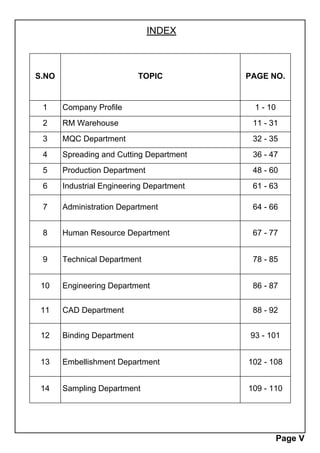

The document is an internship report detailing the authors' eight-week experience at Brandix Apparel India Limited under the guidance of their academic and industry mentors. It includes a comprehensive overview of Brandix, its operational departments, and environmental and social sustainability milestones. The report emphasizes the authors' gratitude for the opportunity and outlines the structure and content of the internship, highlighting the various departments and projects they were involved in.

![Company Profile

Brandix Sri Lanka – Holding Company

Introduction:

The Brandix Group stands as Sri Lanka's largest apparel exporter. As the holding

company for the Brandix Group, it is dedicated to developing, manufacturing, and

marketing comprehensive apparel solutions for global fashion superbrands. The

group's expertise spans casual bottoms, intimate and active wear, woven and

knitted fabrics, and various other segments within the apparel industry. [2]

Founded in 2002, Brandix Lanka serves as the central hub for all Brandix group

companies. It offers a range of core services, including: [2]

Corporate HR

Corporate ICT

Corporate Finance

Corporate Social Responsibility

Corporate Marketing and Branding

Treasury Management

Corporate Communication

Legal and Secretarial Services

Tax Planning

Compliance

BOI Relations

Risk and Control

Engineering and Environment Management [2]

Page 01

Figure 1: Brandix Logo | Source: brandix.com

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-7-320.jpg)

![Company Profile

Management Information System

Brandix Lanka pioneered the concept of providing holistic apparel solutions through

a customer-centric approach. The company is committed to achieving excellence in

manufacturing and supply chain management by collaborating closely with its

partners to deliver innovative solutions. [2]

Brandix Group of Companies:

Brandix Asia

Brandix Apparel

Brandix Apparel Solutions Limited (BASL)

Brandix Apparel India

Brandix Casual Wear Bangladesh Ltd

Brandix Textiles

Brandix i3

Brandix College of Clothing Technology

Brandix Joint Ventures:

Quenby Lanka Prints (Pvt) Ltd

T & S Button Ltd

Textured Jersey Lanka PLC

Ocean Lanka Ltd

Ocean India

Pioneer Elastic

Leading Investment Holding Ltd

Brandix Values:

Integrity

Teamwork

Customer Service

Learning and Development

Ownership

Commitment

Brandix Vision:

“To be the inspired solution for branded clothing.” [2]

Page 02

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-8-320.jpg)

![Company Profile

Andhra Pradesh Special Economic Zone (APSEZ)

The Andhra Pradesh Special Economic Zone (APSEZ) is a prominent economic

zone located in the port city of Visakhapatnam, Andhra Pradesh, on the east coast

of India. Established and developed by the Andhra Industrial Infrastructure

Corporation (APIIC) in April 2007, APSEZ stands as one of the largest multiproduct

special economic zones in the country. [5]

Covering an expansive area of over 2200 hectares in Atchuthapuram and Rambilli

Mandal of Visakhapatnam District, the project involved an investment of Rs. 1600

crores for land and infrastructure development. The projected investment in the

zone is Rs. 30,000 crores. [5]

APSEZ offers significant employment opportunities, with the potential to directly

employ 15,000 individuals and create an additional 25,000 indirect jobs. As a duty

and tariff-free region, it is exempt from goods and services taxes. The zone benefits

from strategic connectivity to international and domestic markets via road, rail, port,

and air. Additionally, APSEZ has established itself as a knowledge hub, featuring

training centers for skilled and semi-skilled operations across various industries. [5]

Page 03

Figure 2: Brandix around the world | Source: brandix.com

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-9-320.jpg)

![Company Profile

Brandix Environmental Sustainability Milestones:

2008: The LEED Gold rating for New Construction by the US Green Building

Council (USGBC) was awarded to the Brandix Essentials Centre in Ratmalana,

making it the first commercial building in Sri Lanka to receive this certification. [3]

2009: Achieved the world's first LEED (Leadership in Energy and Environmental

Design) Platinum Rating for an Apparel Manufacturing Facility by the US Green

Building Council. [3]

2010: Brandix Lanka rated Gold in the Corporate Accountability Rating Survey

(Rated Gold in 2010 and Feb 2011 by LMD Magazine). [3]

2011:

The LEED Gold rating for New Construction by the US Green Building

Council (USGBC) awarded to Brandix Essentials in Koggala.

National Energy Efficiency Award – Large Scale Manufacturing category –

Sri Lanka National Energy Efficiency Awards (Gold Award for BCW

Seeduwa).

