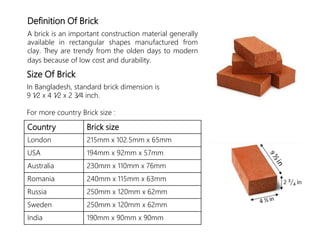

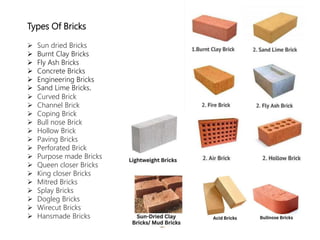

This document provides information on bricks, including their definition, size, constituents, manufacturing process, types, bonding, and advantages and disadvantages. Bricks are clay construction materials that are durable and low-cost. They are standardized at 9 1/2 x 4 1/2 x 2 3/4 inches in Bangladesh. Bricks are made through processes of preparation, molding, drying, and burning. Their quality depends on factors like composition, strength, and water absorption. Bricks are used in various bond patterns and structures.