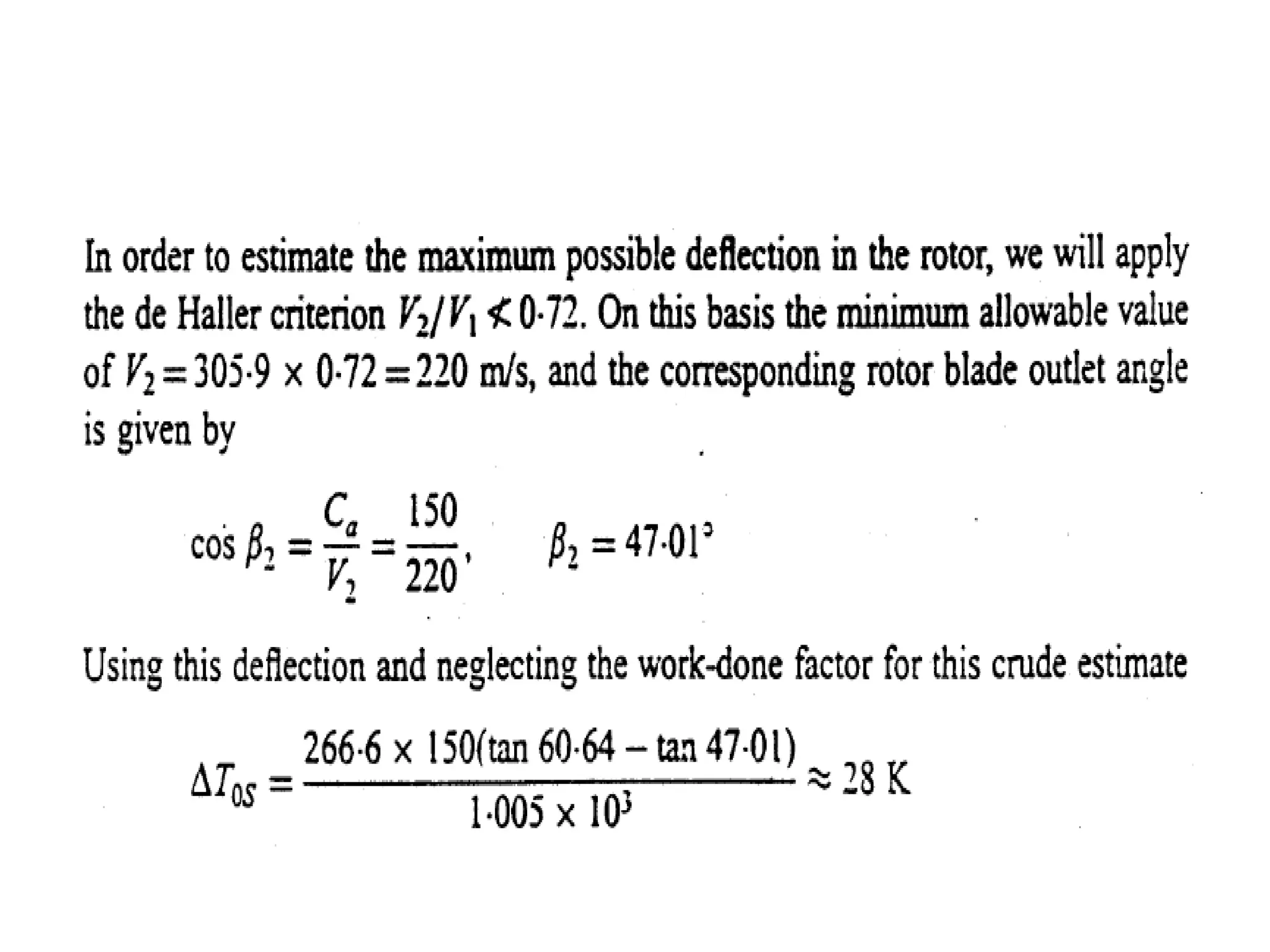

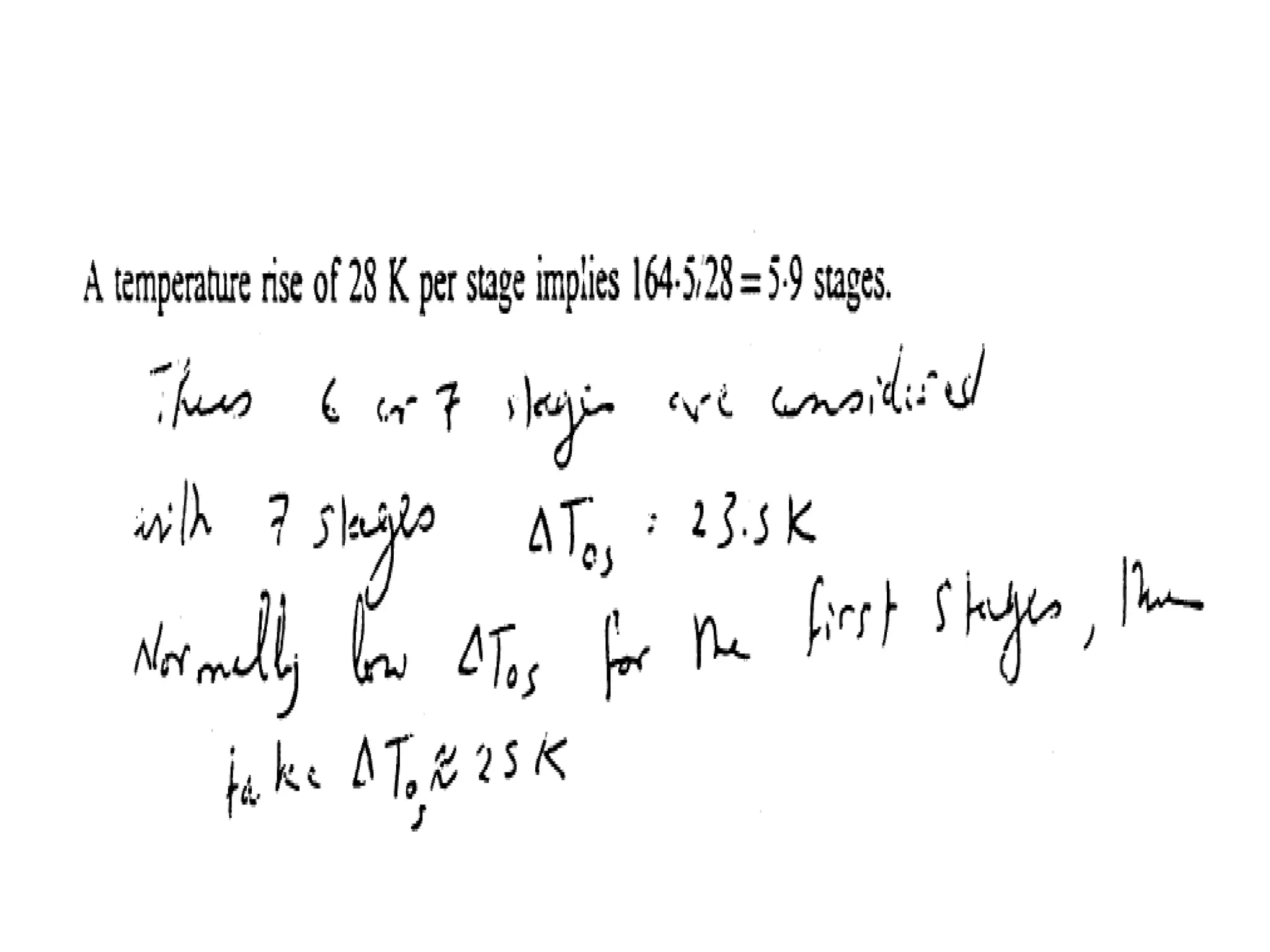

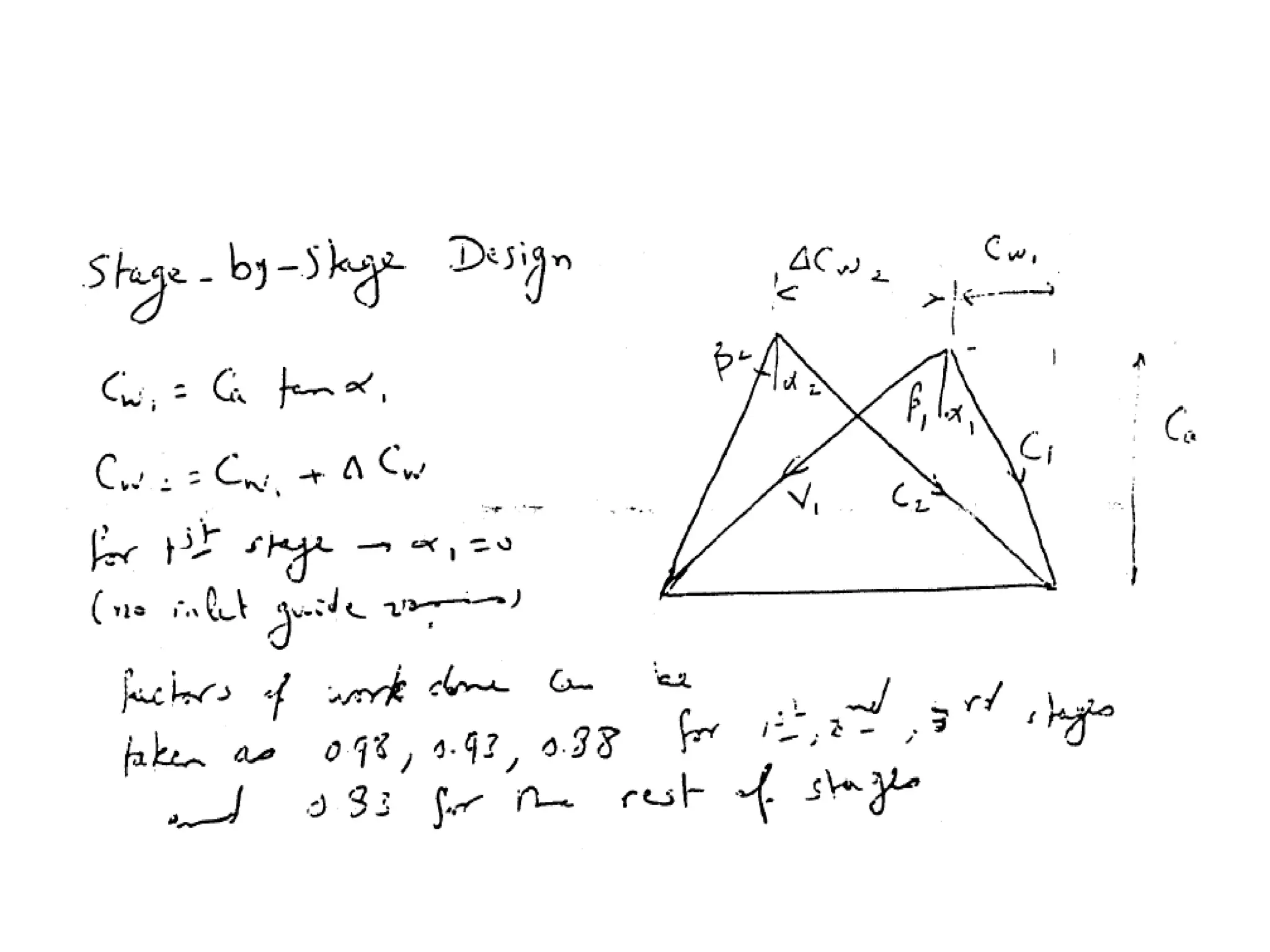

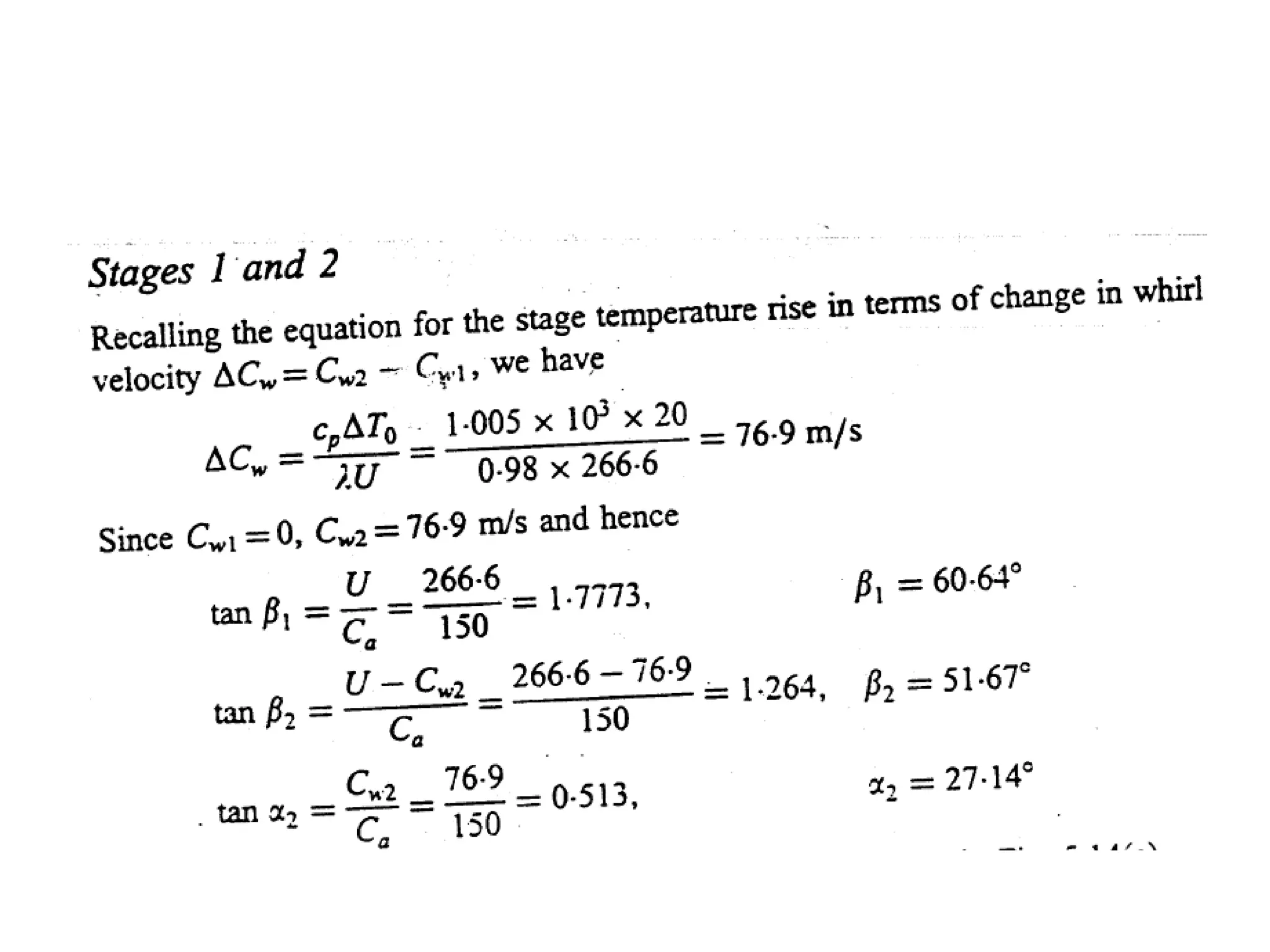

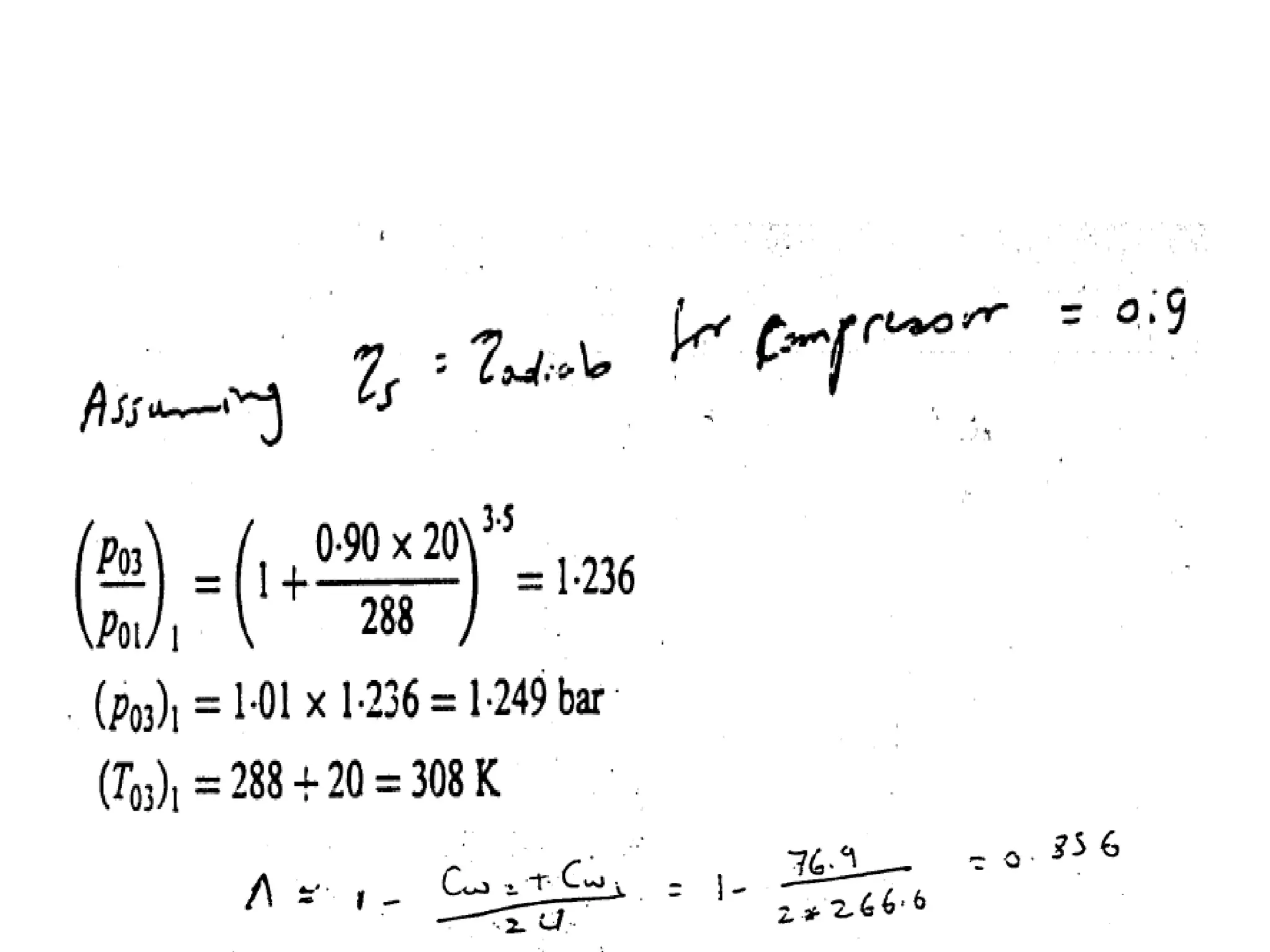

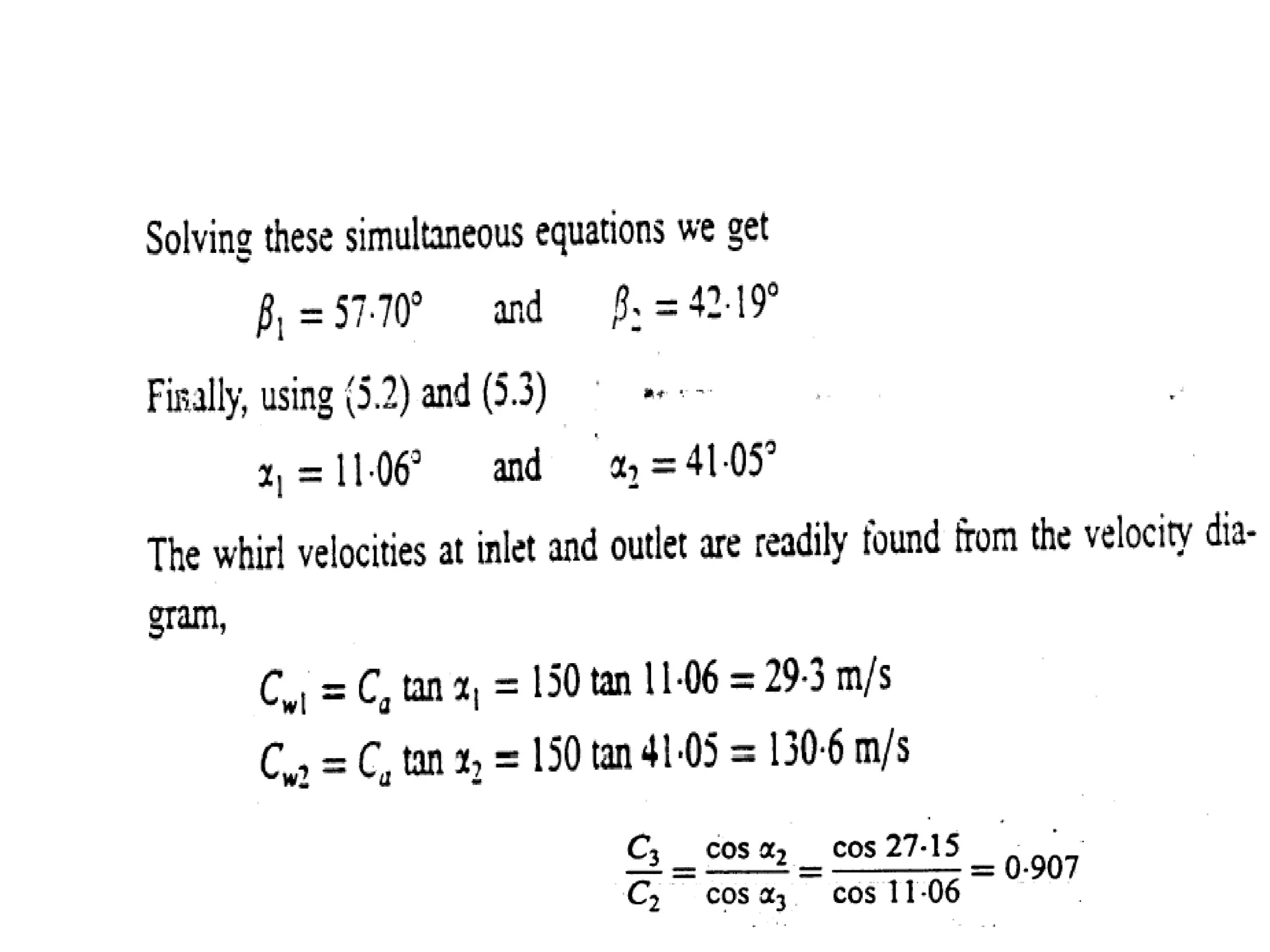

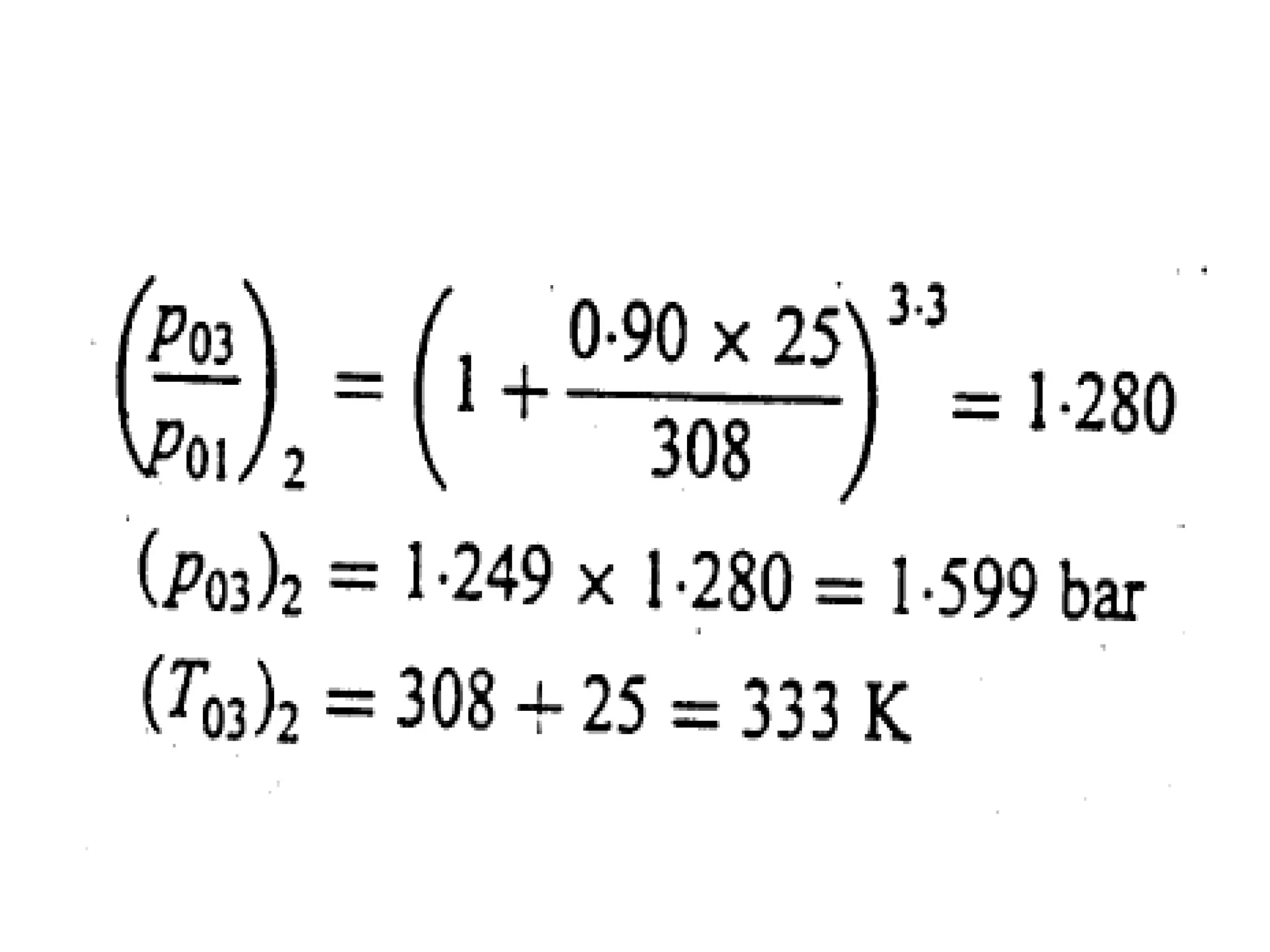

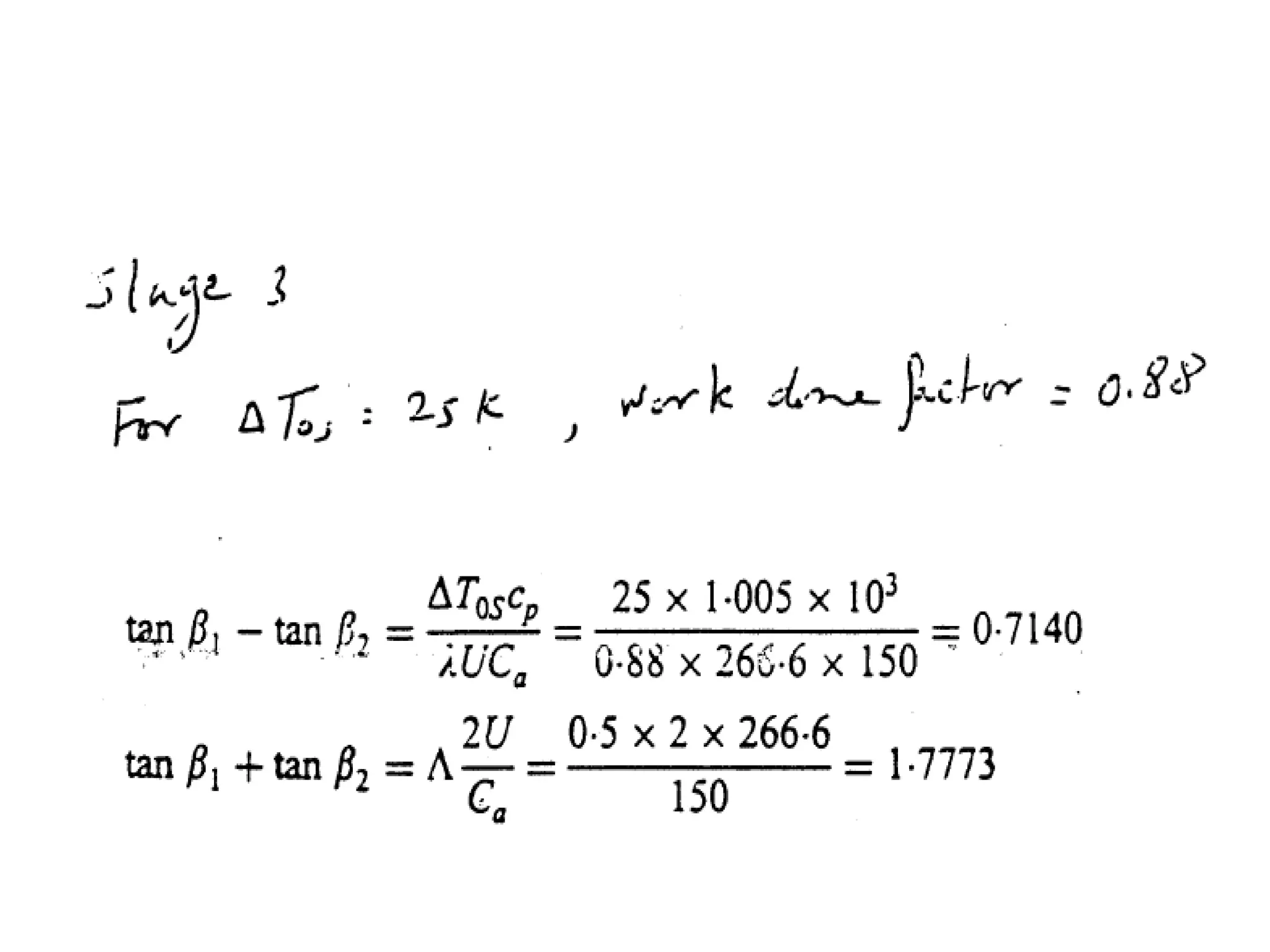

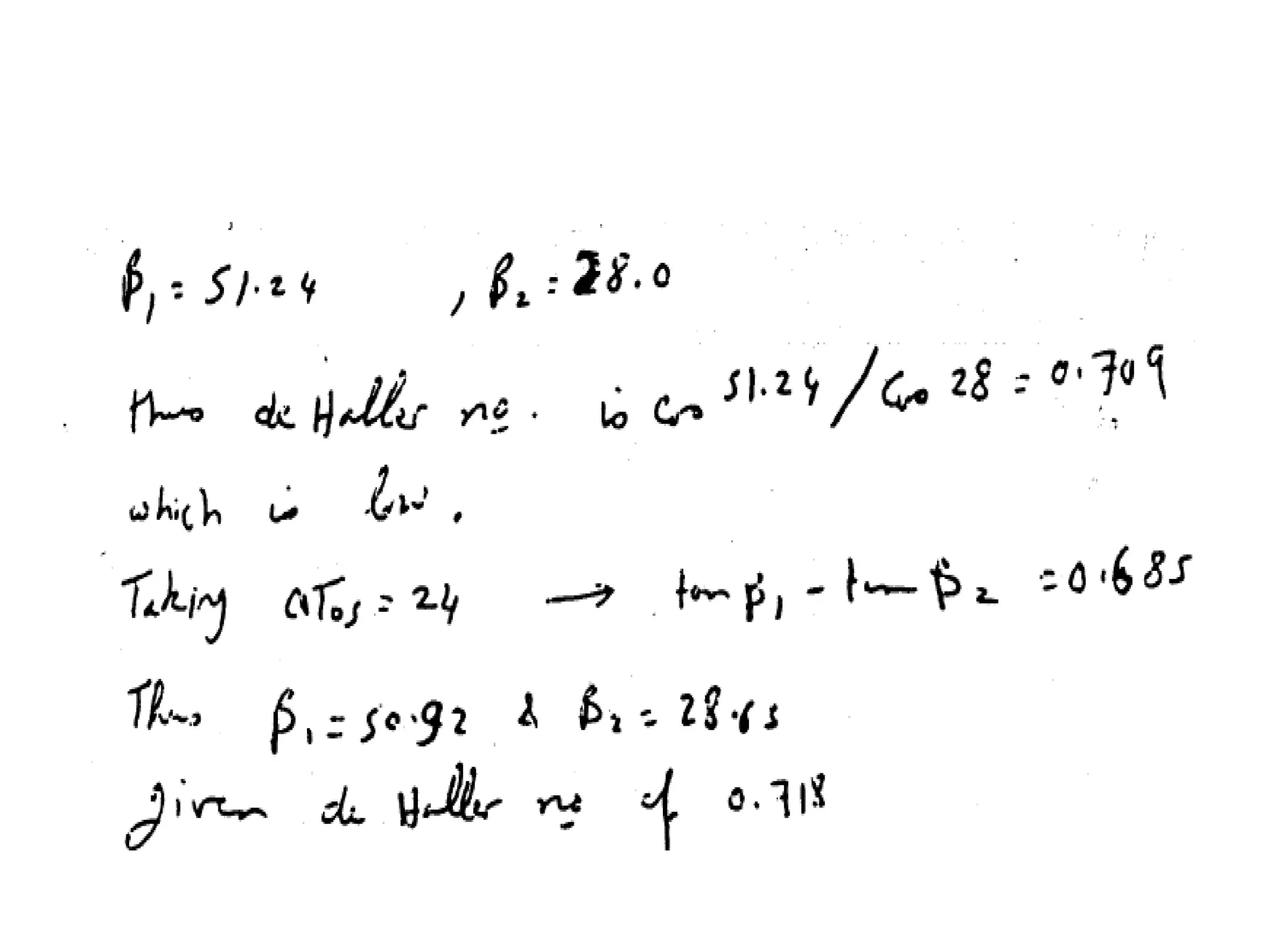

