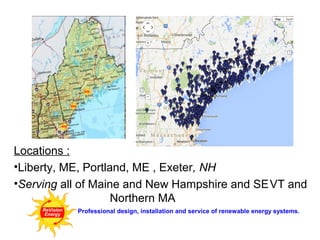

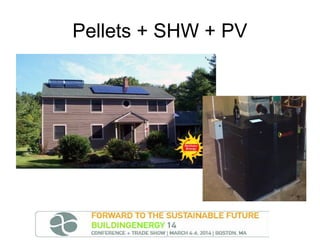

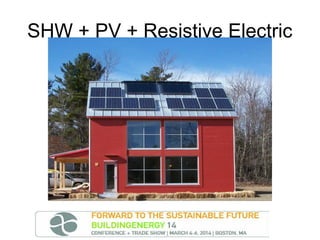

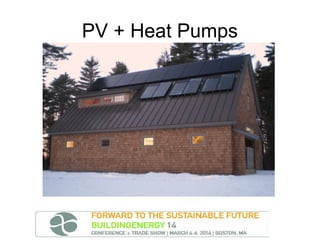

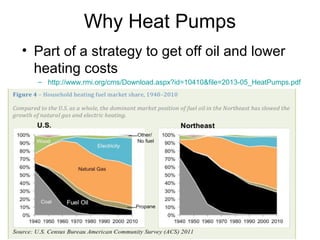

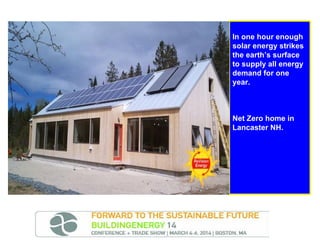

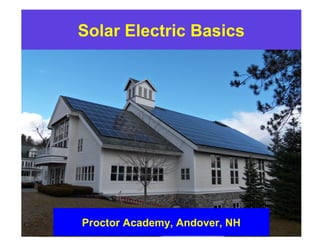

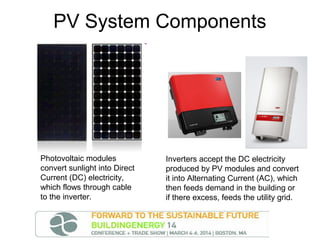

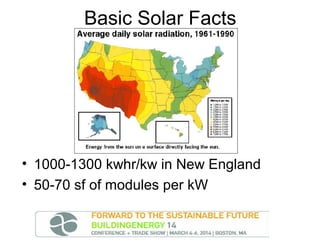

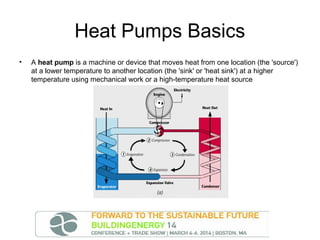

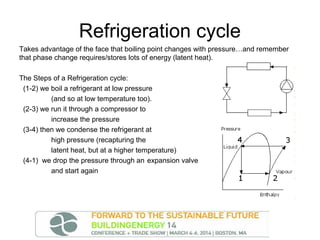

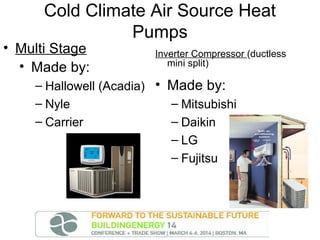

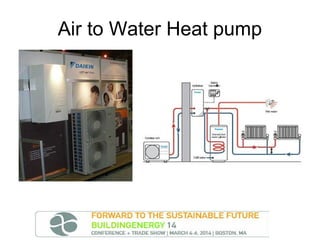

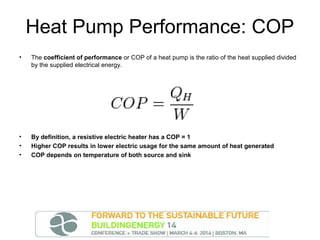

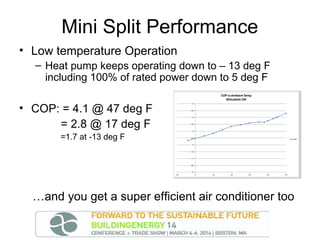

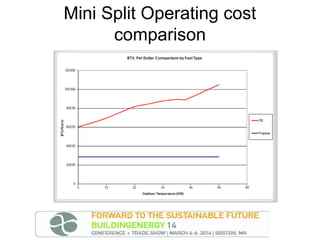

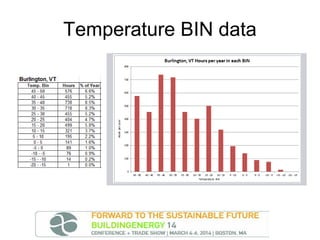

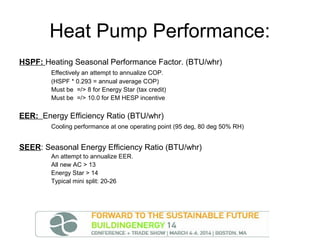

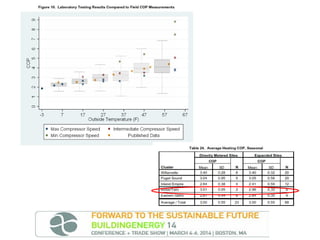

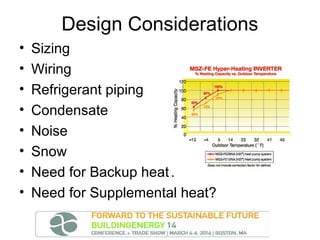

