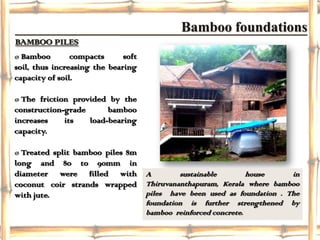

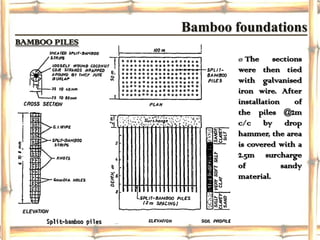

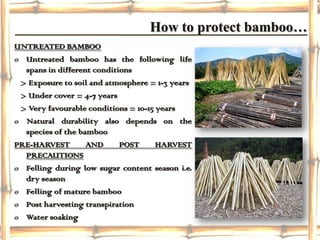

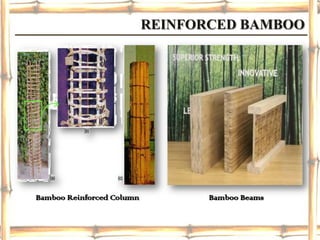

Bamboo is a strong, flexible, sustainable building material that has been used for construction purposes for centuries, however its use has been limited due to a lack of structural design data and exclusion from building codes; the document discusses bamboo's mechanical properties and provides examples of how it can be used for building foundations, walls, roofs, and as reinforcement in concrete as well as methods for protecting bamboo through borax treatment.