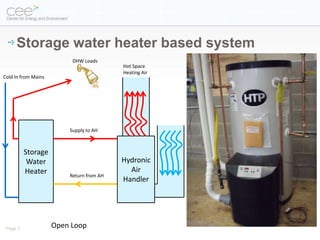

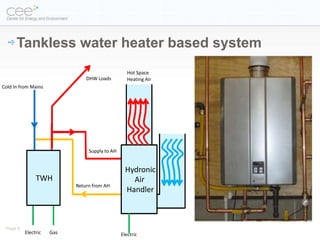

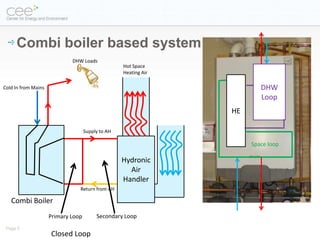

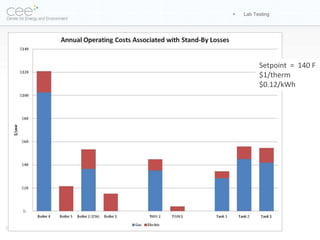

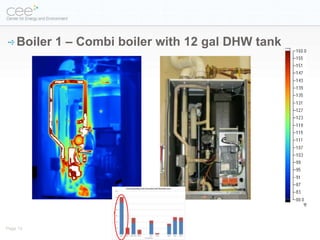

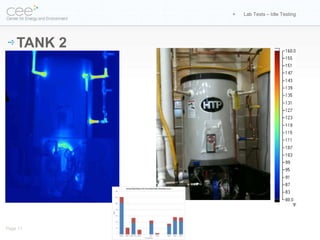

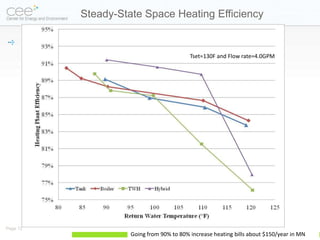

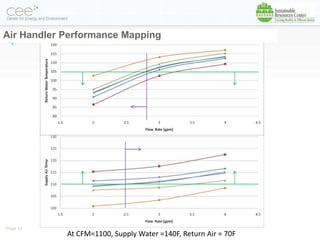

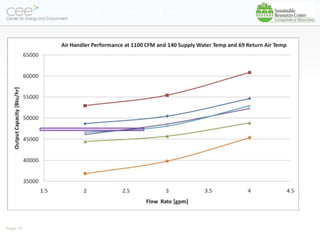

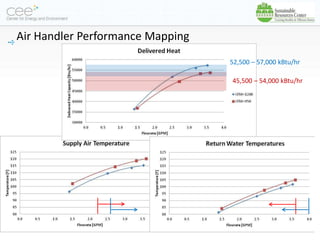

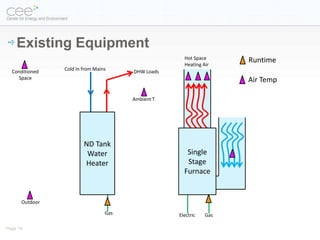

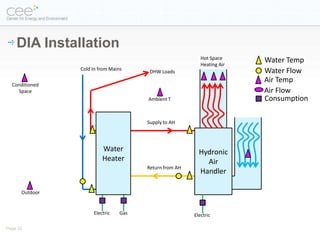

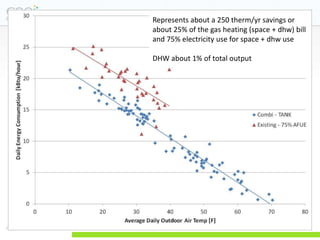

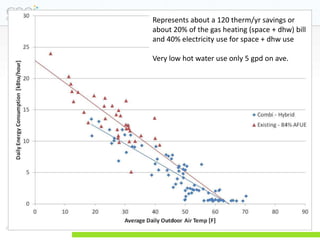

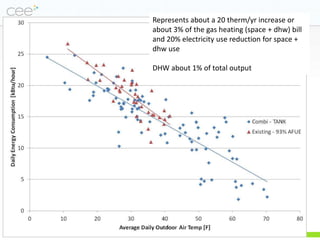

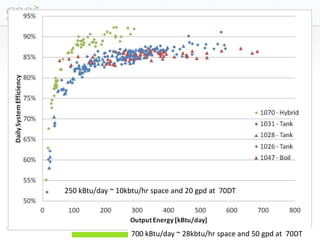

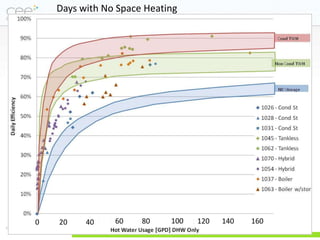

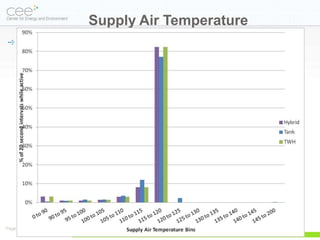

This document discusses research into combining residential space and water heating using a distributed integrated air (DIA) system. It describes how tighter homes require sealed combustion, which has led to installing less efficient water heaters for safety. The research aims to design DIA systems in a lab to provide optimal performance and installation guidelines. Lab testing analyzed idle losses, efficiencies, and full system tests of different DIA designs. Field studies of 300 homes are monitoring installed costs, savings, and system efficiencies to better understand the real-world potential of the DIA approach. Preliminary results suggest gas savings of 20-25% and electricity reductions of 40-75% compared to typical existing equipment.