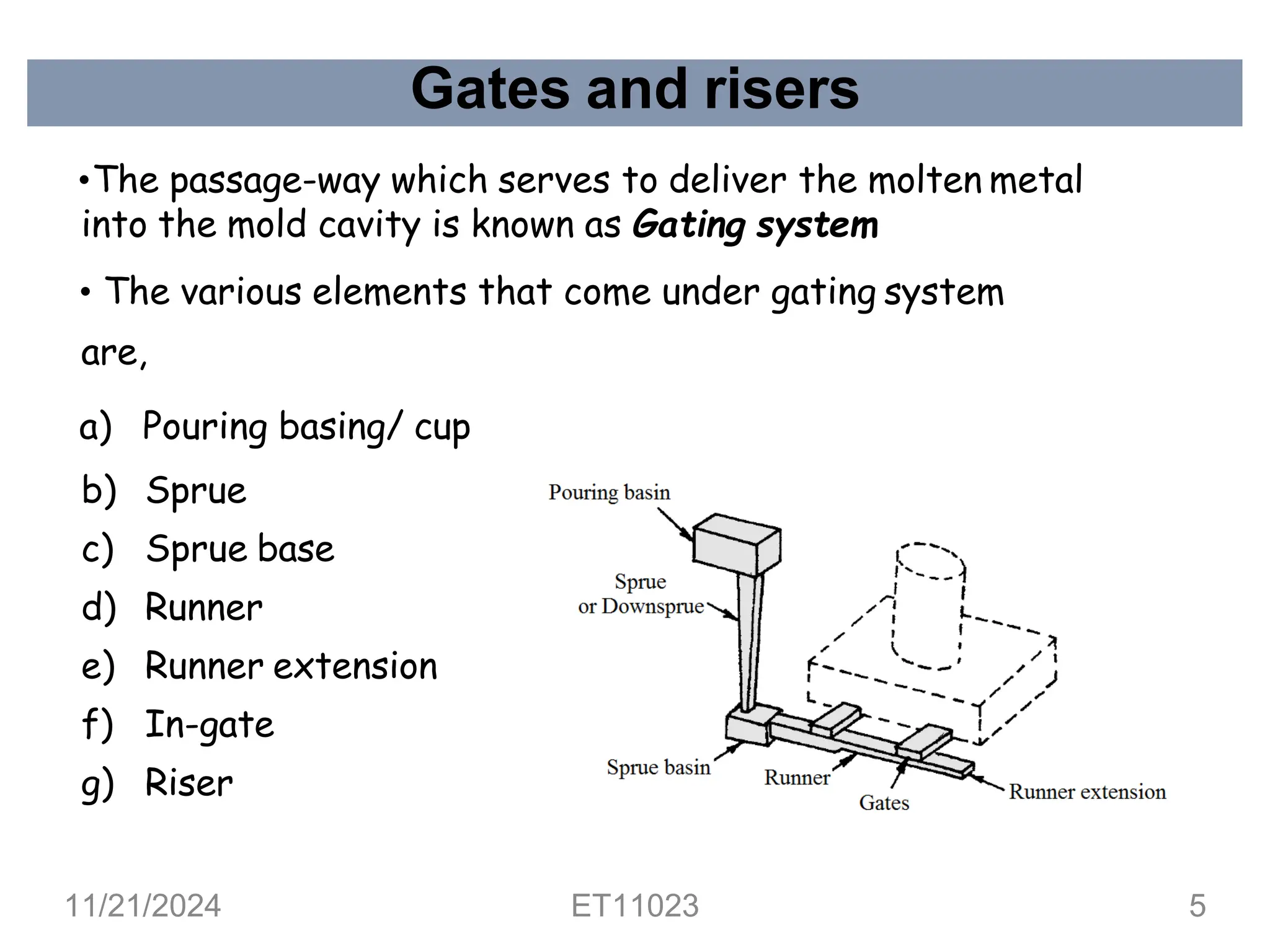

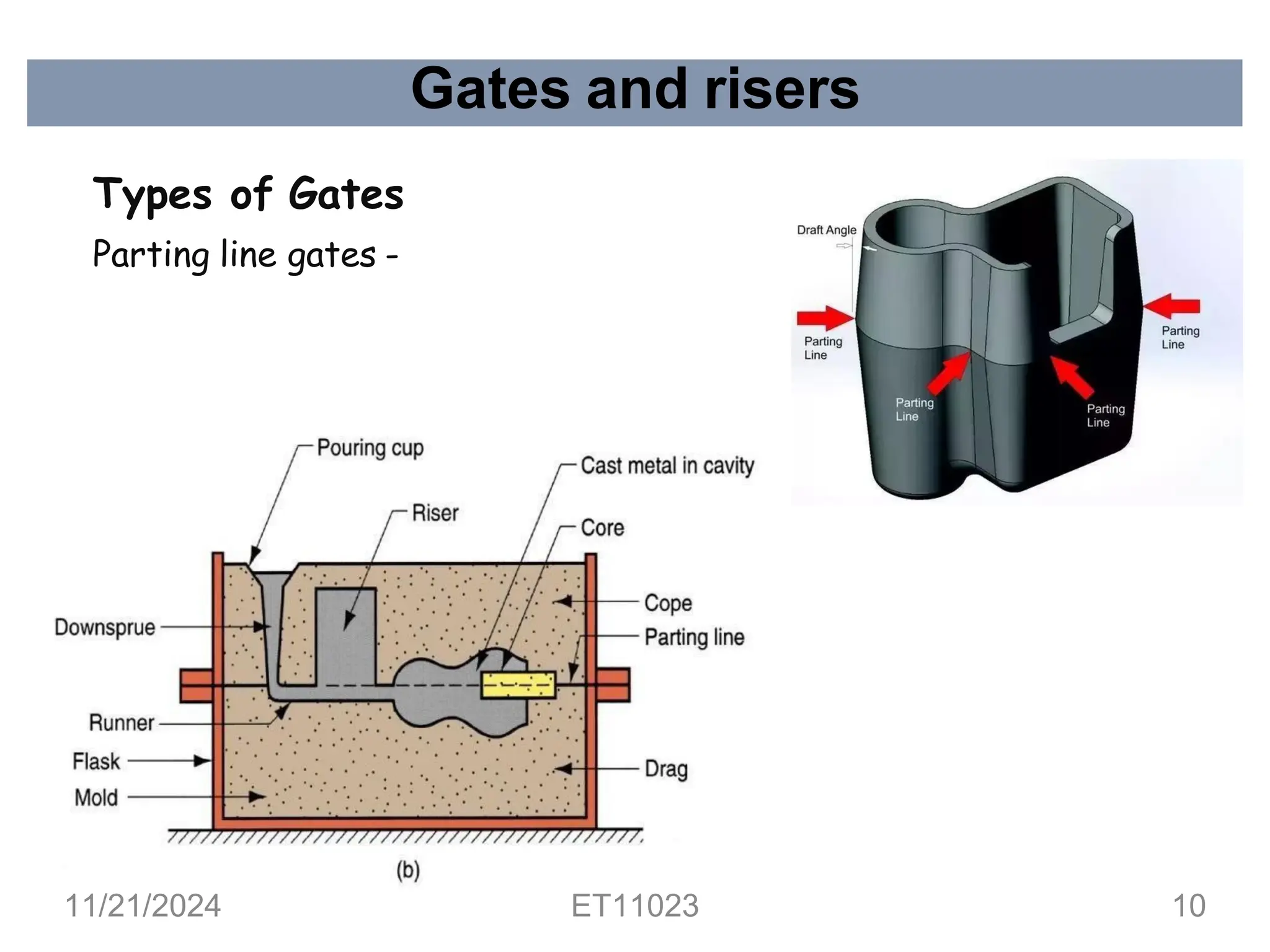

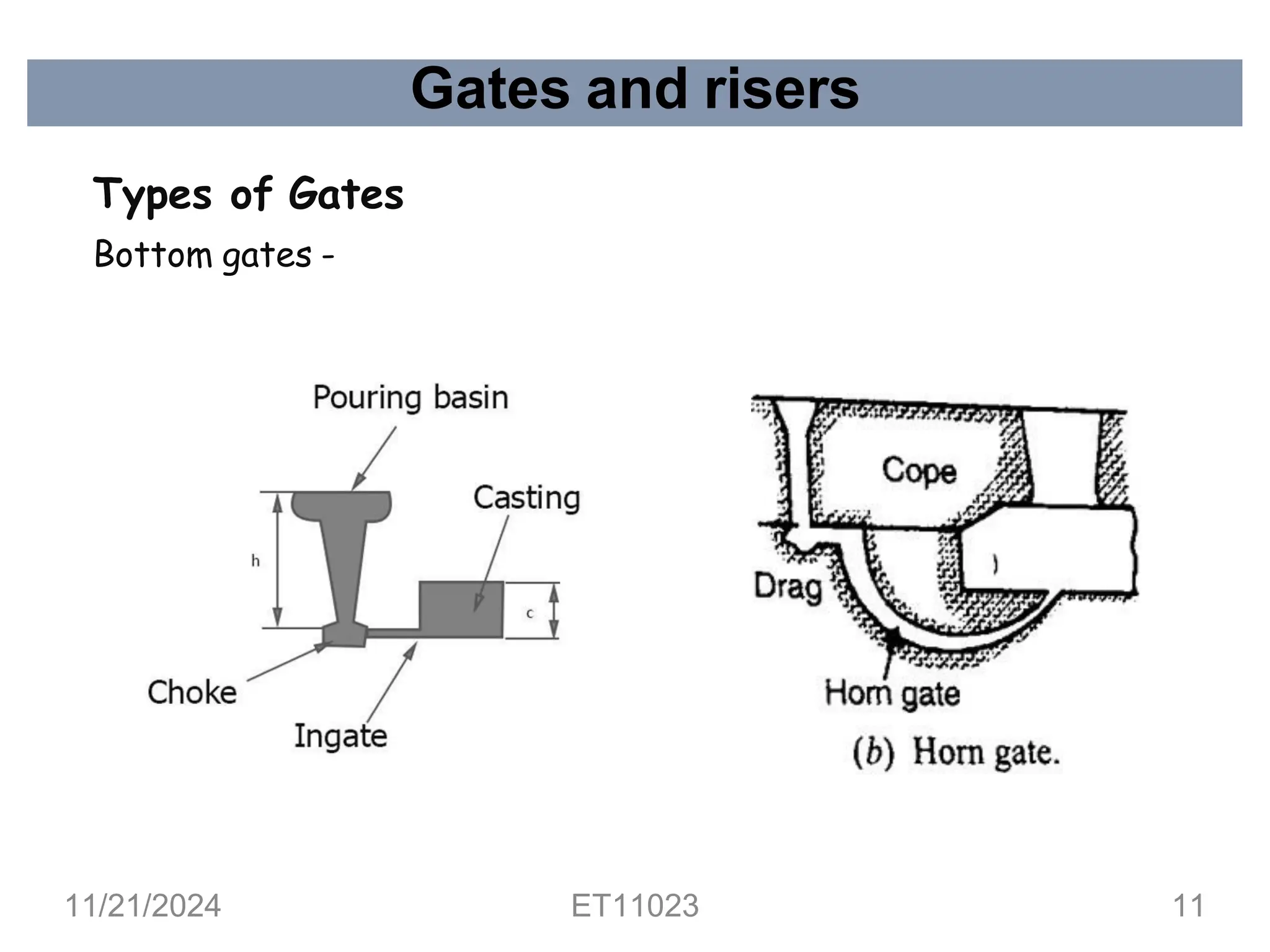

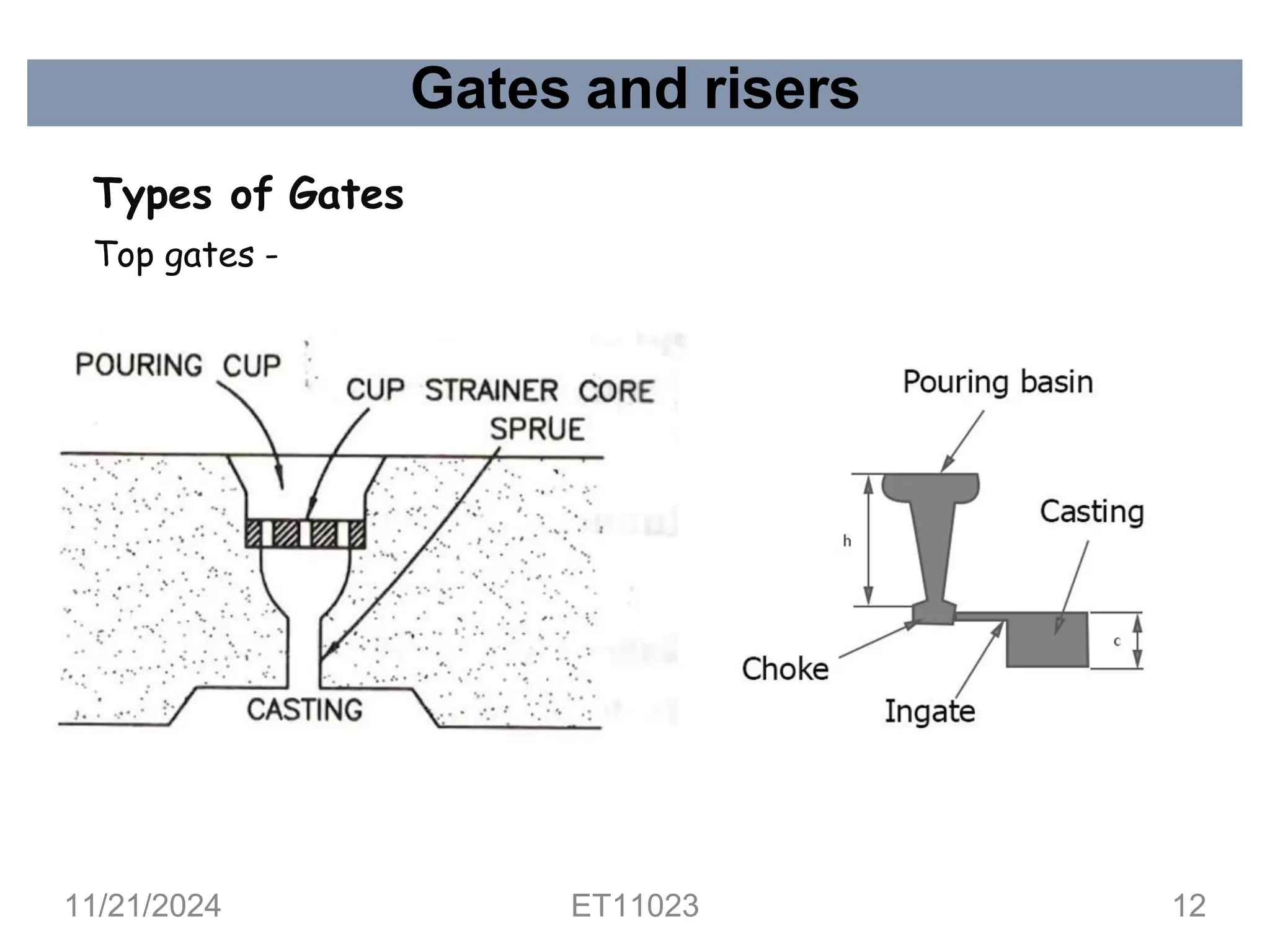

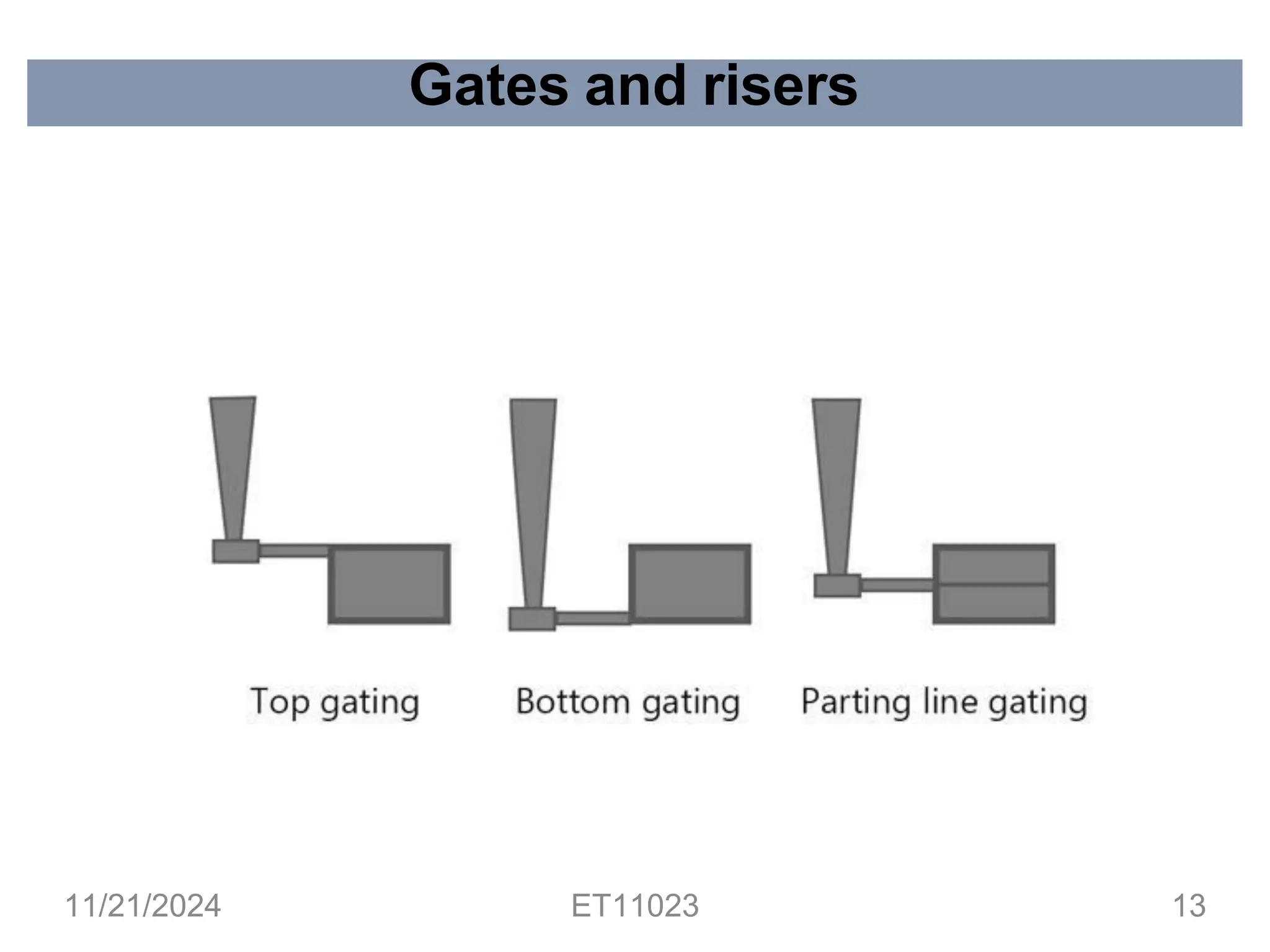

