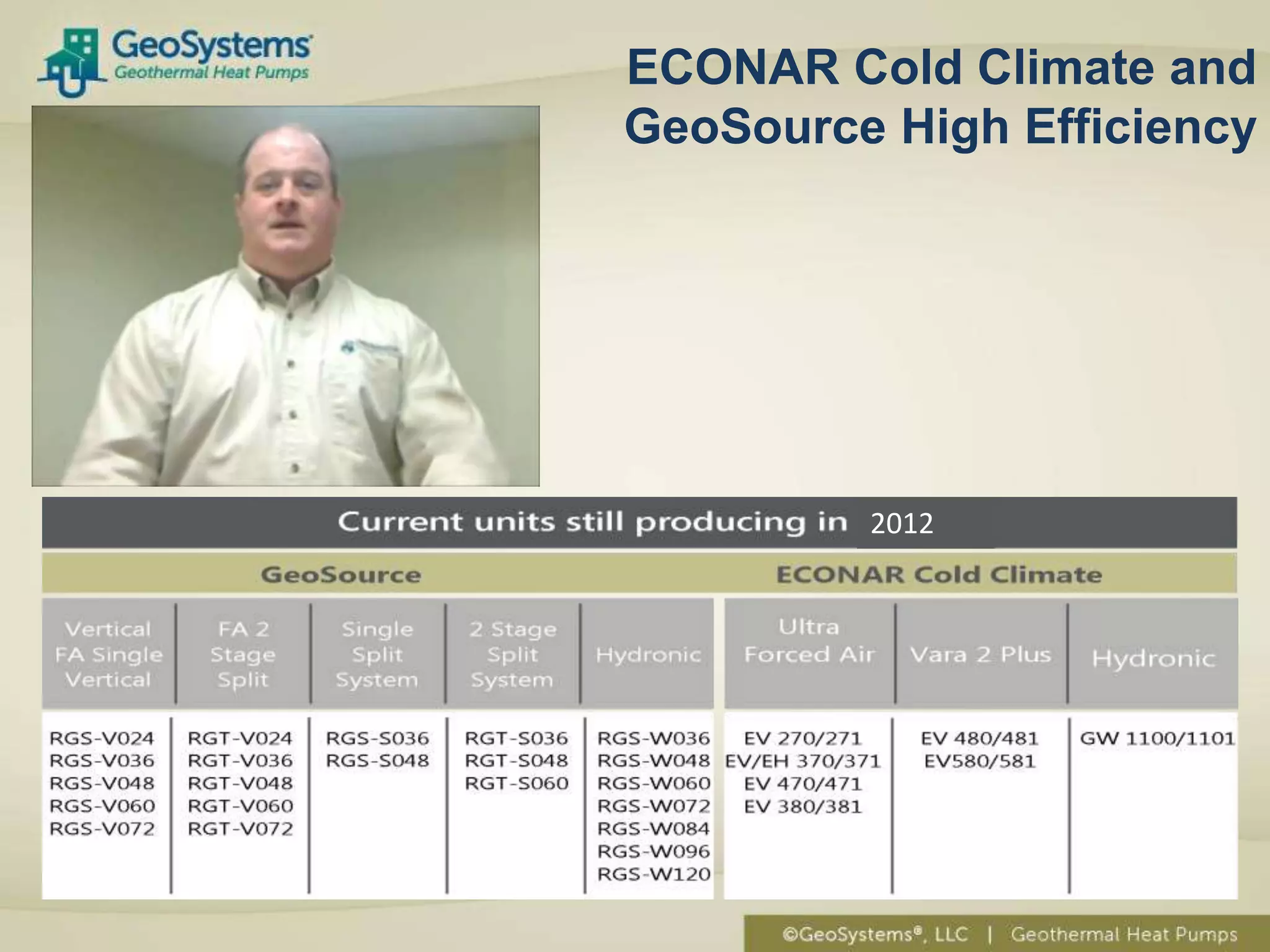

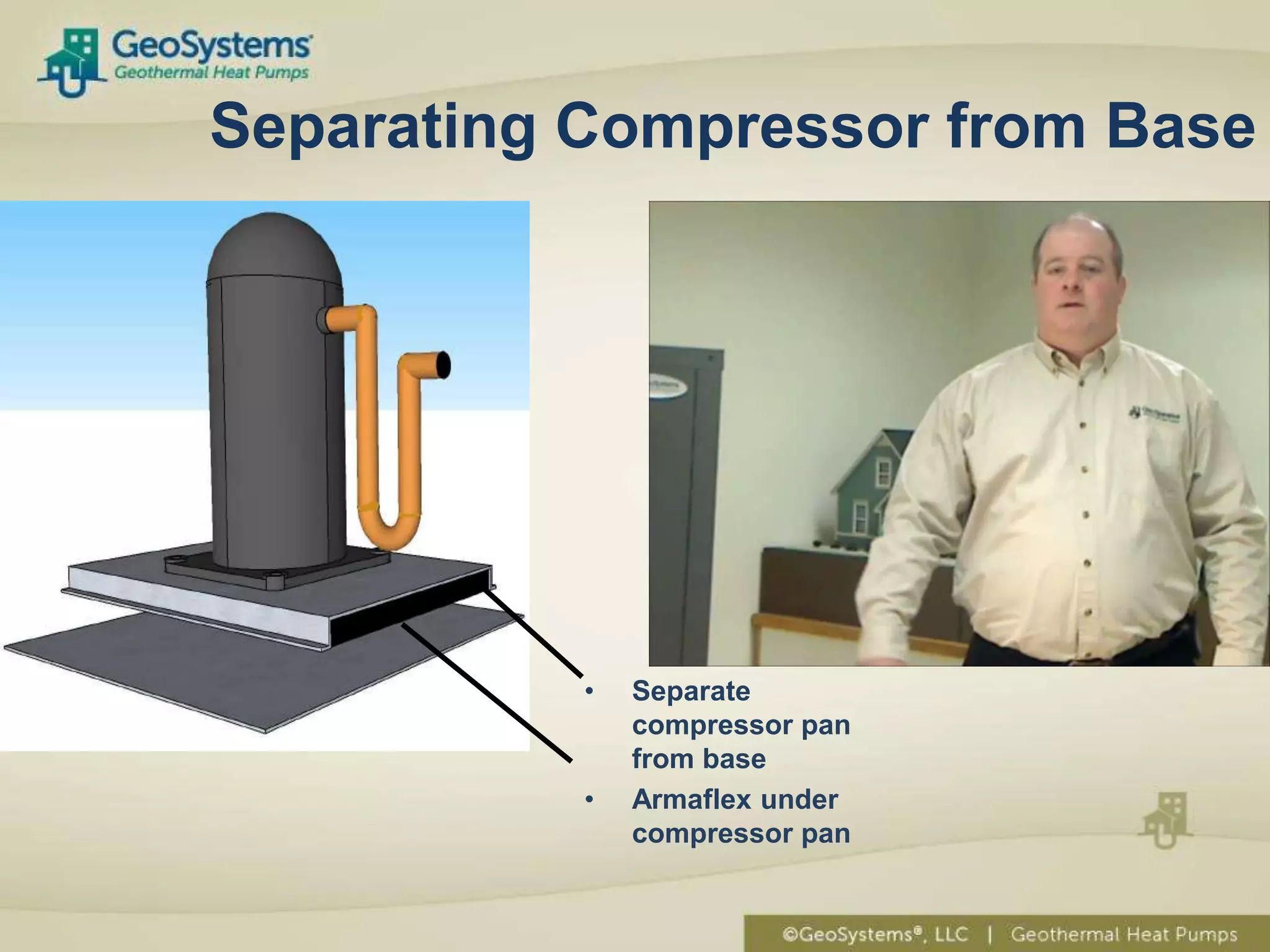

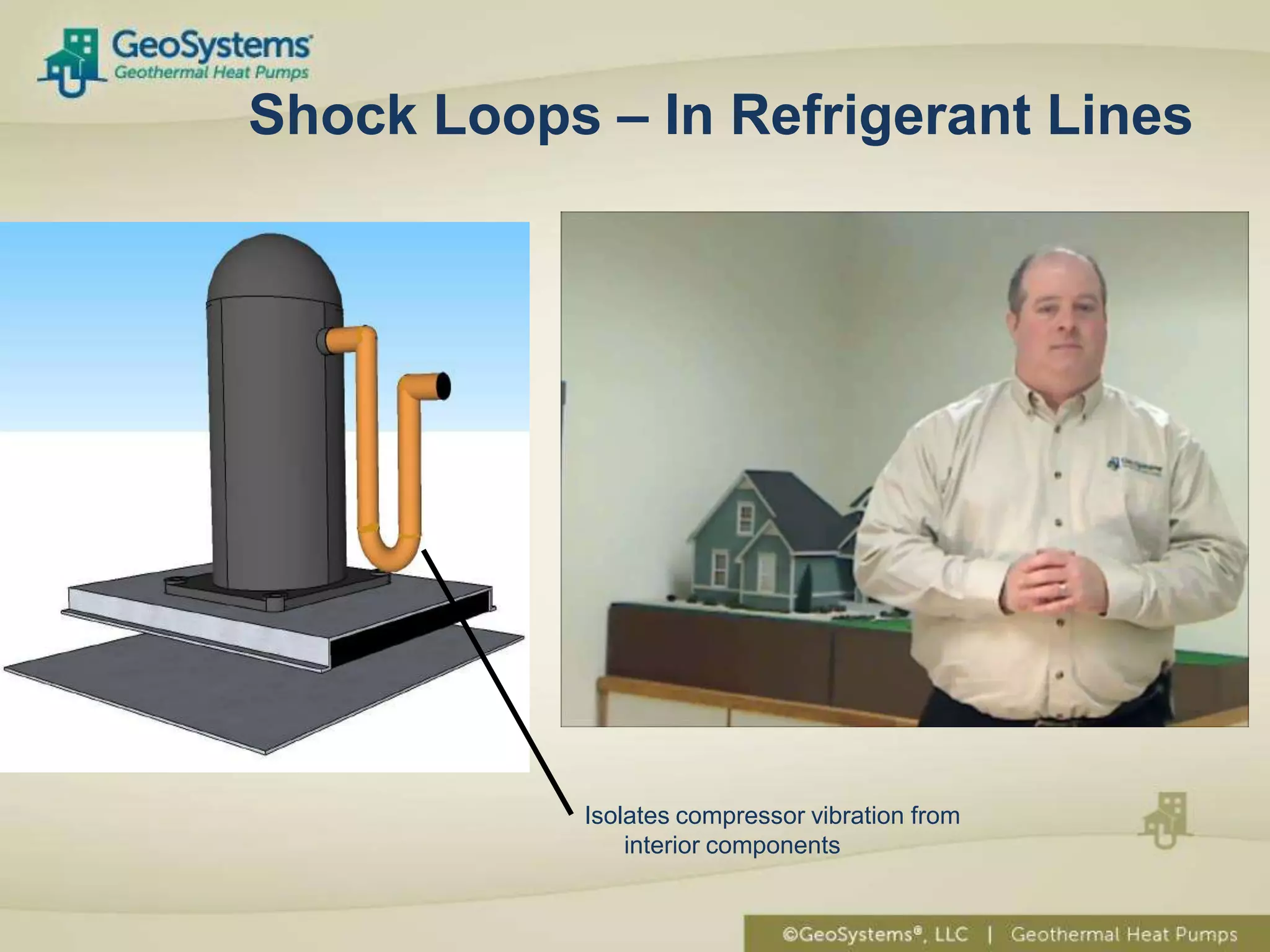