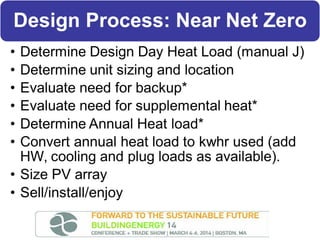

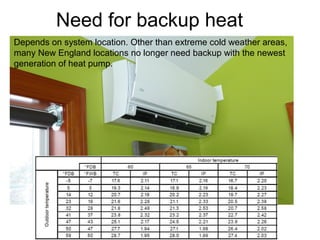

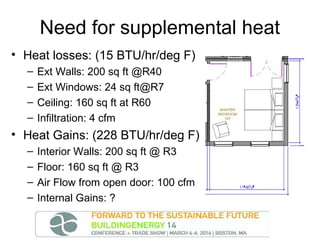

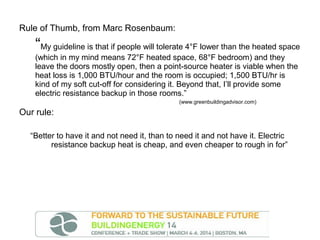

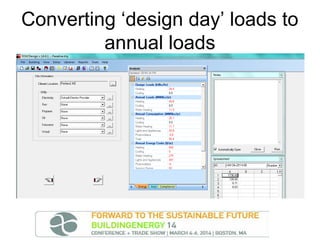

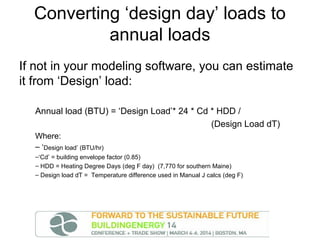

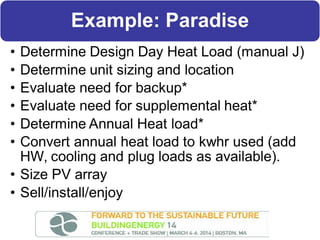

The document discusses net zero heating solutions, highlighting the role of heat pumps and photovoltaic (PV) systems in achieving energy efficiency. Revision Energy, a leader in renewable energy installations in Northern New England, emphasizes the importance of designing systems that allow buildings to produce as much energy as they consume on an annual basis. Key topics include the functioning of PV systems, heat pump technologies, and considerations for achieving net zero energy use in residential buildings.