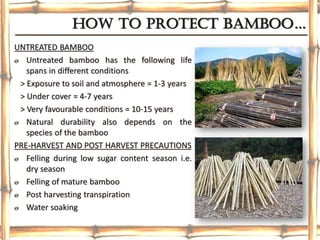

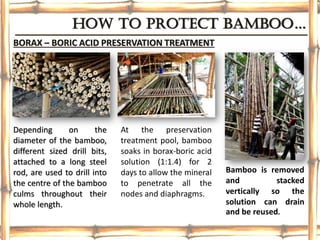

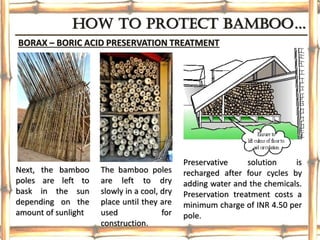

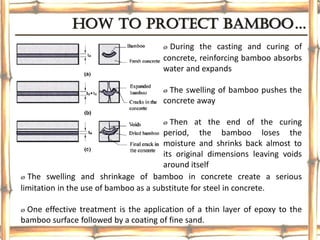

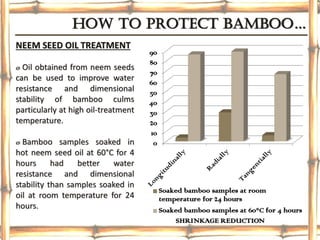

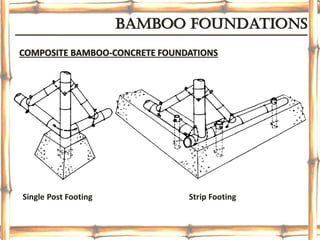

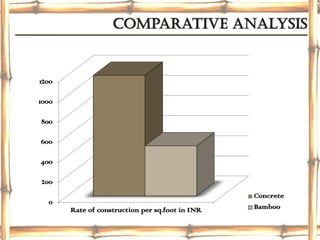

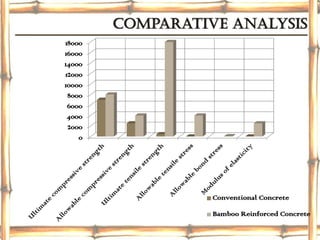

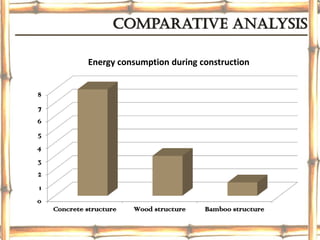

Bamboo is a versatile building material with several advantages like strength, flexibility, earthquake resistance, cost effectiveness and sustainability. However, it also has some limitations like low durability without treatment, issues with shrinkage when used in concrete, and lack of standardized structural design guidance. Various treatment methods can improve bamboo's lifespan, and it has shown great strength and resilience in earthquake-prone areas. When properly harvested, prepared and maintained, bamboo can be a viable alternative to wood and steel in construction.