Brandix Casualwear, Ratmalana: Highest rated facility in the Large Scale

Manufacturing category – Sri Lanka National Energy Efficiency Awards

(Silver Award). [3]

2012:

The Brandix Eco Centre, Seeduwa becomes the first apparel manufacturer

in the world, and only the third manufacturing entity worldwide across all

sectors of industry, to be ISO 50001:2011 certified.

Brandix becomes the first private company in Sri Lanka to release a

Sustainability Report on par with global standards.

Brandix Casualwear Bangladesh – 'Plan A' Eco Attribute – Marks &

Spencer. [3]

2013: Becomes the first corporate entity to be recognized as Sri Lanka's

"Organization Committed to Green" for 2013 by the Green Building Council of

Sri Lanka (GBCSL). [3]

2014: First Time Report Winner in the Large Scale category – Sri Lanka

Sustainability Reporting Awards (ACCA). Excellence in Sustainable

Development. [3]

Page 04

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-10-320.jpg)

![Company Profile

2015:

Brandix HQ – Green Mark – Platinum certification – Ceylon Institute of

Builders (CIOB).

Brandix Essentials Batticaloa rated highest LEED Platinum Facility in Sri

Lanka and second highest in the world.

Brandix HQ – 'Gold Flame' for Commercial Buildings – Sri Lanka National

Energy Efficiency Awards. [3]

2018: Brandix Essentials Batticaloa certified World’s First Net Zero Carbon

Apparel (Scope 1 and 2) Manufacturing Facility and becomes the first Sri

Lankan organization and first apparel manufacturer to join the World Green

Building Council’s Net Zero Carbon buildings commitment. [3]

2022: Committed to SBTi (Science Based Targets initiatives).

2023:

First Sri Lankan organization/apparel manufacturer in the APAC region to

become a signatory to the Climate Pledge.

Five Brandix facilities certified as Net Zero Carbon as part of the company's

Net Zero Carbon building commitment. [3]

Brandix Social Sustainability Milestones:

2006: Roll out of CSR footprint. [4]

2007: Education Scholarships for Grade 5 Students Established: 730

Scholarships. [4]

2010: Water & Sanitation: 4,300+ Projects benefiting 30K+ Beneficiaries. PACE

Program Launched: 9,000+ Graduates. [4]

2012: Chairman’s Fund Established: 161 Beneficiaries, 35 Million Dispersed. [4]

2015:

Model Village Established: 338 Projects benefiting 260K+ Beneficiaries.

Blood Donation: 30,000+ Pints collected; Largest Blood Donor in the

Corporate Sector in Sri Lanka for the 8th consecutive year. [4]

Page 05

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-11-320.jpg)

![Company Profile

2016: Eye Camps: 45,770+ Beneficiaries with 114+ Camps conducted. [4]

2018:

School Essentials Scholarship Established: 22,000+ Packs Annually

benefiting 80K+ Beneficiaries.

Shilpa Vocational Training Established: 600+ Beneficiaries. [4]

2022:

Launch of RightToRead: 1,260 Schools, benefiting 790,683 individuals.

University Scholarship: 29+ Beneficiaries.

Livelihood-Agri Project: 7,000 Beneficiaries. [4]

2024: 100% of Children of our members have been facilitated through school

education. [4]

2027: 90% of key challenges (WASH, Livelihood & Healthcare) impacting the

quality of lives & sustainable living of associates/families fulfilled. [4]

Page 06

Figure 3: Charters and certifications | Source: brandix.com/sustainability

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-12-320.jpg)

![Company Profile

Brandix India Apparel City

Brandix India Apparel City (BIAC), situated within the Andhra Pradesh Special

Economic Zone (APSEZ), is India's first and only special economic zone dedicated

exclusively to textile and apparel manufacturing. Established through a collaboration

between the Brandix Group from Sri Lanka and Mr. Pachipala Doraswamy, BIAC

has evolved into a comprehensive hub for leading apparel brands. [1]

BIAC offers a vertically integrated supply chain, with various suppliers within the

park providing essential inputs such as fabric, thread, labels, and elastic. This

integration significantly reduces lead times and costs, positioning BIAC as a

preferred global sourcing destination for apparel solutions. Companies operating in

BIAC supply renowned global brands like Victoria's Secret, Marks & Spencer, and

Uniqlo. [1]

The surrounding area of BIAC features a large, cost-effective, and easily trainable

labor pool. The park is also the largest employer of female workers in the country.

Located just an hour away from Vizag port and well-connected by road and rail to

other major ports, BIAC benefits from excellent logistical access. [1]

A dedicated substation within the park, with three secure connections to the state

grid, ensures a reliable power supply for all manufacturers. Additionally, the park is

supported by the Godavari River and a 400 million-liter rainwater harvesting pond,

along with an ultramodern water treatment facility capable of processing 60 million

liters of raw water daily. [1]

The park’s common effluent treatment plant adheres to stringent environmental

standards, handling 56 million liters of effluent discharge per day, which is then

piped 9 kilometers offshore via a $7.5 million marine outfall pipeline. [1]

BIAC’s ISO 14001-certified environmental management system ensures ongoing

compliance with environmental regulations. The park also features over 250 acres of

land allocated for non-processing facilities, including a 120-acre green belt. [1]

Page 07

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-13-320.jpg)

![Company Profile

BIAC Mission

The Fastest: Speed and efficiency are vital for global competitiveness. BIAC's

mission is to provide the most efficient ‘fiber-to-store’ concept, with strategically

planned operational units for real-time connectivity and seamless integration.

