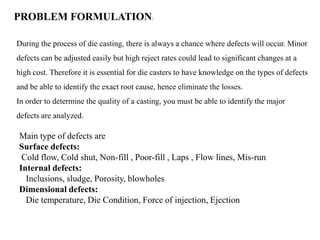

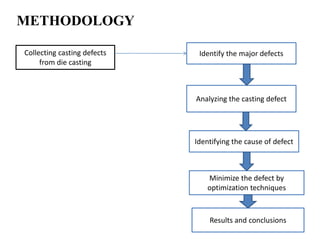

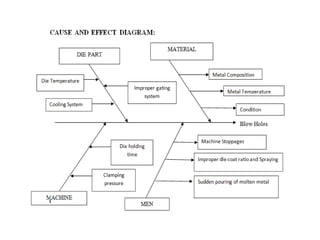

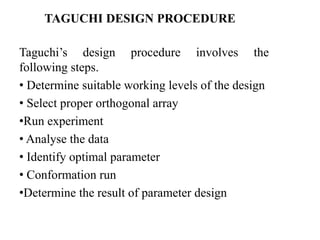

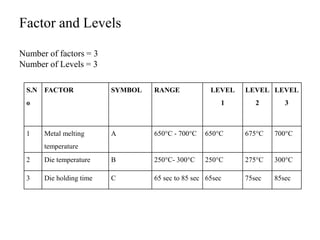

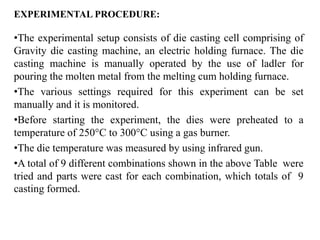

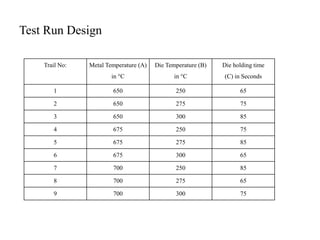

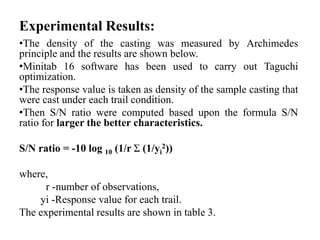

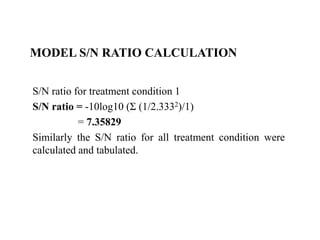

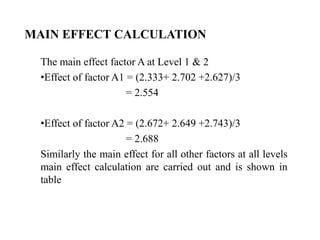

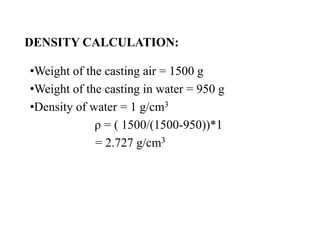

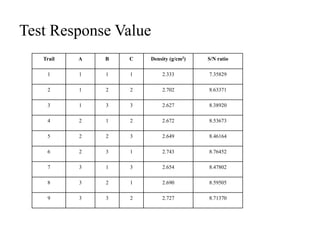

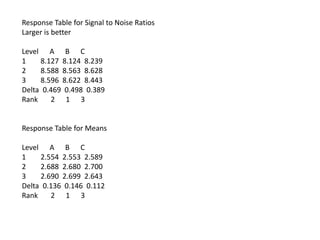

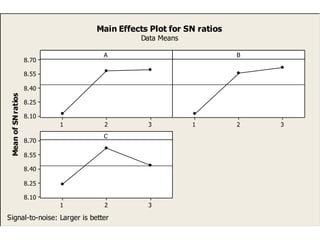

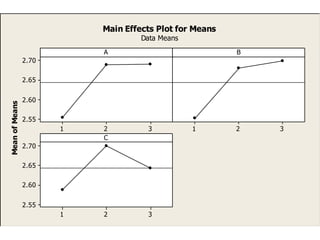

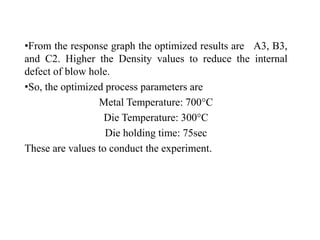

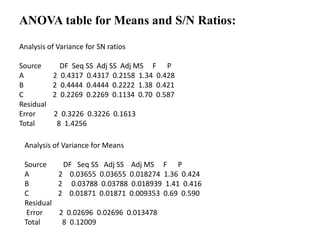

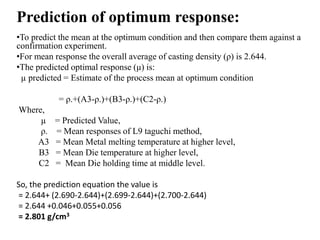

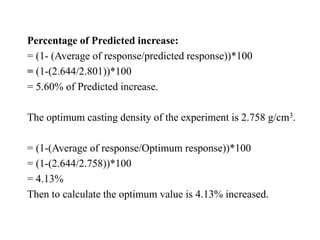

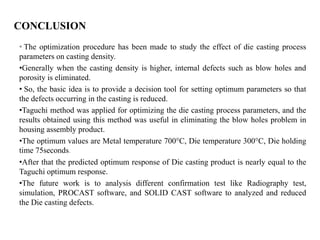

This document summarizes an analysis of blow hole defects in die casting. The objectives were to minimize defects using design of experiments. Process parameters like metal temperature, die temperature, and die holding time were identified as factors affecting blow hole defects. Experiments were conducted using a Taguchi design with three factors at three levels. Analysis of variance showed die temperature was the most significant factor. Optimization found the best parameters were a metal temperature of 700°C, die temperature of 300°C, and die holding time of 75 seconds. This was predicted to increase casting density by 4.13% and reduce blow holes.

