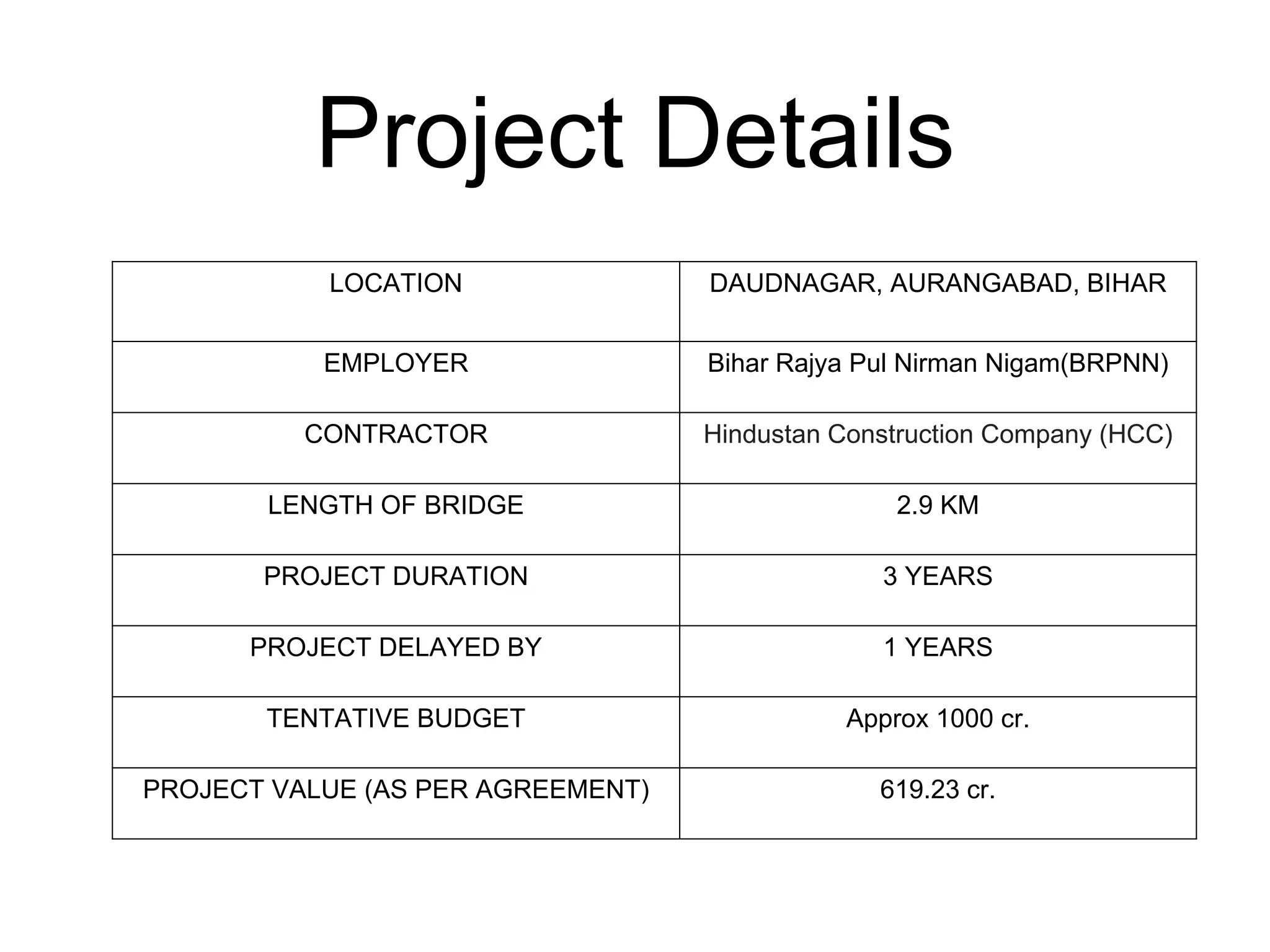

Bihar Rajya Pul Nirman Nigam (BRPNN) was established in 1975 as a government company to facilitate infrastructure development in Bihar, while HCC has executed notable projects across India. A key project involves constructing a high-level bridge connecting Daudnagar and Nasirganj with an estimated budget of 619.23 crore INR, which has faced a one-year delay. The construction employs advanced methodologies and promotes quality management to ensure effective execution and adherence to standards.

