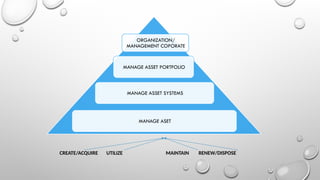

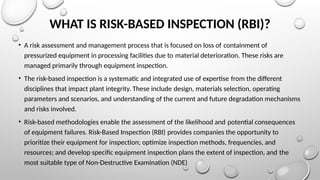

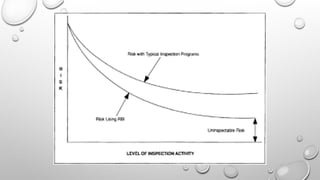

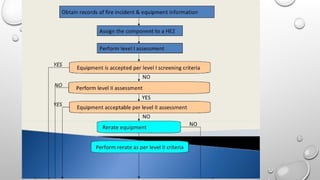

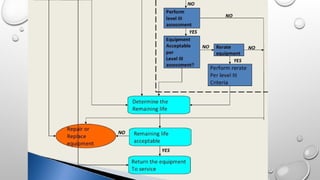

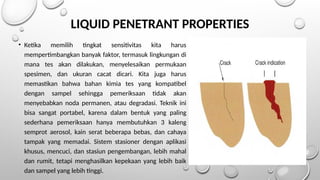

The document outlines a training program focused on asset integrity management, detailing strategies for optimizing asset integrity systems, risk-based inspection methodologies, and maintenance practices. It covers topics such as corrosion management, fitness for service assessment, and inspection techniques, emphasizing the importance of effective asset management throughout the asset lifecycle. Participants will learn to identify threats, enhance productivity, and implement technical approaches to improve operational outcomes and prolong facility life.

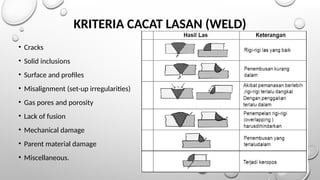

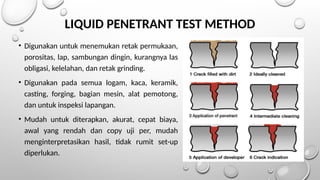

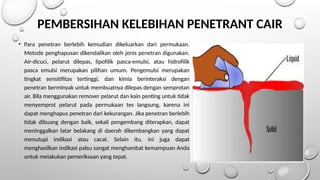

![• Pengembang menarik penetran dari cacat keluar

ke permukaan untuk membentuk indikasi yang

terlihat, umumnya dikenal sebagai berdarah-out.

Setiap daerah yang berdarah-out dapat

menunjukkan lokasi, orientasi dan jenis

kemungkinan cacat di permukaan. Menafsirkan

hasil dan karakterisasi cacat dari indikasi yang

ditemukan mungkin membutuhkan beberapa

pelatihan dan / atau pengalaman [ukuran indikasi

bukan ukuran sebenarnya dari cacat]](https://image.slidesharecdn.com/assetintegritymanagementsystem-book-240923013815-9c282f66/85/ASSET-INTEGRITY-MANAGEMENT-SYSTEM-BOOK-pptx-137-320.jpg)