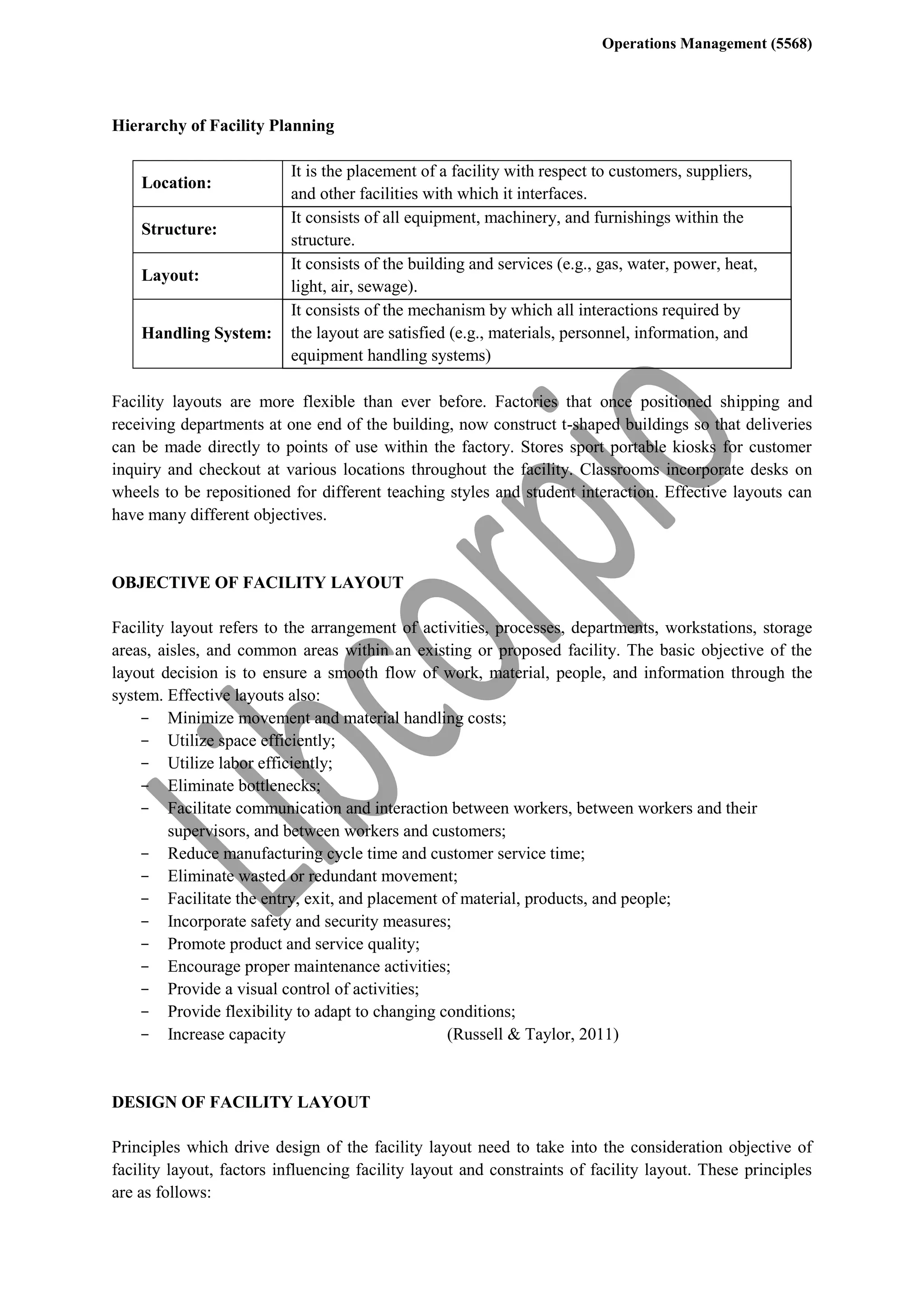

This document discusses capacity planning and facilities planning within operations management, emphasizing their definitions, importance, and strategic approaches. It details various capacity planning strategies (lead, lag, match) and highlights the significance of facilities layout, design principles, and types. The overall aim is to optimize resource utilization and improve operational efficiency to meet market demands effectively.