Right Cost: To ensure healthy profits, BIAC focuses on maximizing returns

through SEZ fiscal benefits, competitive utility costs, economies of scale, and a

cost-effective labor pool. Value chain partners help minimize overhead costs.

Total Convenience: Described as a plug-and-play environment, BIAC aims to

meet all operational needs swiftly, including labor, transport, and

communication.

Absolute Assurance: BIAC promises a favorable investment atmosphere

supported by stringent social and environmental standards. The stable economy

and government promotion of the textile industry reinforce BIAC as an ideal

investment location.

Innovative Solutions: By bringing together world-class partners and expertise,

BIAC seeks to generate innovative solutions that benefit end customers and

complement operating units. [1]

Tax and Trade Benefits

Complete exemption from duty on all imports.

A 20% income tax concession for 15 years.

Duty-free access to Japan under the Indo-Japan Free Trade Agreement. [1]

Current Manufacturers Hosted by BIAC

Brandix Apparel India (Unit 1, Unit 2, Unit 3, Unit 4): Innerwear and Ladies'

underwear.

Seeds Intimate Apparel: Bras and bralettes.

Quantum Clothing: Ladies' innerwear and men’s shirts.

Teejay India: Fabric mill for knitting, dyeing, and printing.

Pioneer Elastics: Manufacturing and dyeing of narrow elastic.

Vardhman AE: Sewing threads.

Ribbest India: Ribbons and bows.

International Trimmings Limited: Manufacturing of tags and labels.

Shore to Shore: Manufacturing of tags and labels. [1]

Page 08

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-15-320.jpg)

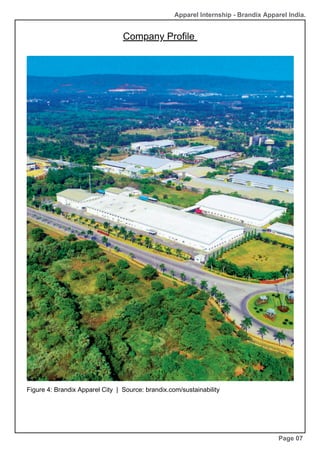

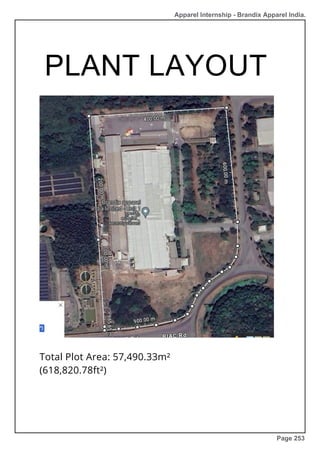

![Company Profile

Brandix Apparel India - Unit 1

Brandix Apparel India, part of Brandix Lanka Ltd., operates its first manufacturing

plant, known as Unit 1 (BAI – 1). Initially established in March 2006 at Pendurthi,

this facility was later relocated to its current site within the Brandix India Apparel City

(BIAC) in the APSEZ. This relocation made it one of the first manufacturing units set

up in the BIAC. As part of the Brandix Essential Limited (B.E.L. cluster), BAI – 1

ranks among the top five plants within the Brandix group. Remarkably, it is one of

the largest exporter of women's underwear from India. [1]

The factory is managed by Mr. Senthil Kumar Balasundaram and is located at Plot

18, BIAC SEZ, Pudimadaka Road, Atchuthapuram Mandal, Visakhapatnam, Andhra

Pradesh, India, covering a land area of 13.5 acres with a built-up space of 146,000

square feet. The facility employs over 4,100 people and operates 2,672 sewing

machines, with an average machine age of 5 to 6 years. The factory runs three

shifts: Shift A from 6:00 AM to 2:00 PM, Shift B from 2:00 PM to 10:00 PM, and a

General Shift from 8:00 AM to 5:00 PM. Its current customers include major brands

like Walmart, VS Pink, and VS Logo. [1]

