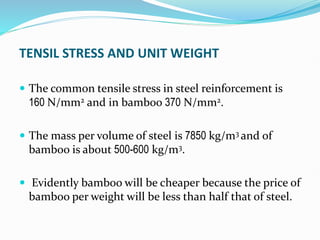

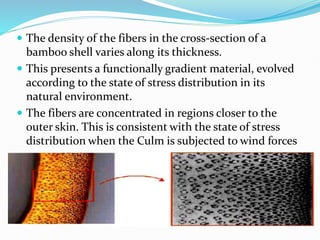

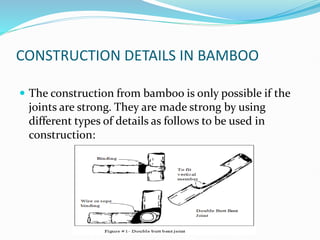

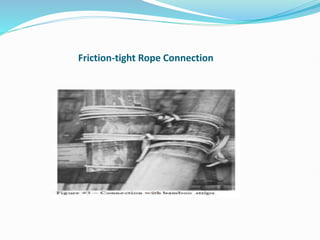

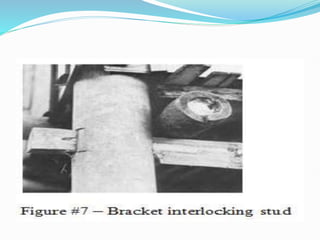

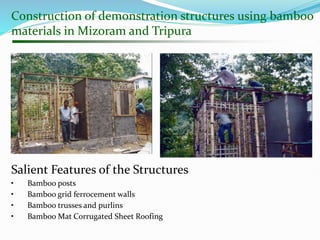

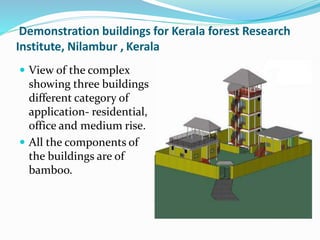

The document discusses the properties and uses of bamboo in construction. It describes bamboo as one of the fastest growing plants, with high tensile strength and low weight compared to steel. The document outlines various uses of bamboo in construction, including for scaffolding, roofing, walling, doors and windows. It also details advantages such as strength, environmental friendliness and low cost. The document provides construction details for bamboo joints and concludes that bamboo is an environmentally friendly and economic material for construction.