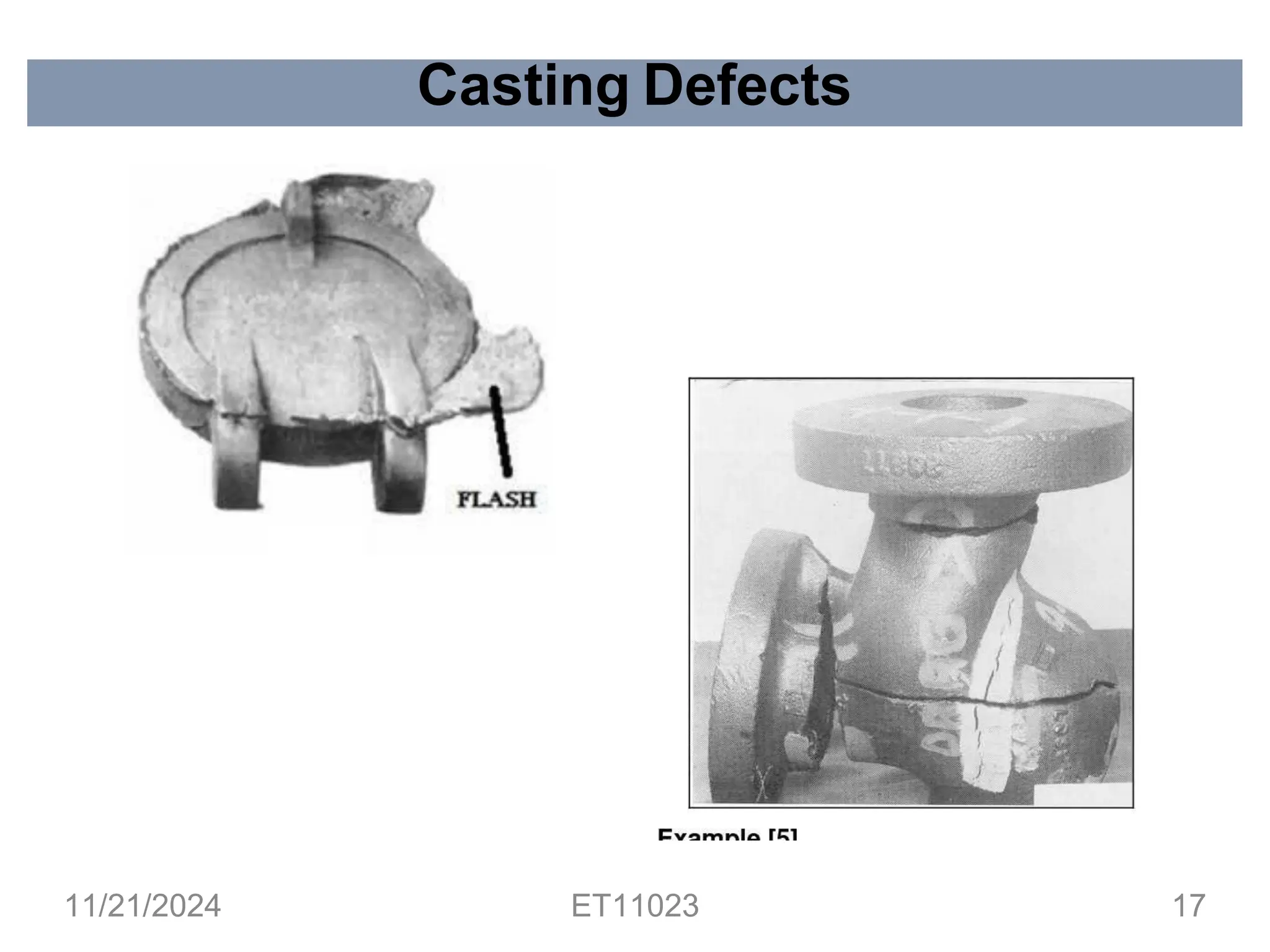

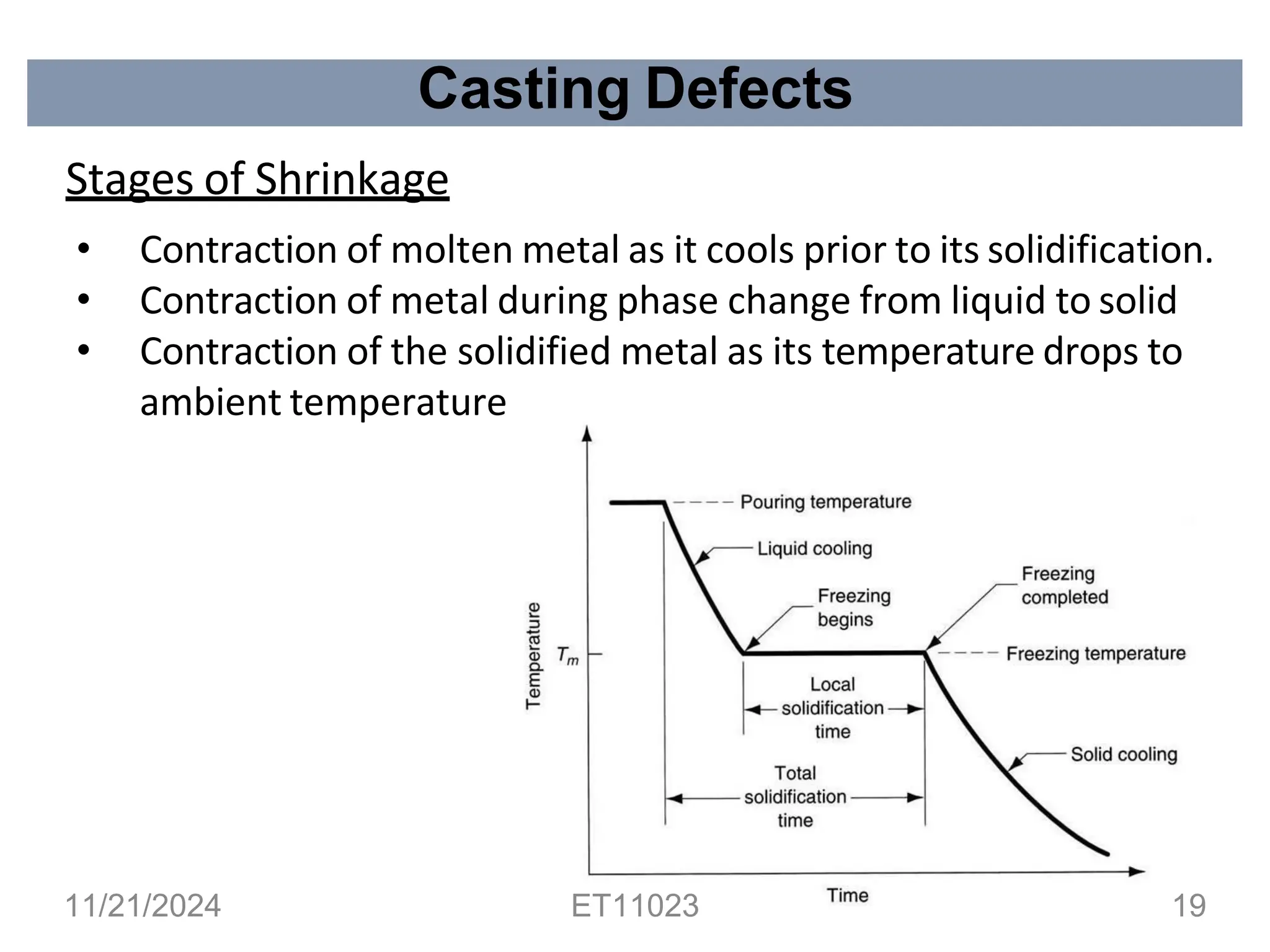

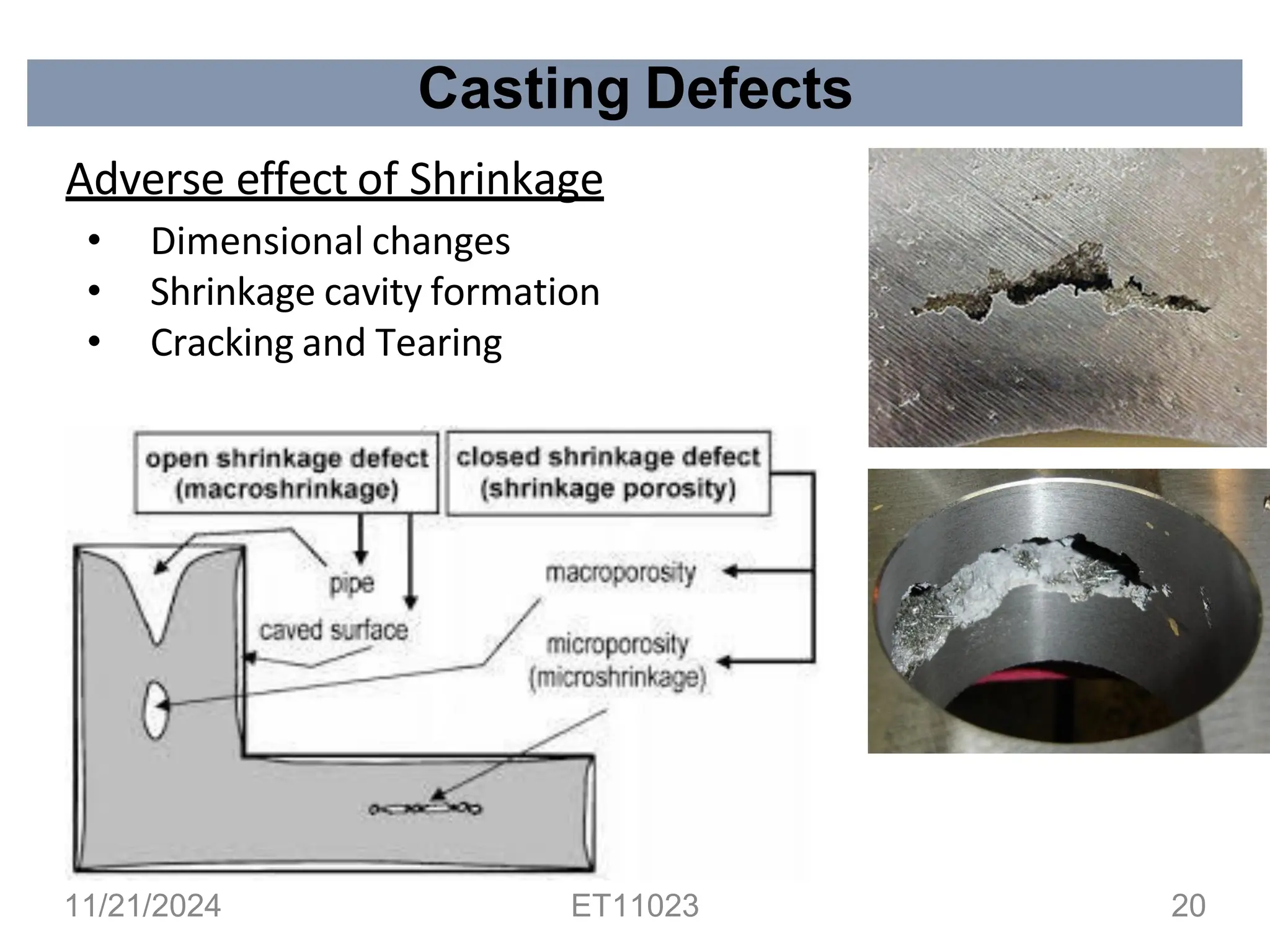

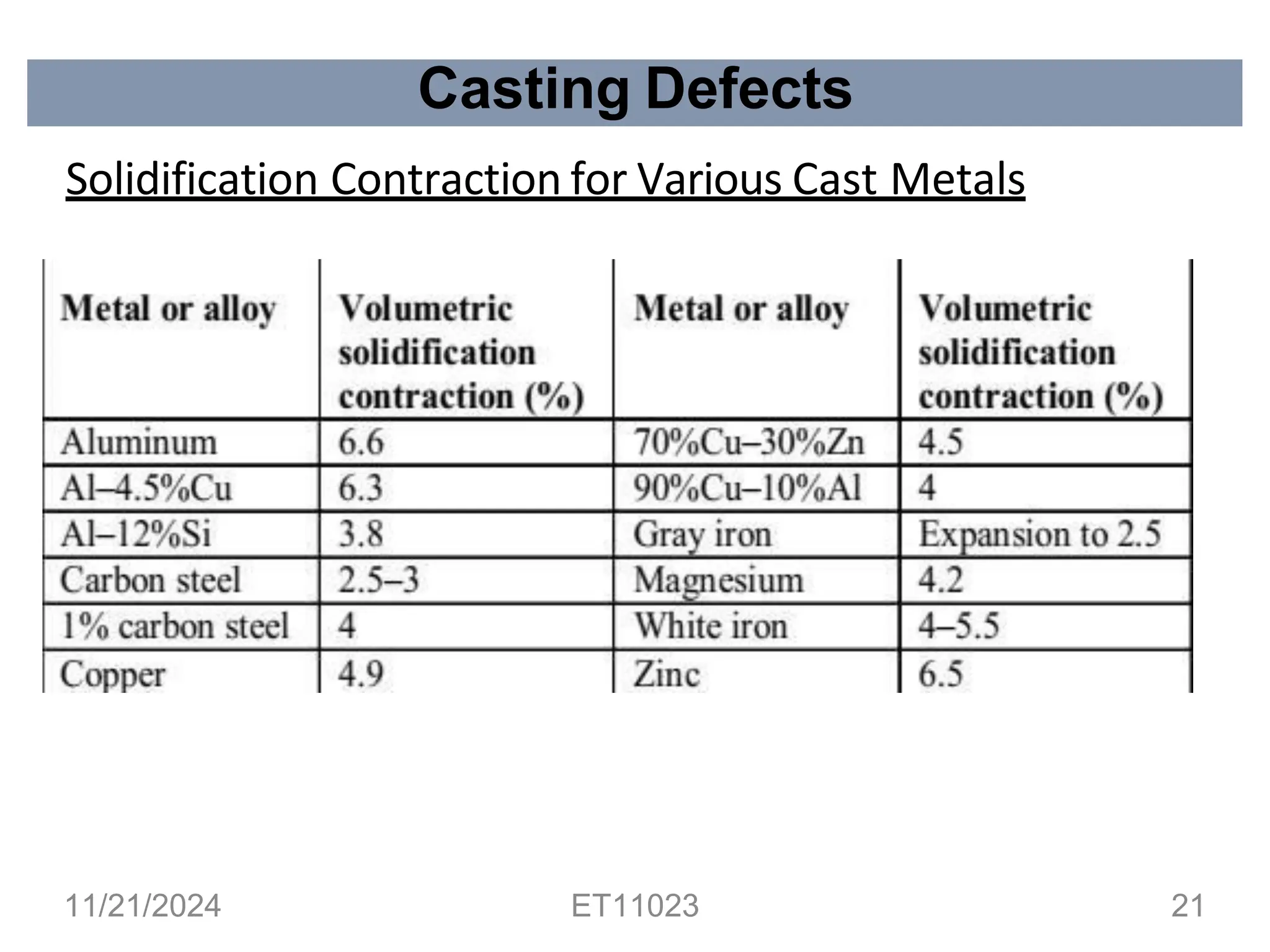

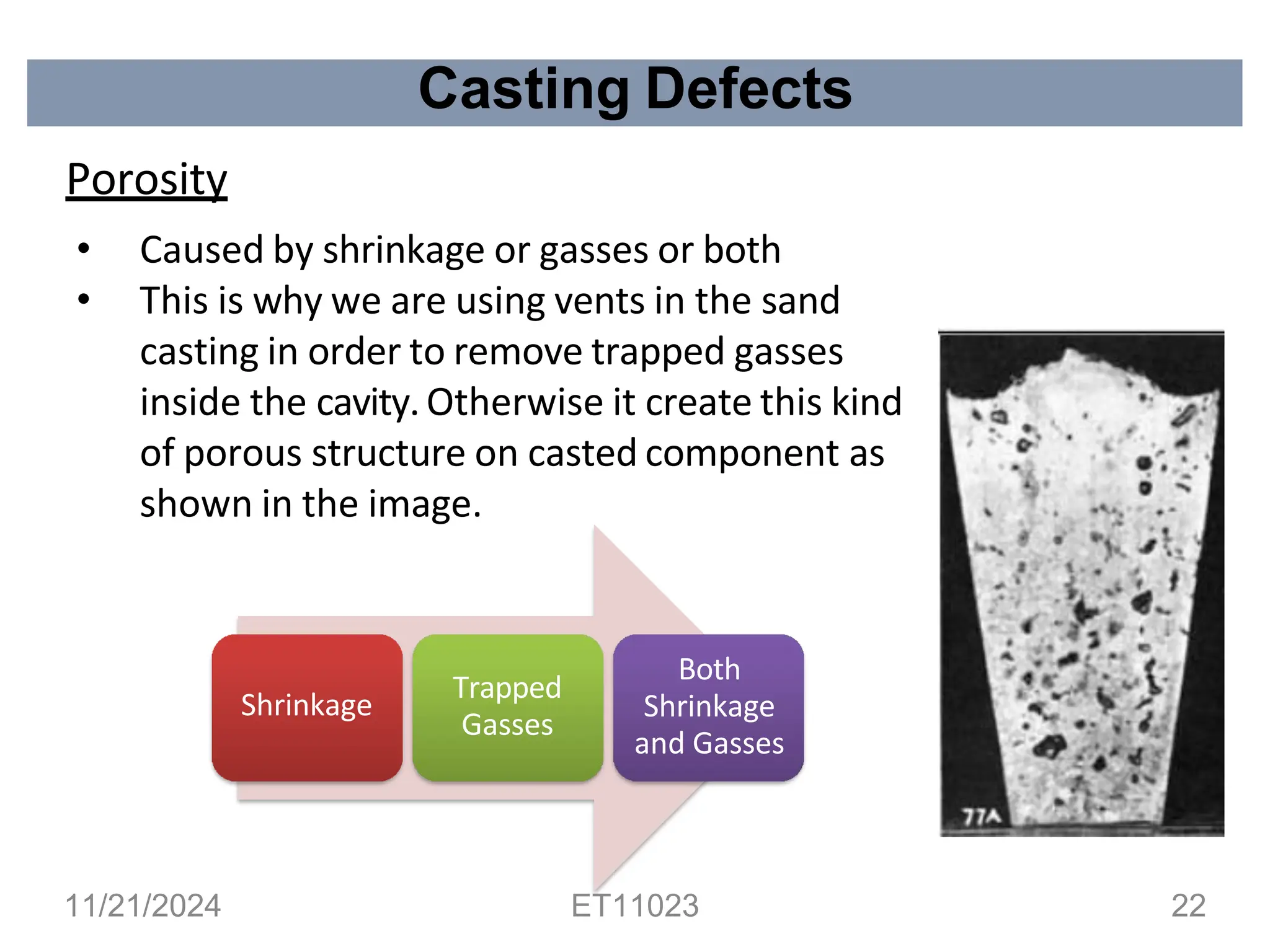

