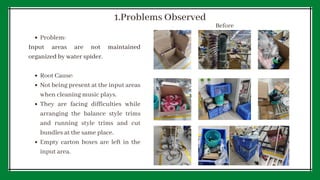

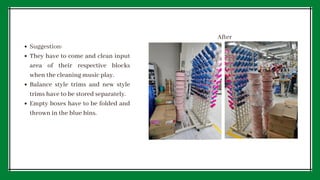

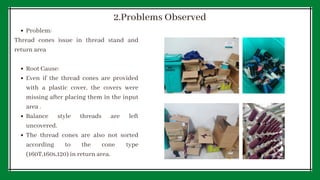

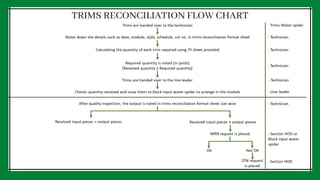

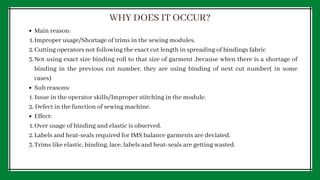

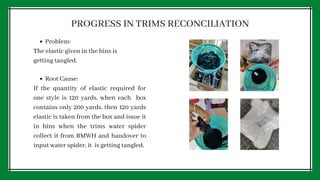

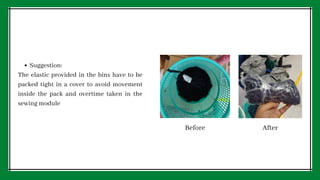

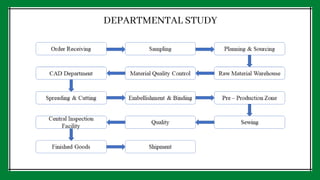

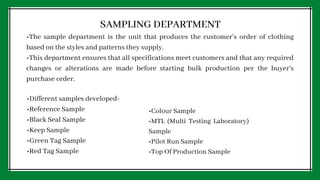

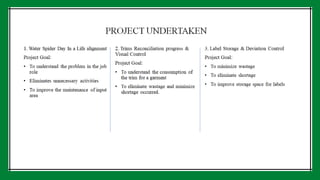

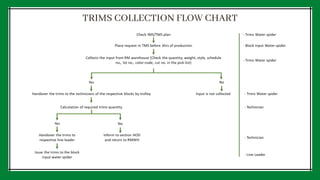

This document summarizes an apparel internship project at Brandix Apparel India Unit-1 in Visakhapatnam. It introduces the internship mentors and interns working on the project. It then provides details about Brandix as a company and gives an overview of the plant layout and departments studied as part of the internship project, including the sampling, planning and sourcing, raw material warehouse, and input water spider roles. Issues observed for input water spiders are summarized along with suggested improvements. The document also discusses problems with trims reconciliation and proposes solutions to better track and allocate trims usage.

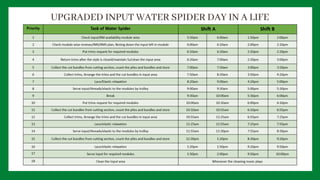

![Checking IMS/TMS/RMS of the modules.

Put input request for TMS and get necessary input based on the module requirement.

Collect the cut bundles from the cutting section, counting the bundles and put signature

in the cutting operators book.

According to the WIP in the sewing module, input quantity is arranged in the input area.

[Trims are issued and arranged in total quantity, cut bundles are arranged for next 2-

3hrs]

Lace relaxation is done.

Elastic is arranged (provided in bins).

Issuing the input to the operators.

Cleaning the input area of sewing module.

Placing the trims in the return trims area (when the style is closed)

INPUT WATER SPIDER JOB ROLE](https://image.slidesharecdn.com/brandixppt-220904183606-cb25a592/85/brandix-ppt-pdf-27-320.jpg)