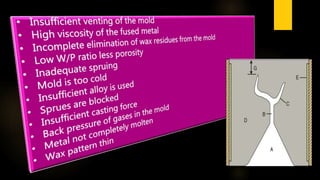

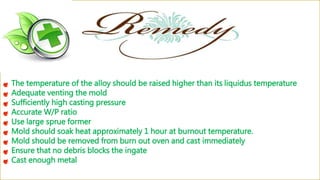

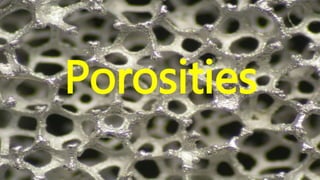

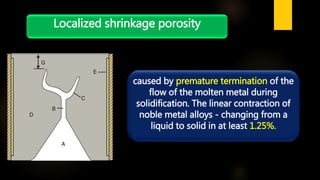

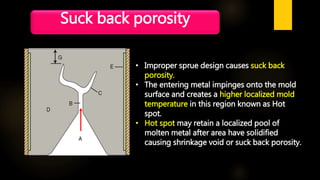

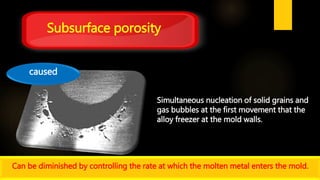

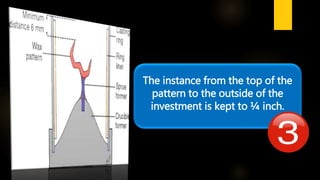

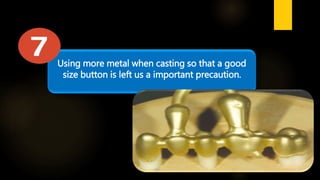

This document discusses common casting defects in dentistry, their causes, and methods to prevent them. It begins by classifying defects and dimensions inaccuracies. It then examines specific defects like distortion, surface roughness, porosities, incomplete castings, and discolored castings. For each defect, it outlines potential causes such as wax pattern issues, improper investments, heating/cooling rates, and gas entrapment. It provides tips to control defects like using the proper water/powder ratio, venting molds, and casting procedures. The conclusion emphasizes that following methods can avoid defects and produce high quality castings for clinical success.