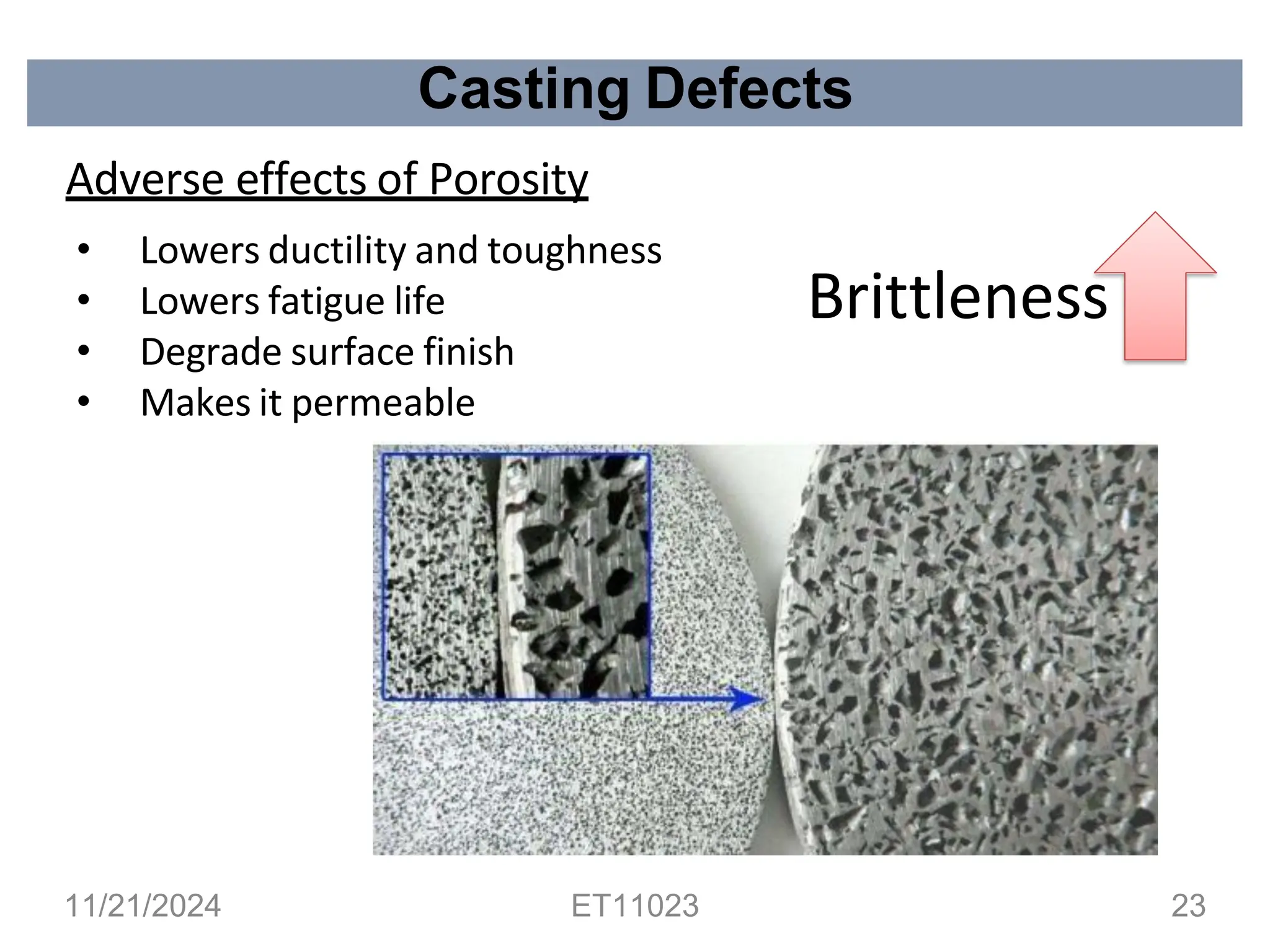

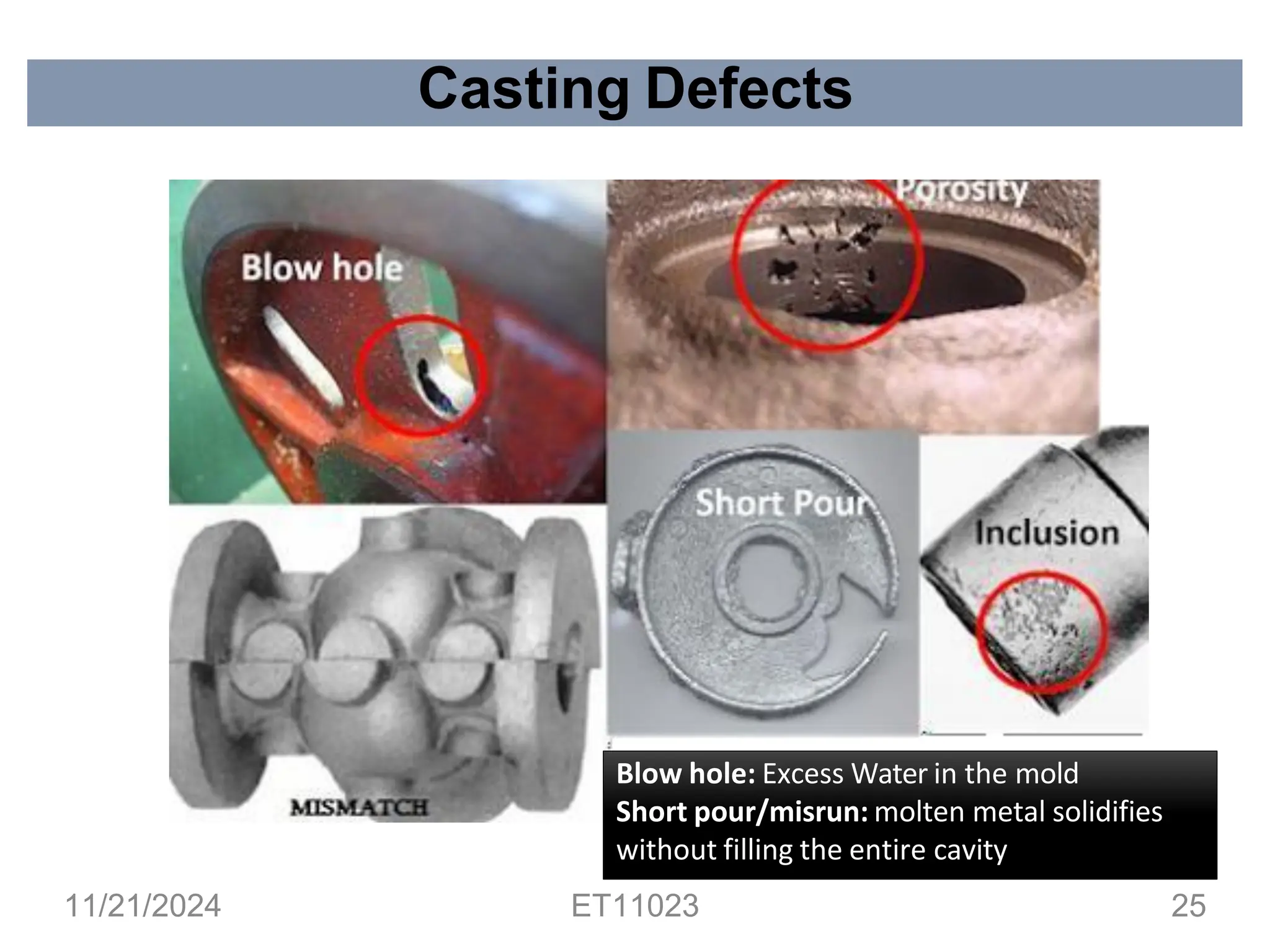

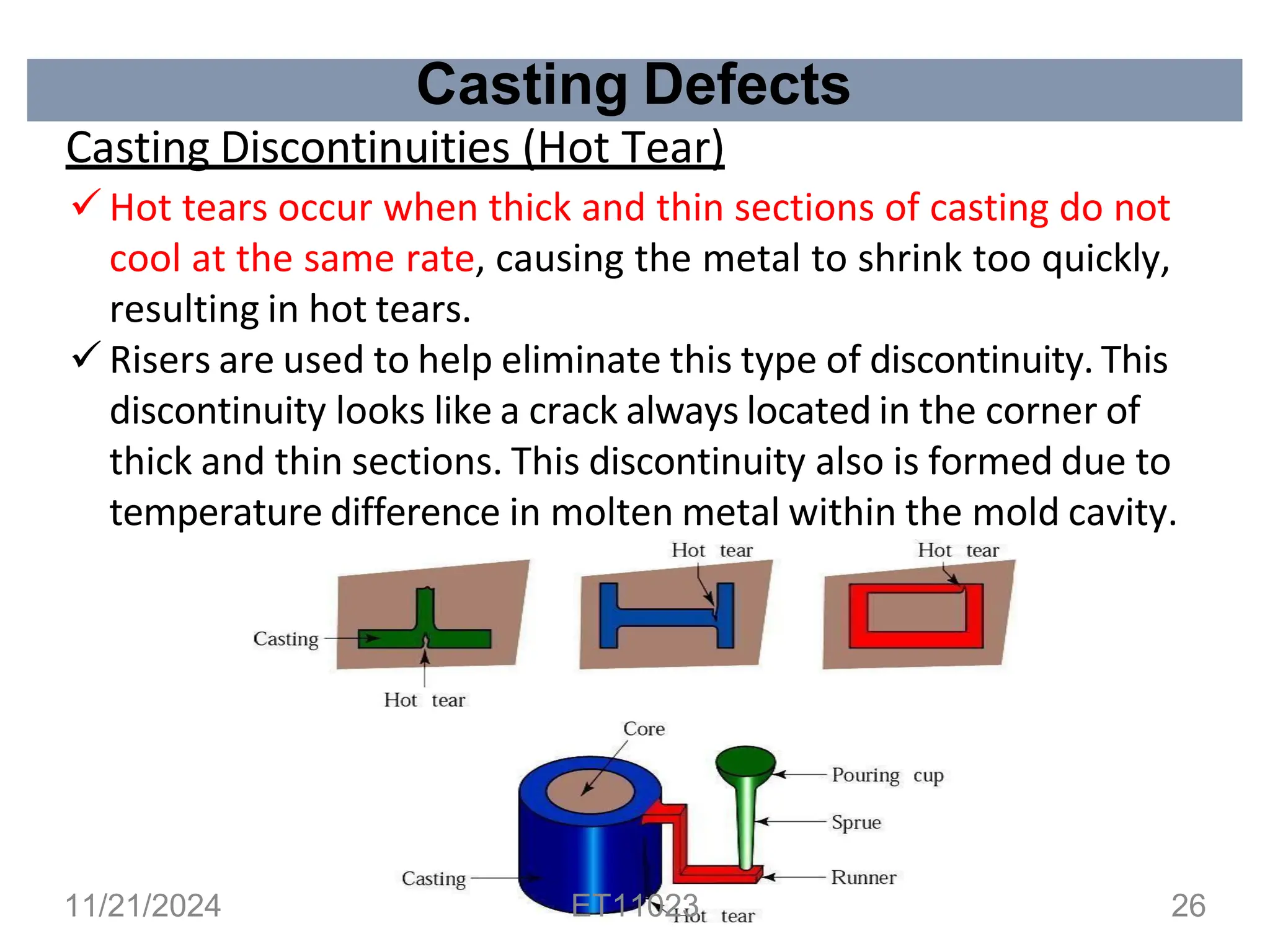

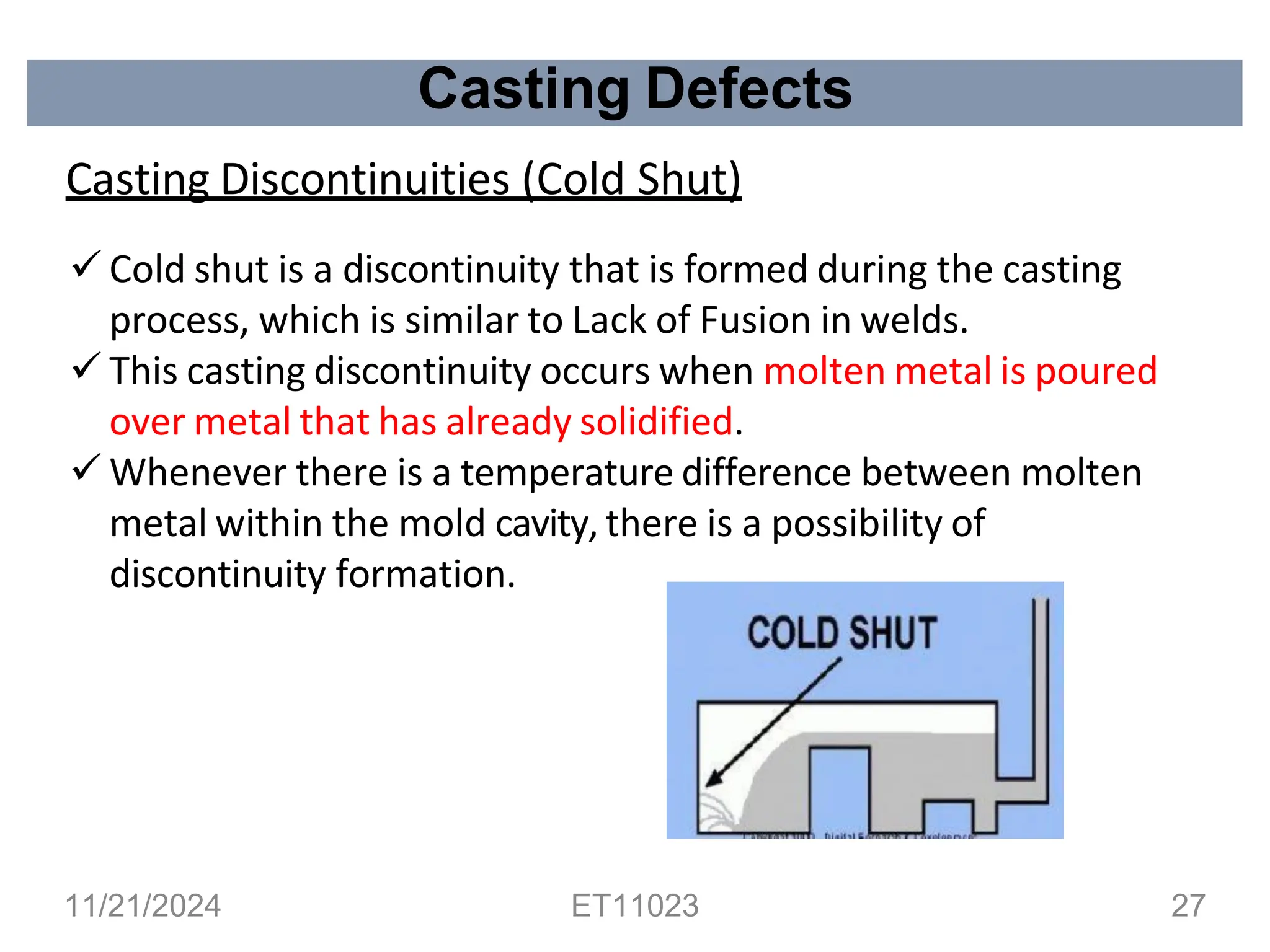