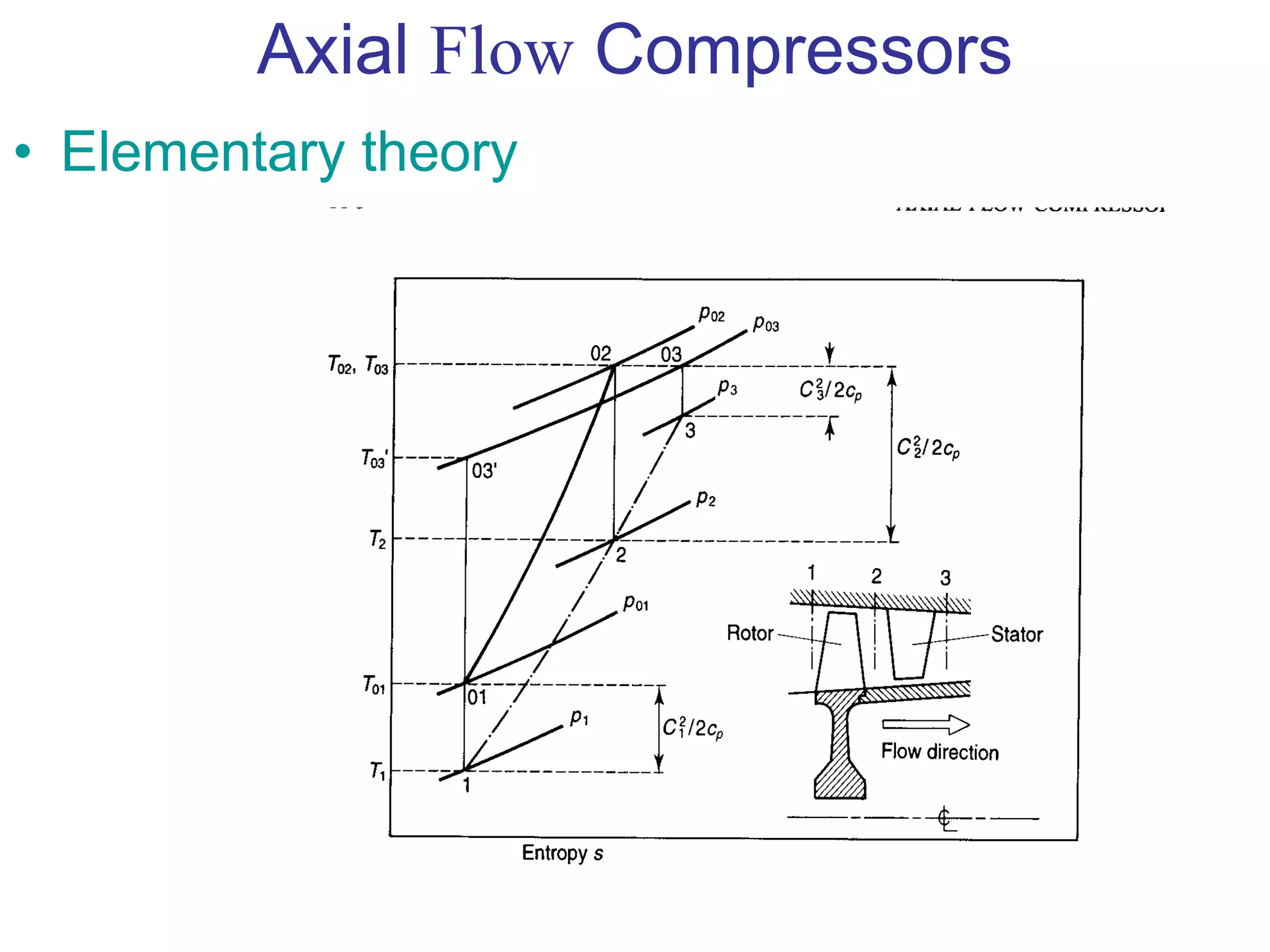

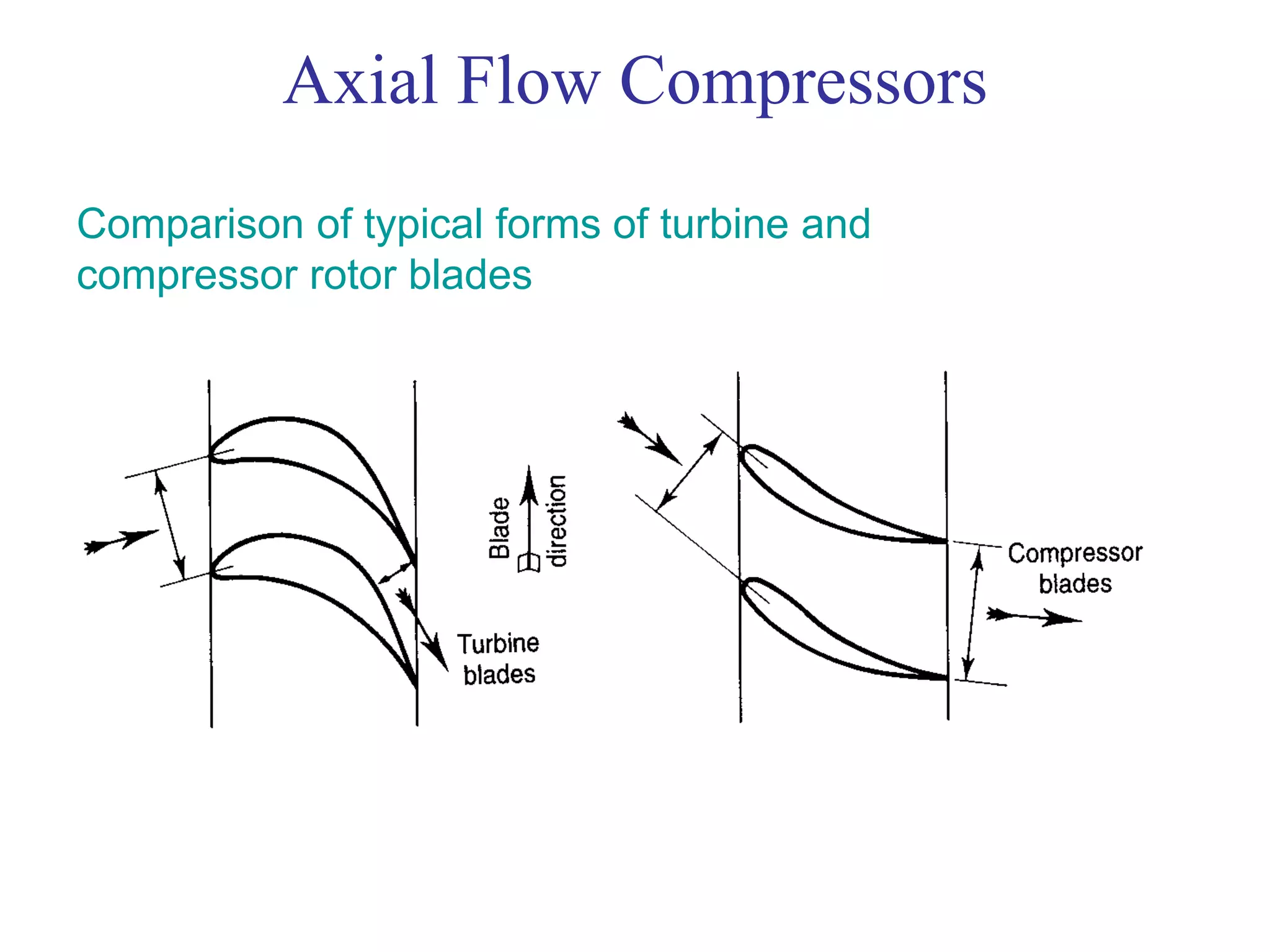

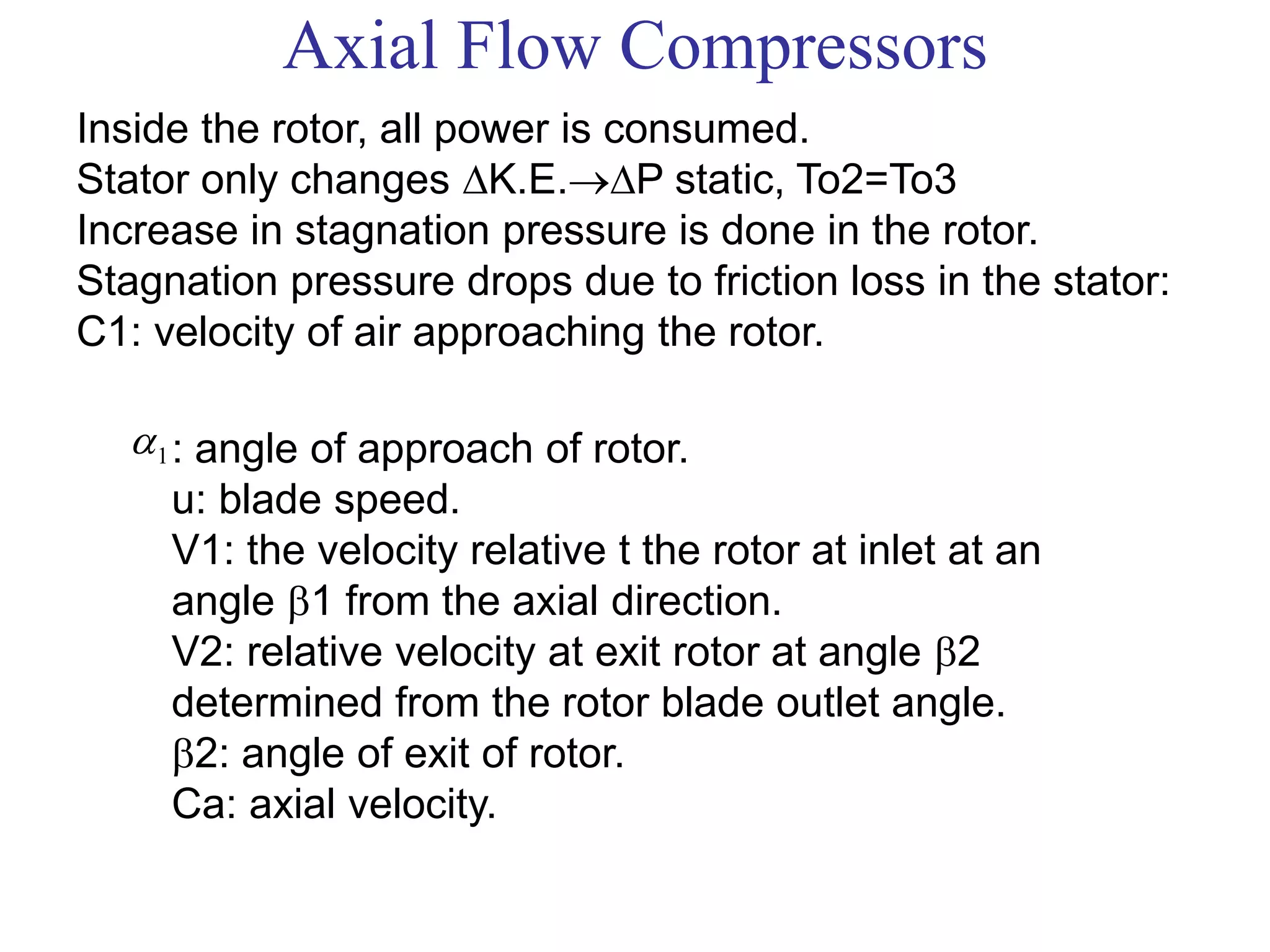

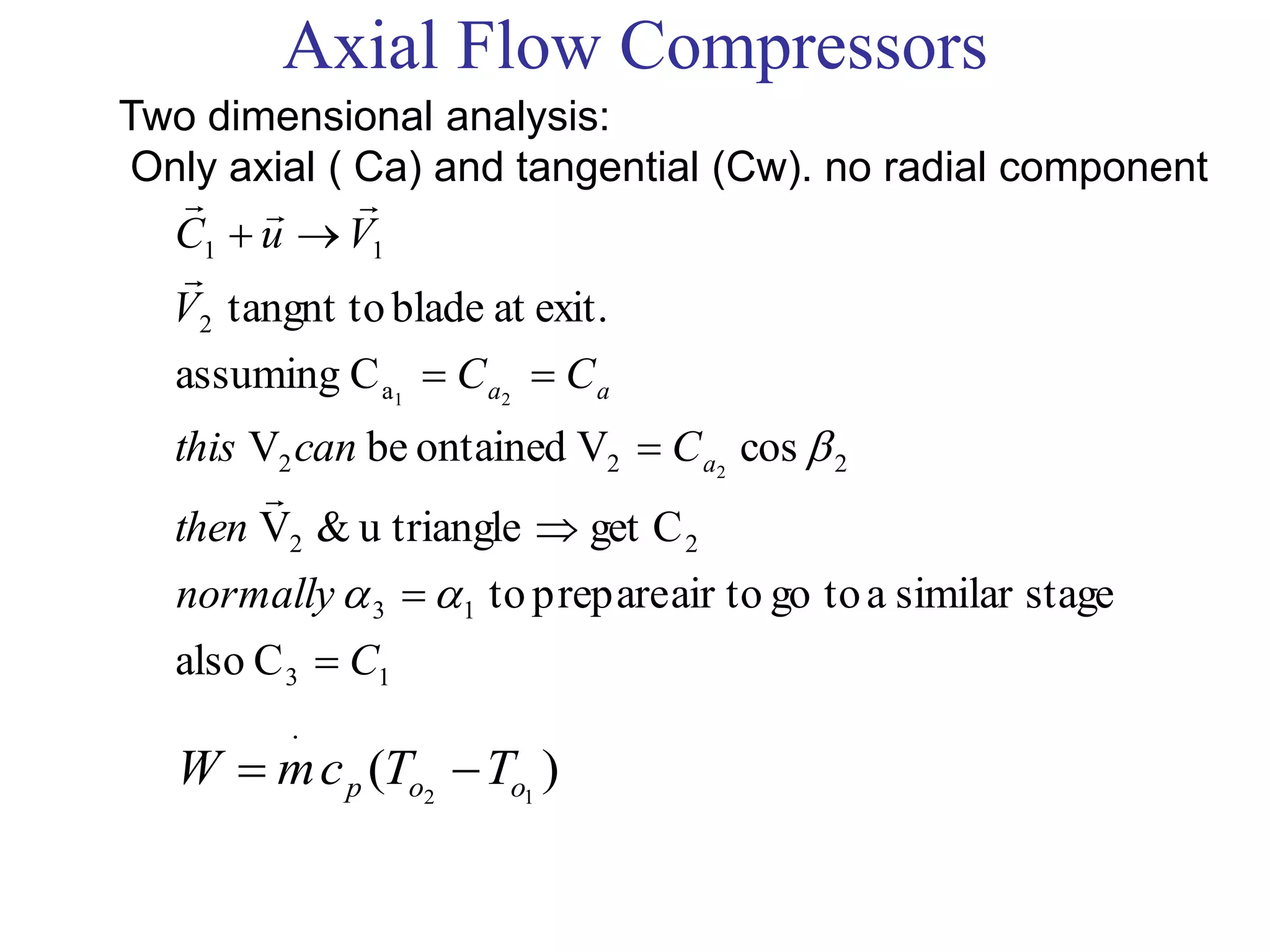

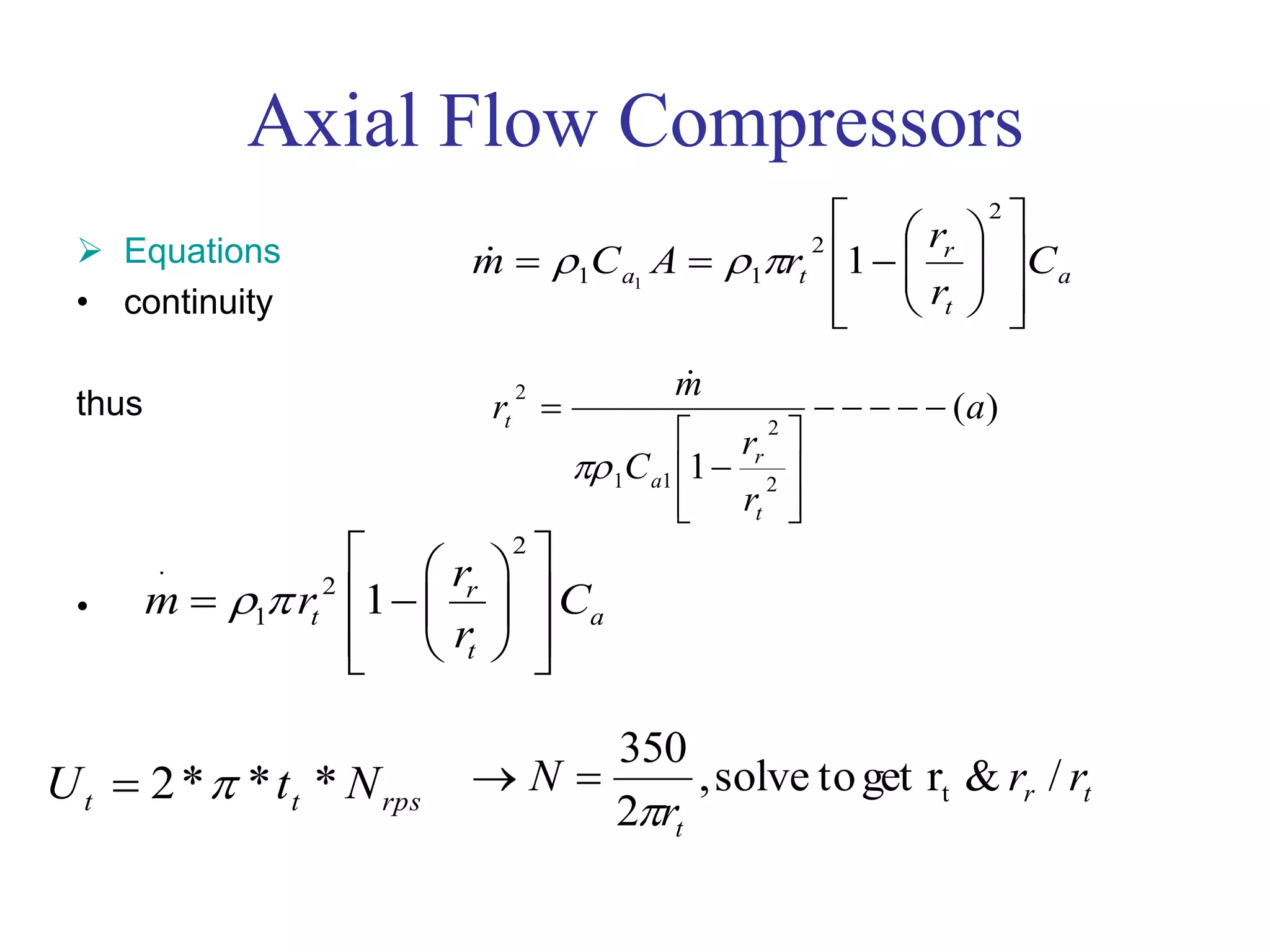

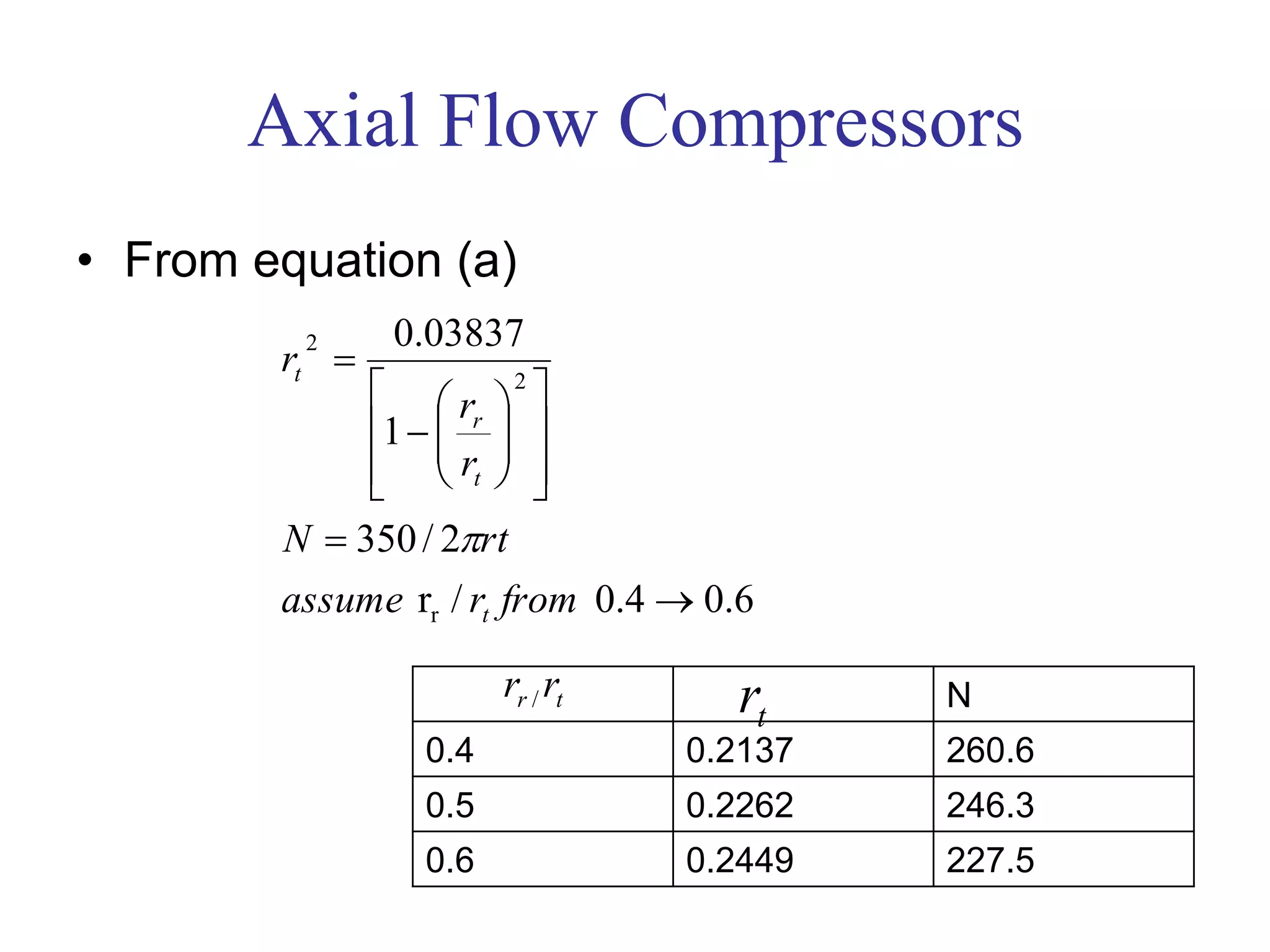

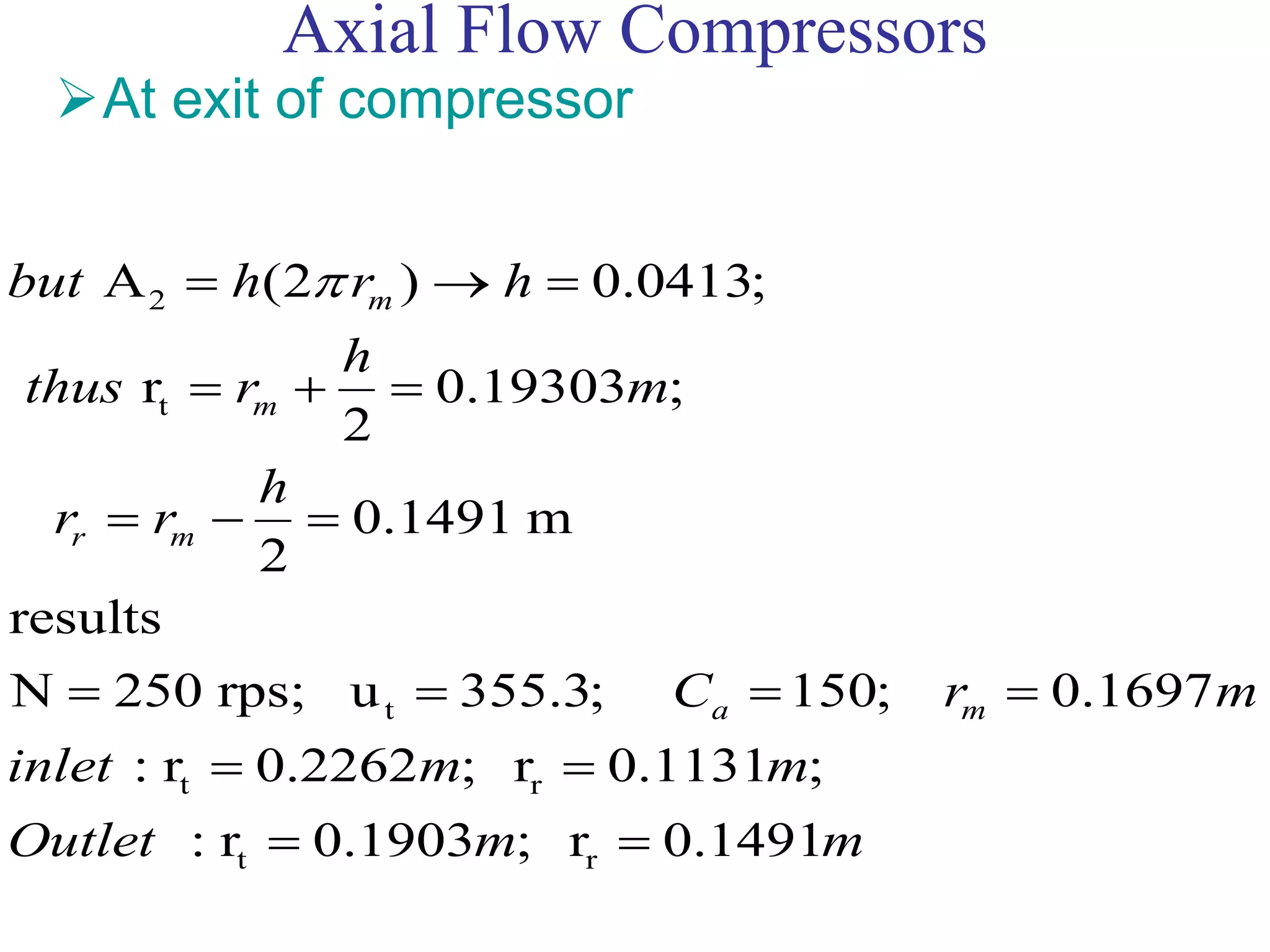

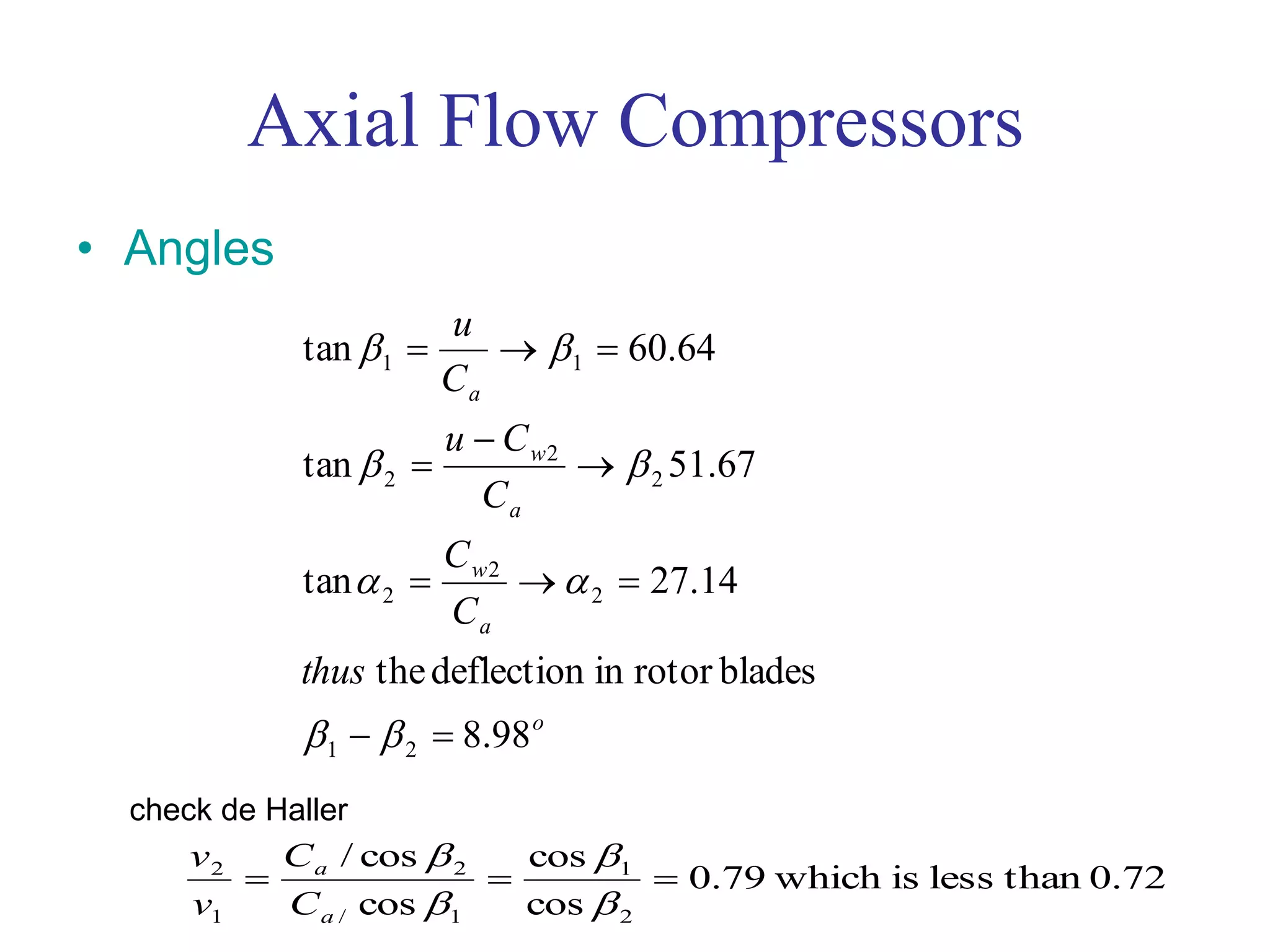

The document discusses axial flow compressors. It begins with an overview that axial flow compressors have multiple stages, each with a row of rotor blades followed by a row of stator blades. The fluid is accelerated by the rotor blades and decelerated in the stator, converting kinetic to static pressure energy. Due to small pressure increases per stage, axial compressors require many stages. The document then provides details on the elementary theory, velocity triangles, degree of reaction, and three dimensional flow effects in axial compressors. It concludes with discussing the design process which includes choosing operating parameters, determining number of stages, calculating air angles, and testing.

