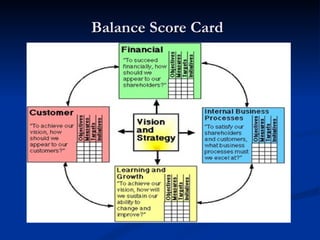

The document discusses various contemporary management practices such as MIS, end user computing, materials requirement planning, just in time manufacturing, total quality management, six sigma, capability maturity model, supply chain management, enterprise resource planning, performance management, business process outsourcing, business process reengineering, benchmarking, and balanced scorecard. It provides details on the objectives, methodologies, benefits, and key aspects of each of these management practices.

![BENEFITS OF JIT

Quality consciousness

Reduced scrap

Reduced cycle times

Smoother flow of production]

Low inventory

High productivity

High worker participation

Reduced space requirements](https://image.slidesharecdn.com/unitviii-120411113705-phpapp01/85/Unit-viii-8-320.jpg)