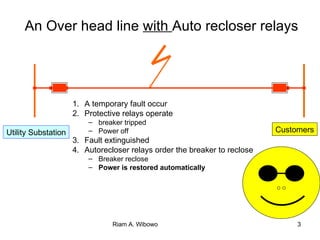

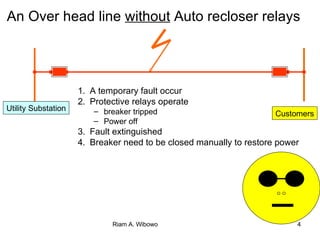

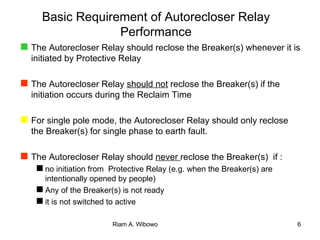

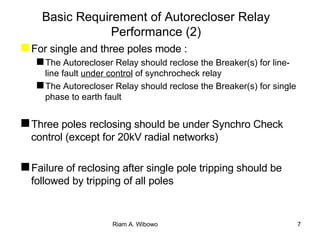

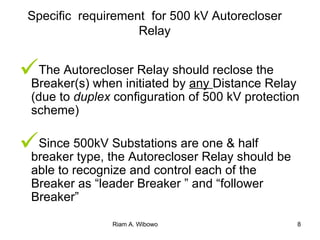

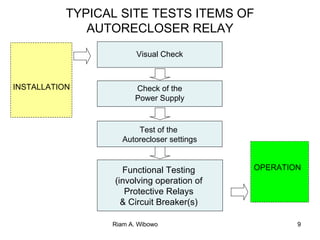

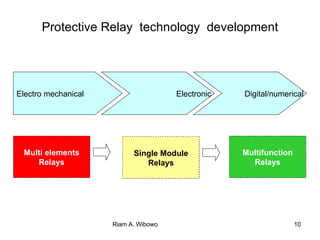

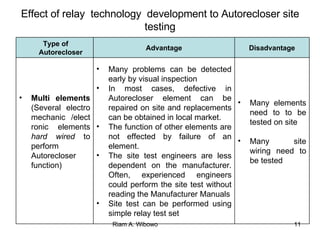

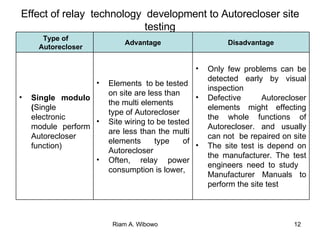

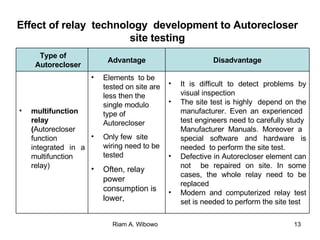

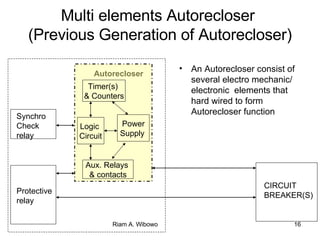

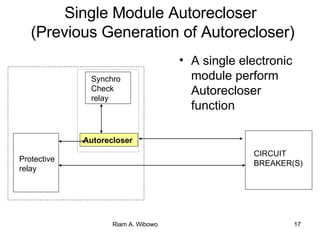

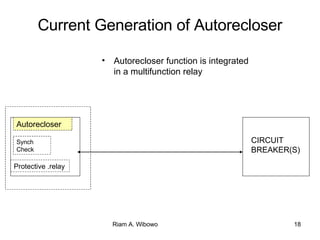

This document discusses the importance of site testing for autorecloser relays in electrical utilities to ensure their proper functioning before operation. It highlights the differences in testing requirements between traditional multi-element relays and modern multifunction relays, indicating that while advancements have reduced the need for extensive site testing, such testing remains essential. The text outlines the basic requirements for autorecloser relay performance and the impact of relay technology development on testing practices.