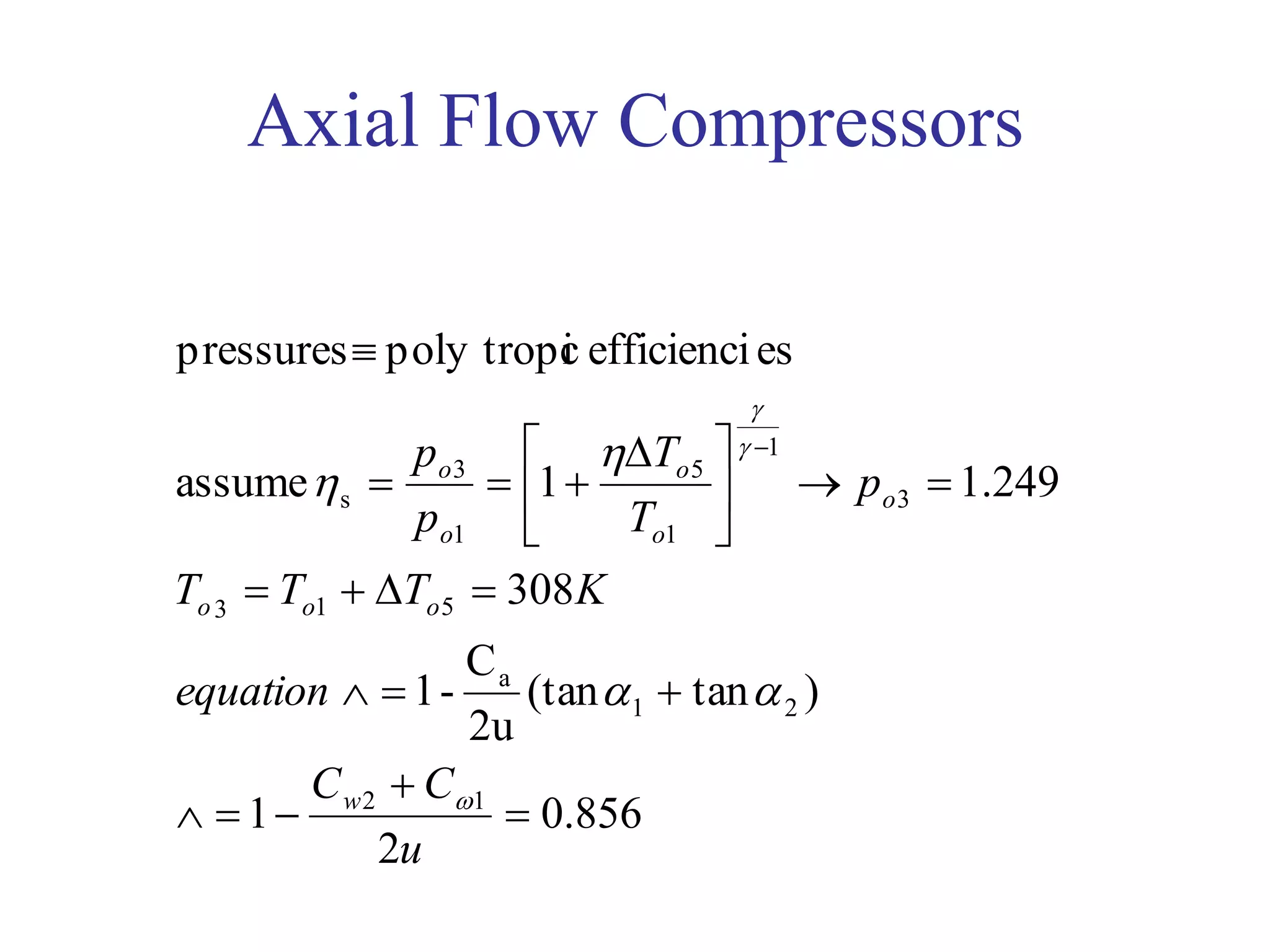

![Axial Flow Compressors

)1/(

11

3

s

21

1213

12

12

11

2211

]1[R

stageperrisepressure

)tan(tan

)tan(tan

)tan(tan

)(

tantantantan

o

ss

o

o

p

a

ooooos

a

a

ww

a

T

T

p

p

c

UC

TTTTT

UCm

UCm

CCUmW

C

U

](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-16-2048.jpg)