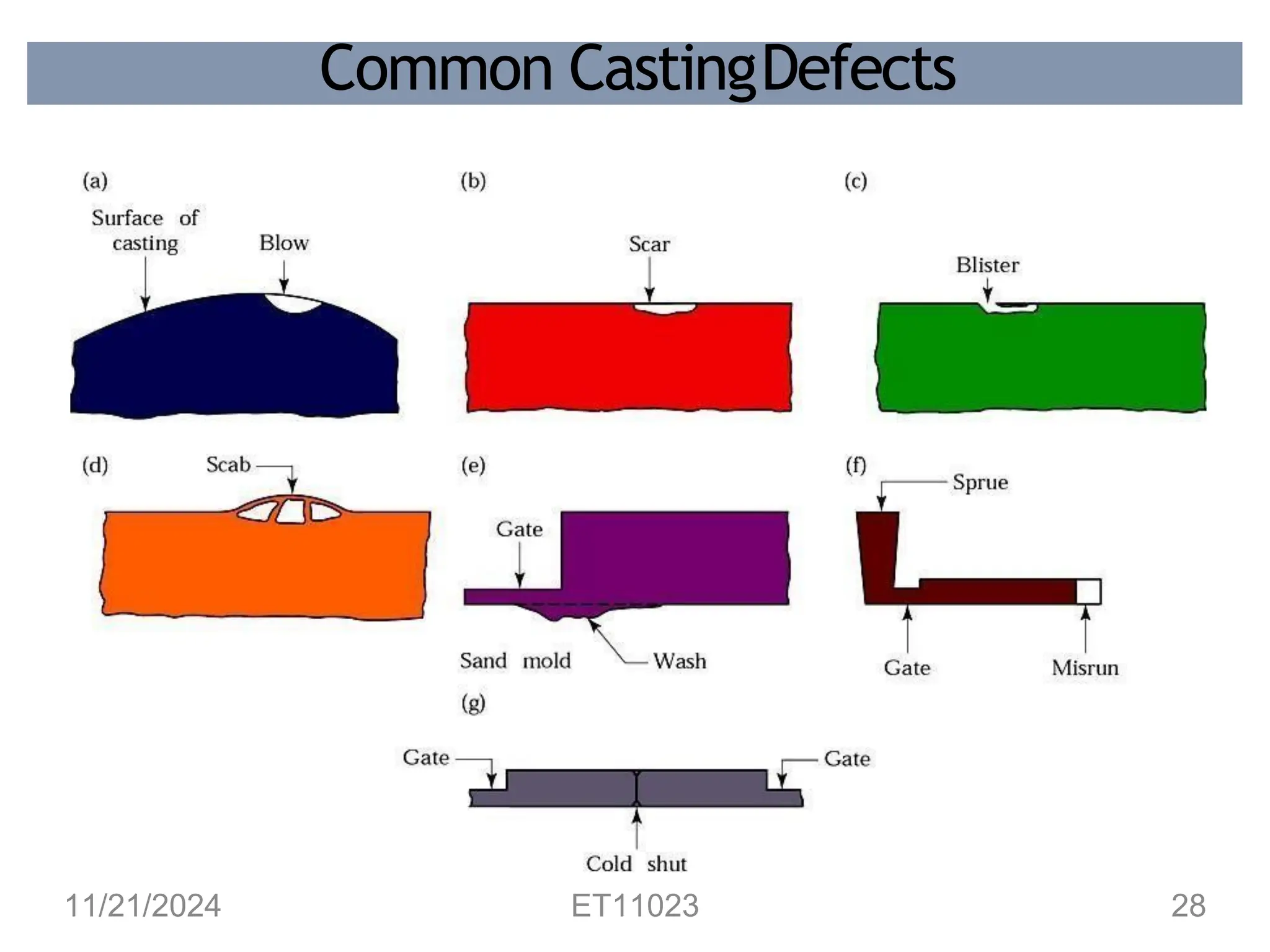

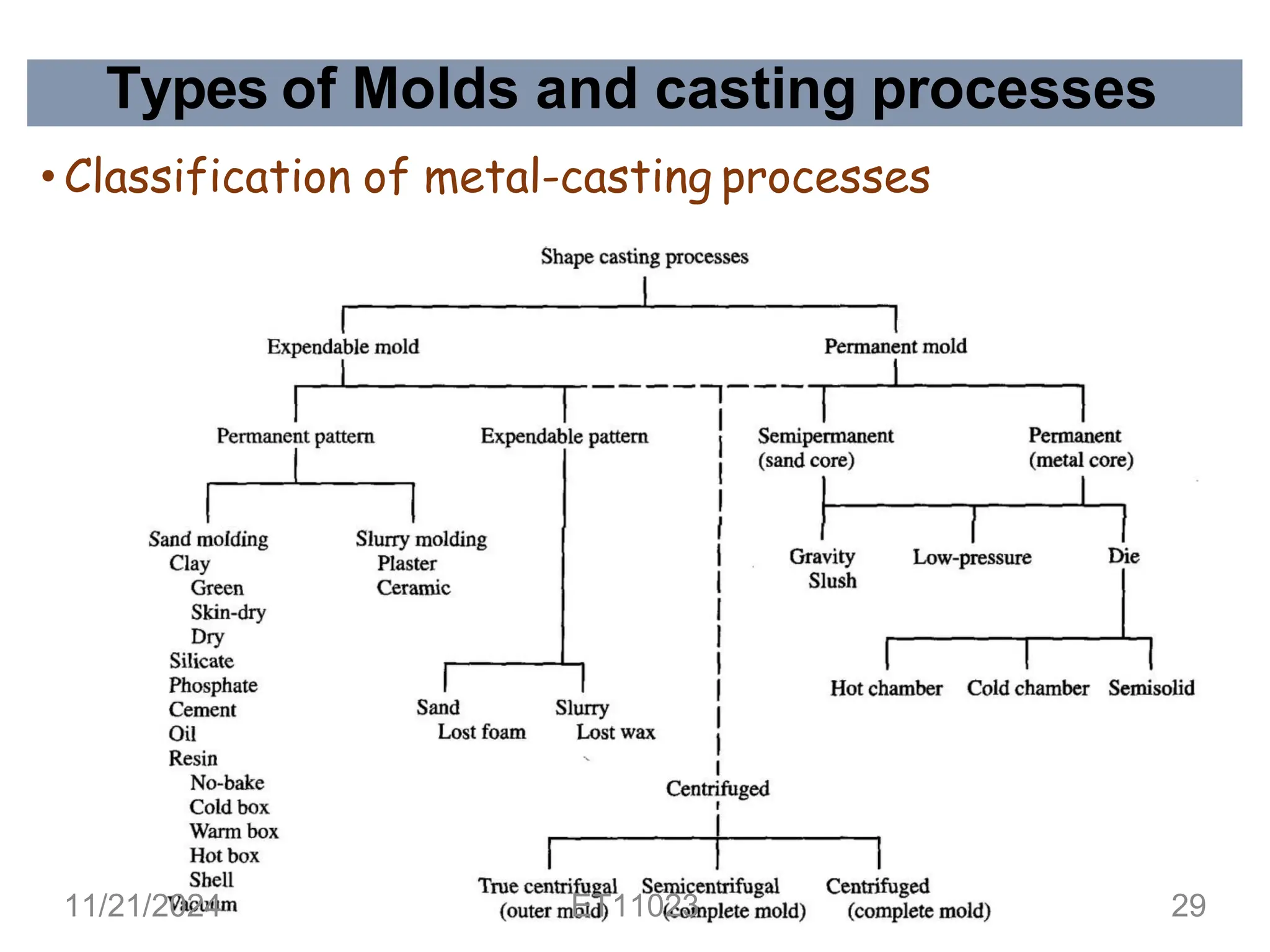

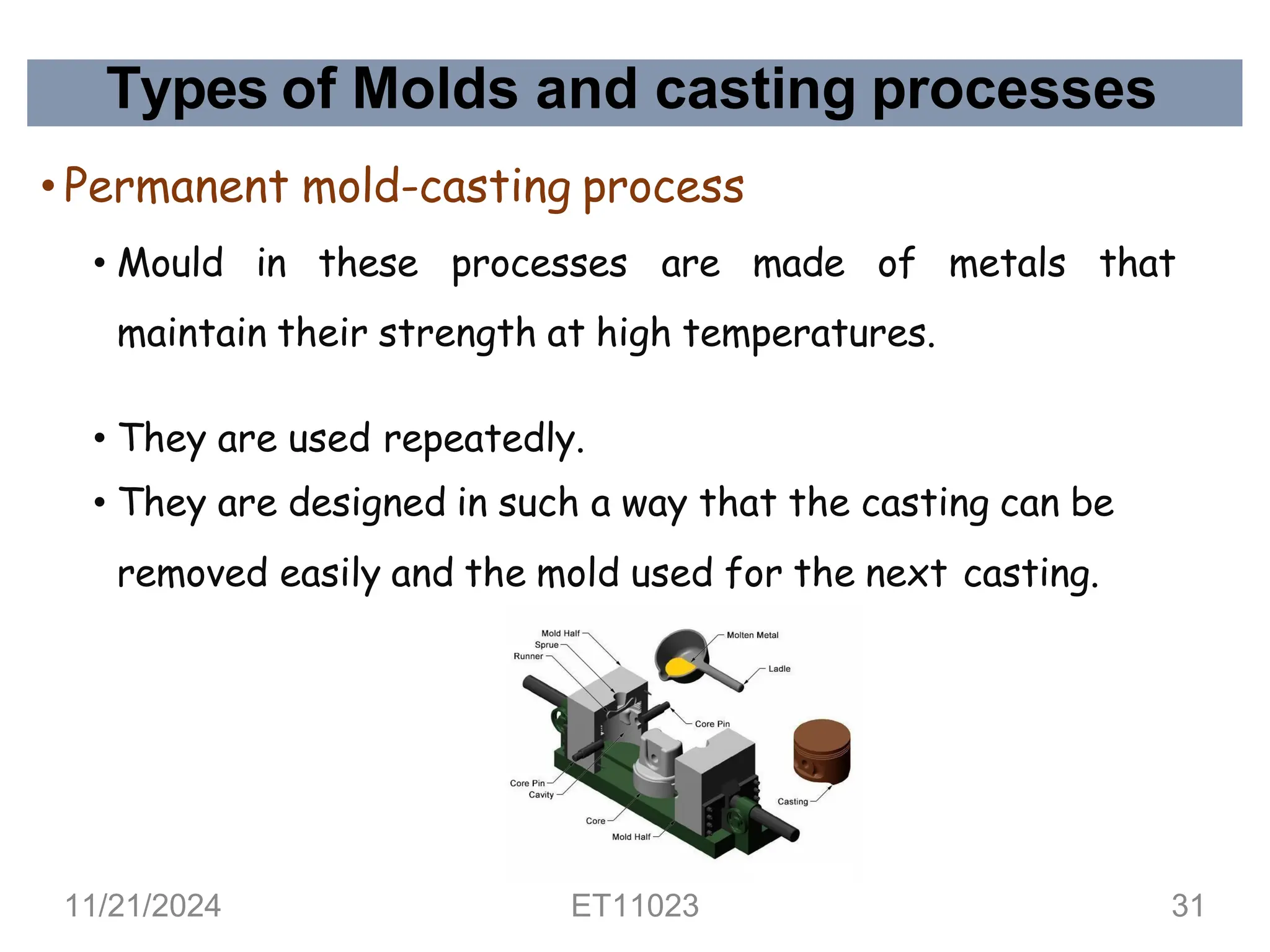

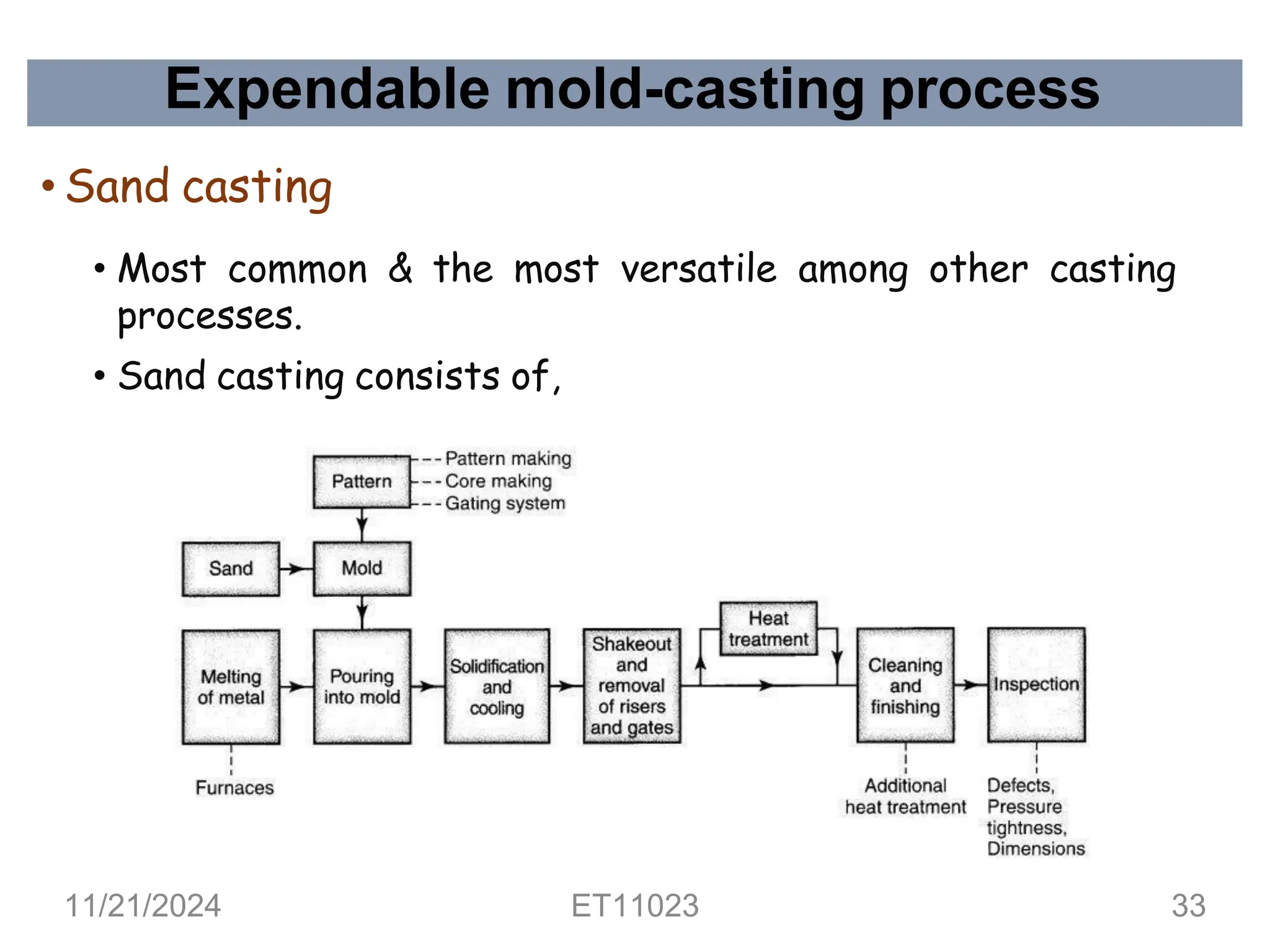

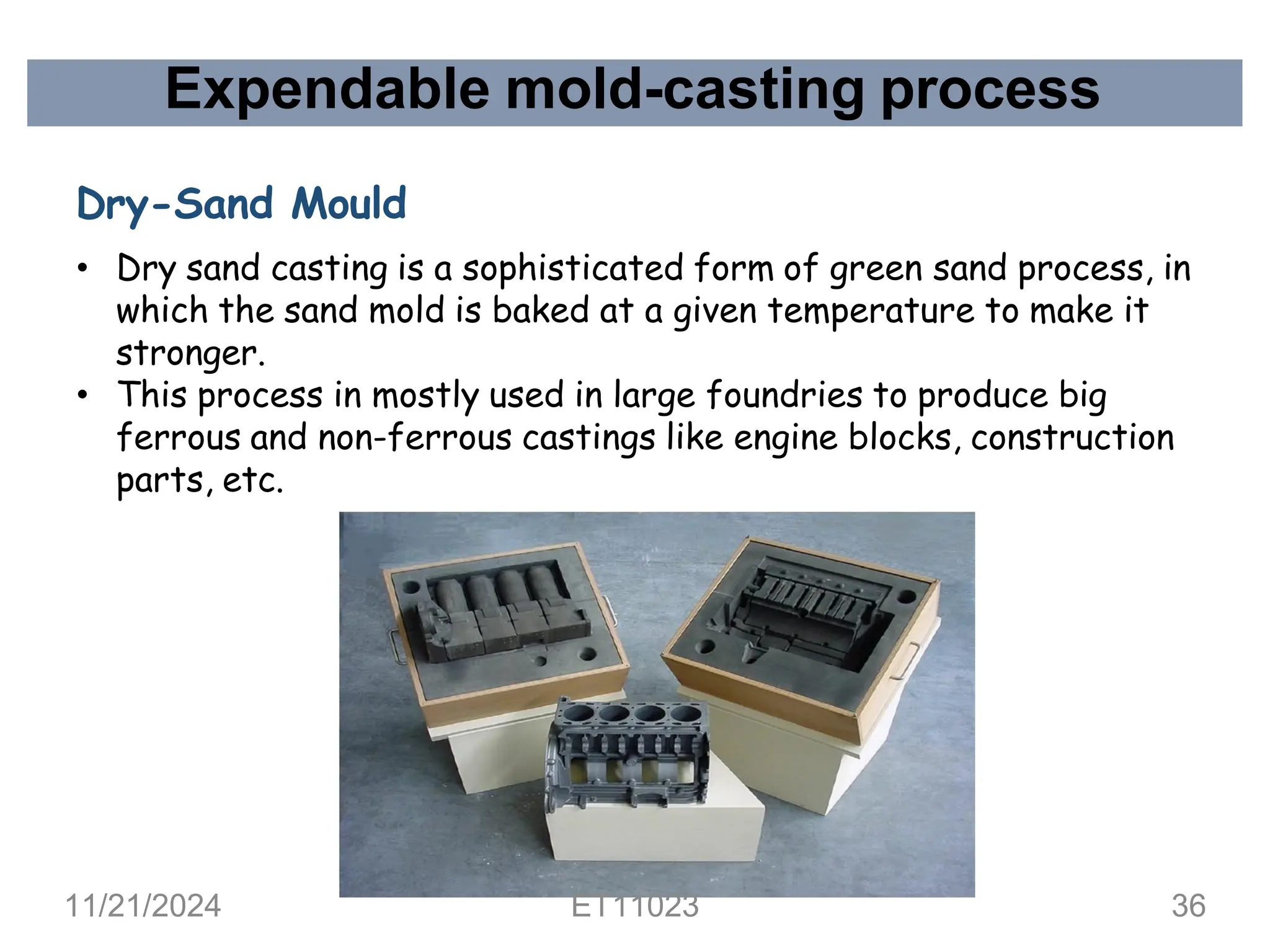

