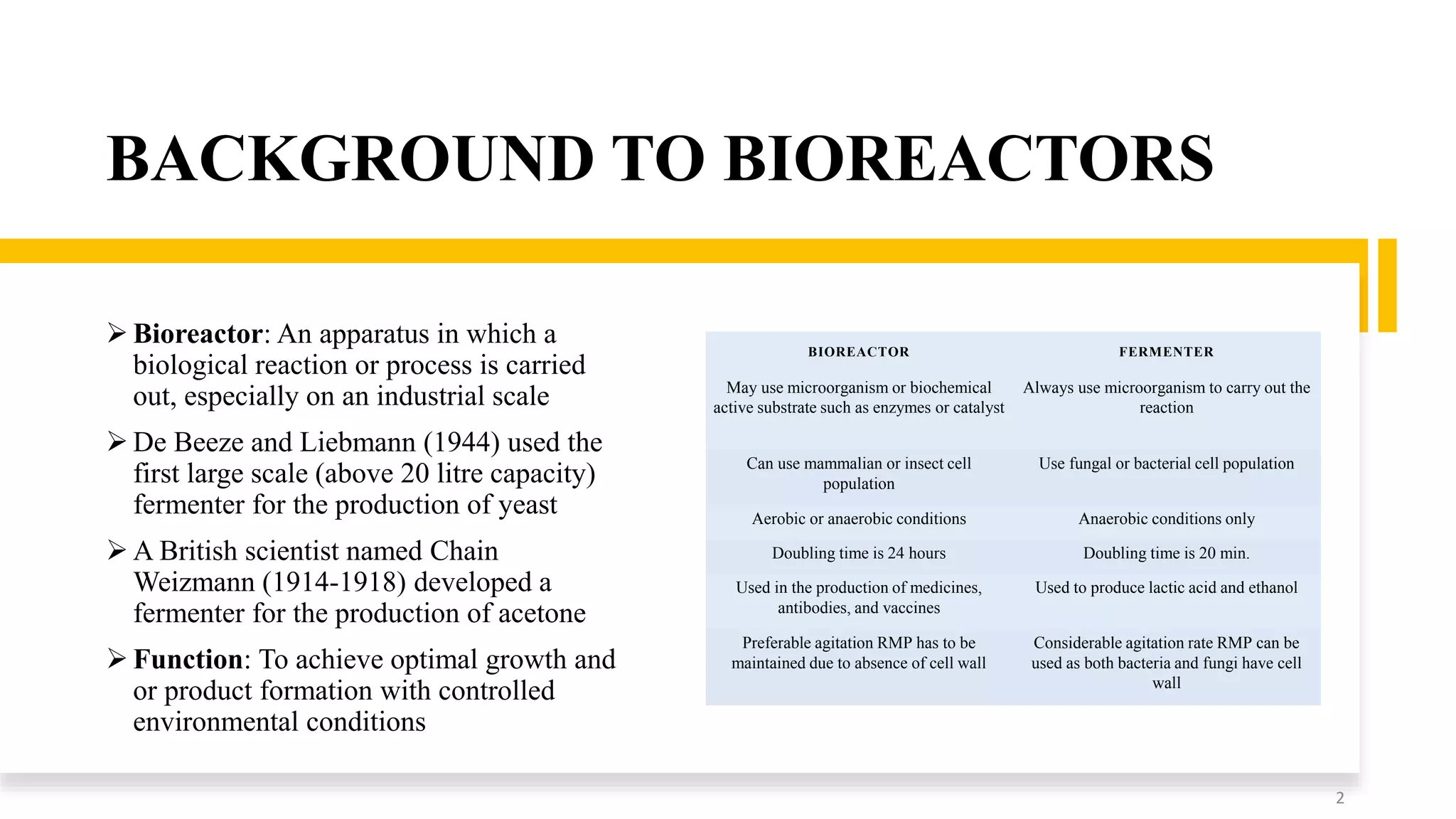

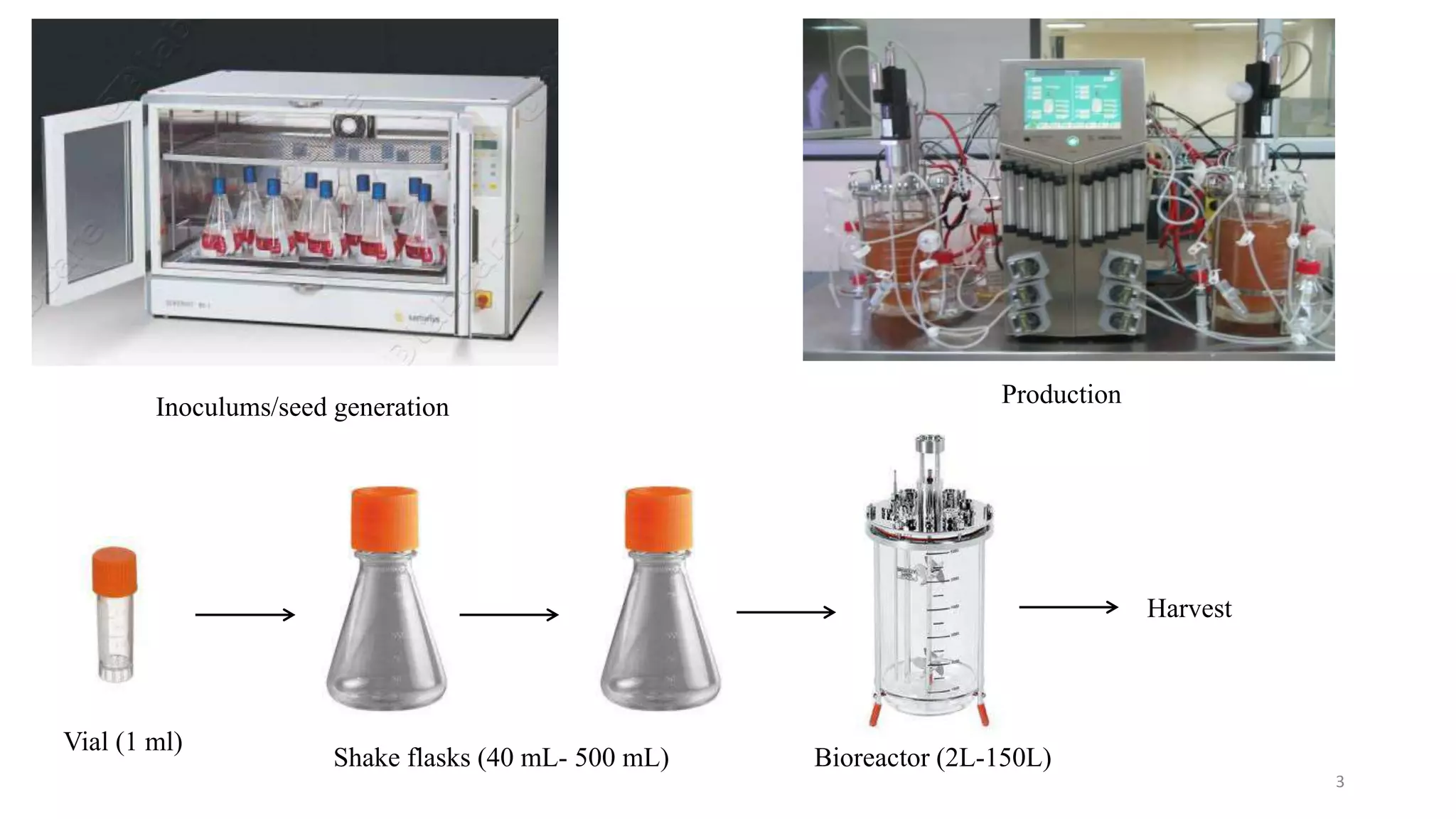

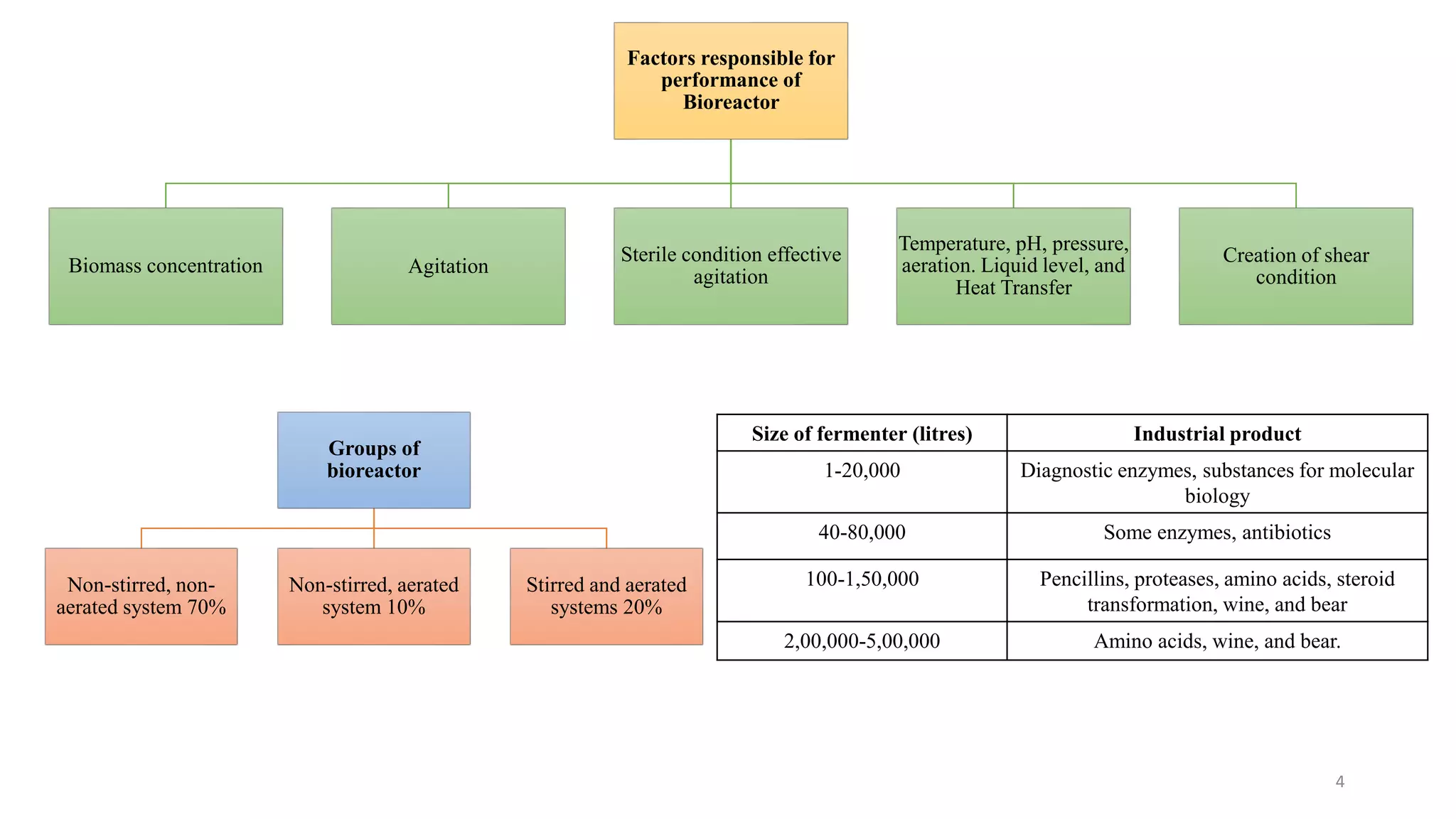