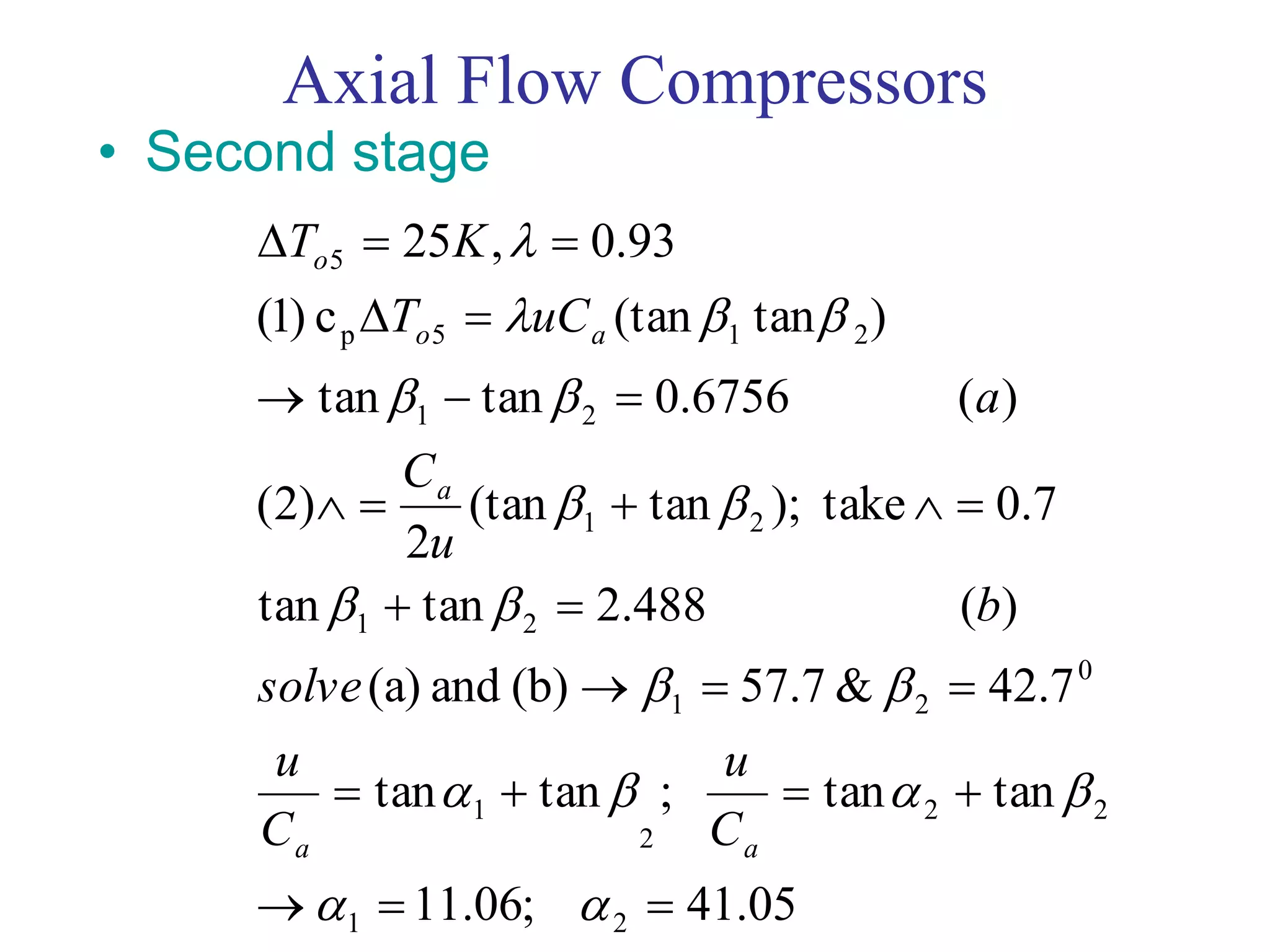

![Axial Flow Compressors

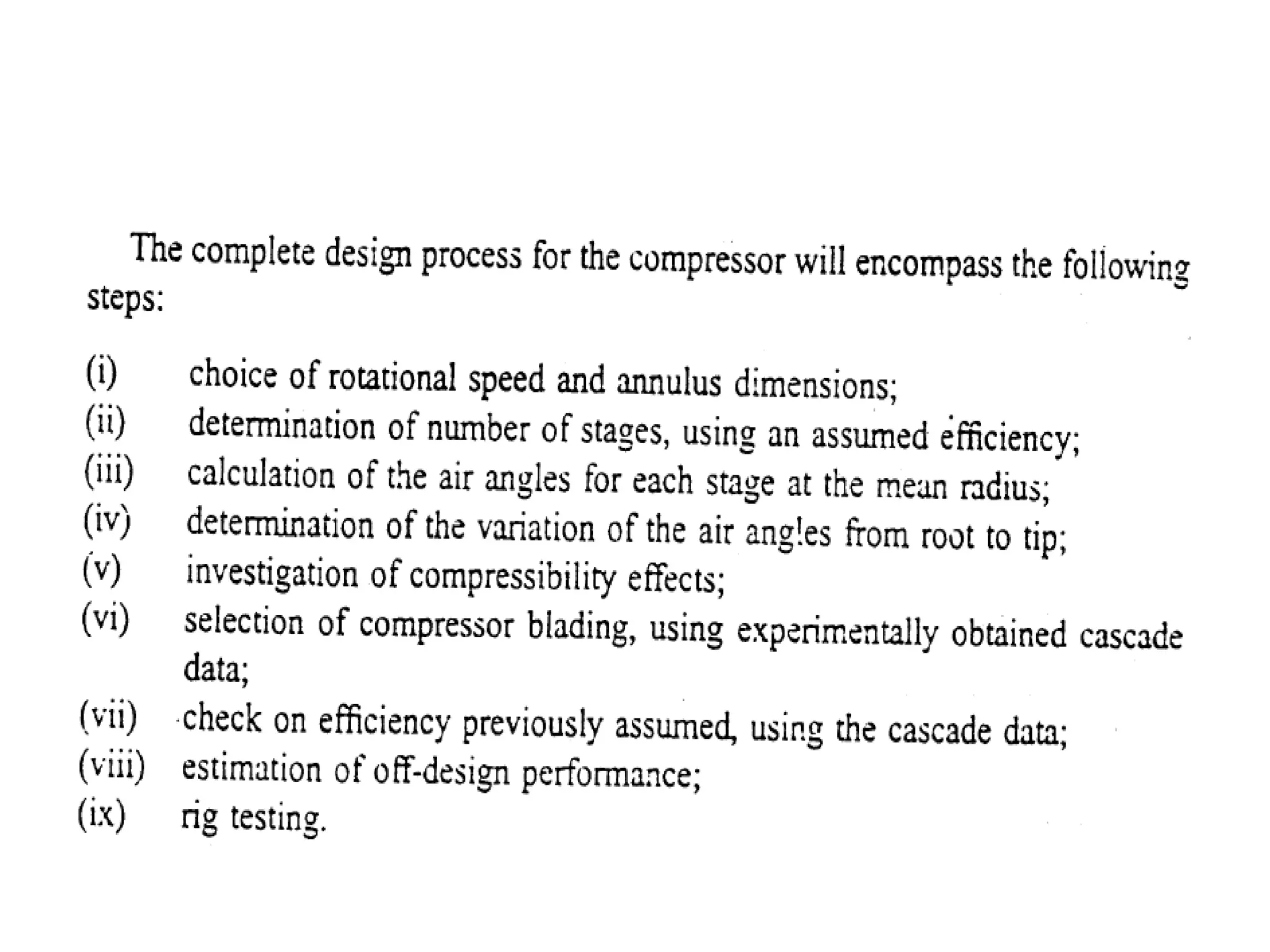

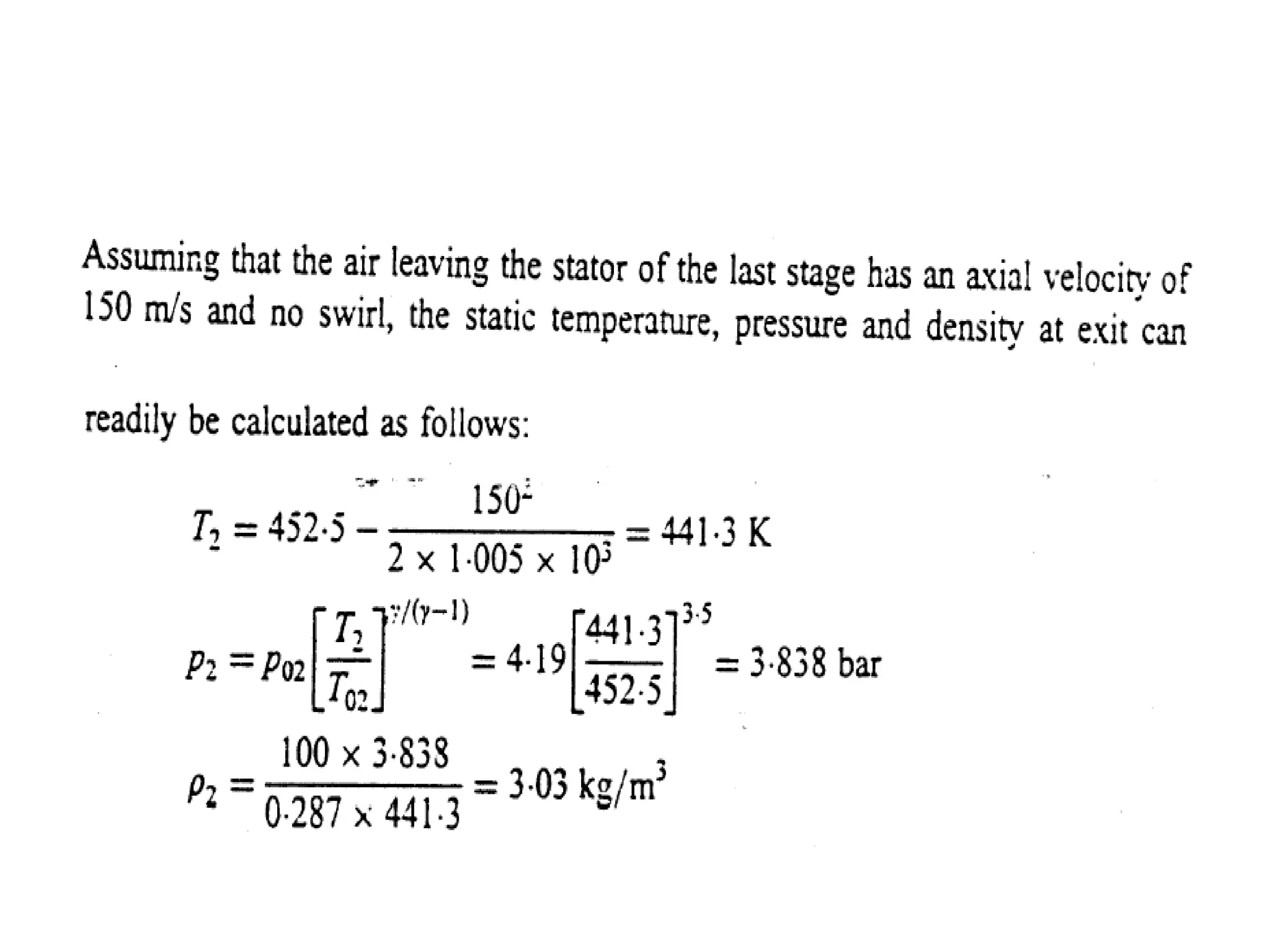

At exit of compressor

2 2 2

2

1 1 1

2

2 2

1

o

2

2 1

2 2

2

o

2

2 2

2

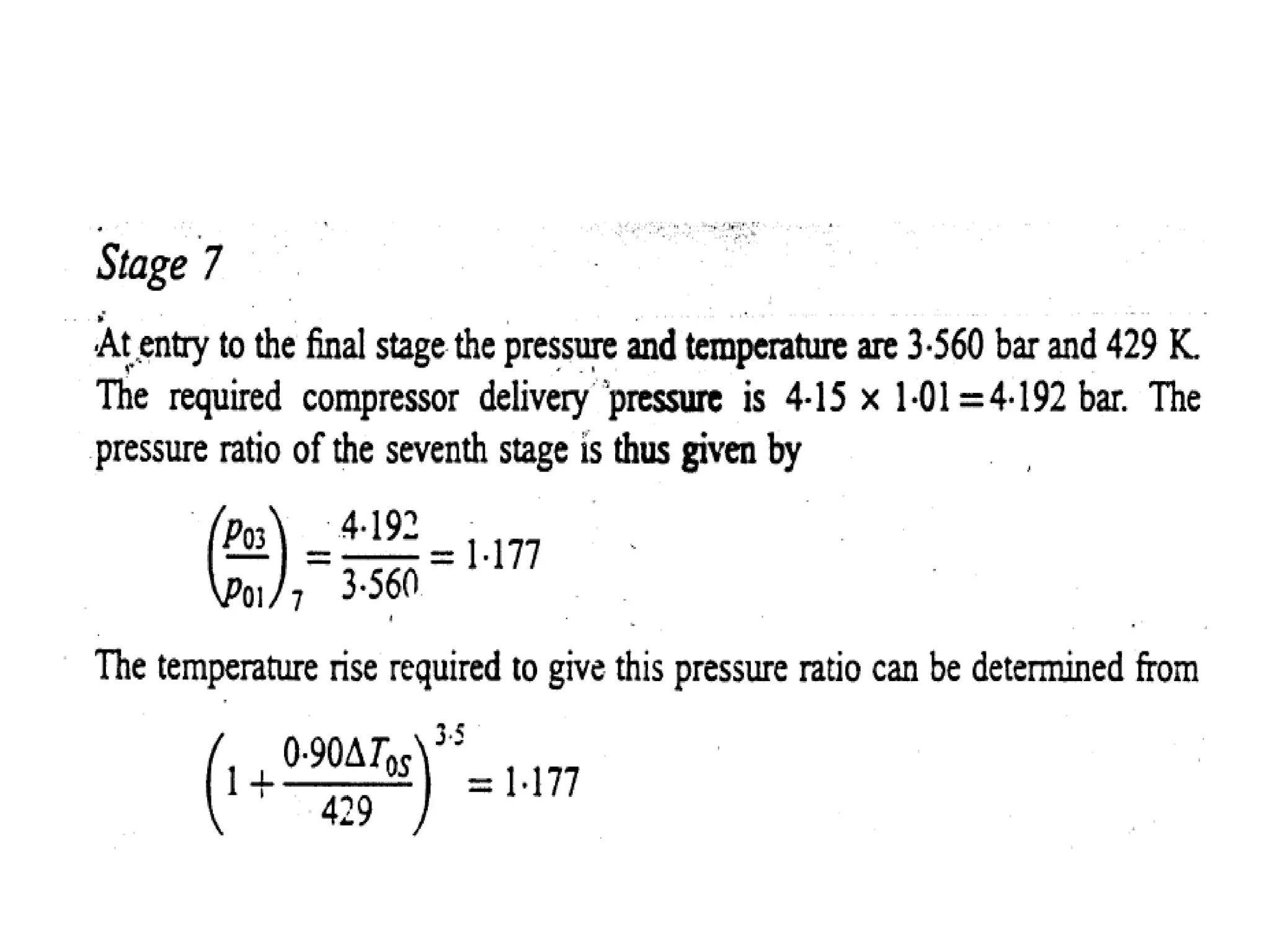

4.15 [ P 4.19 ];

n-1 1 0.4

where 317,

n 1.4

assume 0.9; 452.5 ;

P

441.3 K;

2 P

3.84 bar; 3.03 kg/

n

n

o o o

o o o

o

a

o

p o

P T P

given bar

P T P

T K

C T

T T

c T

P

P

RT

3

2 2 2

m ;

, A 0.044;am A C ](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-25-2048.jpg)

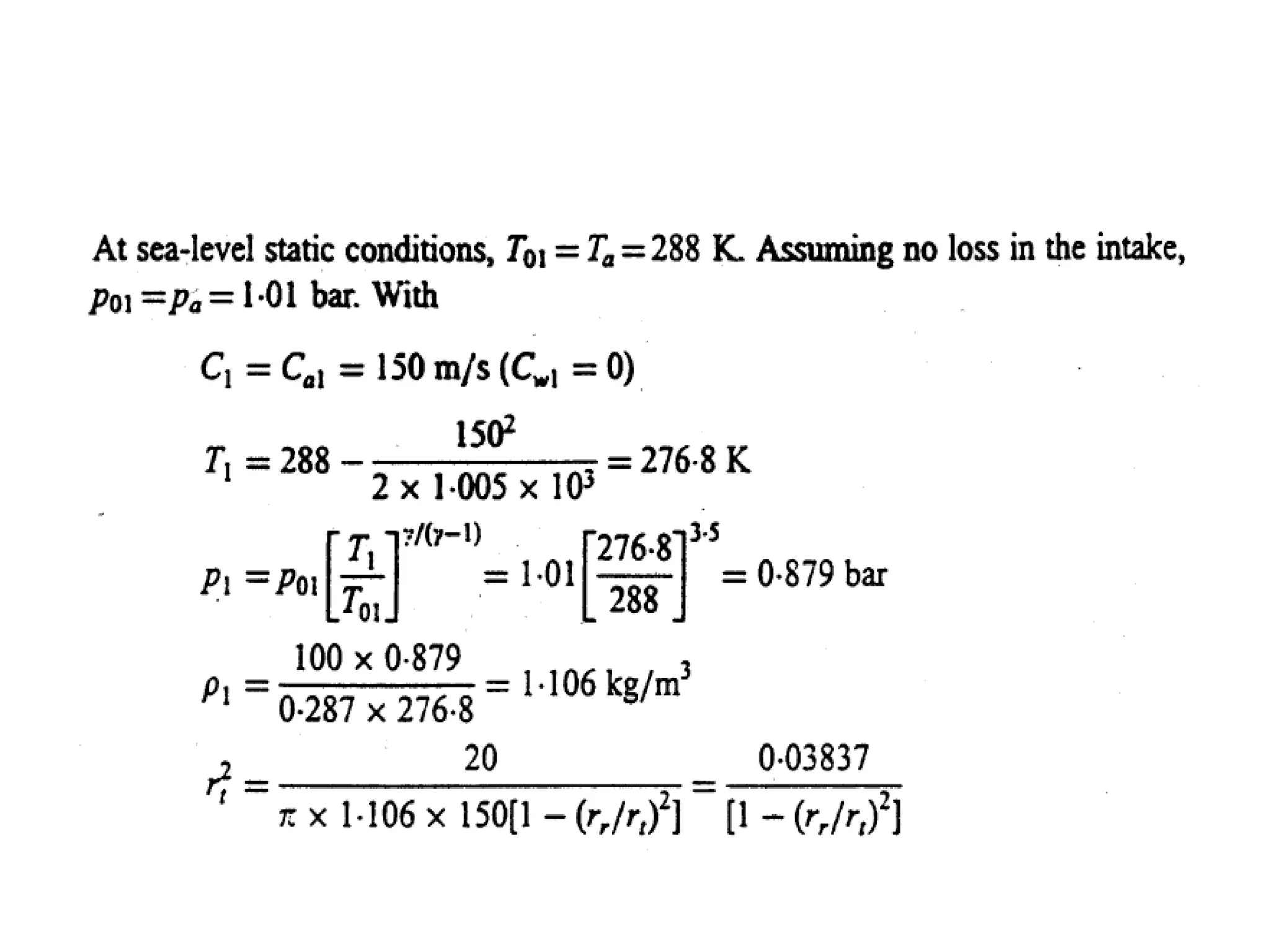

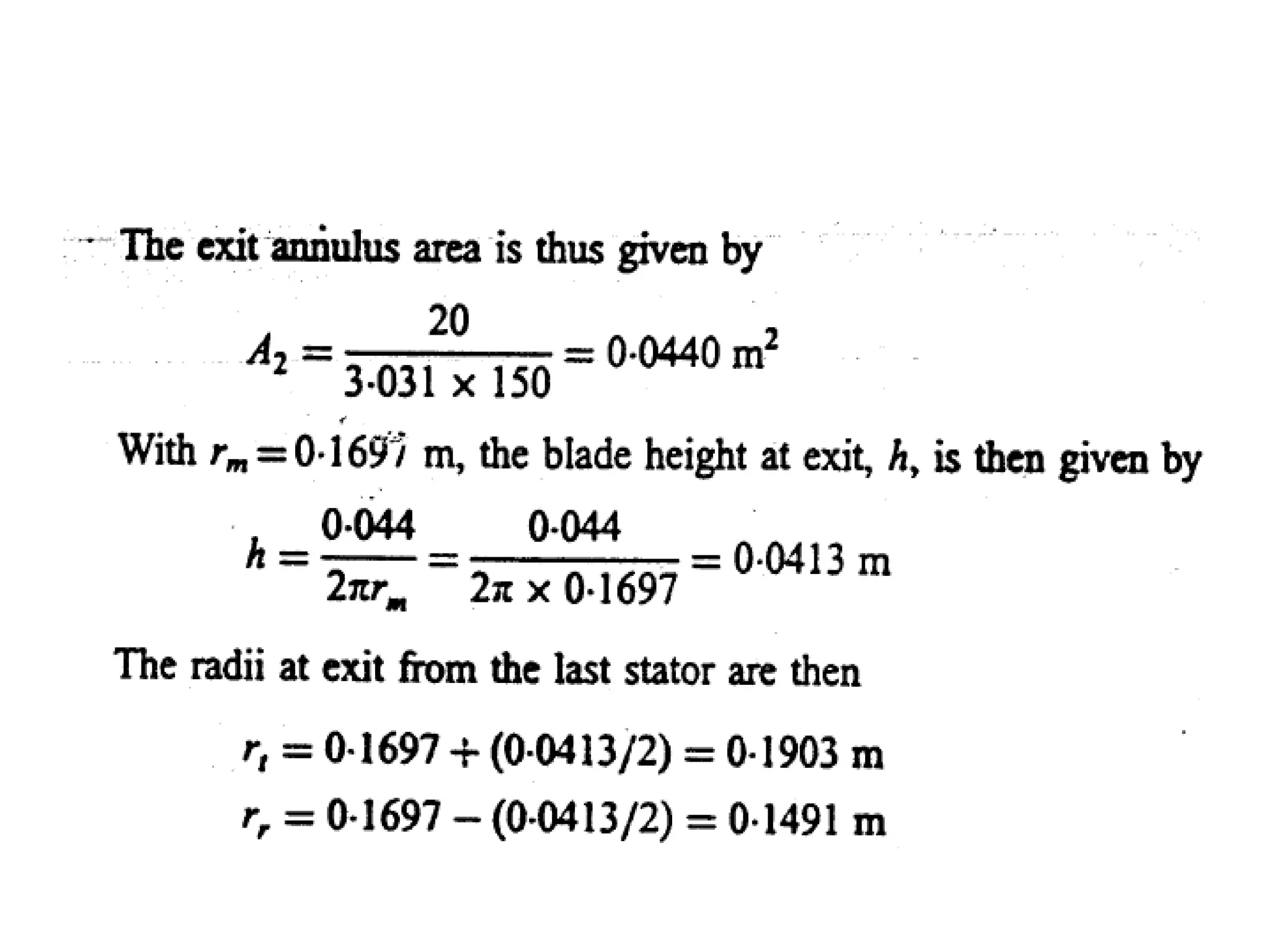

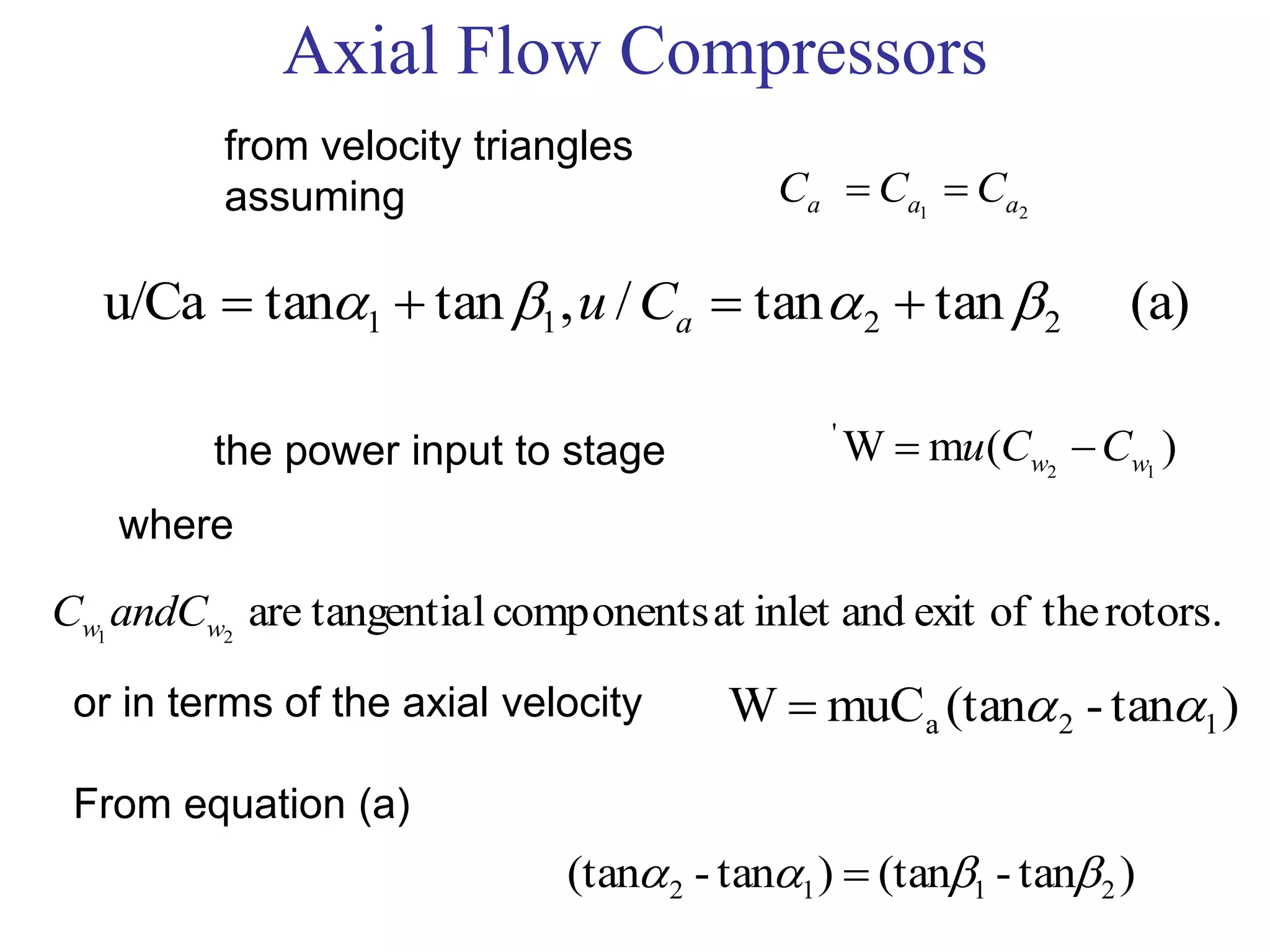

![Design calculations using EES

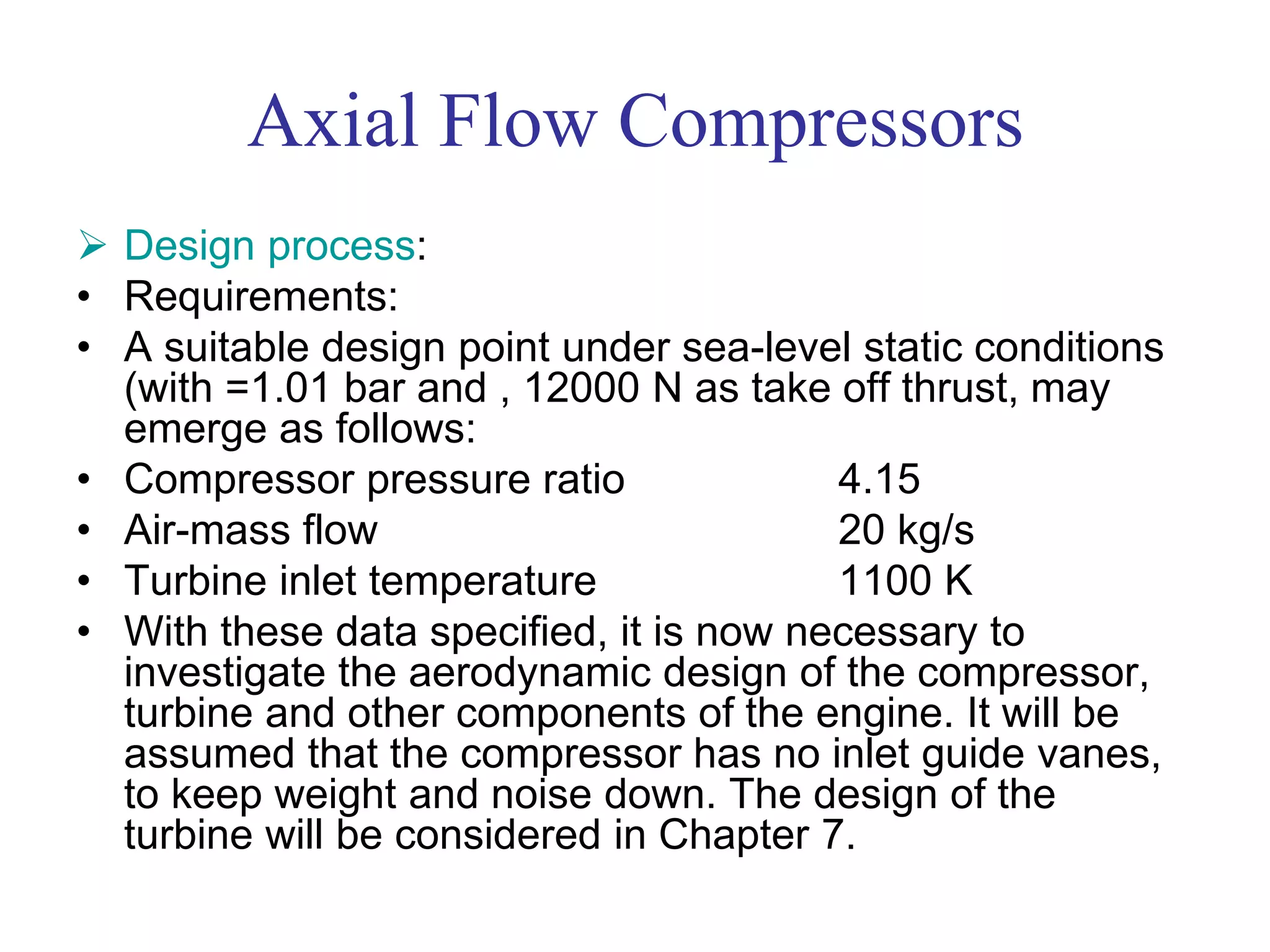

– "Determination of the rotational speed and annulus dimensions"

