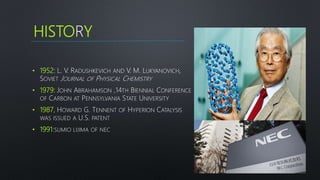

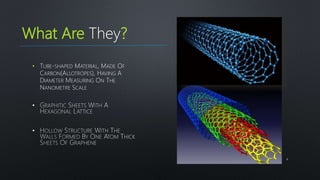

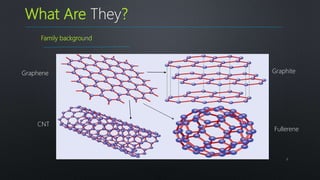

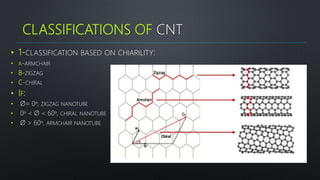

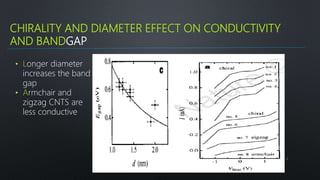

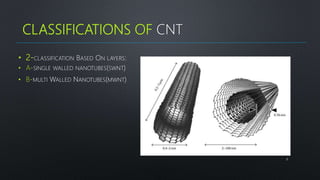

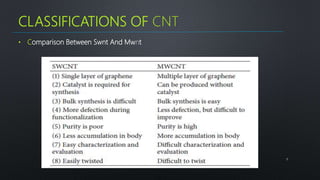

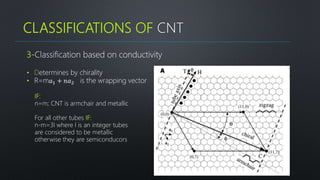

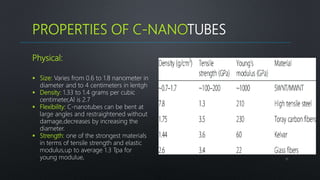

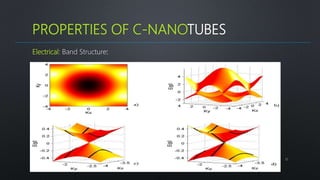

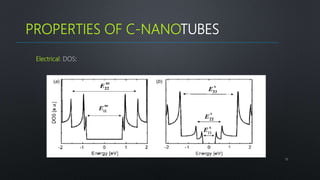

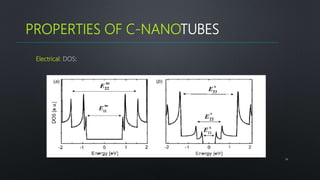

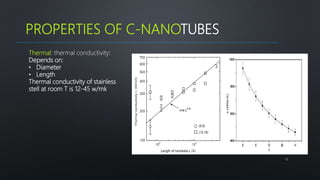

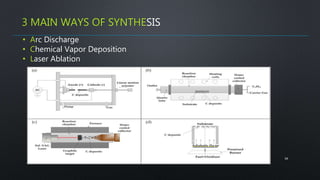

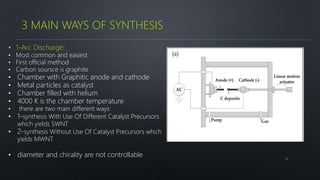

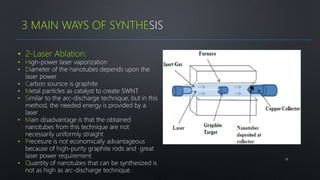

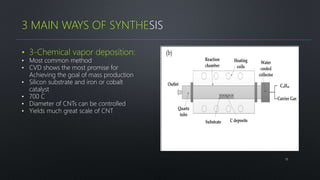

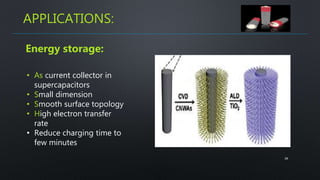

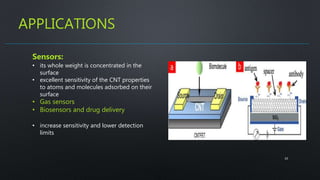

This document provides an overview of carbon nanotubes. It discusses the history of carbon nanotube discovery from the 1950s to 1991. It describes what carbon nanotubes are, which are tube-shaped materials made of carbon that have diameters on the nanometer scale. The document classifies carbon nanotubes based on chirality, layers, and conductivity. It outlines the properties of carbon nanotubes including their small size, strength, flexibility, and thermal and electrical conductivity. Methods for synthesizing carbon nanotubes are described, including arc discharge, laser ablation, and chemical vapor deposition. Applications of carbon nanotubes discussed include use in energy storage, molecular electronics, sensors, composites, and desalination

![[1]:C.H. AHN, Y. BAEK, C. LEE, S.O. KIM, S. KIM, S. LEE, S.H. KIM, S.S. BAE, J. PARK, J. YOONCARBON NANOTUBE-BASED

MEMBRANES: FABRICATION AND APPLICATION TO DESALINATION

J. IND. ENG. CHEM., 18 (5) (2012), PP. 1551-1559

28

[2]8. I. Yakobson, in Fullerenes-Recent Advances in the Chemistry and Physics of Fullerenes and Related Materials, R. S.

Ruoff and K. M. Kadish, Eds. (Electrochemical Society. Pennington. NJ. 1997). vol. 5 (97-

42). pp. 549-56

[3] S. Iijima, “Helical microtubules of graphitic carbon,” Nature, vol. 354, no. 6348, pp. 56–58, 1991.

[4] R. Hirlekar, M. Yamagar, H. Garse, M. Vij, and V. Kadam, “Carbon nanotubes and its applications: a review,” Asian

Journal of Pharmaceutical and Clinical Research, vol. 2, no. 4, pp. 17–27,

2009.

REFRENCES:

[5] B. G. P. Singh, C. Baburao, V. Pispati et al., “Carbon nanotubes. A novel drug delivery system,”International

Journal of Research in Pharmacy and Chemistry, vol. 2, no. 2, pp. 523–532, 2012.

[6] Y.Usui, H.Haniu, S. Tsuruoka, andN. Saito, “Carbon nanotubes innovate on medical technology,” Medicinal

Chemistry, vol. 2, no. 1, pp. 1–6, 2012.

[7] Y. Zhang, Y. Bai, and B.Yan, “Functionalized carbon nanotubes for potential medicinal applications,” Drug

Discovery Today, vol. 15, no. 11-12, pp. 428–435, 2010.

[8] B. Kateb, V. Yamamoto, D. Alizadeh et al., “Multi-walled carbon nanotube (MWCNT) synthesis, preparation,

labeling, and functionalization,” Methods in Molecular Biology, vol. 651, pp. 307–317, 2010.

[9] Z. Liu, X. Sun, N. Nakayama-Ratchford, and H. Dai, “Supramolecular chemistry on water-soluble carbon

nanotubes for drug loading and delivery,” ACS Nano, vol. 1, no. 1, pp.

50–56, 2007.](https://image.slidesharecdn.com/222-181231123632/85/carbon-nanotubes-properties-and-applications-28-320.jpg)