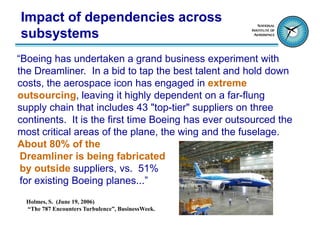

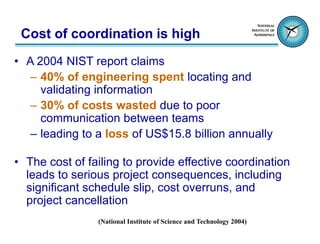

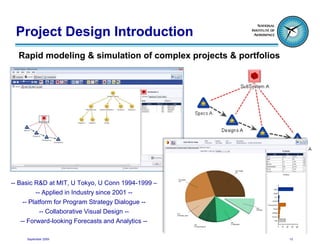

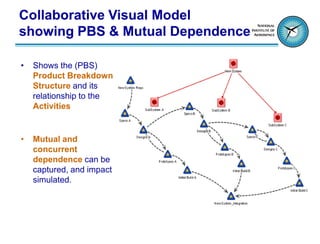

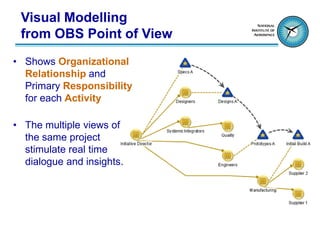

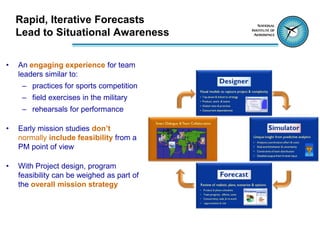

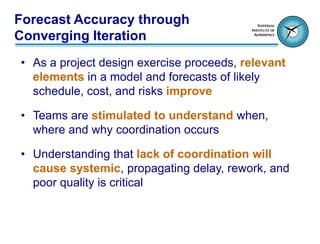

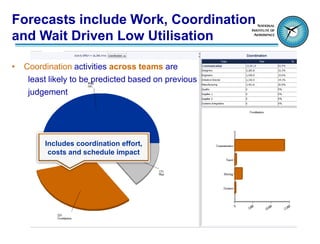

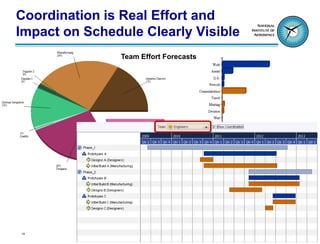

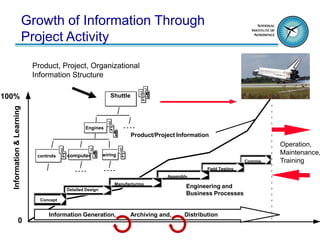

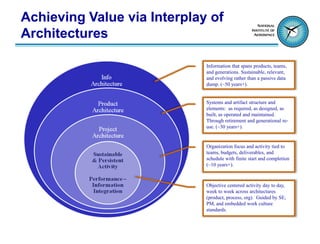

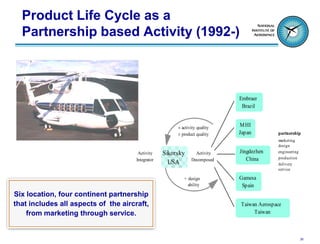

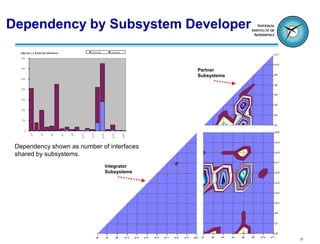

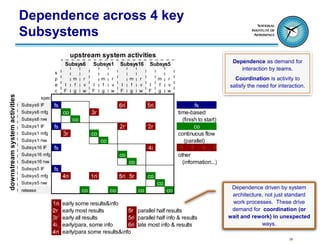

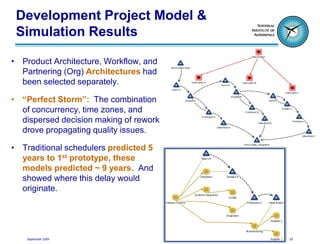

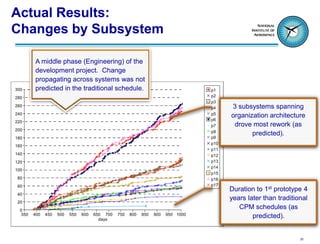

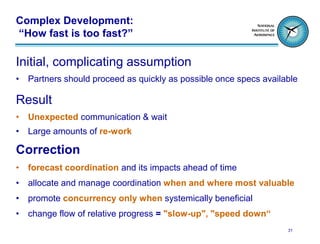

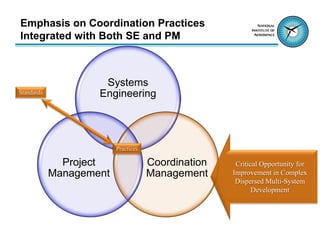

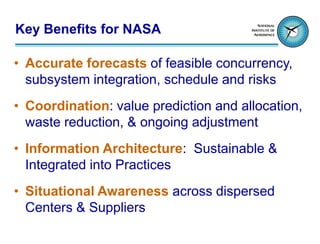

This document discusses coordination challenges for developing complex aerospace systems across dispersed global teams. It outlines how traditional project management approaches are insufficient due to workforce thinning, varying work practices, and high subsystem interdependencies. The authors propose using collaborative visualization and simulation tools to model projects, forecast coordination needs, and integrate information architectures into practices. This improves situational awareness, reduces waste, and leads to more accurate schedules compared to traditional methods.