– "Known Information"

– To_1=288 [K]; Po_1=101 [kPa]; m_dot=20[kg/s]; U_t=350 [m/s]

– $ifnot ParametricTable

– Ca_1=150[m/s];r_r/r_t=0.5;cp=1005;R=0.287;Gamma=1.4

– $endif

– Gamr=Gamma/(Gamma-1)

– m_dot=Rho_1*Ca_1*A_1 "mass balance"

– A_1=pi*(r_t^2-r_r^2)"relation between Area and eye dimensions"

– U_t=2*pi*r_t*N_rps

– C_1=Ca_1

– T_1=To_1-C_1^2/(2*cp)

– P_1/Po_1=(T_1/To_1)^Gamr

– Rho_1=P_1/(R*T_1)

– $TabStops 0.5 2 in](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-38-2048.jpg)

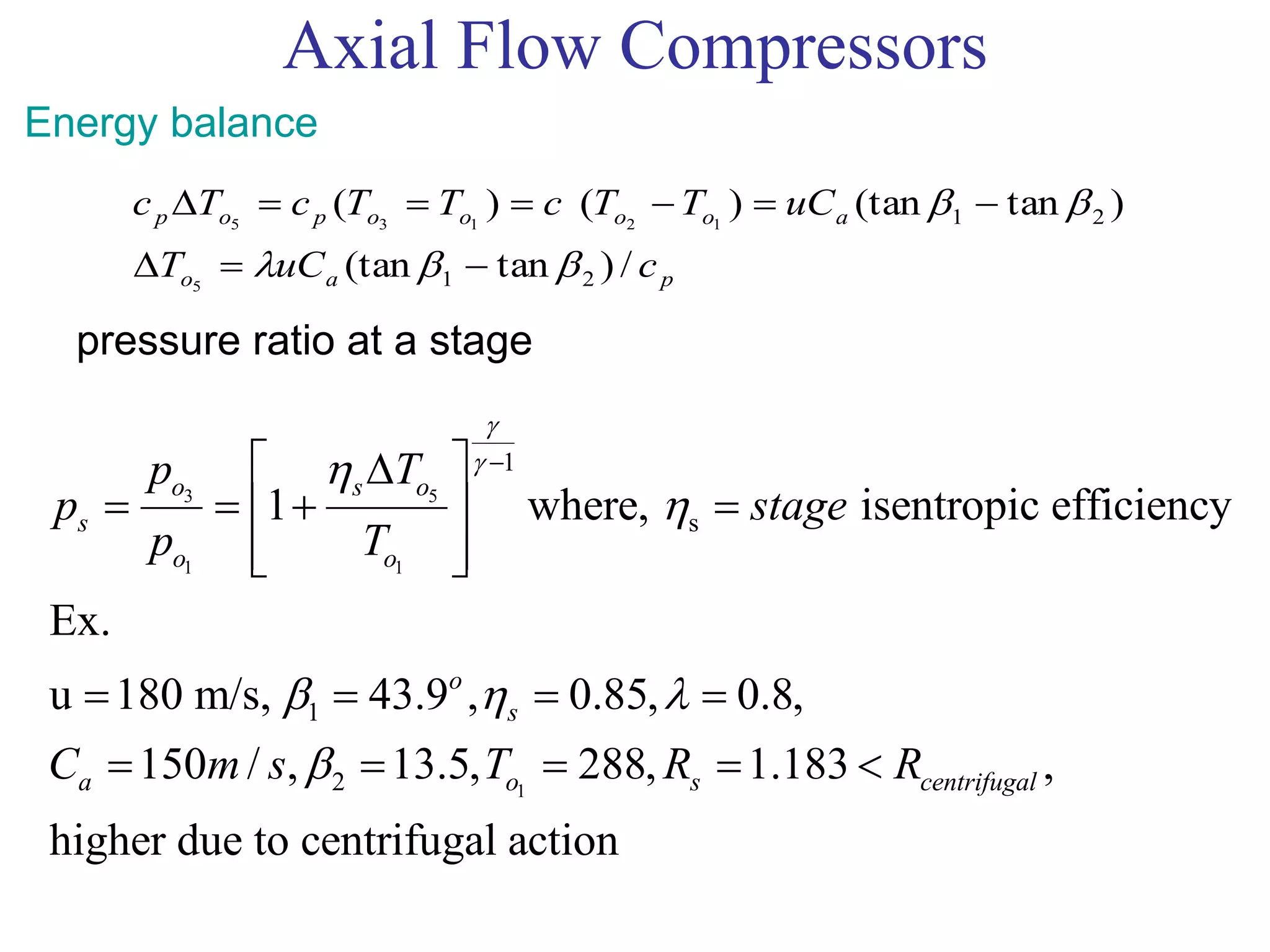

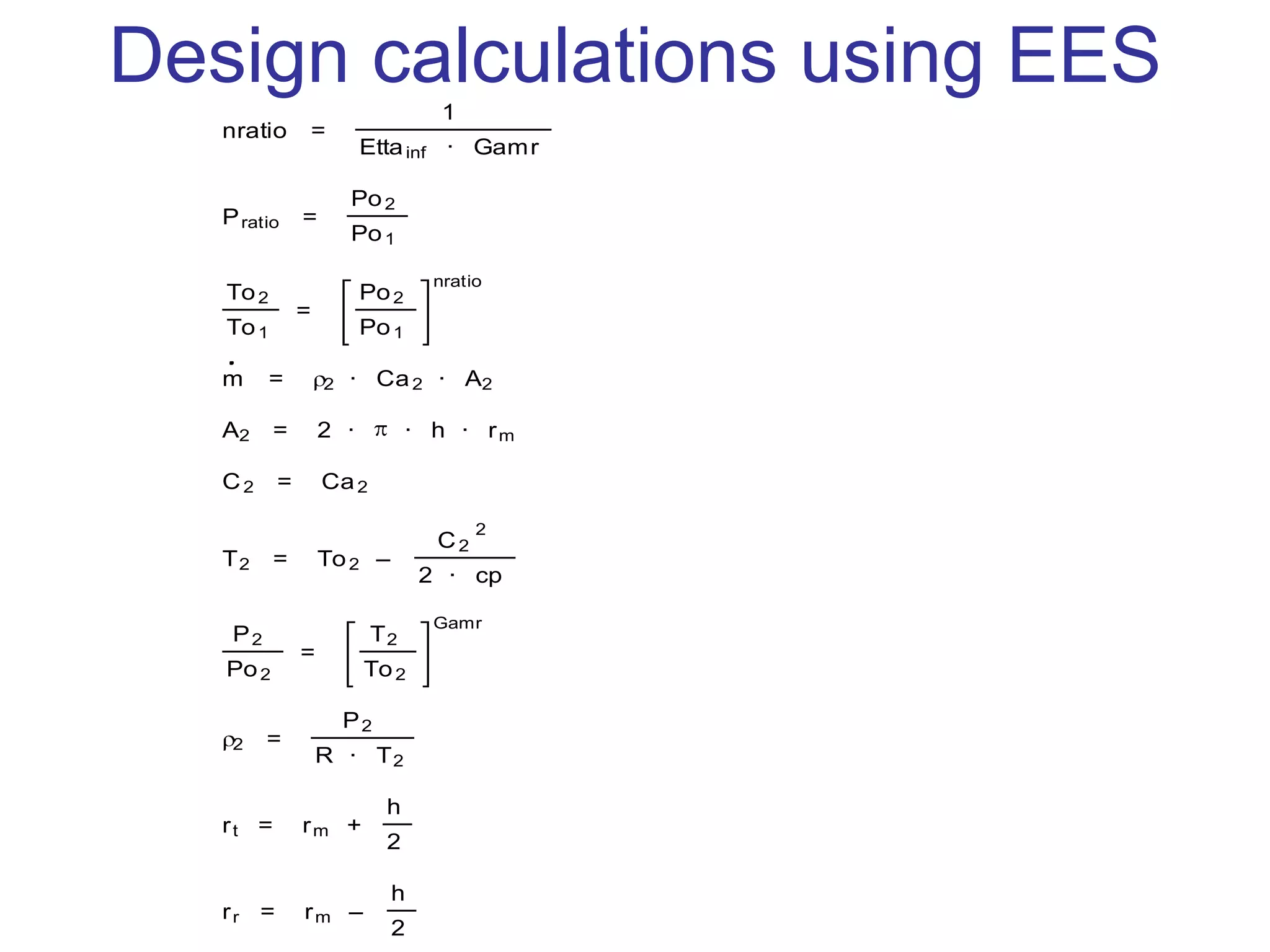

![Design calculations using EES

Determination of the rotational speed and annulus dimensions

Known Information

To1 = 288 [K] Po1 = 101 [kPa] m = 20 [kg/s] Ut = 350 [m/s]

Ca1 = 150 [m/s] rr

rt

= 0.5

cp = 1005 R = 0.287 = 1.4

Gamr =

– 1

m = 1 · Ca1 · A1 mass balance

A1 = · ( rt

2

– rr

2

) relation between Area and eye dimensions

Ut = 2 · · rt · Nrps

C1 = Ca1

T1 = To1 –

C1

2

2 · cp

P1

Po1

=

T1

To1

Gamr

1 =

P1

R · T1](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-39-2048.jpg)