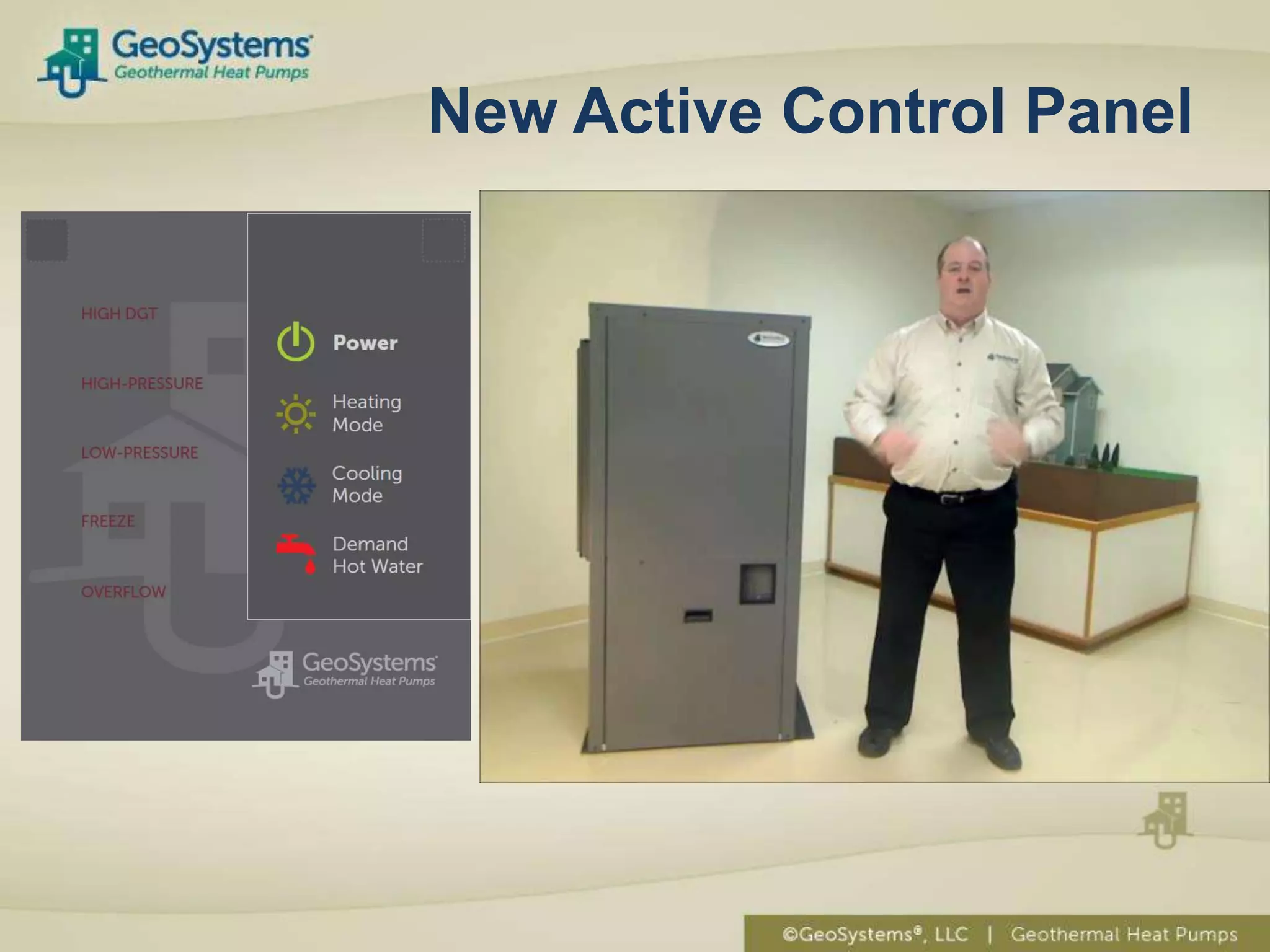

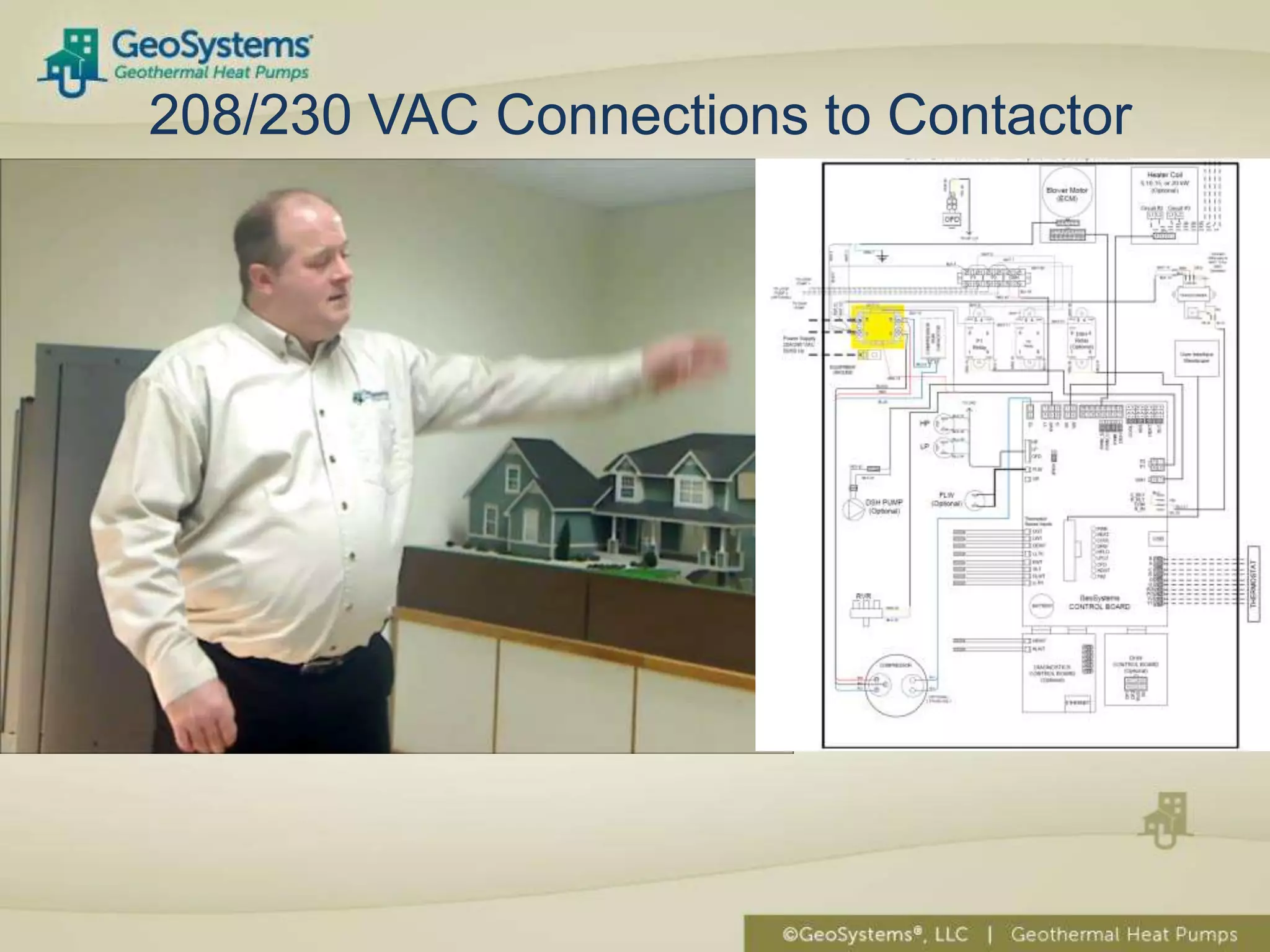

