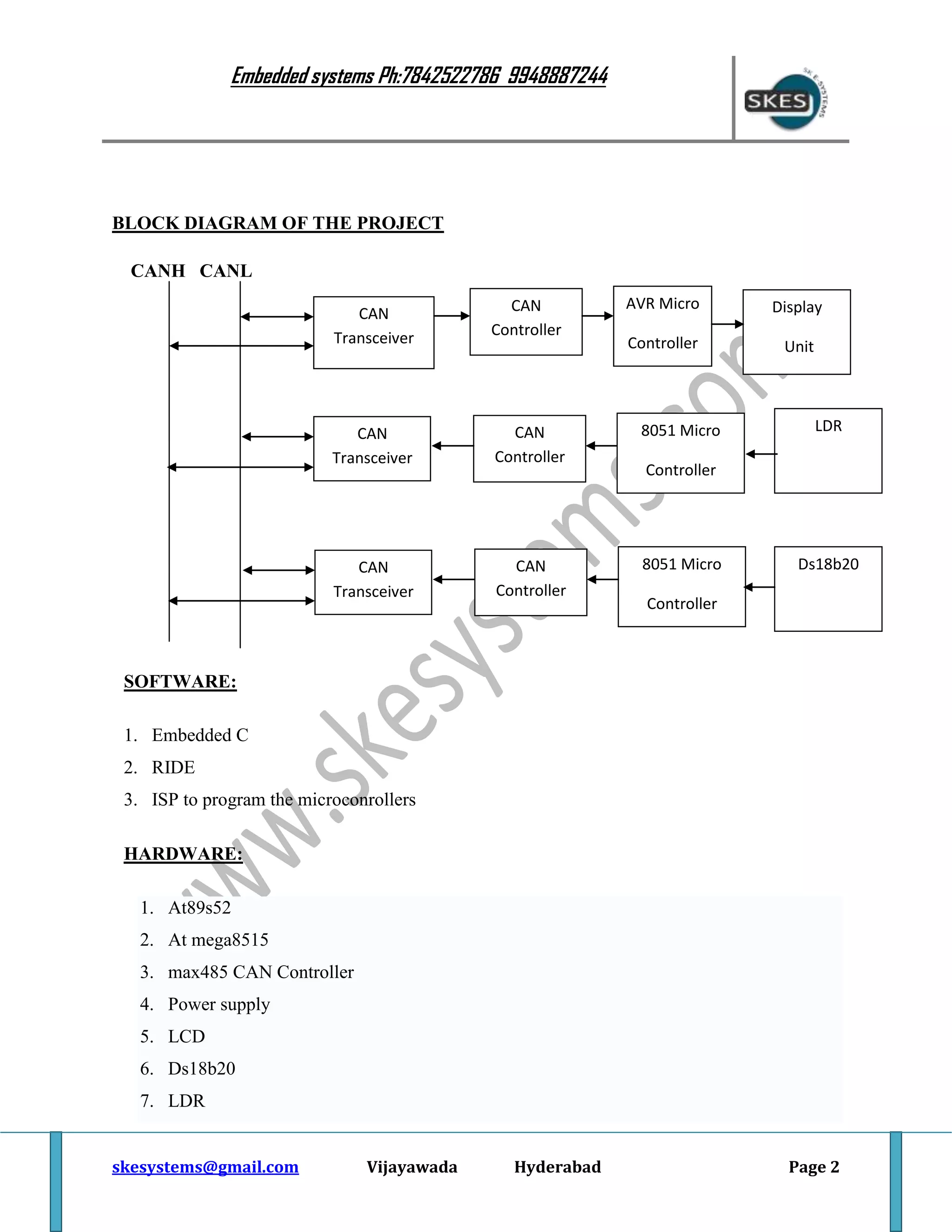

This document describes a project to implement industrial parameter control through the CAN protocol using 8051 and AVR microcontrollers. The main aim is to allow control of sensors, actuators and devices over a CAN network using microcontrollers as host processors. Embedded C and RIDE software along with ISP programming are used to develop software for the AT89C51 and ATmega8515 microcontrollers, MAX485 CAN controllers, LCD display, temperature sensor, and light sensor.