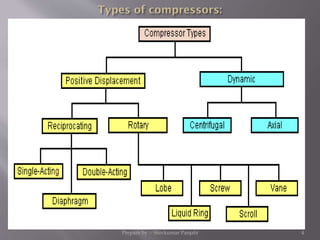

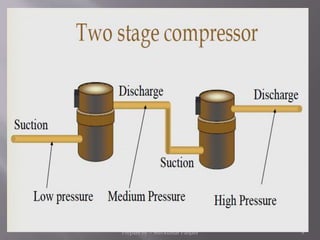

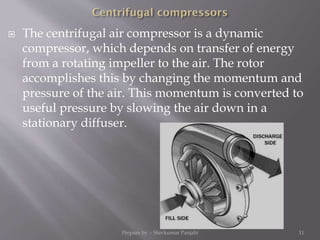

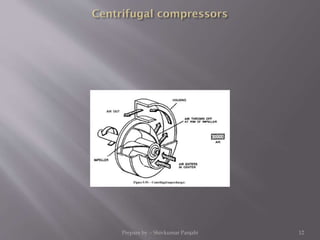

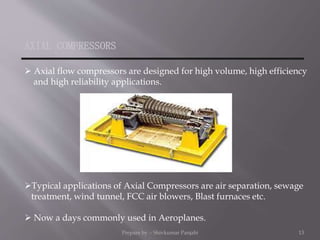

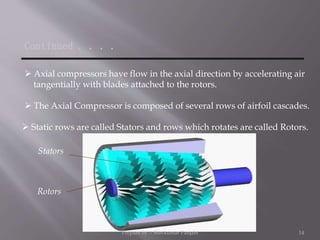

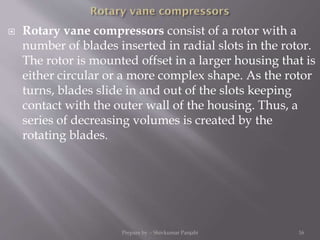

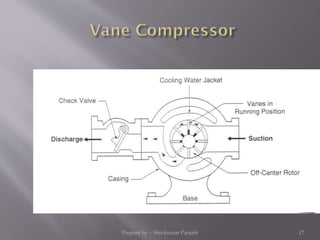

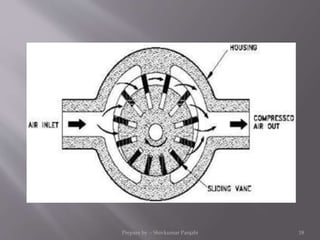

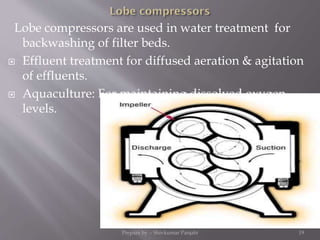

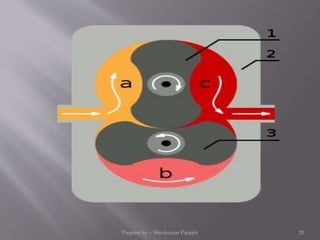

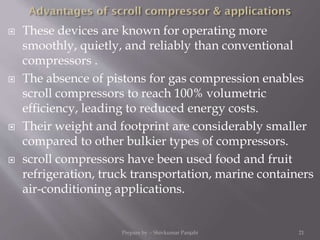

This document provides an overview of different types of compressors and their principles and applications. It discusses positive displacement compressors like reciprocating, screw, vane, and lobe compressors. It also covers dynamic compressors such as centrifugal and axial compressors. Each type of compressor is described in terms of its basic working principles and common industrial applications. The document aims to introduce the key concepts around compressors.