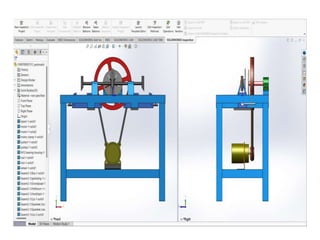

The document describes a student project to design and fabricate a dual side shaping machine. A shaping machine cuts and shapes materials like wood, metal, and plastic. The proposed dual side machine will cut materials on both sides simultaneously, improving efficiency over single side machines. The project team will conduct design calculations, develop 3D models, select components, and build a prototype to test by March 2024. If successful, the dual side shaper could increase production rates for industrial manufacturing applications.

![Design of shaft

Diameter of Shaft = 30mm

Permissible shear stress for mild steel = 34 N/mm2

Shear Stress, Ʈ = _16T_

πd3

T=?

T = _P × 60_ = 20.08 × 103 N-mm

2 ×π×n

Ʈ = _16 × 20.08_

π × 0.033

3.78 N/mm2 < Ʈ Permissible

Therefore design is safe.

V Belt design

Taking Center distance as 1100mm

Length of belt

L = 2C + [π /2(D+d)] + [(D-d)/4C]

L = 2200mm](https://image.slidesharecdn.com/fdssm-240326054216-95c97a7e/85/Both-side-Shaper-machine-with-calculation-pptx-10-320.jpg)

![Groove angle

α = 180- [(D-d)/C] × 60

α = 165.27°

Cutting force

Torque = force × Radius of Crank

T = F × 225

F= 163.33 N](https://image.slidesharecdn.com/fdssm-240326054216-95c97a7e/85/Both-side-Shaper-machine-with-calculation-pptx-11-320.jpg)

![References

[1]. R M Lathe, International Journal of Engineering Research

and Development (IJERD), Volume8Issue2,August-2013.

[2]. M.V.N. Srujan Manohar, International Journal of

Engineering Research and Technology (IJERT),Volume1Issue6

August-2012.

[3]. S. Ravindran, Middle-east Journal of Scientific Research,

12(12): 1710-1714, 2012.

[4]. Khurmi, R.S, and Gupta, J.K.(1997) 'A TEXTBOOK OF

MACHINE DESIGN', S. Chand Publications, New Delhi, India](https://image.slidesharecdn.com/fdssm-240326054216-95c97a7e/85/Both-side-Shaper-machine-with-calculation-pptx-17-320.jpg)