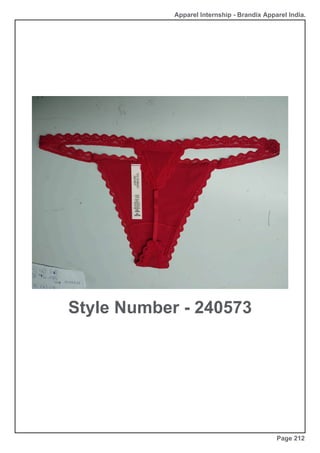

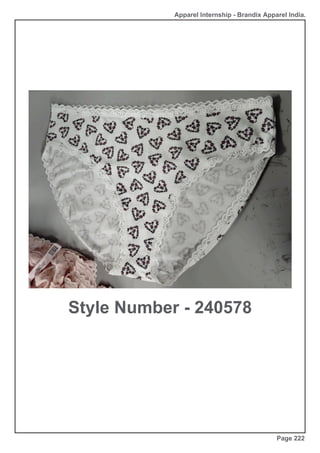

BAI – 1 specializes in producing various types of women’s undergarments, including

bikinis, boy shorts, thongs, V-strings, chicksters, hip huggers, and hipsters. The

factory has an impressive average monthly output of 4.5 million undergarments. It

maintains a cut quantity to order quantity percentage of 102% to 103% and a

rejection rate of 1% to 2%. The facility's shipment percentage targets 102%, typically

achieving between 100.5% and 101.5%. The cut-to-ship ratio target is 99%, with

actual performance ranging between 98% and 99.5%. The factory experiences a

labor turnover of 2% to 3% per month. [1]

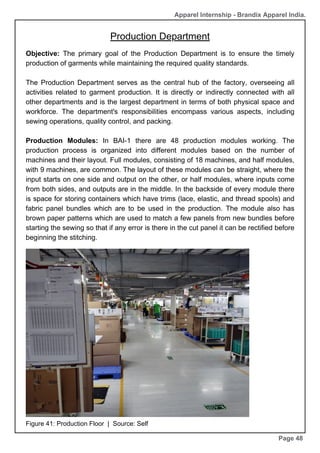

The production floor is organized into four sections, each containing four blocks,

totaling 16 blocks. Each block is equipped with five assembly lines, known as

modules, making up a total of 48 modules. A special feature of BAI – 1 is its "Instant

Undies" service, which offers a 15-day lead time from purchase order receipt to

shipment, catering to urgent orders. Notably, 85% of the workforce at BAI – 1 is

female, highlighting the factory's commitment to employing women in the

manufacturing sector. [1]

Page 09

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-16-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

FJ1380407/8/NM_ELSWVN_7.5mm Elastic

PIONEER ELASTIC (INDIA)

PVT LIMITED

YRD

SSO66839_57%CT38%MOD5%EL_

SD

Fabric

TEEJAY INDIA PRIVATE

LIMITED

YRD

SSO66839_57%CT38%MOD5%EL_

PRNT

Fabric

TEEJAY INDIA PRIVATE

LIMITED

YRD

BTT600A_LACETRIM_1.6cm Lace TIANHAI LACE CO LTD YRD

L12045/8/PS_ELS.WVN_REG_8mm Elastic

BEST PACIFIC TEXTILES

LANKA(PVT)LTD

YRD

L34195/32/B/MP_ELSKNT_REG_32

mm

Elastic

BEST PACIFIC TEXTILES

LANKA(PVT)LTD

YRD

Size STK_JSIN34862 Sticker

AVERY DENNISON LANKA

PVT LTD

PCS

SMA66597_57%CT38%MOD5%EL_

150 G

Fabric TEEJAY LANKA PLC YRD

SMA66597_57%CT38%MOD5%EL_

THTH

Fabric TEEJAY LANKA PLC YRD

SSO66597_57%CT38%MOD5%EL_

SD

Fabric TEEJAY LANKA PLC YRD

SSO66597_57%CT38%MOD5%EL_

PRNT

Fabric TEEJAY LANKA PLC YRD

BU9604A_LACEGLN_7cm Lace TIANHAI LACE CO LTD YRD

BS01799G_LACEALLOVR_122cm Fabric NOYON LANKA (PVT) LTD YRD

VSLB4 - STICKER PAPER

BARCODE

Sticker

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

BAR

CODE_STK.BARCD_ON.OTHR

Sticker

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

LB

5768_TAGPRCTKT_L69XW18mm

Tag

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

L11967/6/PS_ELS.WVN_REG_6mm Elastic

BEST PACIFIC TEXTILES

LANKA(PVT)LTD

YRD

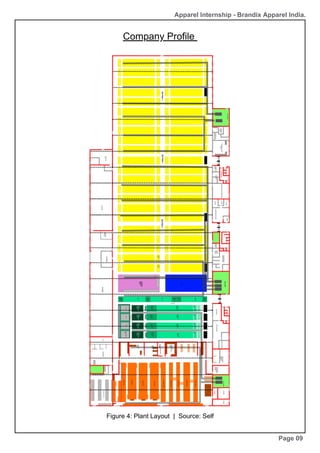

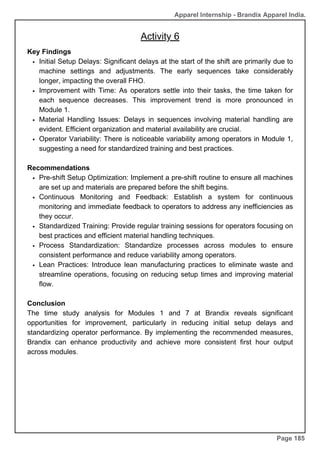

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]