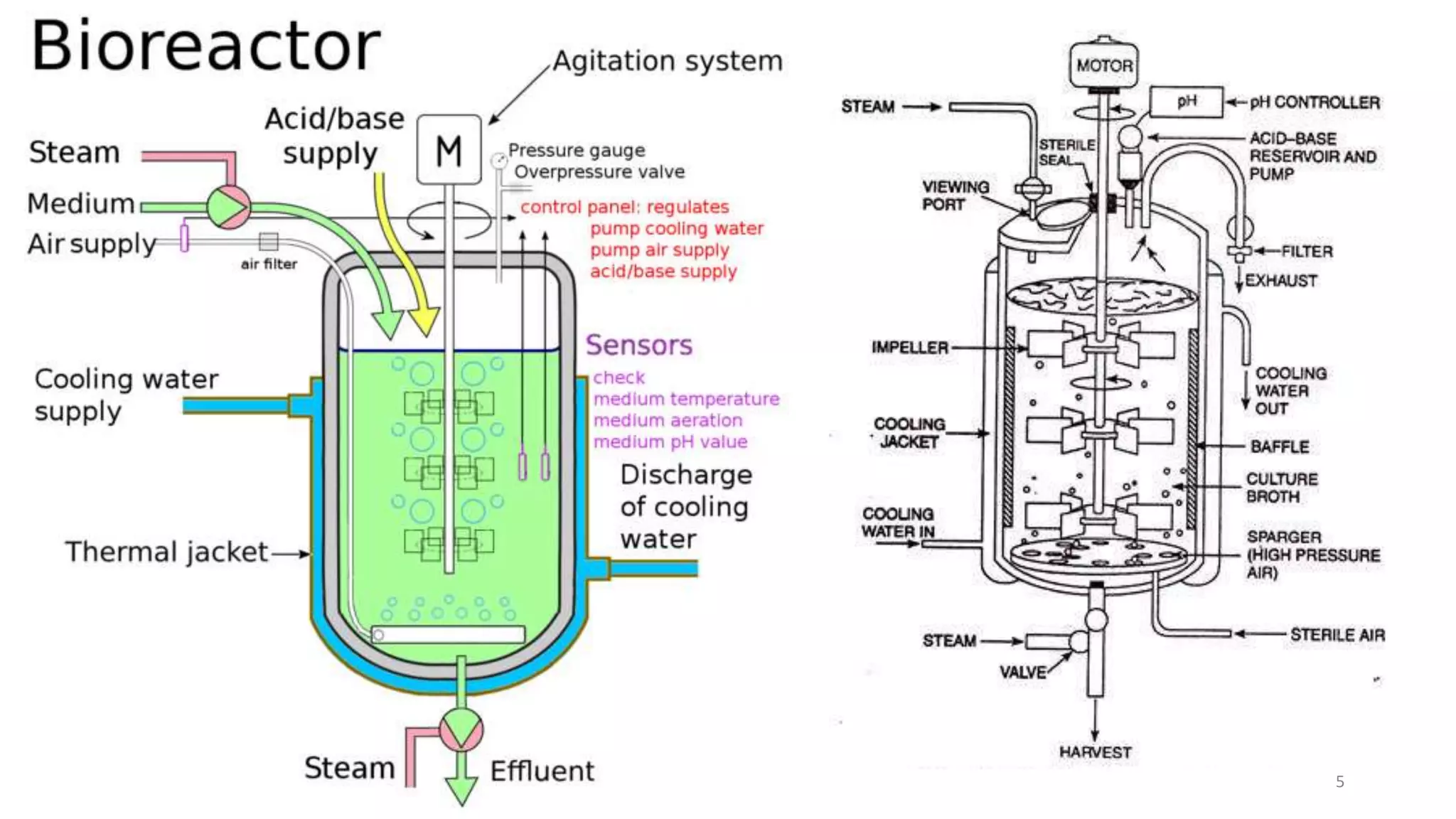

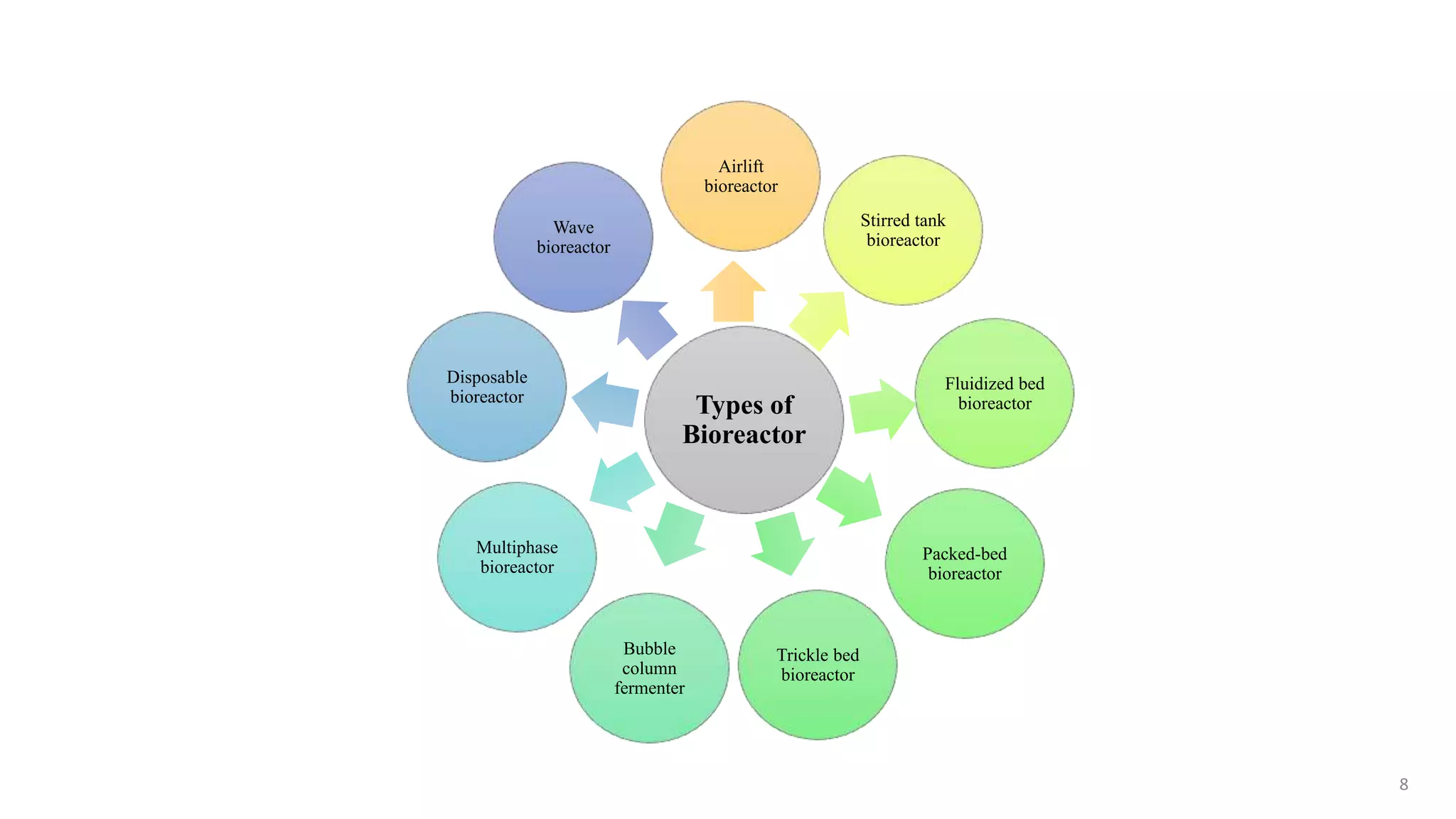