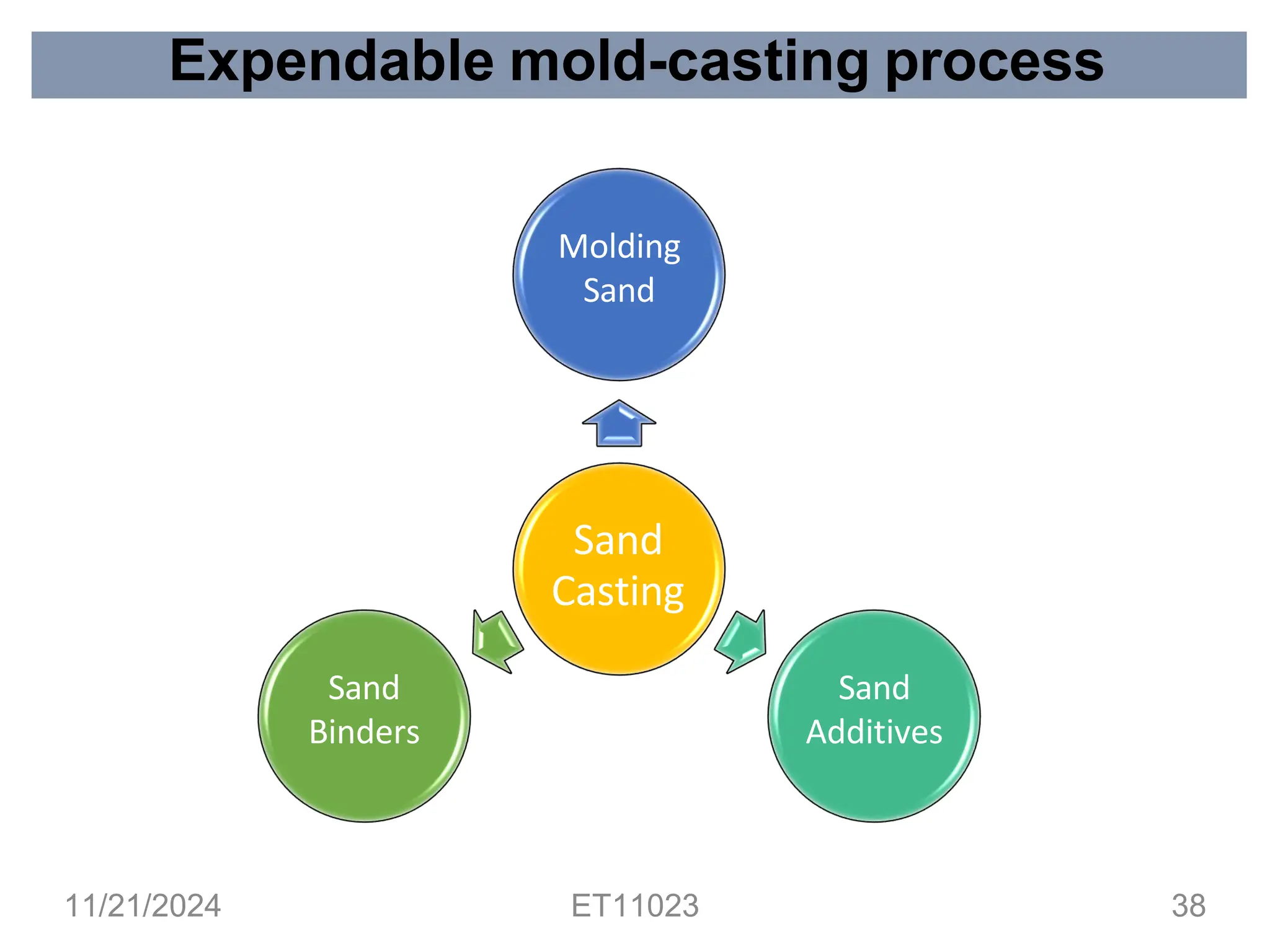

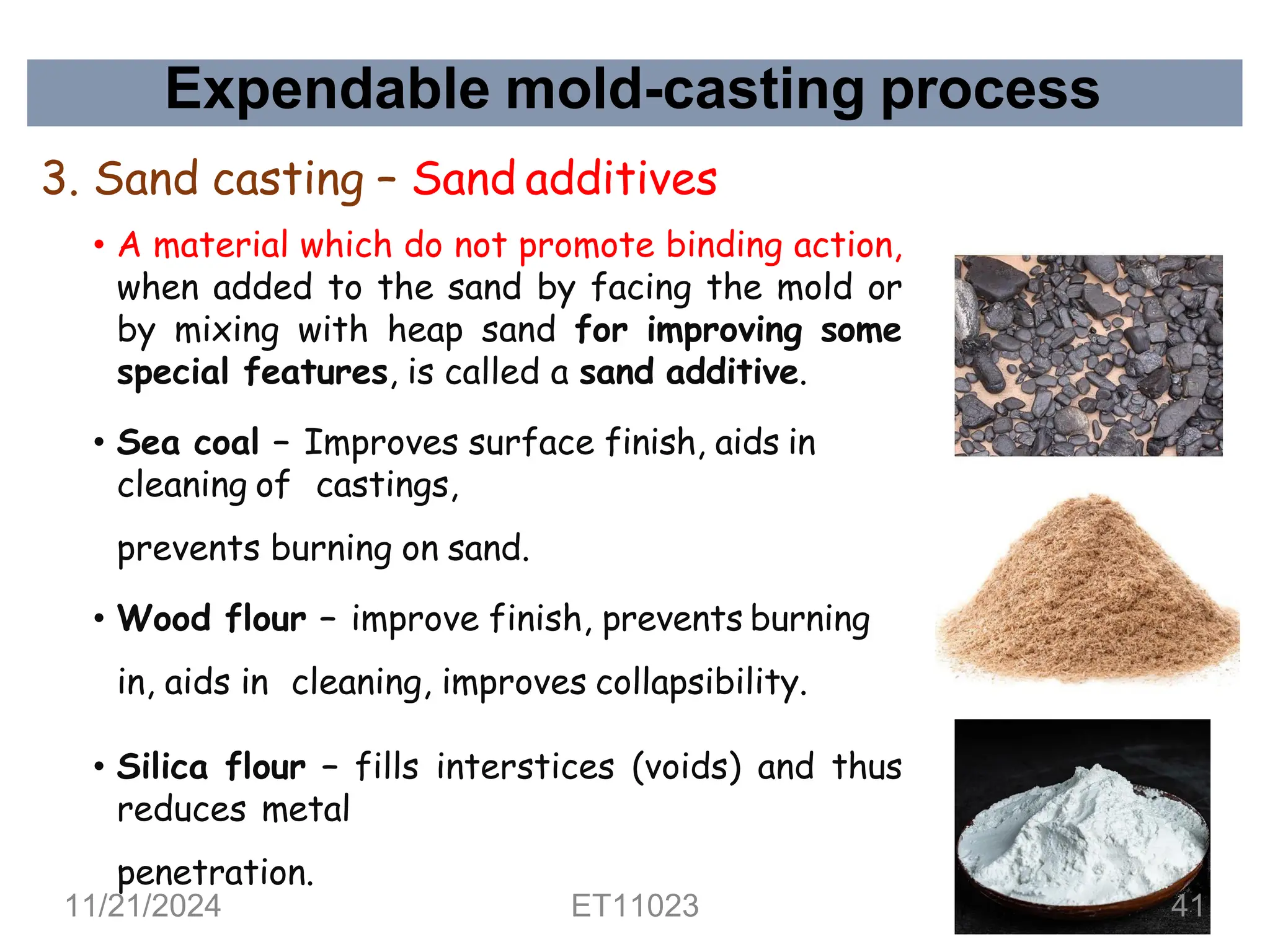

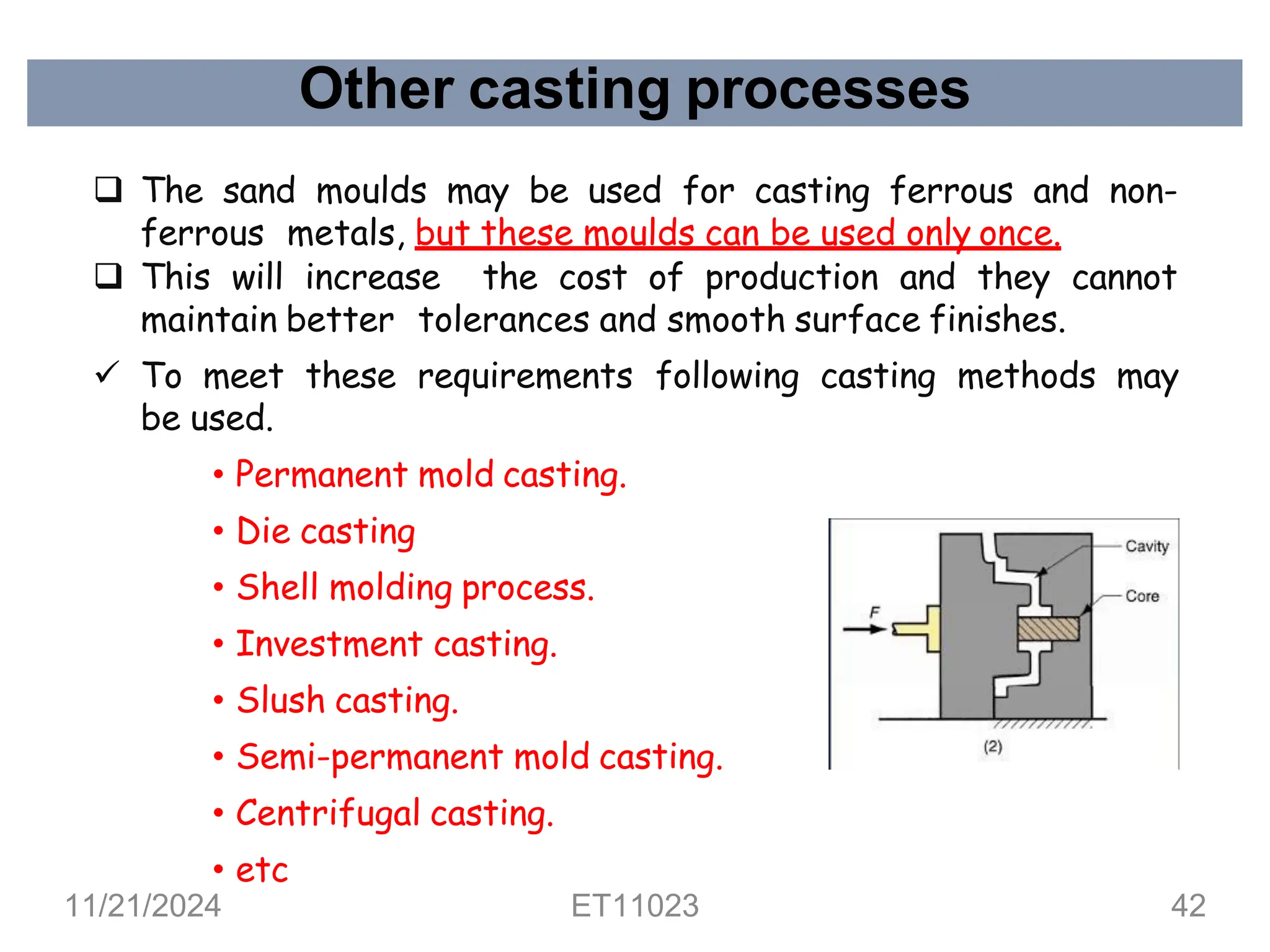

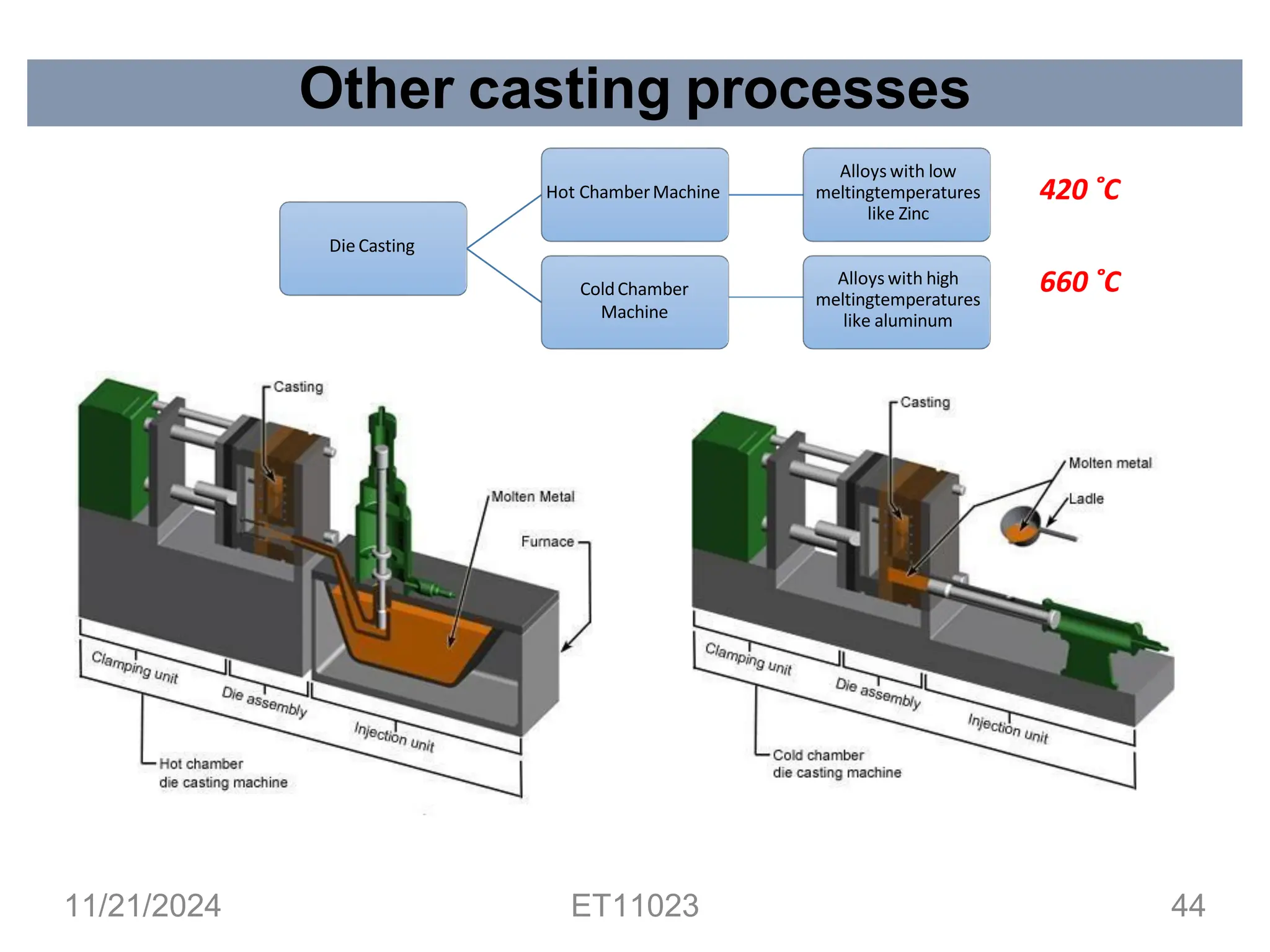

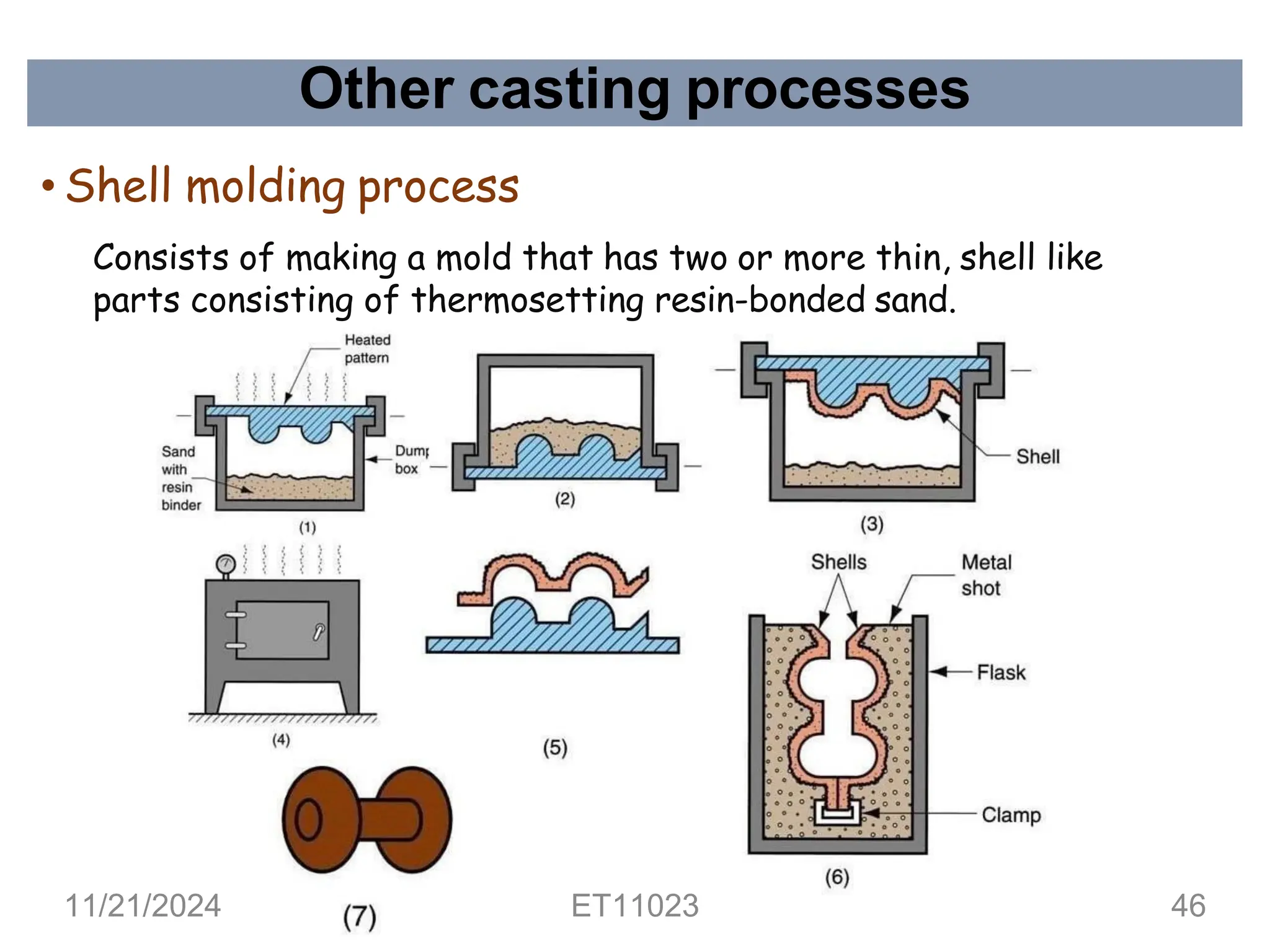

