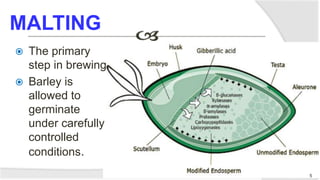

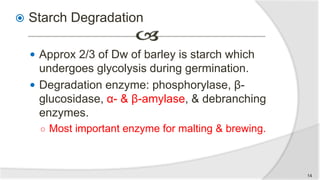

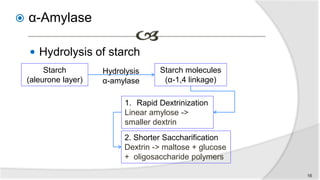

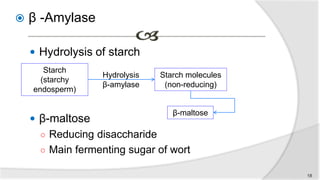

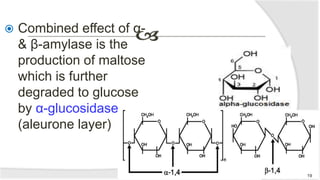

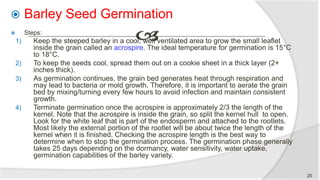

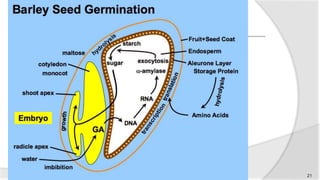

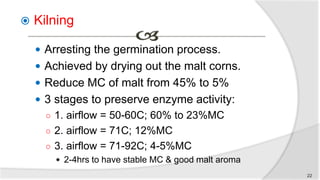

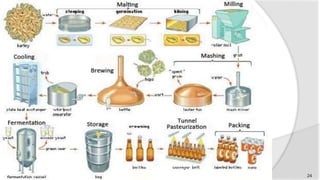

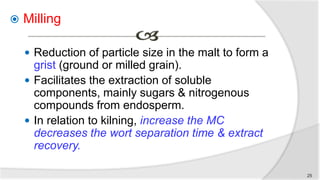

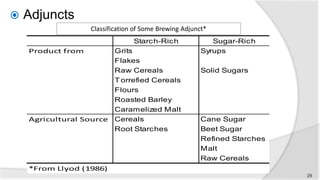

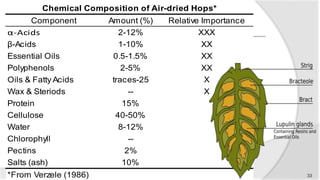

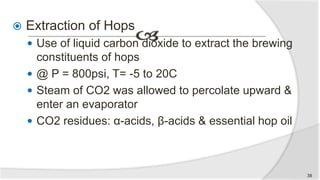

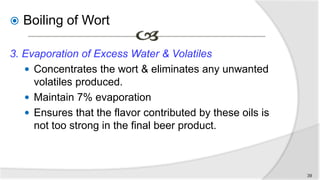

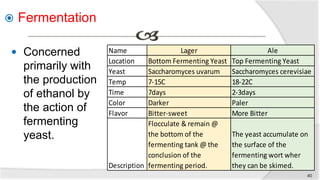

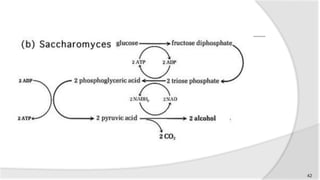

The document provides an overview of the malting and brewing processes. It discusses the steps of malting barley, including steeping, germination, and kilning. In brewing, the milled malt is mashed to extract sugars, then the wort is boiled for sterilization and extraction of bitterness and flavors from hops. Various enzymes degrade starch into fermentable sugars during these processes. The beer is then fermented with yeast to produce the final alcoholic beverage.