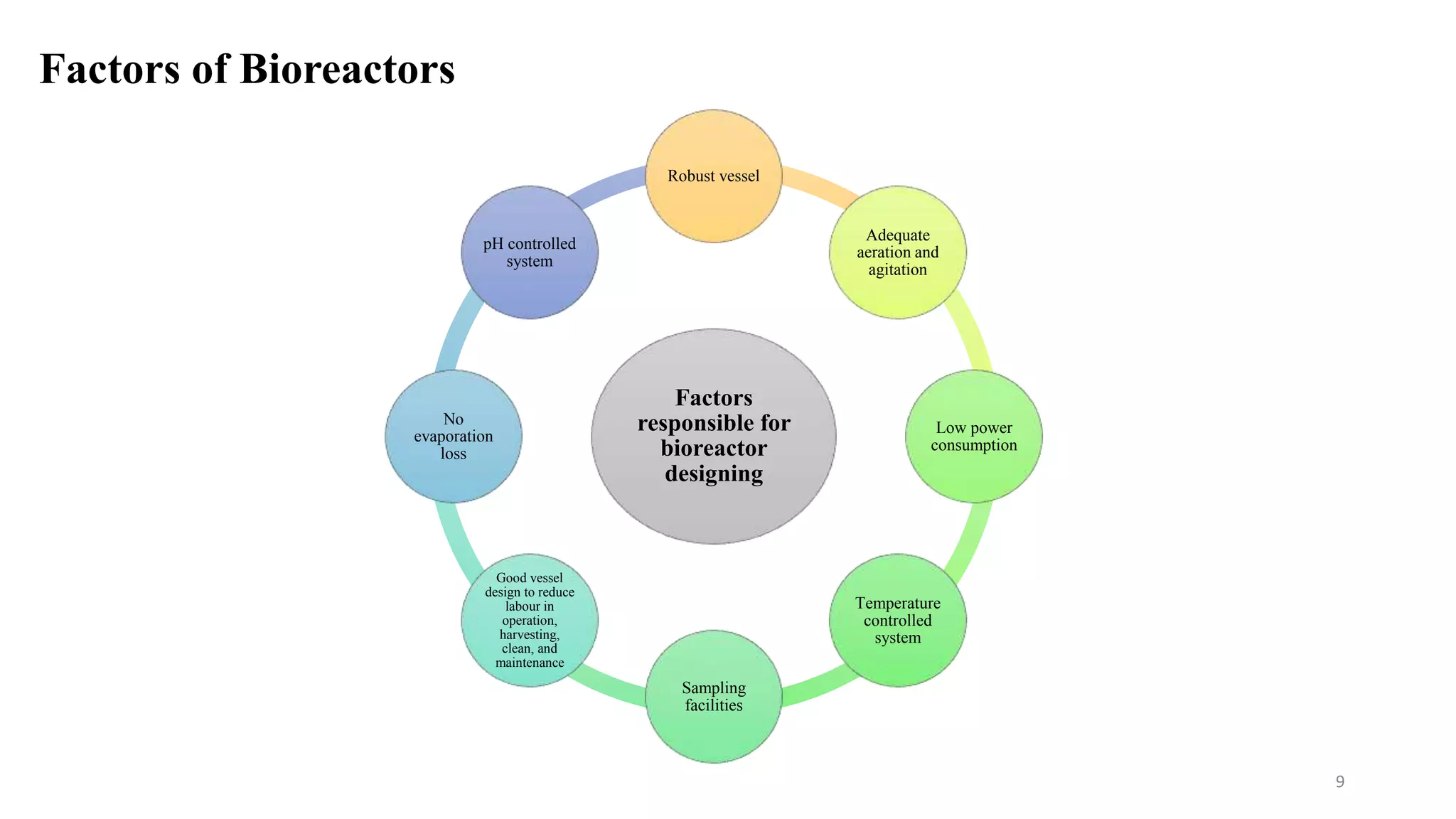

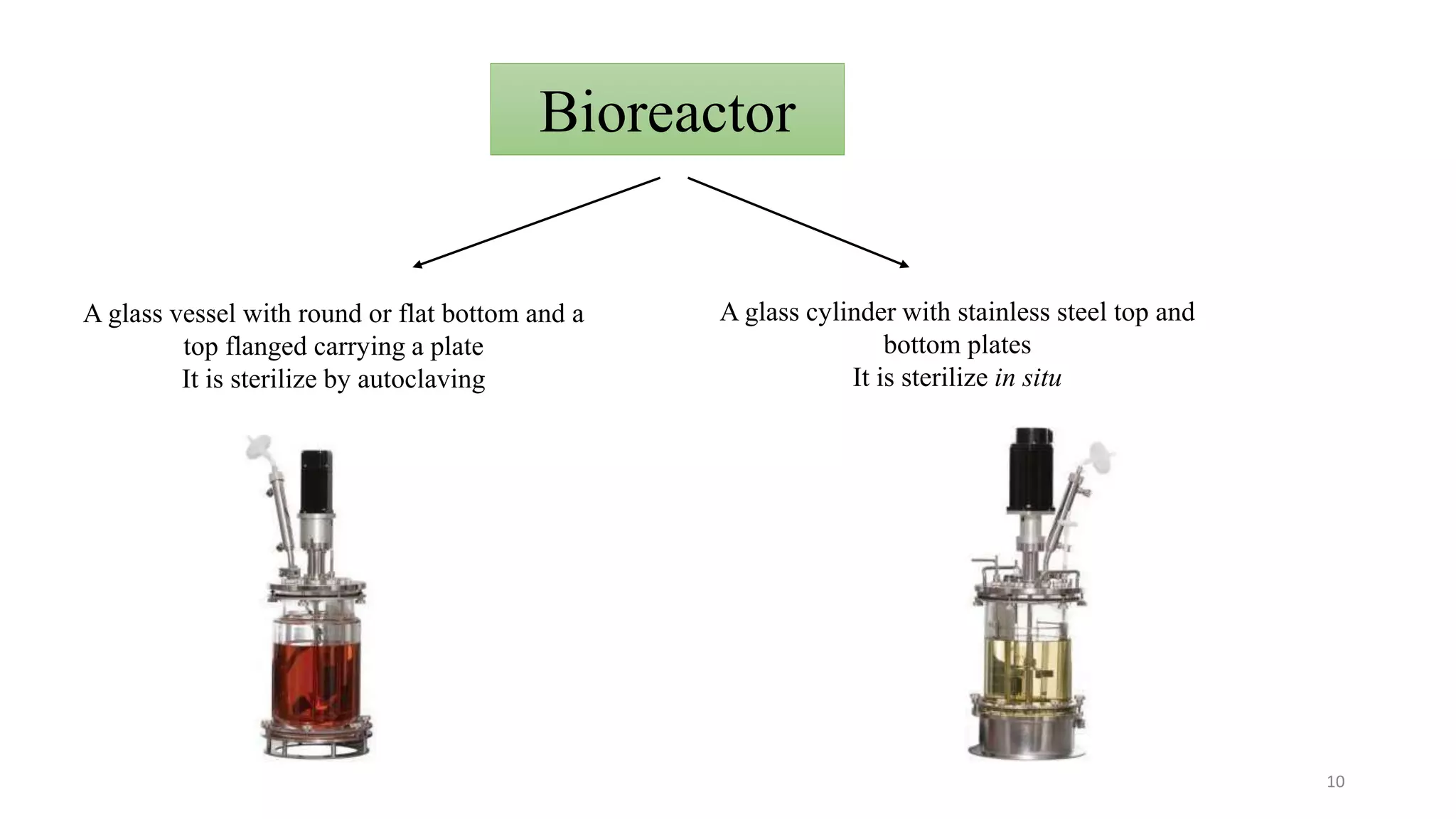

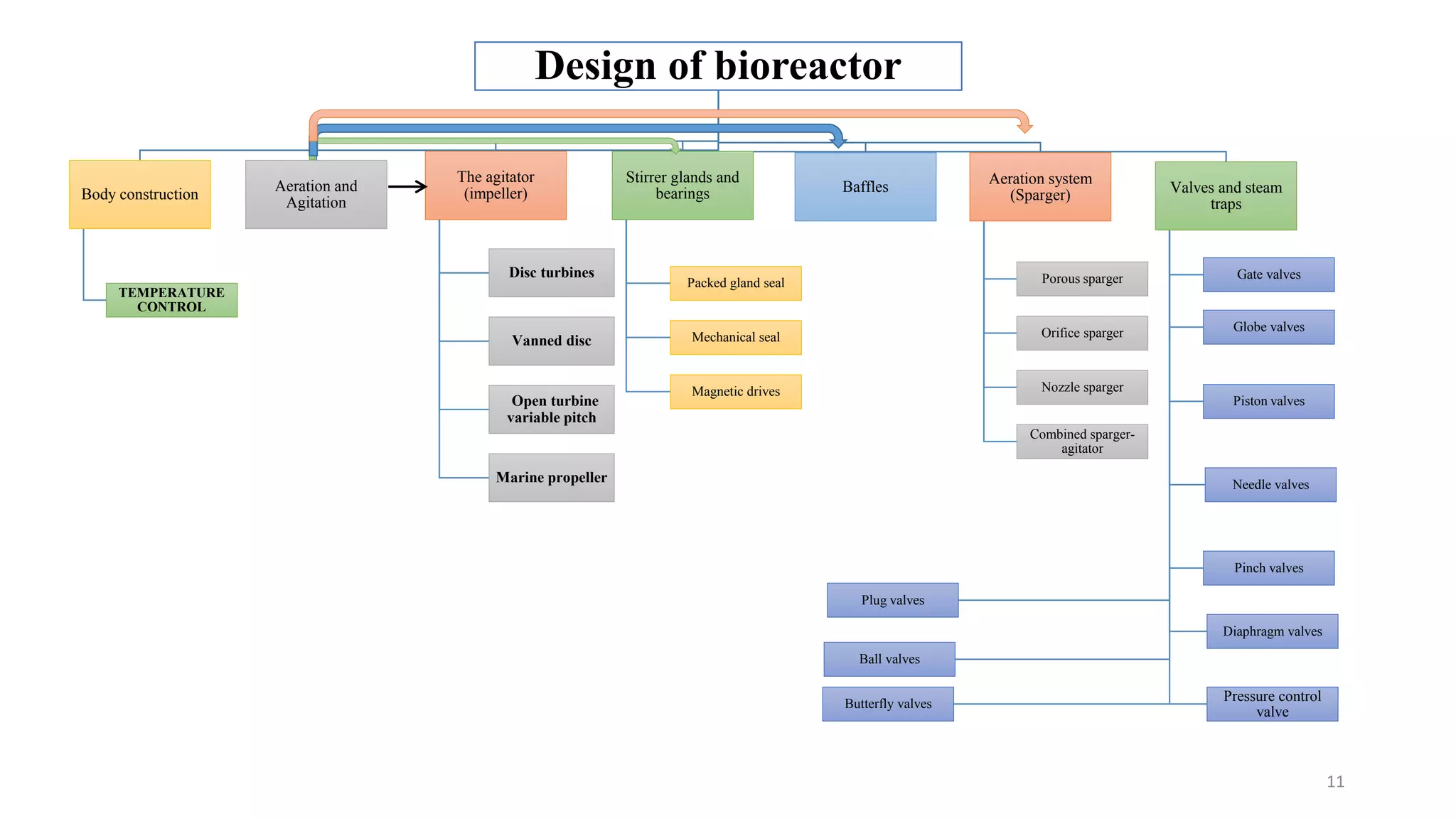

