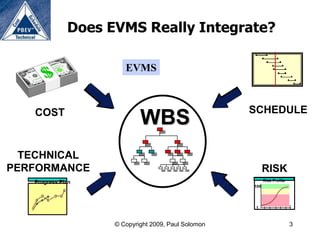

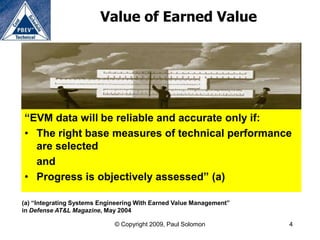

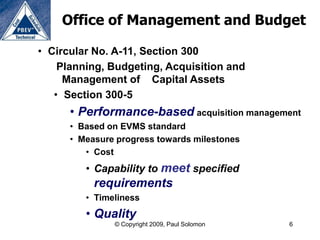

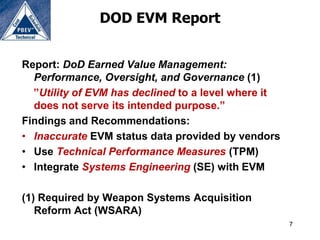

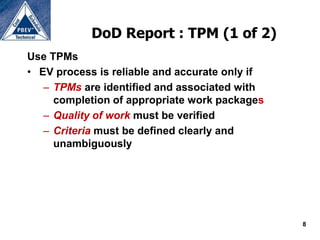

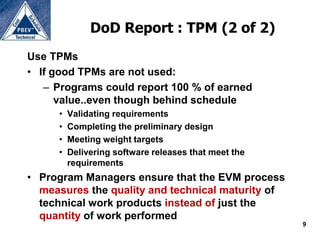

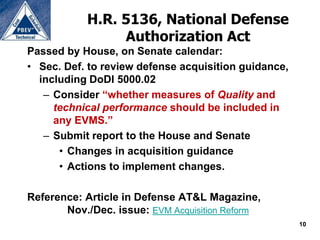

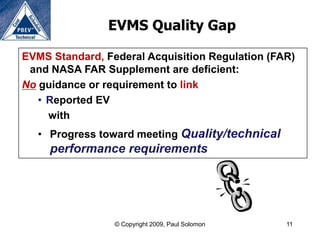

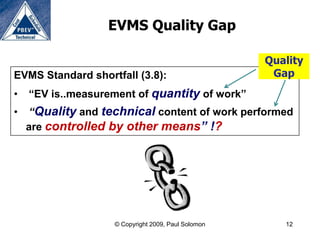

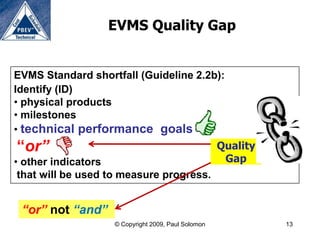

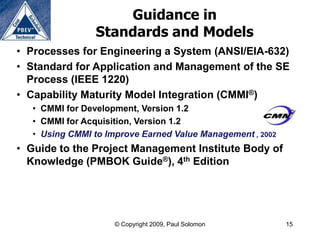

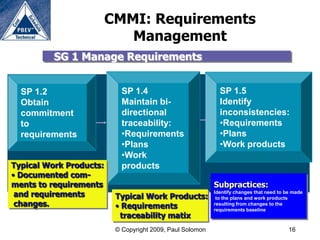

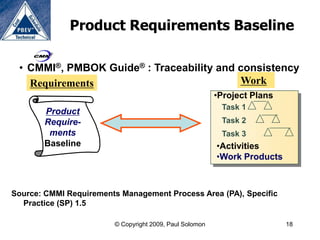

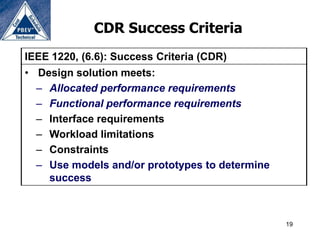

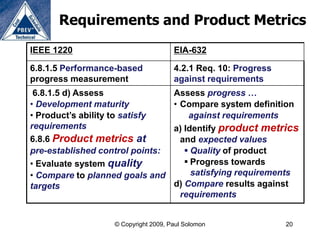

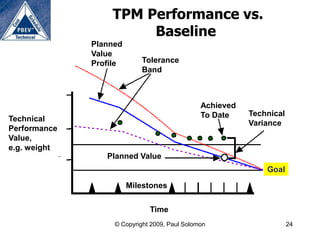

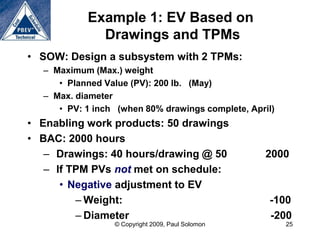

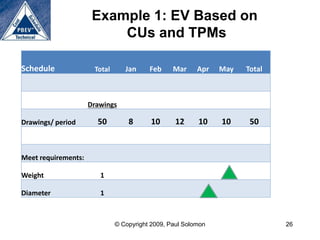

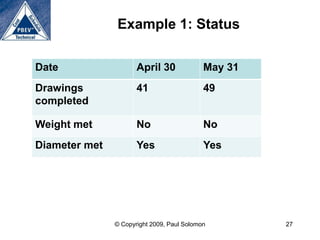

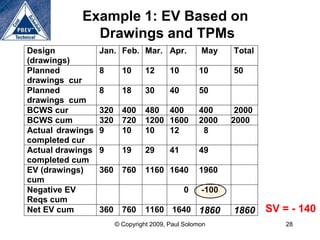

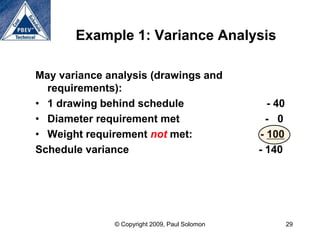

The document discusses integrating technical performance measures with earned value management. It argues that EVM data is only reliable if technical performance is objectively assessed using the right measures of progress. Standards like CMMI and IEEE 1220 provide guidance on using requirements, product metrics, and success criteria to evaluate technical progress. The document provides examples of how to calculate earned value by linking it to completion of drawings and meeting technical performance targets for weight and diameter. It recommends acquisition best practices like requiring technical performance measurement in proposals and verifying integration at contract award and reviews.