![REFERENCES:

1. Atul A. Bhujugade, Vijay B. Sabnis , Minimization of Casting Defects Using Casting

Simulation Technique and Casting Defects Analysis Using Design of Experiment,

International Journal for Research in Applied Science & EngineeringTechnology

(IJRASET)(2015).

2. Satish Kumar, Arun Kumar Gupta, Pankaj Chandna, Optimization of Process Parameters of

Pressure Die Casting using Taguchi Methodology, International Journal of

MechanicalEngineering Vol:6, No:8, 2012.

3. Rajesh Rajkolhe, J. G. Khan Defects, Causes and Their Remedies in Casting Process: A

Review, International Journal of Research in Advent Technology(2014).

4. Kulkarni Sanjay Kumar, J K Sawale , Sampath Rao, Study of effect of process parameter

setting on porosity levels of aluminium pressure die casting process using Taguchi

Methodology, IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE), PP 12-17,

2013.

5. Rasik A Upadhye ,Dr. Ishwar P Keswani , Optimization of Sand Casting Process Parameter

Using Taguchi Method in Foundry , International Journal of Engineering Research &

Technology (IJERT) ,2012.

6. Mr. Siddalingswami. S. Hiremath, Dr. S. R. Dulange, Advanced Tehniques in Casting Defects

And Rejection Analysis: A Study in an Industry, International Journal of Innovations in

Engineering Research and Technology [IJIERT], : ISSN2394-3696VOLUME 2, ISSUE 9, SEP.-

2015.](https://image.slidesharecdn.com/finalreview-14l12-161108172832/85/Blow-Hole-Defect-Analysis-in-Die-Casting-36-320.jpg)