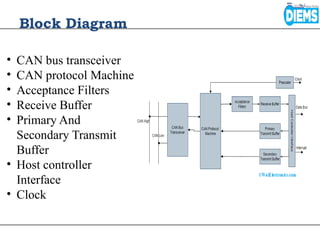

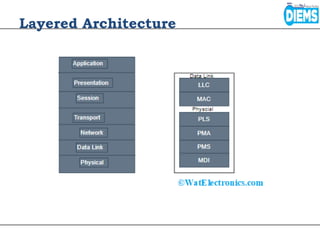

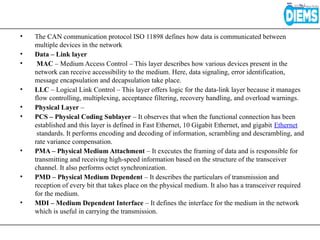

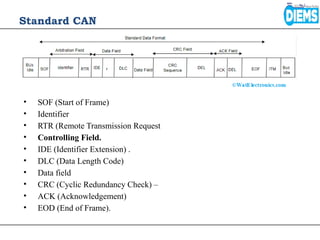

The document provides an overview of the Controller Area Network (CAN) protocol, developed by Robert Bosch in 1989, highlighting its key features, layered architecture, different types, and applications in various fields. It emphasizes the protocol's reliability, error detection capabilities, and multimaster architecture, which allows multiple devices to communicate over a single bus without a central controller. CAN's versatility extends to automotive, industrial automation, and medical devices, making it a vital technology for effective communication in complex systems.