RM Warehouse

Page 12

Apparel Internship - Brandix Apparel India.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-19-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

HT.SL.CARE_LB 2691 Heat Seal

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

L34556/32/01/MP_ELSKNT_32mm Elastic

BEST PACIFIC TEXTILES

LANKA(PVT)LTD

YRD

LBL.CARE_LB 5735 Label

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

BS00194G_LACETRIM_1.5cm Lace NOYON LANKA (PVT) LTD YRD

BS00922G_LACEGLN_3.7cm Lace NOYON LANKA (PVT) LTD YRD

BS00174G_LACEGLN_7cm Lace NOYON LANKA (PVT) LTD YRD

BS05756G_LACEGLN_23cm Fabric NOYON LANKA (PVT) LTD YRD

LPSJ115917_57%CT38%MOD5%E

L

Fabric OCEAN LANKA (PVT) LTD YRD

LPRB005822_95%CT5%EL_200 G Fabric OCEAN LANKA (PVT) LTD YRD

LPSJ115917_57%CT38%MOD5%E

L_SD

Fabric OCEAN LANKA (PVT) LTD YRD

350 GSM Board Body Card

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

LPSJ184703_100%CT_SD_115G Fabric OCEAN LANKA (PVT) LTD YRD

SW108150-

7.5mm_ELSWVN_7.5mm

Elastic STRETCHLINE (PVT) LTD. YRD

LB

5768_TGPRCTKT_L69XW18mm

Tag

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

BR CODE_STK.BARCD_ON.OTHR Sticker

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

Poly Bags Polybag

POLY CREATIONS (PVT)

LTD

PCS

SW050580-

007.0_ELS.WVN_REG_7mm

Elastic STRETCHLINE (PVT) LTD. YRD

SJ106665-032.0_ELSJQRD_32mm Elastic STRETCHLINE (PVT) LTD. YRD

SW106176-

17mm_ELSWVN_17mm

Elastic STRETCHLINE (PVT) LTD. YRD

RM Warehouse

Page 13

Apparel Internship - Brandix Apparel India.

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-20-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

SW41081-

05_ELS.WVN_REG_5mm

Elastic STRETCHLINE (PVT) LTD. YRD

SW41081/4_ELS.WVN_PLN.MT_4

mm

Elastic STRETCHLINE (PVT) LTD. YRD

LBL.MAIN_PWLB-165 Label

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

JCMS51_57%CT38%MOD5%EL_S

D_150G

Fabric HAYLEYS FABRIC PLC YRD

JCMS51_57%CT38%MOD5%EL_S

D

Fabric HAYLEYS FABRIC PLC YRD

BS05866G_LACEGLN_11cm Lace NOYON LANKA (PVT) LTD YRD

JSIN34940-5-MHP Box

AVERY DENNISON LANKA

PVT LTD

PCS

LBL.CRE_LB 5735 Label

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

VSLB4 - STICKER PAPER

BARCODE

Sticker

INT. TRIMMINGS & LABELS

VIZAG INDIA

SET

Pouch pack-PA 95 Pouch

AVERY DENNISON HONG

KONG B.V.

PCS

FC00088A02_71%RNY29%SP_PR

NT

Fabric PACIFIC TEXTILES LIMITED YRD

GH9815(MD)_MTF.BOW Motif

WILSON GARMENT

ACCESSORIES (INTL) LT

PCS

RS02865G_LACETRIM_3.7cm Lace NOYON LANKA (PVT) LTD YRD

RS02835G_LACETRIM_1.6cm Lace NOYON LANKA (PVT) LTD YRD

MSJ40915_100%CT_SD_115 G Fabric

TEEJAY INDIA PRIVATE

LIMITED

YRD

P.EST T160WILD CAT

PLUS2500m

Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

ANESOFT *160S_2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

BE9608A_LACEALLOVR_130.3cm Fabric TIANHAI LACE CO LTD YRD

RM Warehouse

Page 14

Apparel Internship - Brandix Apparel India.

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-21-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

PERMA CORE *C120_2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

P.EST N120BstStretch PLUS2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

S/THRED SPUN T160 TTF PERMA Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

THRD.WLDCT_TKT160_2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

P.EST C120P.CORE2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

VCH101F_TAG.HANG_L95XW35m

m_REG

Tag

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

HT.SL.BRANDED_LB 5177 Heat Seal

INTERNATIONAL TRIMMING

LANKA

PCS

LP60_STK.CRTN_ON.OTHR Sticker

AVERY DENNISON LANKA

PVT LTD

SET

LP98_STK.BARCD(STYL) Sticker

AVERY DENNISON LANKA

PVT LTD

SET

LP60 (L7)_STK.CRTN_ON.OTHR Sticker

AVERY DENNISON LANKA

PVT LTD

PCS

LP98 (1L)_STK.PLYBG_ON.OTHR Sticker

AVERY DENNISON LANKA

PVT LTD

PCS

PILB 497_TAGPRCTKT Tag

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

CTNWDVDR_L265XW225XH200m

m_PRNT

Carton ECONOPACK INDIA PVT LTD PCS

CTNWDVDR_L265XW225XH255m

m_PRNT

Carton ECONOPACK INDIA PVT LTD PCS

Carton Carton ECONOPACK INDIA PVT LTD NOS

CTNWDVDR_L265XW225XH220m

m_PRNT

Carton ECONOPACK INDIA PVT LTD PCS

RM Warehouse

Page 15

Apparel Internship - Brandix Apparel India.