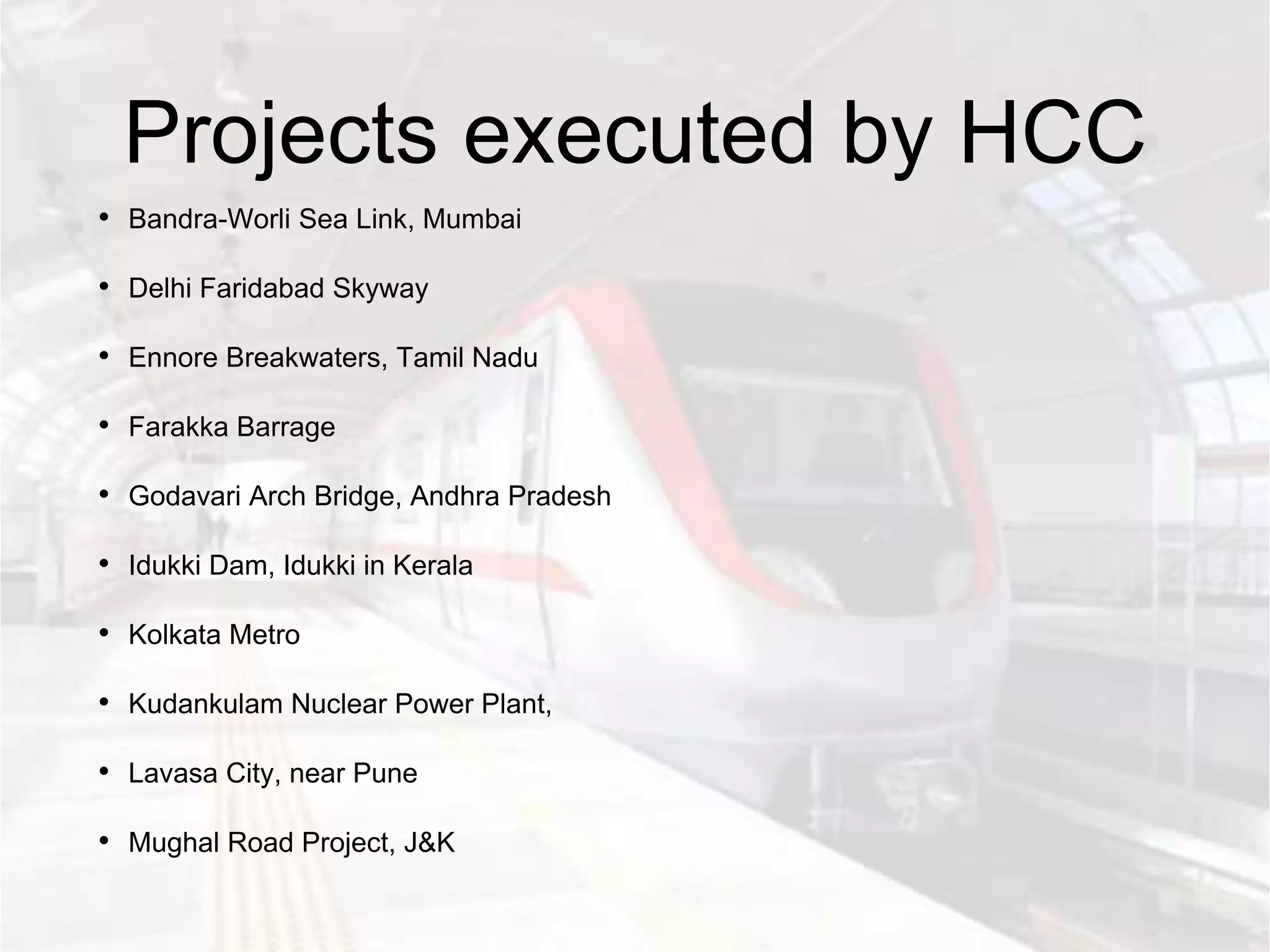

![• Mumbai Pune Expressway

• Nathpa Jhakri Hydroelectric Project: Head Race Tunnel and Surge Shaft

• Nimoo Bazgo Hydel Power Project, J&K

• Pir Panjal Rail Tunnel, J&K

• Rajasthan Atomic Power Plant, Rajasthan

• Aditya Aluminium Project, Sambalpur, ODISHA

• West Bengal Highway Project [NH-34]

• Parama Island Flyover, Kolkata

Projects executed by HCC](https://image.slidesharecdn.com/sujeethcc-190108043249/75/Bihar-Rajya-Pul-Nirman-Nigam-5-2048.jpg)