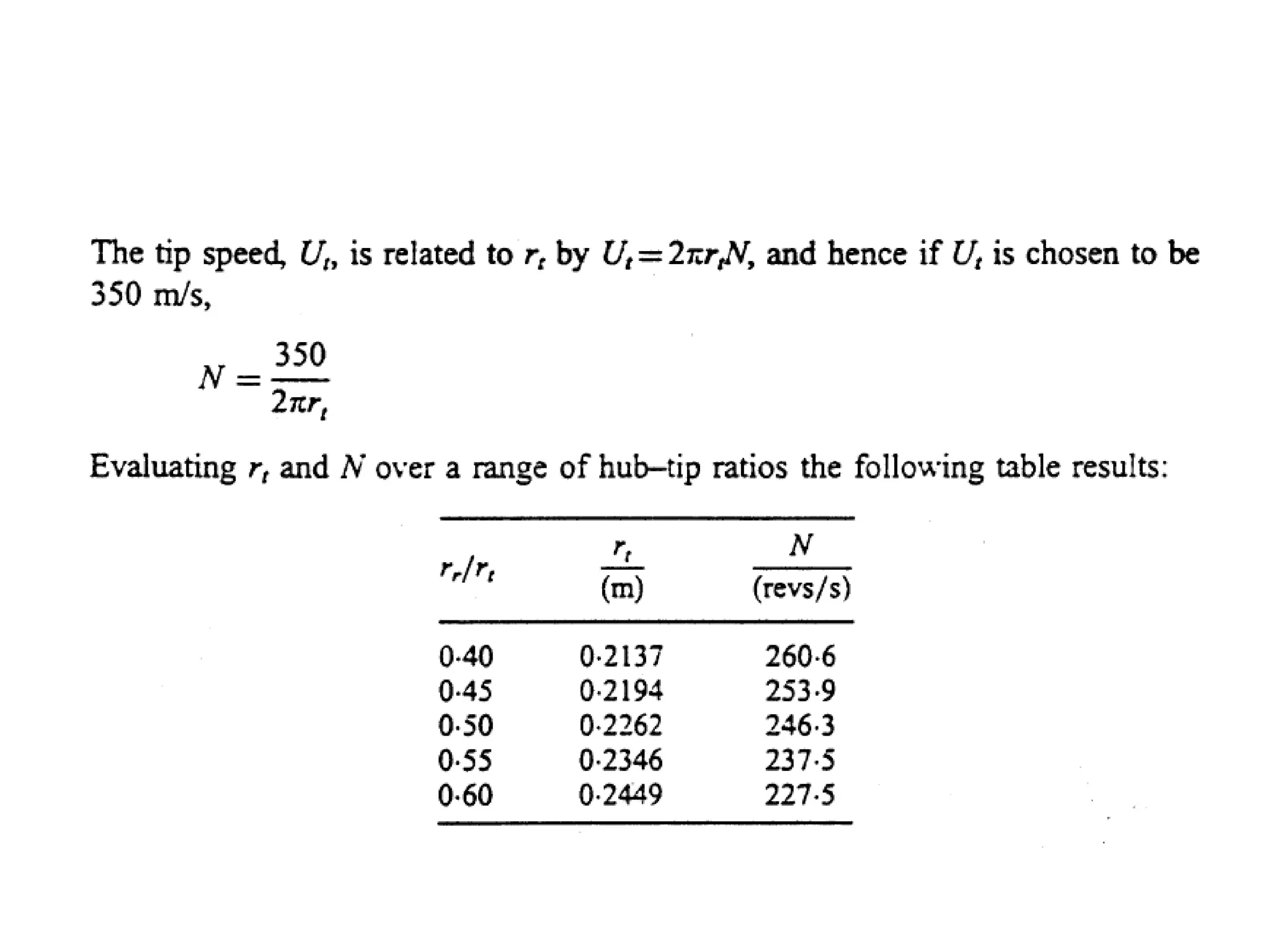

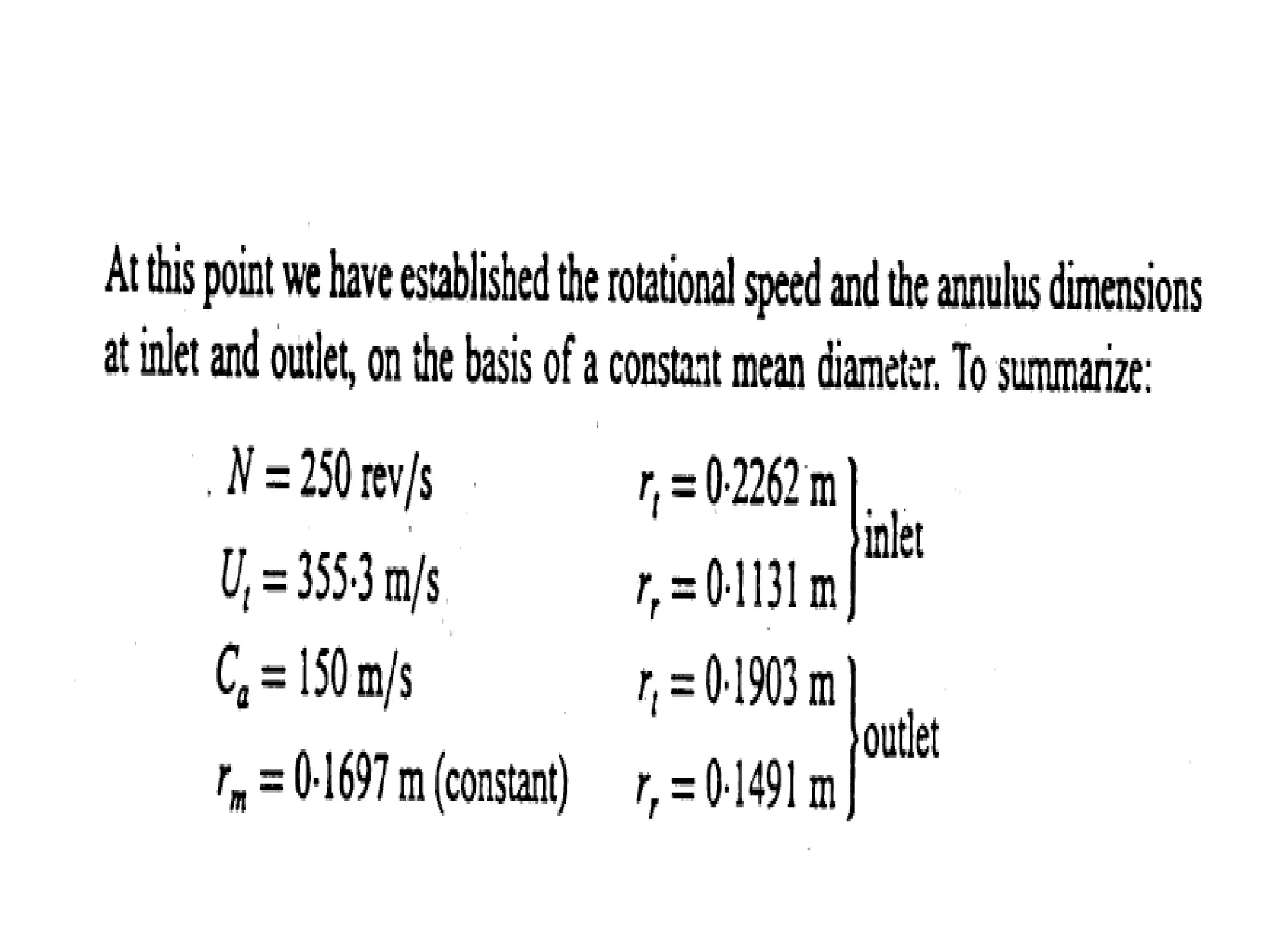

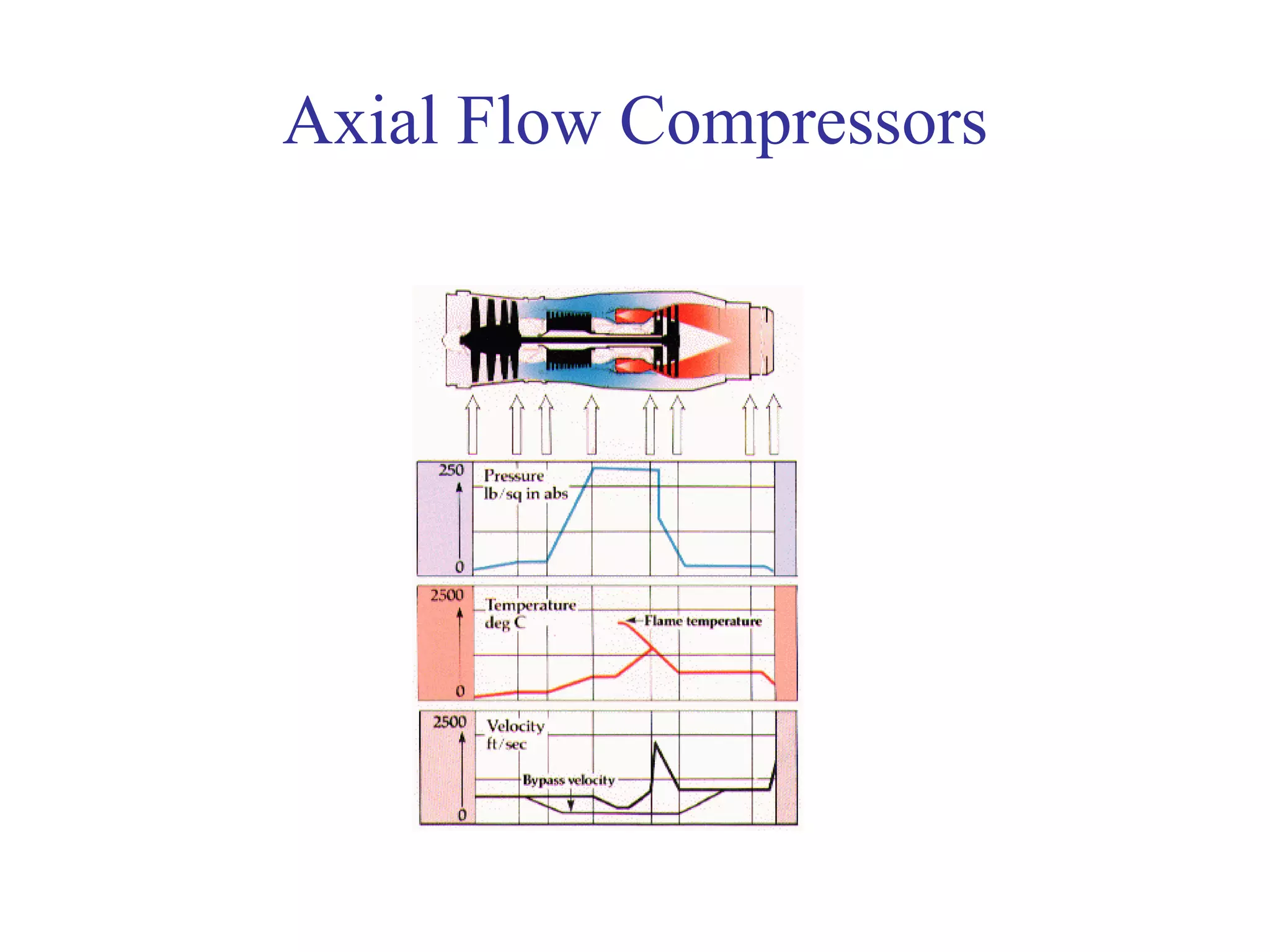

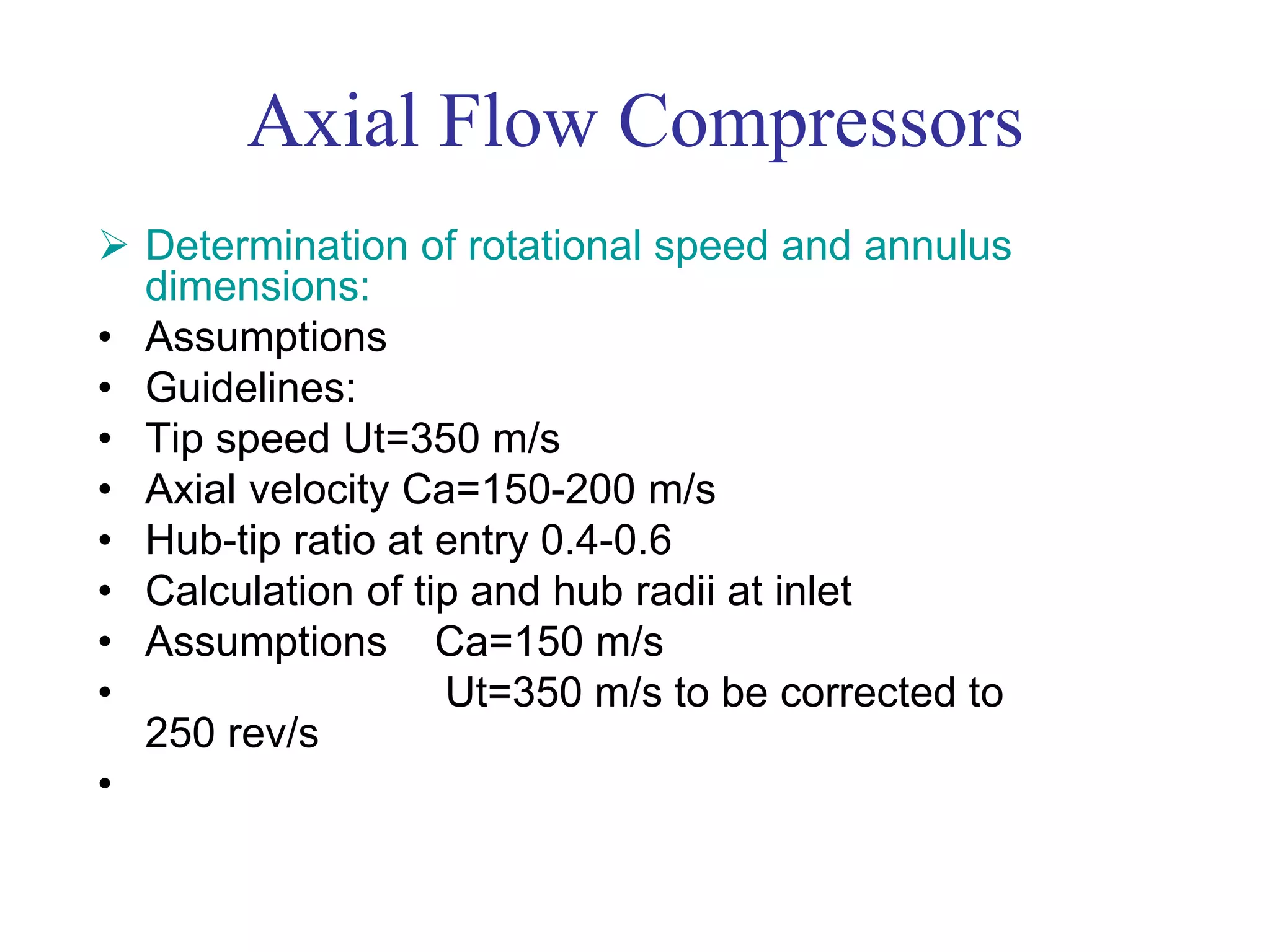

![Design calculations using EES

Calculate radii at exit section

Choose (round) rotational speed as 250 rps

Nrps = 250

Thus calc new value for tip speed

rt1 = 0.2262

Ut = 2 · · rt1 · Nrps

rm = 0.1697

Known Information

To1 = 288 [K]

Pratio = 4.15

Assumptions

Ettainf = 0.9

Ca2 = Ca1

Ca1 = 150 [m/s]

Gamr =

– 1](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-40-2048.jpg)

![Design calculations using EES

A2 = 0.04398 Ca1 = 150 [m/s] Ca2 = 150 [m/s] cp = 1005 [J/kgK] C2 = 150 [m/s] Ettainf = 0.9

= 1.4 Gamr = 3.5 h = 0.041 [m] m = 20 [kg/s] nratio = 0.3175 Nrps = 250 [revper sec]

Po1 = 101 [kPa] Po2 = 419.2 P2 = 384 [kPa] Pratio = 4.15 R = 0.287 [kJ/kgK] 2 = 3.032

rt1 = 0.2262 [m] rm = 0.1697 [m] rr = 0.1491 [m] rt = 0.1903 [m] To1 = 288 [K] To2 = 452.5 [K]

T2 = 441.3 [C] Ut = 355.3 [m/s]](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-42-2048.jpg)

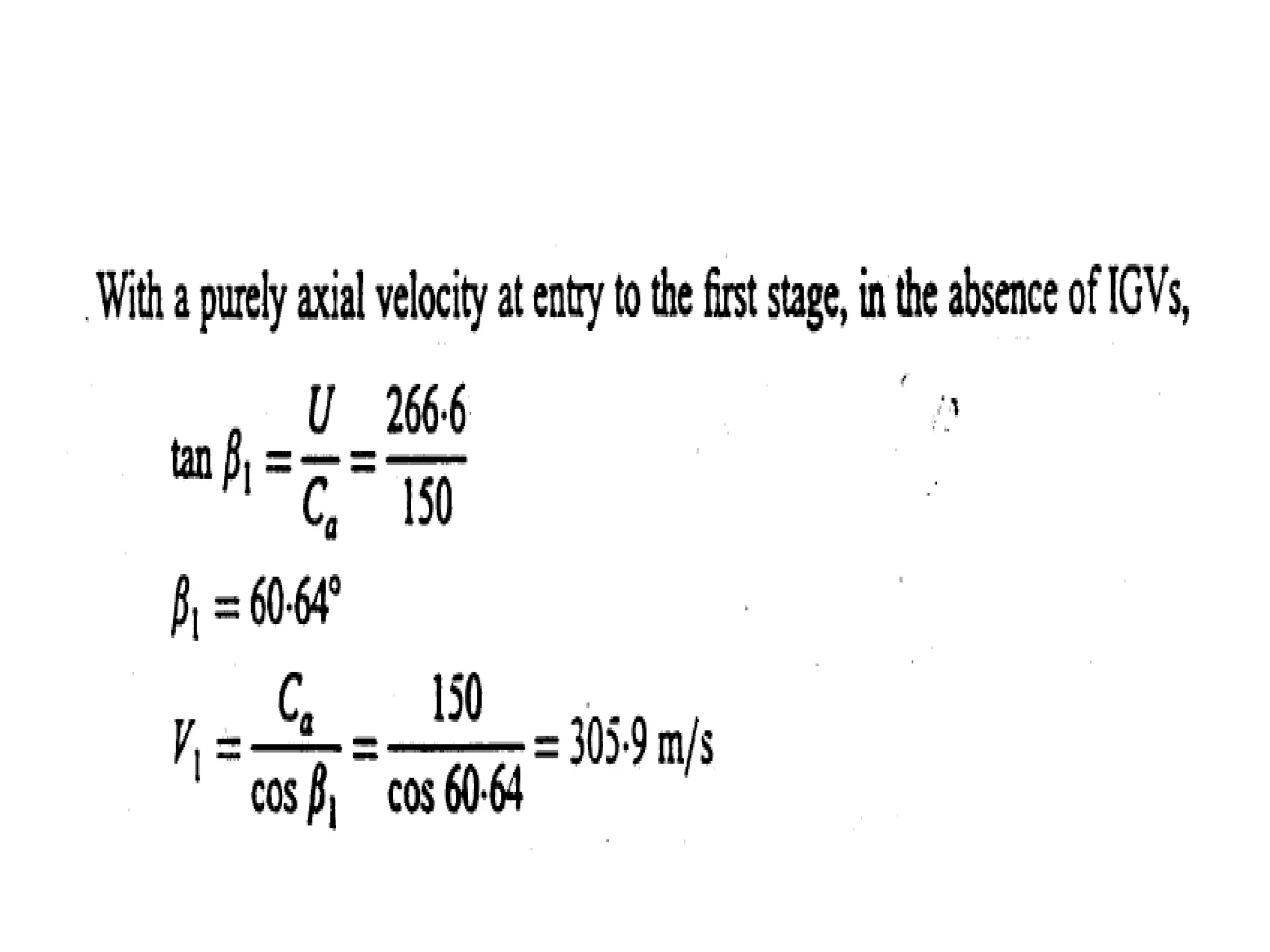

![Design calculations using EES

Calculate number of stages

Known Information

To1 = 288 [K] Po1 = 101 [kPa] m = 20 [kg/s]

Pratio = 4.15 Tooutlet = 452.5

Assumptions

delTstage = 25

Ca1 = 150 [m/s] cp = 1005 R = 0.287 = 1.4

Gamr =

– 1

delTov = Tooutlet – To1

Nstages =

delTov

delTstage](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-43-2048.jpg)

![Design calculations using EES

Ca1 = 150 [m/s] cp = 1005 [J/kgK] delTov = 164.5 delTstage = 25 = 1.4 Gamr = 3.5 m = 20 [kg/s] Nstages = 6.58

Po1 = 101 [kPa] Pratio = 4.15 R = 0.287 [kJ/kgK] To1 = 288 [K] Tooutlet = 452.5](https://image.slidesharecdn.com/5axialflowcompressorsmod-190326170443/75/5-axial-flow-compressors-mod-44-2048.jpg)