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-22-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

HT.SL.CRE_LB 2691 Heat Seal

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

BU9605A_LACEGLN_3.8cm Lace TIANHAI LACE CO LTD YRD

JSIN34940-2-MT Box

AVERY DENNISON LANKA

PVT LTD

PCS

JSIN34940-3-MHP Box

AVERY DENNISON LANKA

PVT LTD

PCS

JSIN34940-5-MBK Box

AVERY DENNISON LANKA

PVT LTD

PCS

JSIN34940-3-MBK Box

AVERY DENNISON LANKA

PVT LTD

PCS

JSIN34940-5-MMBR Box

AVERY DENNISON LANKA

PVT LTD

PCS

JSIN34940-3-MMBR Box

AVERY DENNISON LANKA

PVT LTD

PCS

P.EST C180P.CORE2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

SCOTCH TAPE 5910 Tape

MCLARENS LUBRICANTS

LTD

ROL

LB

5770_TAGPRCTKT_L69XW18mm

Tag

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

LBL.MAIN.CARE_PWLB-165 Label

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

RS01249G_LACEALLOVR_130.9c

m

Fabric NOYON LANKA (PVT) LTD YRD

BAR CODE_STK.BRD_ON.OTHR Sticker

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

HTL.MAIN_WHITE Heat Seal

R-PAC PRINTCARE LANKA

PVT LTD

PCS

HTL.MAIN_BLACK Heat Seal

R-PAC PRINTCARE LANKA

PVT LTD

PCS

RM Warehouse

Page 16

Apparel Internship - Brandix Apparel India.

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-23-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

VL5020_88%NY12%SP_SD_140G Fabric

GUANNGZHOU VERY

TEXTILE COMPANY LTD

YRD

SSO68416_100%CT_SD_120G Fabric

TEEJAY INDIA PRIVATE

LIMITED

YRD

UPC sticker LB 4389 Sticker

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

PERMA CORE *C180_2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

Polybags Polybag

POLY CREATIONS (PVT)

LTD

NOS

LPSJ184703_100%CT_SD_115 G Fabric OCEAN LANKA (PVT) LTD YRD

HT.SL.CARE_PWLB-169 Heat Seal

INT. TRIMMINGS & LABELS

VIZAG INDIA

PCS

SJ108679-032.0_ELSKNT_32mm Elastic STRETCHLINE (PVT) LTD. YRD

SW108150-

007.5_ELSWVN_7.5mm

Elastic STRETCHLINE (PVT) LTD. YRD

SJ108651-032_ELSJQRD_32mm Elastic STRETCHLINE (PVT) LTD. YRD

Best Stretch_100% Nylon120 120 Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

S193303/11_ELS.KNT_PC.MT_11

mm

Elastic

PIONEER ELASTIC (HONG

KONG) LTD

YRD

EDI Sticker Sticker

DPJ BARCODE AND LABEL

PRINTERS (PVT)

ROL

FC00088G08_71%RPAMD29%EL Fabric PACIFIC TEXTILES LIMITED YRD

D49-

123067MZM_LACEALLOVR_125c

m

Fabric

DECORINE LACE AND

TEXTILES LIMITED

YRD

2051135/32/JP_ELSWVN_32mm Elastic

PIONEER ELASTIC (INDIA)

PVT LIMITED

YRD

BH/H836_BLK Hanger

B & G INTERNATIONAL

PRODUCTS LTD

PCS

RM Warehouse

Page 17

Apparel Internship - Brandix Apparel India.

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-24-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

LBL_JSIN34828_JS12404 Label

R-PAC PRINTCARE LANKA

PVT LTD

PCS

EJ85360MS1_77%RPAMD23%EL Fabric

BEST PACIFIC TEXTILES

LANKA(PVT)LTD

YRD

SSO66839_57%CT38%MOD5%EL

_150 G

Fabric

TEEJAY INDIA PRIVATE

LIMITED

YRD

PLB-

1186_TAGHANG_L25XW90mm

Tag

AVERY DENNISON LANKA

PVT LTD

PCS

THRD.PRM.SPN_TKT120_2500m Thread

VARDHMAN YARNS AND

THREADS LTD

CNS

LB

5260_TAG.HANG_L90XW25mm_R

EG

Tag

AVERY DENNISON LANKA

PVT LTD

PCS

RS01249G_LACEALLOVR_135cm Fabric NOYON LANKA (PVT) LTD YRD

EDI_STK_82850-AD_EDI Sticker

AVERY DENNISON INDIA

PVT LTD

PCS

Q64584_95%CT5%EL_200 G Fabric

TEEJAY INDIA PRIVATE

LIMITED

YRD

BH5092M_LACEGLN_23cm Fabric TIANHAI LACE CO LTD YRD

4899/8/PS_ELS.WVN_REG_8mm Elastic

PIONEER ELASTIC (INDIA)