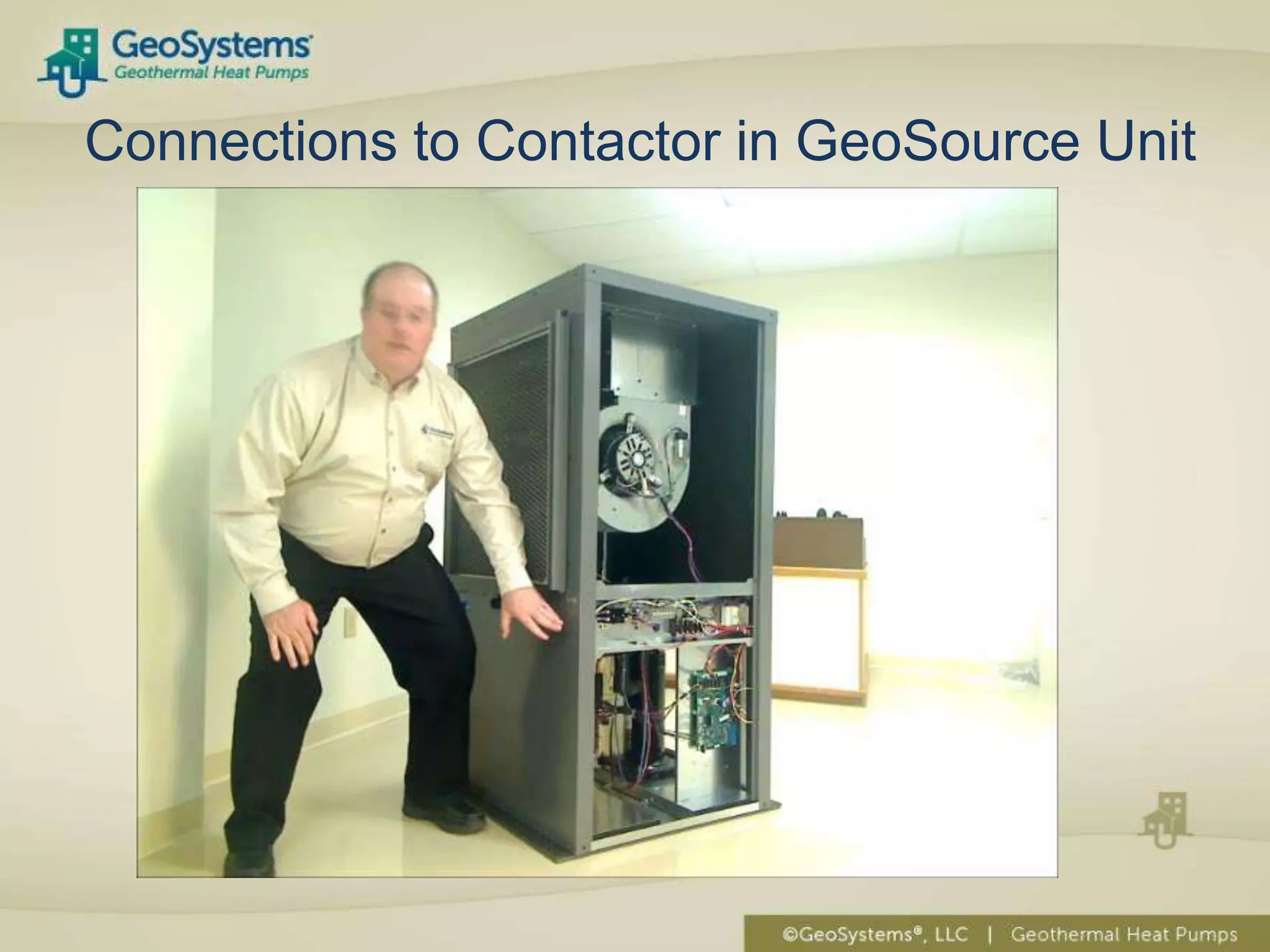

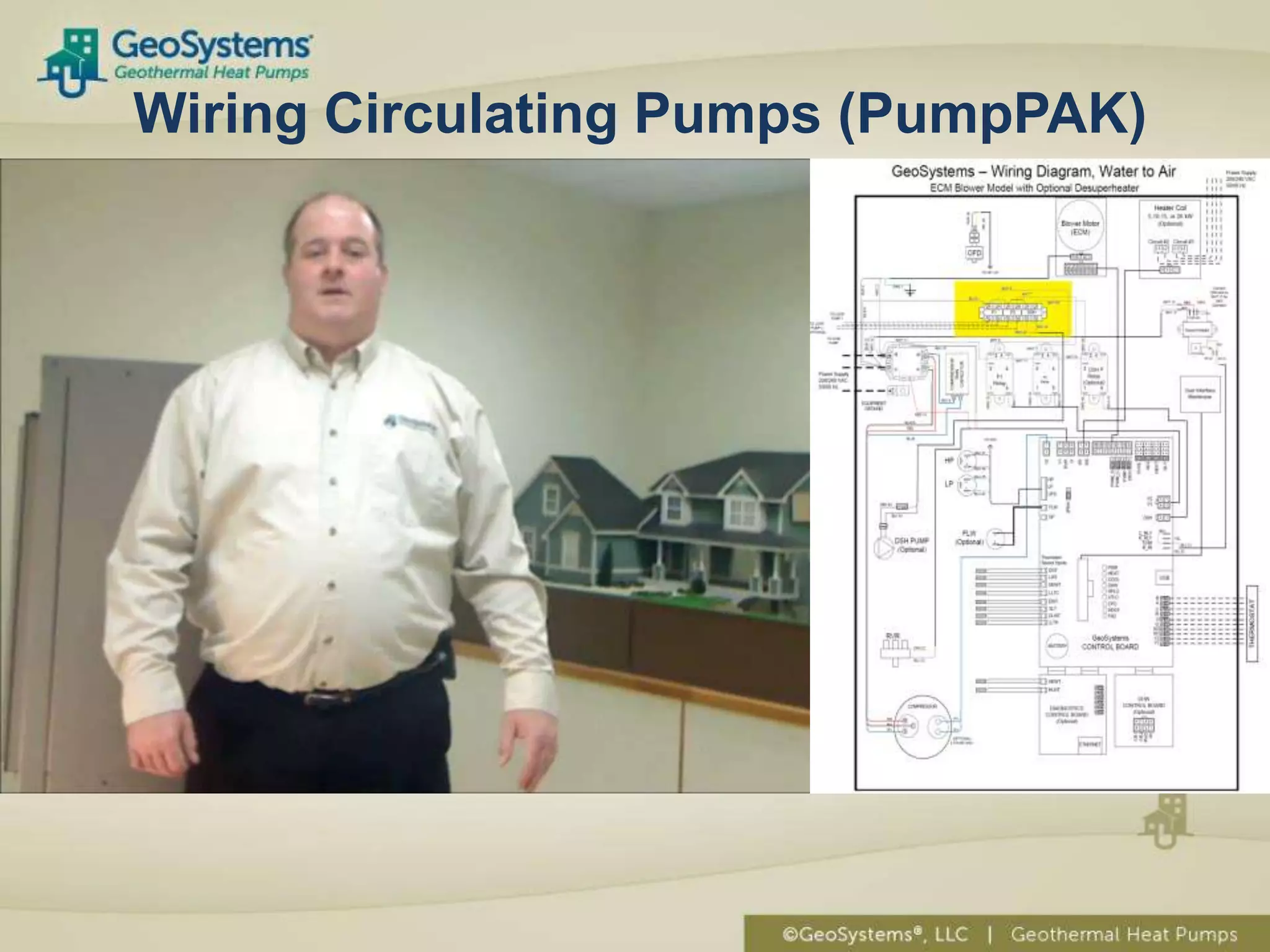

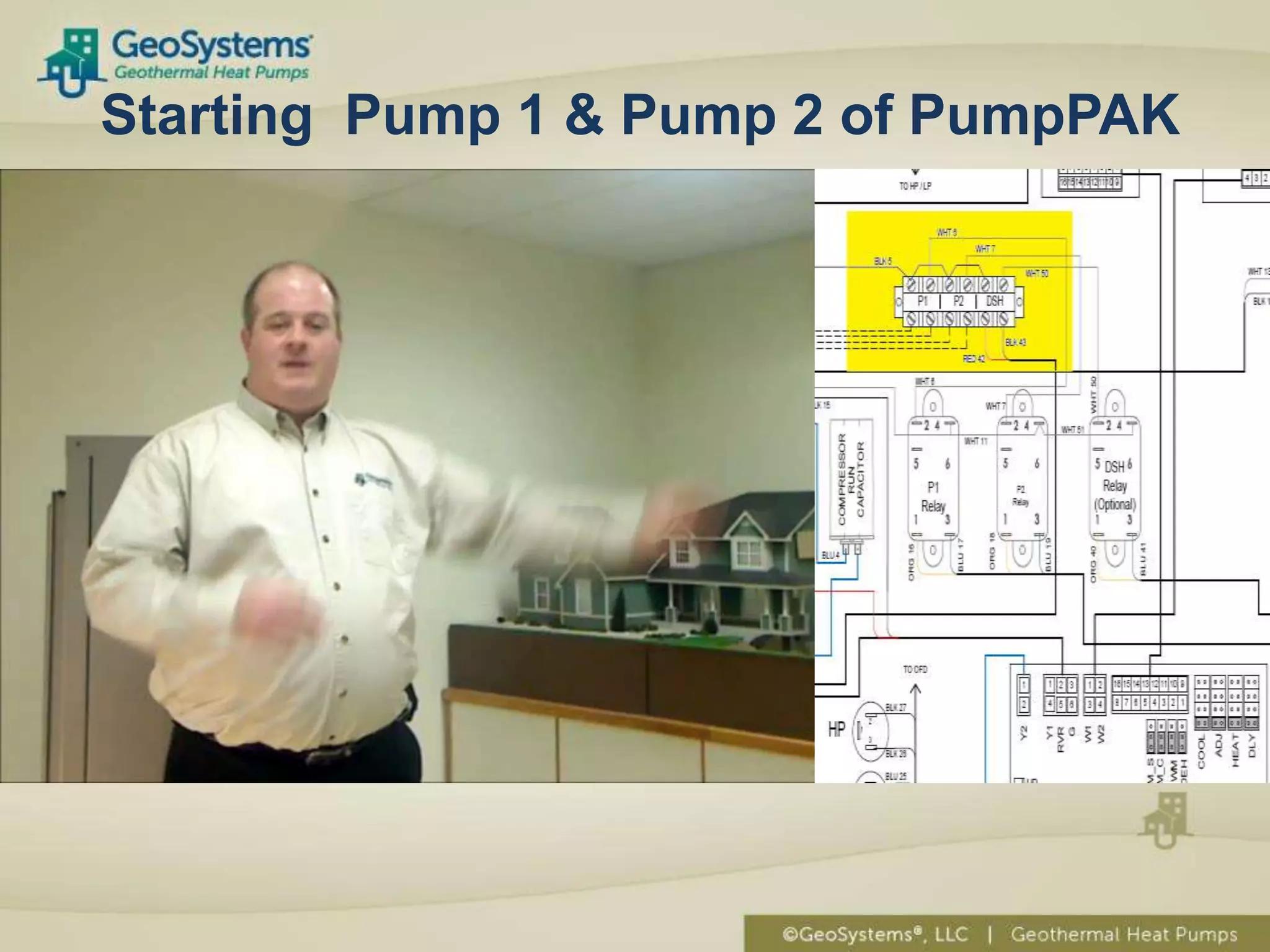