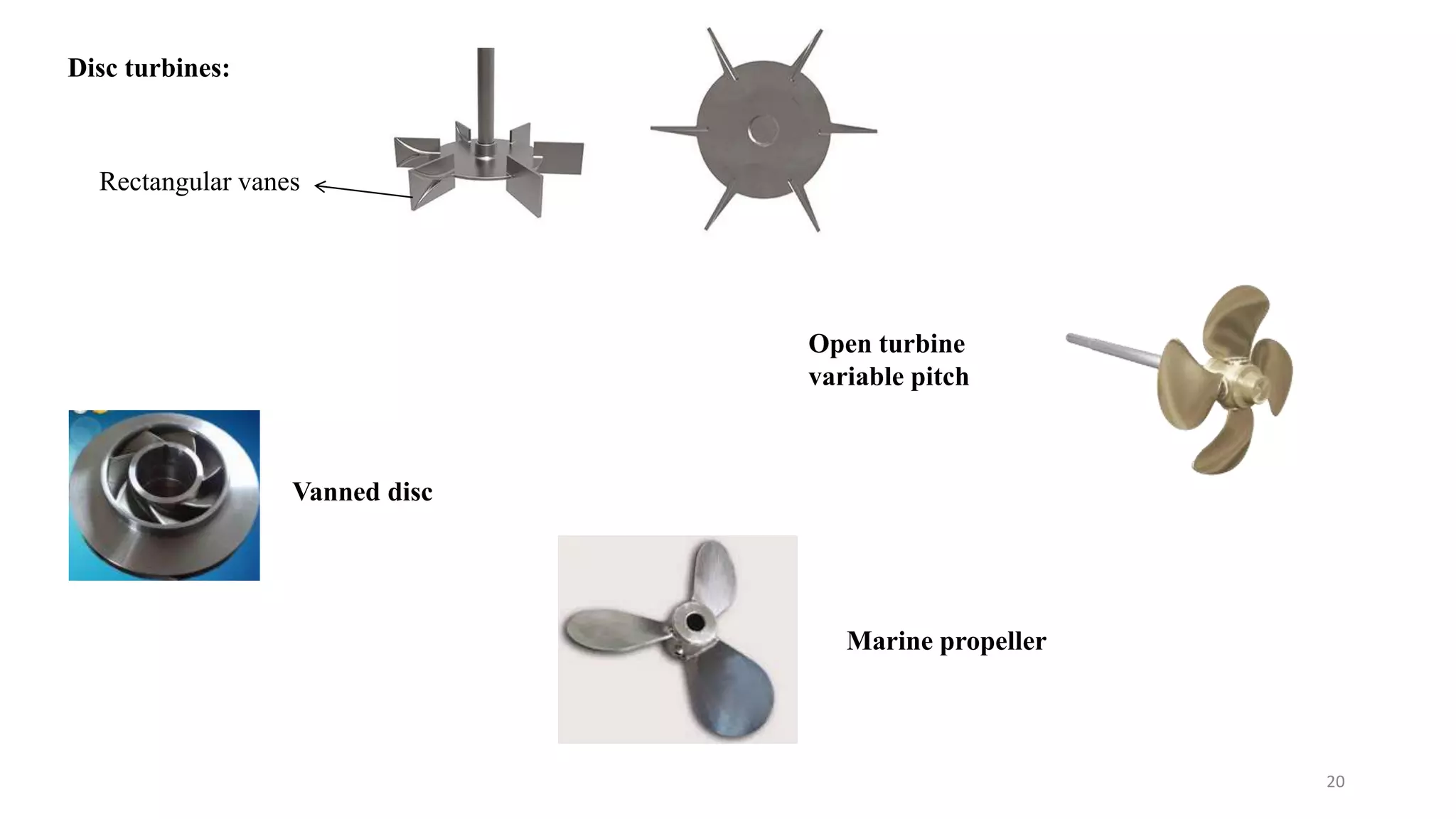

This document provides an overview of bioreactor design and control, detailing the types of bioreactors, their functions, and the factors influencing their performance. It discusses the historical context, development of fermenters, and specific engineering considerations for optimal operation, including temperature control and agitation. Additionally, it highlights various materials and designs used in bioreactor construction for efficient biochemical processes.