PVT LIMITED

YRD

HTL.MAIN_WHITE Heat Seal

AVERY DENNISON INDIA

PVT LTD

PCS

BH5092A_LACEGLN_23cm Fabric TIANHAI LACE CO LTD YRD

D111-23017JR_LACEGLN_7cm Lace

DECORINE LACE AND

TEXTILES LIMITED

YRD

5549/8/PS_ELS.WVN_REG_8mm Elastic

PIONEER ELASTIC (INDIA)

PVT LIMITED

YRD

JCMS75_57%CT38%MOD5%EL_S

D_150G

Fabric HAYLEYS FABRIC PLC YRD

CTNWDVDR_L26” X W18’’ X 10” Carton ECONOPACK INDIA PVT LTD PCS

RM Warehouse

Page 18

Apparel Internship - Brandix Apparel India.

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-25-320.jpg)

![Item Name Item Type Supplier Name

Unit of

Measure

UPC STK_RFID Sticker

R-PAC PRINTCARE LANKA

PVT LTD

PCS

D116-23016JR_LACEGLN_11cm Lace

DECORINE LACE AND

TEXTILES LIMITED

YRD

RM Warehouse

Page 19

Apparel Internship - Brandix Apparel India.

Figure 6: Fabric Rolls in RM Warehouse | Source: Self

Some important documents available at the RM warehouse are the packaging list and

the Invoice list. The packaging list has the packaging number which is common for one

entire consignment. The invoice includes the purchase order (PO) number, which is

consistent for the same product. The PO number is assigned based on supplier

requirements and contains detailed information about the supplied materials, such as

color, quantity, and type. This standardization ensures that suppliers have clear

instructions and can commence supply as soon as they receive the PO number,

without needing additional specifications on the quantity, color, or type of fabric to be

supplied.

Various Raw materials (trims and fabric) available at the RM warehouse and all the

companies supplying those materials are as follows:- [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-26-320.jpg)

![Apparel Internship - Brandix Apparel India.

Human Resource Department

Page 68

Absenteeism Monitoring:

Operators must complete an absenteeism forecast sheet each Friday for the following

week, which is maintained by the team leader. The HR team tracks forecasted versus

actual absenteeism. The budgeted absenteeism rate is 6% (64 operators per shift per

day). Floaters are available to cover absences. An employee absent for 10

consecutive days without notice will be terminated after receiving three warnings: on

the 3rd, 5th, and 7th days. On the 11th day, termination will be enforced. Modules with

100% attendance for three consecutive days receive chocolates, and those with 100%

attendance for one week are designated as "happy modules" and can choose a song

to play on the company intercom.

Welfare Schemes and Concepts: [6]

Employee of the Year: Awarded based on absenteeism records, working

efficiency, and output delivery during the annual BAI-1 day.

Marriage Benefits: For employees with one year of experience, includes a car with

a driver for distances up to 60 km and a monetary gift of Rs. 10,000 upon

submission of marriage proof.

First Baby Scheme: Employees with one year of experience receive 6 months of

maternity leave and a home visit from the section H.O.D. with a baby gift.

Experience Gift Amount:

1 year: Rs. 500

2 years: Rs. 750

3 years: Rs. 1000

4 years: Rs. 1250

5 years and above: Rs. 1500

[6]

Buddy Concept: New employees are assigned an HR member for the first three

months to monitor their progress and assist them as a friend.

Junior Scholarship Program: Provides books, stationery, and bags for children of

employees with one year of experience, from class 1 to 10.

Senior Scholarship Program: Offers Rs. 2000 per year to employees with one year

of experience for their children until they are employed.

5 Years’ Appreciation Award: Employees with five years of experience receive a

gold coin worth Rs. 10,000.

Health and Eye Check-Up Camps: Health check-ups are conducted on the 1st and

4th Sundays of the month, and eye check-ups on the 2nd and 3rd Sundays. [6]](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-75-320.jpg)

![Apparel Internship - Brandix Apparel India.