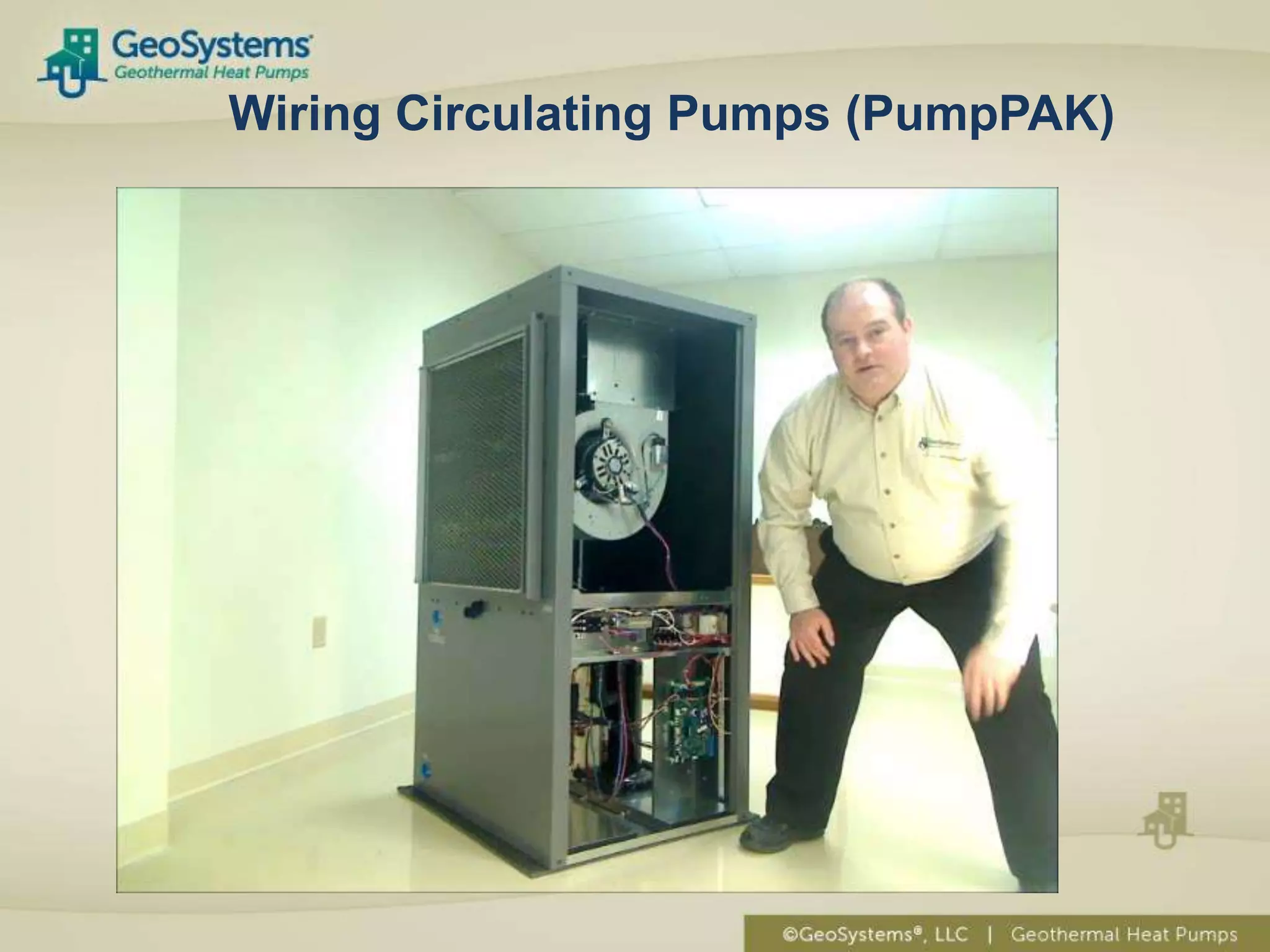

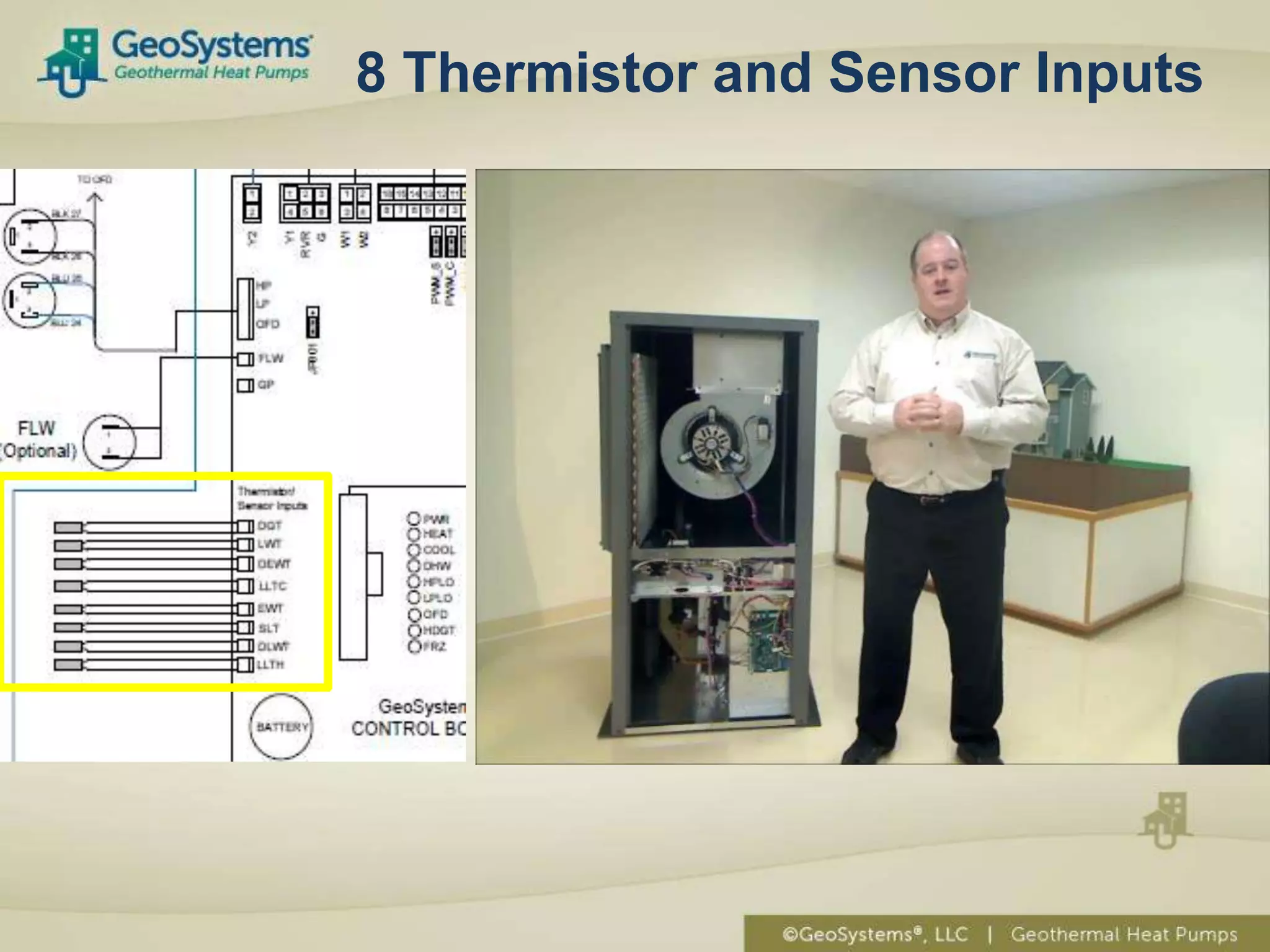

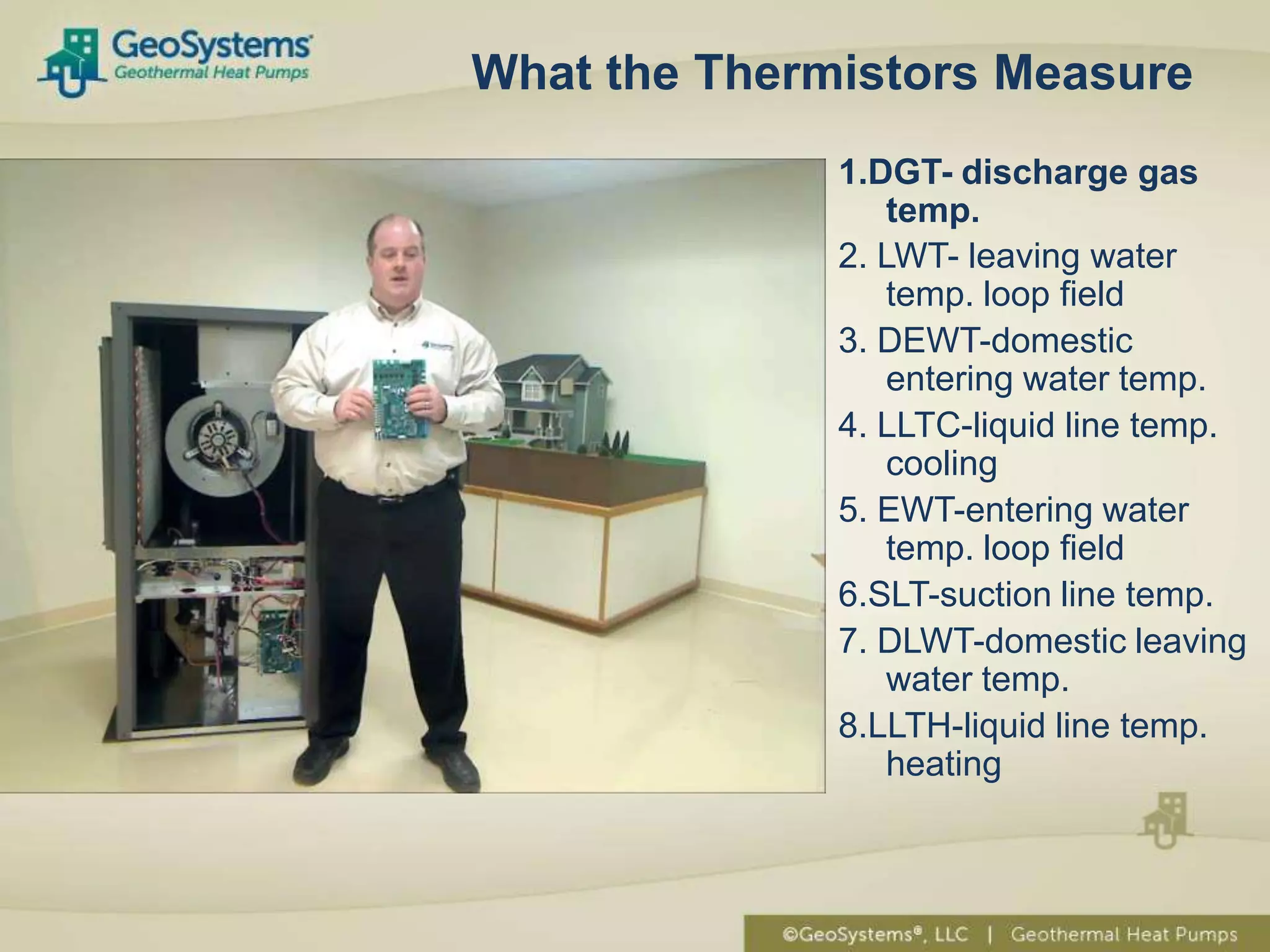

Jeff Johnson will provide training on GeoSystems' new geothermal heat pump product lines, the ECONAR Cold Climate and GeoSource High Efficiency. The training will cover the new cabinet designs, components, and control systems, including installation of circulating pumps, thermistor inputs, and operating the control interface. The technical update aims to familiarize trainees with the new product offerings and review installation and operation.