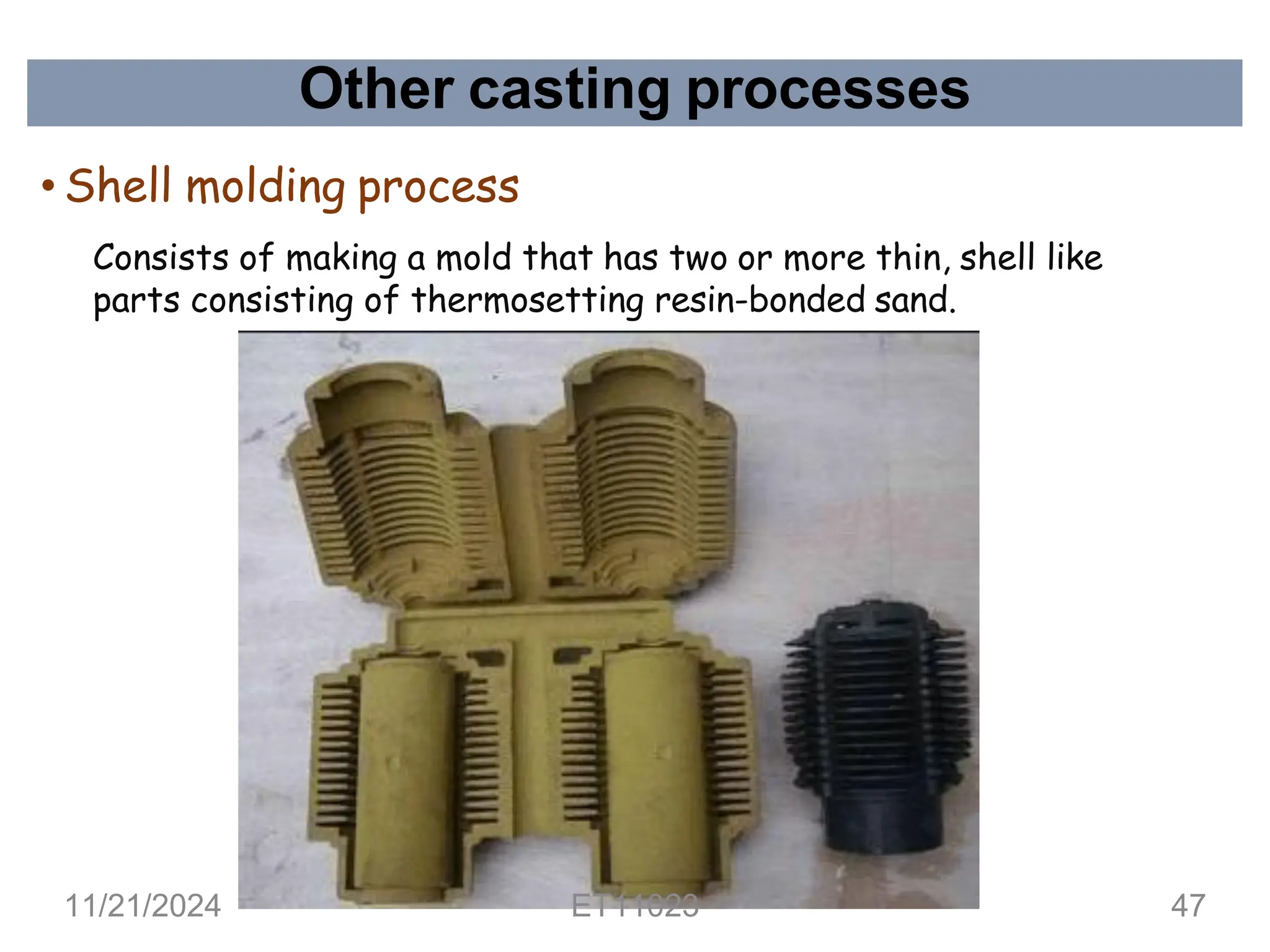

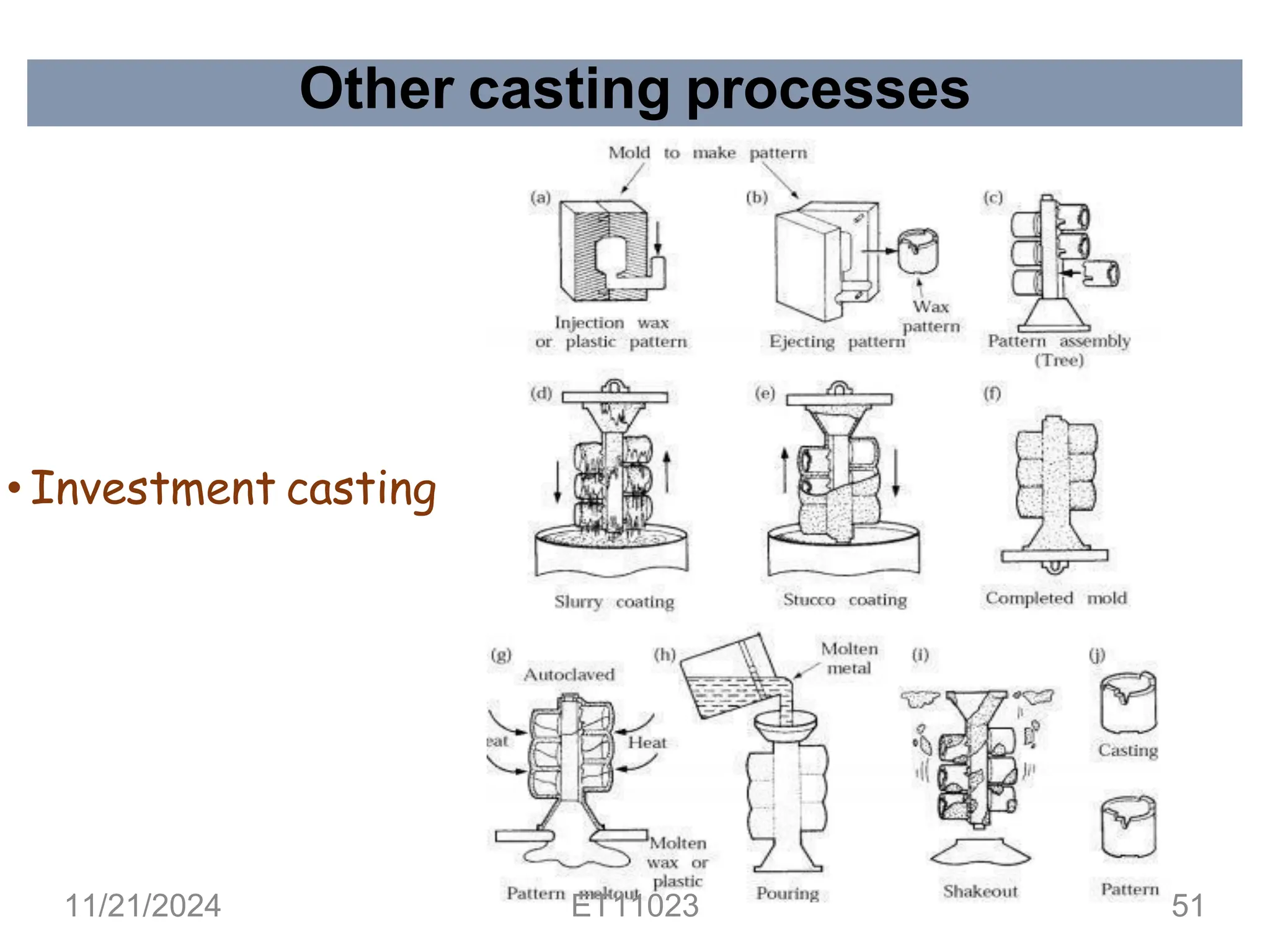

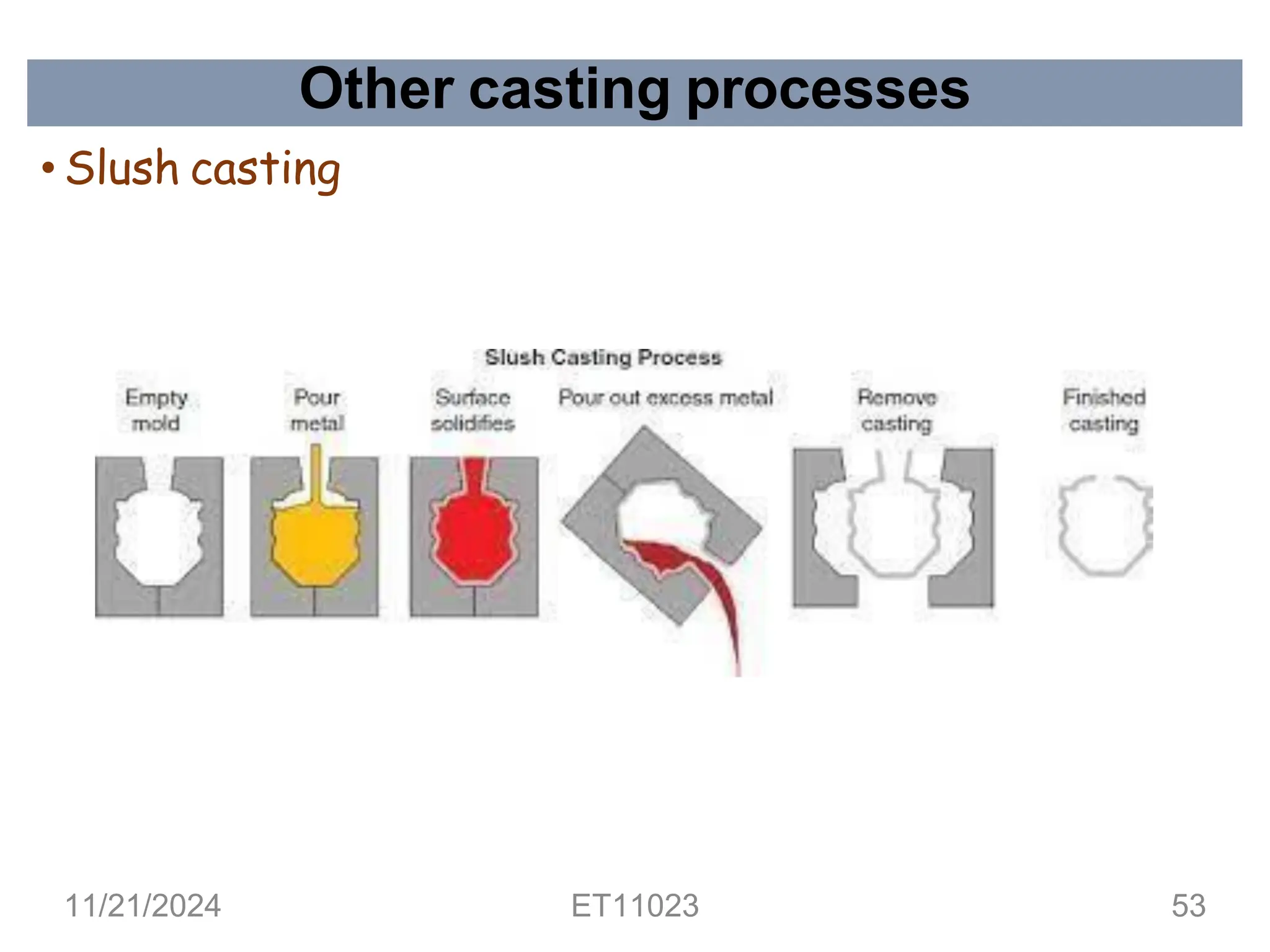

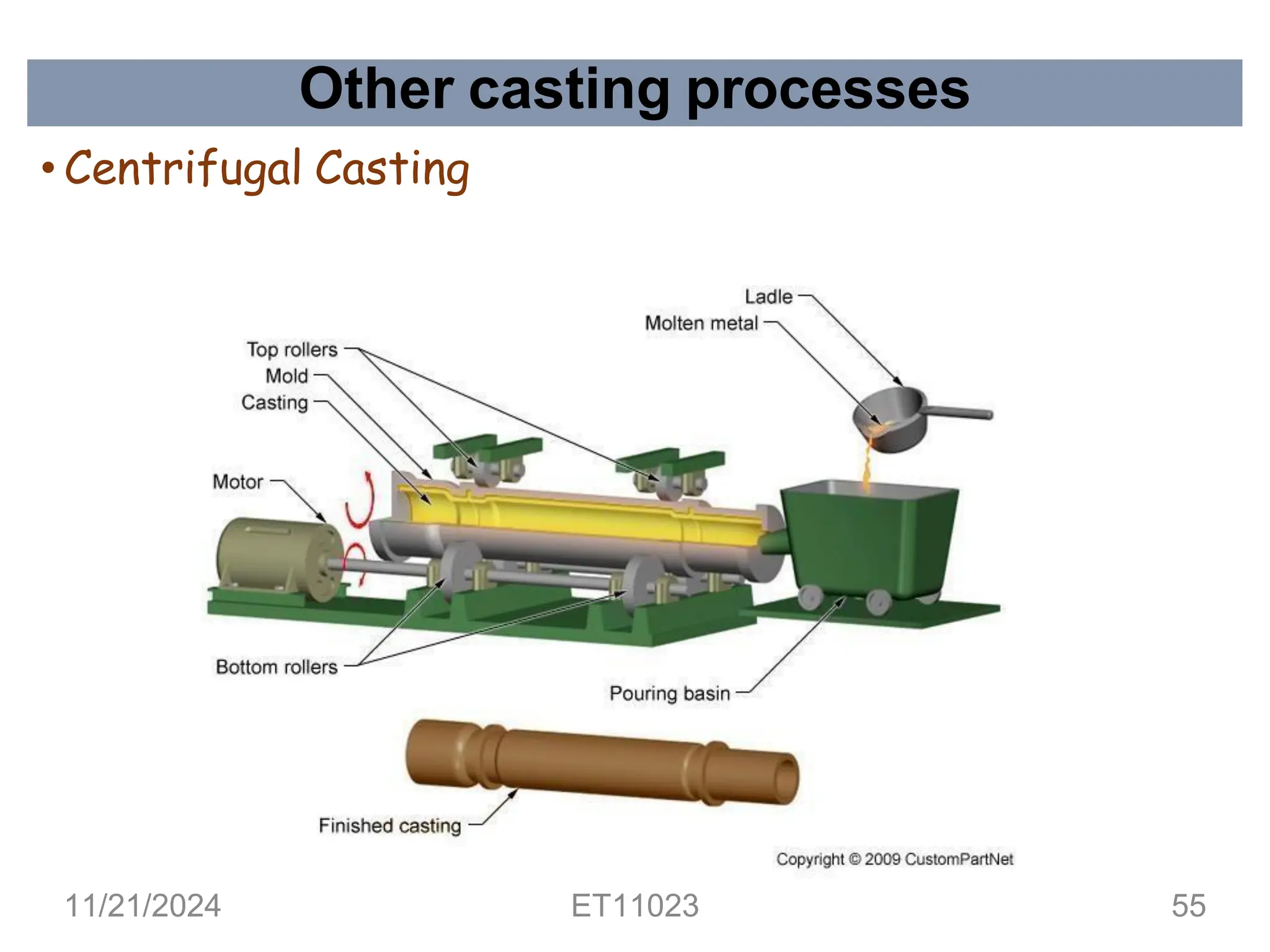

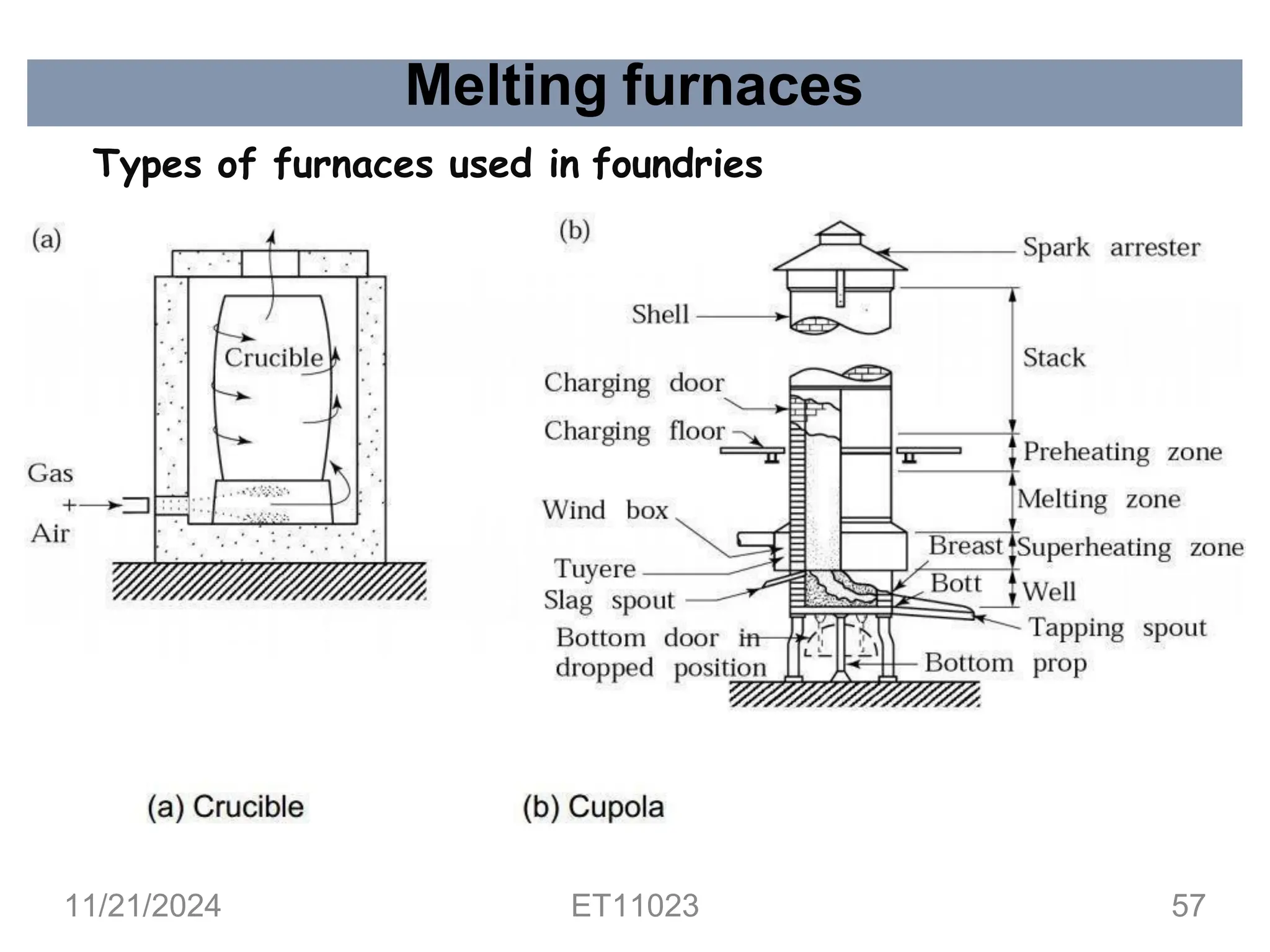