Human Resource Department

Page 70

Crèche Facility:

Available to all regular, probationary, and contract employees with children aged 0.6 to

6 years. The trainer-to-child ratio should not exceed 1:5. Activities in the crèche

include:

06:00 AM: Arrival at Brandix

06:00 AM to 07:30 AM: Rest

07:30 AM to 08:00 AM: Morning food

08:00 AM to 09:00 AM: Classroom session

09:00 AM to 10:00 AM: General recreation

10:00 AM to 10:30 AM: Refreshments

10:30 AM to 12:00 PM: Rest

12:00 PM to 01:00 PM: Recreation

01:00 PM to 01:30 PM: Food serving

01:30 PM to 02:00 PM: Preparation to go [6]

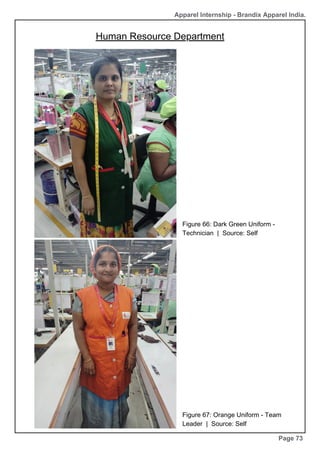

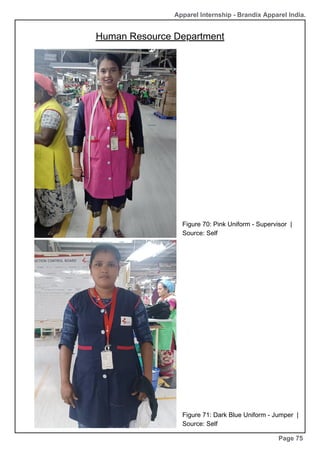

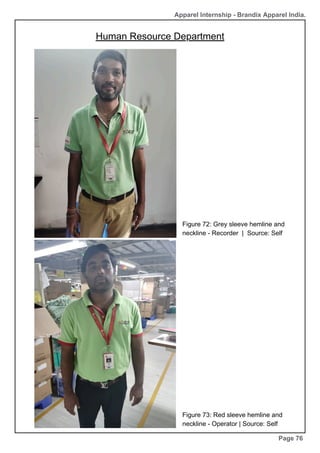

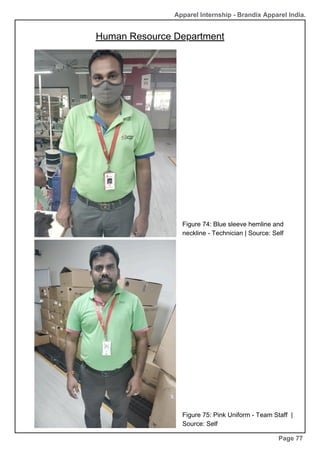

Dress Codes:

Women: No sindoor, hanging earrings, nail paints, long nails, or excessive jewelry.

Dupatta should be properly pinned, and jeans are not allowed except on

Saturdays.

Men: Full sleeve formal shirts are required; hand sleeves cannot be folded, and

jeans are not allowed except on Saturdays. Round-neck T-shirts are also not

permitted.

Figure 62: HR Department Poster | Source: Self](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-77-320.jpg)

![C. Number of steam points, exhaust, water points and

sanitation points(dustbin ,washroom) TROLLY PARKING AREA , HANDICAPED

CHAIRparking temprorystorageetc.

Have to evalute

Incanteenarea outsideofitthereithave 14longbasinsattachedtothewall each basin have 4

taps for drinking water points total 6 points have 2 tap on each points

waterdirectlycomefromfilterarea.3onmessneartogeneratorroom and2tothe mess near

to machine parking area

b. Per square meter concentration of light points and fan points in each department

with height from floor

LIGHT QUANTITY

In middle of grid have 4 light and side grid s have two in every grid

FAN /CHILLER

The centralized cooling duct has five openings: one in the center of the walking area

and two above each module that it passes over.

The height of the duct from the ground is 101 inches.

steam points,

exhaust,

water points and

TROLLY PARKING AREA ,

Parking area [on production floor]

sanitation points(dustbin , washroom) In

canteenarea5dustbinsforfoodwaste(near water point/basin),3dustbin for

normal dry waste each basins have 2 soap dispenser, 2 table for keeping

washed utensils 2 on generator mess area and 1 to the other side

Apparel Internship - Brandix Apparel India.

Page 266](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-275-320.jpg)

![Apparel Internship - Brandix Apparel India.

Page 330

Bibliography

[1] — https://www.brandixapparelcity.com

[2] — https://brandix.com

[3] — https://brandix.com/wp-content/uploads/2024/06/Brandix-ESG-Report-

2022_23_optimized.pdf

[4] — https://brandix.com/sustainability

[5] — https://apiic.in/sezs-in-andhra-pradesh/

[6] — Company’s database

[7] — https://www.akshayapatra.org

Note: Most of the content in the departmental study is derived from the learnings and

observations gathered during our time at the company. For the annexures, details

were filled in based on manual observations, interviews conducted with company

personnel, and records we meticulously kept, such as manual time recordings used

for the time study.

All visuals included in the report were captured by our team using a mobile camera

with the explicit permission and authority of the company. No visuals were taken

without the company's consent. Only a few pictures in the report were sourced

externally, and for those, the sources have been clearly cited below each image.](https://image.slidesharecdn.com/apparelinternshipreportbrandix-240829161433-5aef1e8e/85/Apparel-Internship-Report-Brandix-Unit-1-pdf-339-320.jpg)