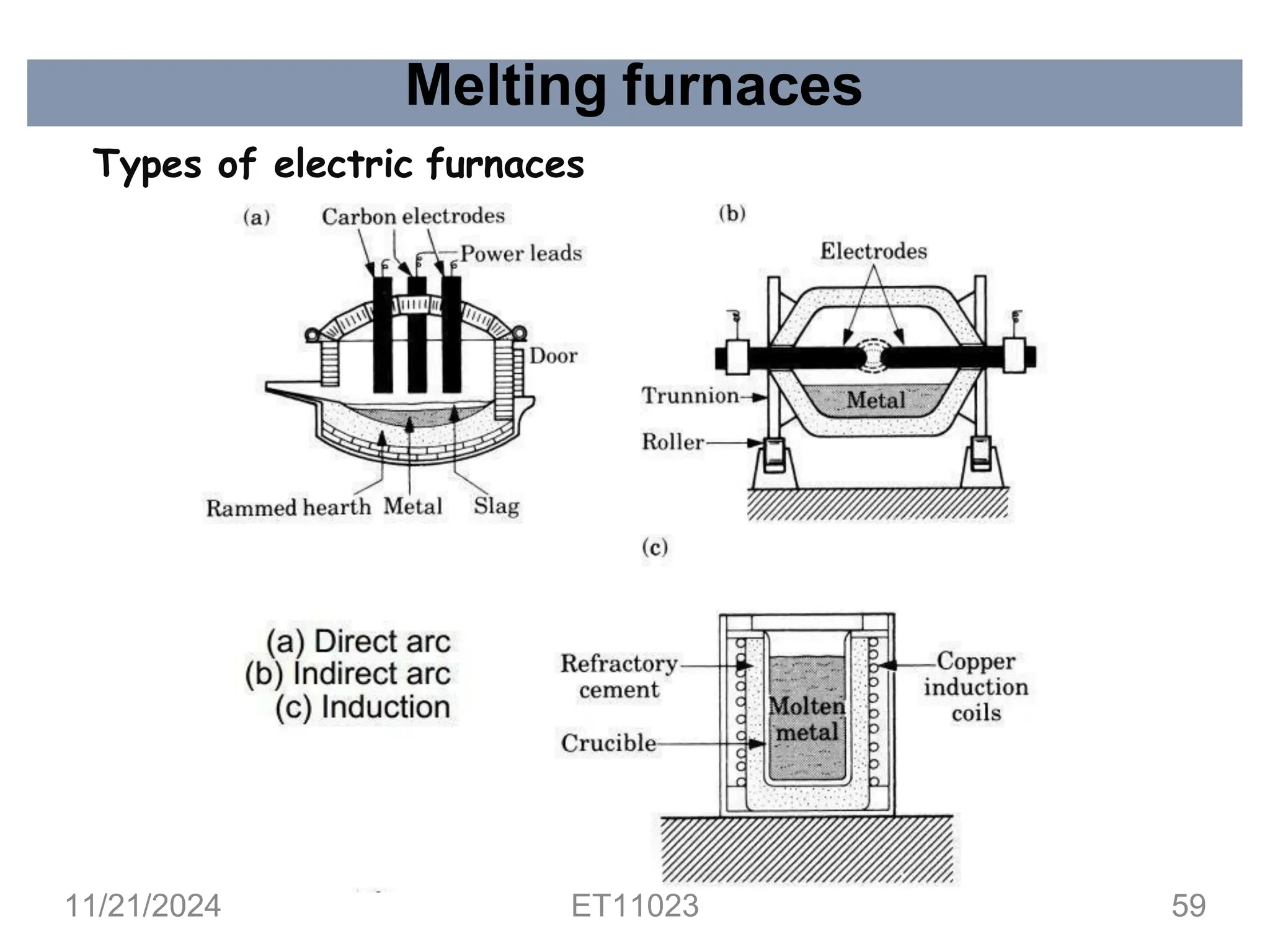

The document outlines various aspects of workshop technology and practices, focusing on foundry processes and metal joining techniques. It discusses safety practices, types of molds and casting processes, and common casting defects. Additionally, it describes methods used to improve casting quality and details several types of furnaces utilized in metal melting.